Turtle Diagrams Registrar Auditors and More Waste

Diunggah oleh

kaibouDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Turtle Diagrams Registrar Auditors and More Waste

Diunggah oleh

kaibouHak Cipta:

Format Tersedia

Auditors, Turtle Diagrams and Waste

Less is more

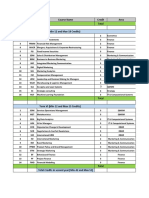

by Mike Micklewright In the past several months, registrar auditors strongly recommended to three former or current clients that they develop and install turtle diagrams for each of their processes. Two auditors from one registrar actually taught a former client how to develop a turtle diagram during a surveillance audit. In the stand-up quality comedy routine that I perform for ASQs section meetings, conferences and corporate events, I reveal my sarcastic list of seven basic habits of highly effective registrar auditors. Habit no.2 is, Inform the auditee that you arent allowed to give advice, and then give advice. I then reveal a double-billed cap, and say that, in the spirit of ISO 9001 clause 7.5.3, Identification and traceability, registrar auditors should be required to identify their service at the time of provision. So, when auditors are auditing, they should show the auditor side of the cap. As soon as they start giving advice, they should flip the cap around and show the word consultant. Registrar auditors must not give advice, because by doing so, they lose their objectivity. What is a turtle diagram? Two registrar auditors suggested the turtle diagram format below. The typical turtle diagram has inputs and outputs surrounding the process in question. How does this diagram do what the procedure or agenda forms dont? Such diagrams defeat their own purposethey arent written in process format. For example, how do the three support processes and the two linkages fit in, and when do they fit in? Furthermore, the document is written in batch form rather than process flow.

Two registrar auditors developed this turtle diagram during a surveillance audit for their clients. It is easy to see how it would be helpful for the auditor and his report, but it isnt easy to see how this adds value to the companys quality system.

Following is a more typical turtle diagram, containing the following sections (turtle parts):

Each section contains a list of internal information under that heading, listed in batches and in no particular process order.

Of the three companies that developed the turtle diagrams for their auditors, none of them have found any value in them. The diagrams arent used to train employees or in any other capacity within the company. In some case, they have even confused employees. They serve no value, except to the auditors. Dont change your quality management system (QMS) for your auditors. Change your QMS only to make your system more effective and then ensure that it meets your standard requirement goals, not some auditors interpretation of them. Why do auditors suggest turtle diagrams Because it makes their job easier. As part of the process auditing approach, they need to show proof in their records that you have identified the inputs, outputs and objectives of each process. If they can just copy your turtle diagram, their job is lot easier and there is more time to talk about the weather. If registrar auditors ask you to develop turtle diagrams or any other document: 1) Ask them to show where in the standard it says that you need such a document. 2) Ask them to show you their own turtle diagrams, as examples, of the contract review process used in your company, the auditing process currently being used, the customer complaint process you might use and the issuance of the registration process you expect to be used in the near future. Does ISO 9001 require turtle diagrams? No, it doesnt. If you read the standard, you will find no reference to a turtle diagram anywhere. In fact, the closest the standard comes to anything that might be interpreted as a turtle diagram is in section 0.2, of the process approach section: An activity using resources, and managed in order to enable the transformation of inputs into outputs, is considered as a process. Often the output from one process directly forms the input into the next. This is a great definition, and it doesnt state that a turtle diagram must be drawn to demonstrate these processes. Clause 4.1 of the general requirements section of ISO 9001 states, The organization shall a) identify the processes needed for the QMS and their application throughout the organization b) determine the sequence and interaction of these processes. This can be done thousands of ways. There is no requirement for a turtle diagram. What is a procedure? We all know the classical definition. Its a document that explains who does what, when and where. Its a document that defines a process and cuts across functional or departmental lines (whereas, a work instruction can be done by one person or one department).

A well-written procedure will have most of the requirements of a turtle diagram in the body of the document. Below, is an excerpt out of a companys process control procedure. Compare the colored words in this procedure excerpt to the parts of the turtle diagrams above.

The process name is the title of the document, the inputs and outputs are obvious when reading how the document flows from one step to the next, and the performance indicators can be located in the purpose section of this procedure, in a single objectives and goals form, or in a balanced score card organized by process. So whats wrong with turtle diagrams? Theyre slow and wasteful, because theyre redundant. They are antilean. The information in a turtle diagram should already be in your procedures. You dont need them, and they probably wont be used. They only help auditors to do their job, while adding complexity to your QMS. Most QMSs are way too big and theyre growing larger, more complex and nonuser-friendly. When entropy,the law of disorder, sets in and you have no way to control it, and your auditor strongly suggests more documents, it further complicates your QMS. If the QMS becomes too complex, it wont be put into practice. One of my clients, after reading my article on the Two-Page Quality Manual hired me to reduce his corporate quality manual. His quality manual was 75 pages in length. He had added a 20-page Six Sigma policy manual and, at the Registrars suggestion, added 27 pages of turtle diagrams. When I told the corporate management representative that his 27 turtle diagrams served no value and they were probably not used at all within the company, he admitted that this was correct. He had added them into the system primarily because of the auditor. I eventually showed him how to reduce these referenced documents from 122 pages to 5 pages, eliminating redundancy, not important content. By simply getting rid of waste, his document is now user-friendly and meets all the requirements of the standard. Turtles move slow, and turtle diagrams make your system slower, because they add waste to your QMS. Lean quality systems You need to ensure your QMS becomes lean. This doesnt mean vague. It means getting rid of the redundancy, of which you probably have a lot. No requirement, specification, instruction or procedure should ever be repeated in another document. Turtle diagrams are redundant. Ive seen some companies repeat a specification in five or six different places (e.g. print, work order, inspection sheet, control plan and work instruction). In this chaotic system, anytime a change is made, some documents dont get changed as they should. Your obligation as a quality manager is to do your job to ensure your QMS is lean, useful and user-friendly.

Registrar auditors need to do their job Regarding the client that received training on how to draw turtle diagrams from two auditors I found out about this only after recently providing them with internal auditor training. Five years ago, I consulted with them until they got their registration. Since then this company hadnt written a single preventive action, had only two internal audit findings and they were still registered. Registrars need to do their job by putting companies on probation or decertifying them if they have major nonconformities. This is their job and they must uphold the spirit of the standard, their true customer. They must stop consulting and advising, and start auditing correctly to ensure that companies are truly qualified to claim registration to a standard. Use lean principles in your documentation system In effect, some auditors advice encourages excessive nonvalue-added documentation. Most auditors have had little or no training in lean and elimination of waste. Anything or anyone encouraging waste (e.g. turtle diagrams or a 50-page quality manual) is only encouraging ineffectiveness. Many of you have allowed entropy into your QMS by blindly accepting whatever auditors suggest. Remember that for any nonconformity written or advice given, auditors have to quote a requirement that isnt being met Simply ask them to show you in the standard where turtle diagrams or a lengthy quality manual is required. Its your responsibility to ensure an effective system. Effectiveness is only possible when the system is easy to use. Look for the waste. Look for the inefficiencies and the ineffectiveness within your system. Teach your internal auditors about lean, value-added actions, value stream management, waste elimination, 5S, and quick changeover, so that they can help you achieve your goals. About the author Mike Micklewright is an independent consultant based in the Chicago area who specializes in improving internal auditors abilities and programs, and in demonstrating to companies how to lean out their documentation system to make it more effective. He specializes in lean, Six Sigma and anything ISO 9001-related.

Copyright 2006 QCI International. All rights reserved. Quality Digest can be reached by phone at (530) 893-4095.

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Tradesphere Industrial Commodities, Inc.: Chua, Kelvin Uy, Rachel Wu, Ziling Exprodu Te001 (Midterm)Dokumen18 halamanTradesphere Industrial Commodities, Inc.: Chua, Kelvin Uy, Rachel Wu, Ziling Exprodu Te001 (Midterm)Kim UyBelum ada peringkat

- HSE TrainingDokumen12 halamanHSE Trainingpaeg6512100% (1)

- Customer Satisfaction and Promotional Activity of NexaDokumen63 halamanCustomer Satisfaction and Promotional Activity of NexaRaghunath AgarwallaBelum ada peringkat

- Introduction To Banking: Basics, Savings, Current, CCOD, Remittance, CashDokumen54 halamanIntroduction To Banking: Basics, Savings, Current, CCOD, Remittance, CashcutesunyBelum ada peringkat

- Impact of Packaging On Generation Y's Consumer BehaviourDokumen76 halamanImpact of Packaging On Generation Y's Consumer BehaviourRohith Thampi100% (3)

- TPM PDFDokumen18 halamanTPM PDFSaad Khadur EilyesBelum ada peringkat

- AS-Fill The Skill - 2Dokumen2 halamanAS-Fill The Skill - 2Eema AminBelum ada peringkat

- Roll No . Sushant University, Gurgaon End Term Examination, Jan 2022Dokumen2 halamanRoll No . Sushant University, Gurgaon End Term Examination, Jan 2022Kartik ChoudharyBelum ada peringkat

- 40 Easy Ways To Make Money QuicklyDokumen3 halaman40 Easy Ways To Make Money QuicklyDotan NutodBelum ada peringkat

- Answers To Cost Accounting Chapter 8Dokumen4 halamanAnswers To Cost Accounting Chapter 8Raffy Roncales54% (13)

- Chapter 1-Problems Problems 1 Problems 2Dokumen3 halamanChapter 1-Problems Problems 1 Problems 2Angela Ricaplaza ReveralBelum ada peringkat

- Electives Term 5&6Dokumen28 halamanElectives Term 5&6GaneshRathodBelum ada peringkat

- Mankiw10e Lecture Slides Ch04Dokumen43 halamanMankiw10e Lecture Slides Ch04Anggi YudhaBelum ada peringkat

- MB0045 Financial ManagementDokumen4 halamanMB0045 Financial ManagementAbhinav SrivastavaBelum ada peringkat

- Marketing Plan - ArongDokumen13 halamanMarketing Plan - ArongMarshal Richard75% (4)

- Final Zayredin AssignmentDokumen26 halamanFinal Zayredin AssignmentAmanuelBelum ada peringkat

- Group 6 Environmental ScanningDokumen9 halamanGroup 6 Environmental Scanningriza may torreonBelum ada peringkat

- CH 07Dokumen72 halamanCH 07Ivhy Cruz Estrella100% (1)

- HR Operations SpecialistDokumen3 halamanHR Operations SpecialistMuhammad FarhanBelum ada peringkat

- Assignment 2 - Termination of EmploymentDokumen5 halamanAssignment 2 - Termination of EmploymentAraceli Gloria-FranciscoBelum ada peringkat

- Customer Journey MappingDokumen1 halamanCustomer Journey MappingPriyanka RaniBelum ada peringkat

- Annual Return of A Company (Other Than A Company Limited by Guarantee)Dokumen5 halamanAnnual Return of A Company (Other Than A Company Limited by Guarantee)ramiduyasanBelum ada peringkat

- Electrocomponents - RS Group - Investor - Event - 2022 - Presentation - 30.03.2022Dokumen105 halamanElectrocomponents - RS Group - Investor - Event - 2022 - Presentation - 30.03.2022sydubh72Belum ada peringkat

- QuestionnaireDokumen5 halamanQuestionnaireNouman ShahBelum ada peringkat

- Operations and Supply Chain Management B PDFDokumen15 halamanOperations and Supply Chain Management B PDFAnonymous sMqylHBelum ada peringkat

- Ardra - MBA FINAL PROJECTDokumen90 halamanArdra - MBA FINAL PROJECTKochuthresia JosephBelum ada peringkat

- Types of Maintenance and Their Characteristics: Activity 2Dokumen7 halamanTypes of Maintenance and Their Characteristics: Activity 2MusuleBelum ada peringkat

- FA GP5 Assignment 1Dokumen4 halamanFA GP5 Assignment 1saurabhBelum ada peringkat

- Actividad de Aprendizaje 12 Evidencia 4 Questionnaire HR VocabularyDokumen12 halamanActividad de Aprendizaje 12 Evidencia 4 Questionnaire HR VocabularyJhonJaLopezBelum ada peringkat

- Is Enhanced Audit Quality Associated With Greater Real Earnings Management?Dokumen22 halamanIs Enhanced Audit Quality Associated With Greater Real Earnings Management?Darvin AnanthanBelum ada peringkat