Quality Director or VP of Quality

Diunggah oleh

api-121458377Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Quality Director or VP of Quality

Diunggah oleh

api-121458377Hak Cipta:

Format Tersedia

ROBERT LEVY 913 Rhett Butler Dr. Collierville, TN 38017 (901) 861-2518 rl13daf50@westpost.

net SUMMARY OF QUALIFICATIONS: * Professional with more than 25 years Quality Assurance experience and a comm itment to high standards. * Experienced in consumer products, telecommunication, automotive, railroad, & aerospace-defense products & manufacturing processes. * Competent & familiar with domestic & international manufacturing in USA, Chi na, Taiwan, Thailand, Europe, Canada & Mexico. * Proficient in die-casting, injection molding, metal fabrication, paint & pla ting, and printed circuit board manufacturing. * Adept in manufacturing, quality systems, APQP, DOE, FMEA, PPAP, SPC tools, & Change Notice procedures. * Effective team builder with excellent interpersonal, communication and motiv ational skills. * Familiar with MS Office, Microsoft Access, Statistical SW, AS400, & blue-pri nt software. EXPERIENCE: HUNTER FAN COMPANY, Memphis, Tennessee November 200 4 - Present Global Director of Quality Developed, implemented & manage a supplier quality score card system to measure vendor performance monthly, quarterly & semi-annually to enhance supply base imp rovements in quality systems, warranty & on-time delivery. Utilized Lean concept s to help the manufacturers achieve maximum output & yield that led to vendors m eeting or exceeding expectations: 1. Most suppliers warranty has reduced to <2.5% 2. Most suppliers have increased their on-time delivery rate to >97% & 3. Most suppliers finished goods lot acceptance rates are between 97% - 100%. 4. These systems helped drive improvements that led to Hunter warranty being red uced by $5,000,000 over the last 5 years. Experienced with assessing, starting-up, & developing manufacturers in Asia, Eur ope & Mexico on best practices & processes for fabricating consumer products. Re sponsible for the continuous evaluation of new & existing vendors to determine t he capabilities of the vendor in achieving quality standards & requirements. Upo n completion of the review determine if this is a potential supplier or not. If a potential supplier, draft a plan on the areas requiring focus/improvement & be gin the execution of the improvement plan. Manage the transition of complete pro duct categories from USA to China; Thailand to China; Taiwan to China; China to China & ensure the start-up of new vendors is timely & meets all customer expect ations. Responsible for drafting & maintaining the corporate quality organizatio n budget of approximately $750,000 annually. Set-up & manage a quality staff bot h in USA & China (20 auditors, 8 engineers & 1 manager). Establish goals & objec tives for the department & evaluate the staff performance annually. HUNTER FAN COMPANY, Memphis, Tennessee November 2001 - Nove mber 2004 Senior Quality Engineer Product & Supplier Development Assisted in the development, qualification & production implementation of over 1 500 products & 400 finishes with US & overseas manufacturers. Compose product qu alification test & reliability plans for validating product and reducing product development lead times by 25%. Drafted company Product Approval Procedure (PPAP ), training material and implementation plan for both company personnel and over seas suppliers. Train company personnel & vendors on PPAP. Perform advanced qual ity vendor training on SPC, Capability Studies, Failure Mode Effect Analysis (FM

EA), and Graphical Analysis for improving yield, quality, and reducing factory P PM. Test product in accordance to engineering specifications, quality standards, and Underwriter Laboratories guidelines. Perform color analysis using spectroph otometer and gloss meter to verify adherence to company standards. Review materi al discrepancies and product returns to determine root cause of issue and utiliz e quality tools to drive corrective actions/improvements. Perform supplier asses sment audits of domestic & overseas suppliers. NOKIA INC., Las Colinas, Texas April 1999 - October 2001 Quality Engineer Research & Development Coordinated the quality planning and documentation for the development & tra nsfer of new products from the R&D prototype facility to the manufacturing plant s overseas. Drafted project quality documents that specified program targets & g oals, such as Cpk, manufacturing yield, PPM, and supplier targets. Developed Nok ia Production Part Approval Procedure (PPAP) and trained Nokia personnel and ven dors on the procedure, which assisted in reducing Nokia product development proc ess & incoming inspections. Developed and trained personnel on Failure Mode Effe ct Analysis (FMEA) and Control Plans to evaluate and improve manufacturing proce sses. Drafted and trained personnel on a 1st phase program Change Notice procedu re that reduced scrap and rework during the prototype manufacturing. Consulted w ith vendors to review areas of concern and review corrective actions that target the root cause of the problem. ISO 9000 site contact for internal audits. REVCOR MOLDED PRODUCTS, Haltom City, Texas May 1997 April 1999 Quality Engineer Manufacturing Designated the ISO 9000 Lead Auditor and Management Representative for ISO 9001 registration upon completion of Perry Johnson ISO 9000 Lead Auditor Training dr afted second and third tier procedures in accordance to ISO 9000. Established a n Internal Auditor Training Program to train all internal auditors within the co mpany. Overseen all calibrations including the design and implementation of a s ystem which saved the company $5,000 annually. Integrated Statistical Process C ontrol (SPC) software and conducted training sessions on SPC and examine data co llection techniques to provide supervisors and lead personnel with real time ana lysis to reduce scrap and rework costs. Programmed a Coordinate Measuring Machi ne (CMM) to perform initial layout inspections and Process capability studies on both internal and vendor products. Consulted with customers to review areas of concern and submit corrective actions that targeted the root cause of the proble m. GUARDIAN AUTOMOTIVE TRIM, Grand Prairie, Texas March 1996 May 1997 Assistant Quality Manager Manufacturing Supervised a ten-employee Quality department that verified the fabrication, ass embly and painting of a $14.5 million annual sales injection molding operation. Liaison for major accounts such as Ford, GM and Delco and resolved customer con cerns/inquires through FMEA or 8D Corrective Action team analysis. Drafted contr ol plans, process flow diagrams and quality inspection procedures to improve man ufacturing processes. Applied SPC techniques and analyzed all data collection ch arts and process capability studies to evaluate & improve manufacturing processe s to provide a better quality product to the customer. Planned and prepared prod uction schedules and assigned employees to specific duties, estimating employee hour requirements for completion of assignments. Organized and conducted personn el training on product quality and reliability programs. Assisted with engineeri ng changes, interpreted specifications, blueprints, and verify part specificatio ns using inspection hand tools and CMM. Performed lab analysis using colorimete r, viscometer & melt flow equipment to verify adherence to standards. FM INDUSTRIES, INC., Fort Worth, Texas 1993 - March 1996

Quality Inspector Manufacturing Performed in-process/receiving inspections on vendor and manufactured units for conformance to specifications and standards using micrometers, dial indicators, calipers, ohmmeter, magnaflux and dye penetrant testing, volume control tests, and ultrasonic testing for weld penetration and thickness. Utilized SPC to decr ease rejected parts and production rework from manufacturing by 25%. MILITARY BACKGROUND: UNITED STATES AIR FORCE, Fort Worth, Texas May 1984 - Feb ruary 1993 Missile Maintenance Supervisor / Trainer Missile Maintenance Team Member * Top Secret Clearance (B-I) EDUCATION: EAST TEXAS STATE UNIVERSITY, Commerce, Texas August 1991 Bachelor of Science in Industrial Technology Minor: Production and Operation Management TARRANT COUNTY JUNIOR COLLEGE, Fort Worth, Texas Associate of Arts in General Education December 1991

COMMUNITY COLLEGE OF THE AIR FORCE, Montgomery, Alabama December 1991 Associate of Applied Science in Munitions Systems Technology

Anda mungkin juga menyukai

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Cash Flow Risk and Capital Structure DecisionsDokumen17 halamanCash Flow Risk and Capital Structure DecisionsMuhammad UsmanBelum ada peringkat

- AmrtasiddhiDokumen218 halamanAmrtasiddhiJoão AbuBelum ada peringkat

- Research MethodolgyDokumen4 halamanResearch MethodolgyRizwan BalouchBelum ada peringkat

- 2549 5147 1 SM PDFDokumen8 halaman2549 5147 1 SM PDFNurul AisyahBelum ada peringkat

- PROG-111 Week 1-9Dokumen89 halamanPROG-111 Week 1-9Jaspher0% (1)

- Encyclopedia of Clinical Pharmacy by Joseph T. DiPiroDokumen958 halamanEncyclopedia of Clinical Pharmacy by Joseph T. DiPiroAlex Pieces100% (1)

- Study On Consumer Behaviour For Ayurvedic Products With Special Reference For Consumers in Kolkata-4Dokumen9 halamanStudy On Consumer Behaviour For Ayurvedic Products With Special Reference For Consumers in Kolkata-4Raj AtulBelum ada peringkat

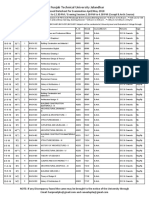

- Prposed Date Sheet Upload Web SiteDokumen154 halamanPrposed Date Sheet Upload Web SiteShaheer ShafatBelum ada peringkat

- A Study On Training & Development in Kurnool: Yamaha Motors P.Chakrapani ReddyDokumen7 halamanA Study On Training & Development in Kurnool: Yamaha Motors P.Chakrapani ReddybagyaBelum ada peringkat

- Overload Learning, Attachment and Coping Styles Predictors of Mental and Physical Health of Teenage High School Students in RomaniaDokumen5 halamanOverload Learning, Attachment and Coping Styles Predictors of Mental and Physical Health of Teenage High School Students in RomaniaERIKA FAITH AQUINOBelum ada peringkat

- Carufel-Bye2020 Article ExplorationOfTheBodyGarmentRelDokumen28 halamanCarufel-Bye2020 Article ExplorationOfTheBodyGarmentRelAyşegül Yıldız KonukcuBelum ada peringkat

- Clinical Risk Management Systems 1Dokumen11 halamanClinical Risk Management Systems 1Dharmik ninama100% (4)

- Practical Design of Experiments (DOE)Dokumen26 halamanPractical Design of Experiments (DOE)Majid ShakeelBelum ada peringkat

- Improving Attendance and Academic Performance Among Grade 12 Students PDFDokumen22 halamanImproving Attendance and Academic Performance Among Grade 12 Students PDFPede CasingBelum ada peringkat

- Key Organizational Risk Factors A Case Study of Hydroelectric Power Projects, MyanmarDokumen161 halamanKey Organizational Risk Factors A Case Study of Hydroelectric Power Projects, Myanmarhtoochar123100% (3)

- Homework and Practice Workbook Holt Middle School Math Course 2 AnswersDokumen4 halamanHomework and Practice Workbook Holt Middle School Math Course 2 Answersd0t1f1wujap3100% (1)

- BATL050Dokumen11 halamanBATL050Roxana TroacaBelum ada peringkat

- Nonparametric Statistics and Model Selection: 5.1 Estimating Distributions and Distribution-Free TestsDokumen10 halamanNonparametric Statistics and Model Selection: 5.1 Estimating Distributions and Distribution-Free TestshalijahBelum ada peringkat

- HR Planning ArticleDokumen17 halamanHR Planning Articlegagan_9989495Belum ada peringkat

- OCR-A-Level Psychology Study-Summaries Core-SampleDokumen15 halamanOCR-A-Level Psychology Study-Summaries Core-SampleAyaBelum ada peringkat

- Viral Markers Screening: King Khalid Hospital, NajranDokumen1 halamanViral Markers Screening: King Khalid Hospital, NajranCristal TannerBelum ada peringkat

- OR II Lecture NotesDokumen15 halamanOR II Lecture NotesGiramia Moniquea OmodingBelum ada peringkat

- Mat 2377 Final 2011Dokumen12 halamanMat 2377 Final 2011David LinBelum ada peringkat

- ResearchDokumen6 halamanResearchDomBelum ada peringkat

- Minat Baca Siswa Kelas Rendah Dalam Pelaksanaan Literasi Sekolah Di SD Islam Al Azhar 34 Makassar Hasninda DamrinDokumen11 halamanMinat Baca Siswa Kelas Rendah Dalam Pelaksanaan Literasi Sekolah Di SD Islam Al Azhar 34 Makassar Hasninda DamrinMariaUlfaBelum ada peringkat

- Morecambe Marina Feasibility Study Main Report PDFDokumen59 halamanMorecambe Marina Feasibility Study Main Report PDFharyanto99100% (1)

- Bititci Et Al-2012-International Journal of Management ReviewsDokumen23 halamanBititci Et Al-2012-International Journal of Management ReviewsdinolanmBelum ada peringkat

- Ielts Academic Writing Sample ScriptDokumen6 halamanIelts Academic Writing Sample Scriptkc103038Belum ada peringkat

- 3 Types of Nursing Research PDFDokumen2 halaman3 Types of Nursing Research PDFPxPPxH ChanBelum ada peringkat

- Integenx Rapid DnaDokumen14 halamanIntegenx Rapid Dnaapi-400796139Belum ada peringkat