Rigging Plan Tracking Conveyor

Diunggah oleh

rtyuibnmDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Rigging Plan Tracking Conveyor

Diunggah oleh

rtyuibnmHak Cipta:

Format Tersedia

12

11

10

PROJECT

OUT OF PIT CRUSHING AND CONVEYING (OPCC) SYSTEMS

RIGGING PLAN TRACKING CONVEYOR

OWNER

PT ADARO INDONESIA, Tbk

Menara Karya, 23rd Floor Jalan H.R. Rasuna Said Block X-5, Kav. 1-2 Jakarta 12950, Indonesia Phone: +6221-521-1265

CONTRACTOR

FLSmidth Indonesia

Gedung BRI II, 21st floor, Suite # 2101 Jalan Jendral Sudirman Kav. 44-46 Jakarta 10210, Indonesia Tel +62 21 251 27 38/2739 Fax +62 21 251 27 40

A

PT WIJAYA KARYA (Persero), Tbk

Jl. DI Panjaitan Kav 9 Jakarta 13340 Phone : (62-21) 819 2808, 850 8640, 850 8650 Fax : (62-21) 856 4463, 819 1235

DRAWING NUMBER :

12 11 10 9 8 7 6 5 4 3 2 1

PRELIMINARY Document Number OPCC-90-RIG-0002

INSTALLING APRON FEEDER

Rev. : A 29 July 2011 Page 1 of 2

OWNER CONTRACTORS PROJECT NAME LOCATION

: PT ADARO INDONESIA : PT WIJAYA KARYA (PERSERO) Tbk : Out of Pit Crushing and Conveyor System : TUTUPAN-KALIMANTAN SELATAN

29 July 2011

Issued For Review

HaGun

SAFETY Reviewed By

CM Approved By Reviewed By Approved By

Made By REV DATE DESCRIPTION

PT WIJAYA KARYA

FLSmidth

PRELIMINARY Document Number OPCC-90-RIG-0002

INSTALLING APRON FEEDER

Rev. : A 29 July 2011 Page 2 of 2

TABEL OF COUNTENT

No 1 2 3 Chapter Number CHAPTER 1 CHAPTER 2 CHAPTER 3 CHAPTER 4 CHAPTER 5 CHAPTER 6 CHAPTER 7 CHAPTER 8 CHAPTER 9 CHAPTER 10

Title Method Of Work Job Safety Assessment Procedure Safe Work Method Statement Risk Management Safe Work Method Statement (SWMS) Rigging Plan Rigging Tools Critical Lift Worksheet Lift Study Crane Study General Scaffolding Safety Checklist

4 5 6 7 8 9 10

PRELIMINARY Document Number OPCC-90-RIG-0003

METHOD OF WORK INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 1 of 11

CHAPTER 1

PRELIMINARY Document Number OPCC-90-RIG-0003

METHOD OF WORK INSTALLING TRACKING CONVEYOR

TABLE OF CONTENT

Rev. : A 29 July 2011 Page 2 of 11

TABLE OF CONTENT .................................................................................................................. 2 1 2 3 GENERAL ............................................................................................................................. 4 PURPOSE ............................................................................................................................ 4 GENERAL NOTE .................................................................................................................. 4 3.1 3.2 Inspection ....................................................................................................................... 4 Safety ............................................................................................................................. 4 A safety officer presents all times Safety Briefing. .................................................. 4 Job Safety Assessment (JSA) must be carried out for all crane lifts and all other

3.2.1 3.2.2

tasks that have potential risk to personnel of equipment. ..................................................... 4 3.2.3 Install scaffolding where necessary to install bolt in trestles / support legs

connection. ........................................................................................................................... 4 3.2.4 3.2.5 Pre lift study before any lifting activity. .................................................................... 4 Lift briefing and Safety briefing before any lift; assign responsibility to all personnel

involved. (Hand signals, Rigger to crane driver, etc.) ........................................................... 4 3.2.6 Insure all equipment required for installation is on hand and in position before lift

i.e. Chain blocks, Level blocks, Podgy, Drifts, Hammer, Spanners. Etc. .............................. 4 3.2.7 3.2.8 3.2.9 Tag lines must be used to control lift. ...................................................................... 4 Ground conditions must be ready before activities. ................................................ 4 Set up safety rope around lifting area of Tracking Conveyor area and put notice

board entered KEEP OFF EXCEPT PERSONEL CONCERNED. ..................................... 4 3.2.10 3.2.11 3.3 3.4 4 Lifting equipment should be in certification and tagged. ......................................... 4 Crane and other machinery shall be inspected and certified. ................................. 4

Lifting .............................................................................................................................. 4 Assembly and erection ................................................................................................... 5

RESPONSIBILITY ................................................................................................................ 5 4.1 Construction Manager .................................................................................................... 5

PRELIMINARY Document Number OPCC-90-RIG-0003

METHOD OF WORK INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 3 of 11

4.2 4.3 4.4 4.5 5

Field Engineer ................................................................................................................ 5 Field Superintendent and Supervisor ............................................................................. 5 Quality Control Engineer ................................................................................................ 5 Supporter Activities ....................................................................................................... 5

BASIC REQUIREMENT ....................................................................................................... 5 5.1 5.2 5.3 5.4 5.5 Schedule and Planning .................................................................................................. 5 Erection Drawing and Erection Manual .......................................................................... 5 Packing List .................................................................................................................... 6 Storage Area and Warehouse ........................................................................................ 6 Resources ...................................................................................................................... 6

PREPARATION WORK ........................................................................................................ 6 6.1 6.2 6.3 6.4 Checking of Tracking Conveyor Erection Drawings ...................................................... 6 Checking of Client Supplied Material and Equipment .................................................... 6 Checking of Erection Materials, Equipment, Tools and Machinery ................................ 6 Checking of Labour ........................................................................................................ 6

TRACKING CONVEYOR ERECTION SEQUENCE ............................................................. 7 7.1 7.2 Preparation ..................................................................................................................... 7 Step of Works ................................................................................................................. 8 Unload the Tracking Conveyor from Landing Craft Tank to Jetty Land Yard .......... 8 Delivered the Tracking Conveyor from Landing Craft Tank to project area ............ 9 Placed Object on the Work Floor .......................................................................... 10 Rotating Process ..................................................... Error! Bookmark not defined. Leaving the object at the destination lifting ............. Error! Bookmark not defined. Object on Position ................................................................................................. 11

7.2.1 7.2.2 7.2.3 7.2.4 7.2.5 7.2.6

PRELIMINARY Document Number OPCC-90-RIG-0003

METHOD OF WORK INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 4 of 11

GENERAL This procedure provides information about the erection of Tracking Conveyor at Out of Pit Crushing and Conveyor System Project.

PURPOSE This Procedure is to make sure that all people involve in the erection, assembly and welding of Tracking Conveyor activity understand and familiar to doing the work with quality control system for getting quality result as per client specification and requirement, drawing, standard and code.

3 3.1

GENERAL NOTE Inspection As per the works required inspection, carry out inspection under attendance of Superintendent / Engineer and as surreally record is result.

3.2 3.2.1 3.2.2

Safety A safety officer presents all times Safety Briefing. Job Safety Assessment (JSA) must be carried out for all crane lifts and all other tasks that have potential risk to personnel of equipment.

3.2.3 3.2.4 3.2.5

Install scaffolding where necessary to install bolt in trestles / support legs connection. Pre lift study before any lifting activity. Lift briefing and Safety briefing before any lift; assign responsibility to all personnel involved. (Hand signals, Rigger to crane driver, etc.)

3.2.6

Insure all equipment required for installation is on hand and in position before lift i.e. Chain blocks, Level blocks, Podgy, Drifts, Hammer, Spanners. Etc.

3.2.7 3.2.8 3.2.9

Tag lines must be used to control lift. Ground conditions must be ready before activities. Set up safety rope around lifting area of Tracking Conveyor area and put notice board entered KEEP OFF EXCEPT PERSONEL CONCERNED.

3.2.10 Lifting equipment should be in certification and tagged. 3.2.11 Crane and other machinery shall be inspected and certified. 3.3 Lifting All conditions adapted to the lifting procedure. Prior to commencement of lifting works, assuredly carry out check of lifting equipment.

PRELIMINARY Document Number OPCC-90-RIG-0003

METHOD OF WORK INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 5 of 11

3.4

Assembly and erection Assembly and erection of Tracking Conveyor, accordance to manual book and relevant drawing

4 4.1

RESPONSIBILITY Construction Manager Responsible for the overall planning, coordination and control of erection work.

4.2

Field Engineer Responsible for field erection work implementation and maintaining acceptable quality standard.

4.3

Field Superintendent and Supervisor Responsible for the actual performance of the erection crew and examine the actual progress of work to ensure that it fit the drawing specifications and standards.

4.4

Quality Control Engineer Responsible to monitor and inspect the erection activities to ensure it is being done in compliance with procedure, ITP (Inspection and Test Plant), drawing, Project specification and other reference standard document and procedures.

4.5

Supporter Activities These activities will support by Material Control, Quality Control, Welding Section, and others section related with these activities.

5 5.1

BASIC REQUIREMENT Schedule and Planning Master schedule is usually provided by FLSmidth. The detailed schedule is prepared by Wijaya Karya according to his planning which is based on FLSmidths master schedule. The milestone and the critical path can be identified which require proper planning. The sequence of erection activities and the resources required is included in the planning.

5.2

Erection Drawing and Erection Manual Erection drawing and manual usually provided by Wijaya Karya. The Field Engineer and Superintendent shall check all drawings intended for Tracking Conveyor erection. All the information required is completed and all drawings shall be of current revision.

PRELIMINARY Document Number OPCC-90-RIG-0003

METHOD OF WORK INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 6 of 11

5.3

Packing List Packing List shall be made available by FLSmidth. This included all the listing of materials, equipment and parts that are supplied. The Packing List should indicate the quantity of the material and equipment supplied and its specification as described in the erection drawing. This will also indicate the size and the total weight of the component and the method of storage. Also the packing number and material coding is very essential.

5.4

Storage Area and Warehouse Upon a thorough check on the drawing and the packing list, the quantity of materials and equipment is already known, including the method of storing, the size of the storage area and the warehouse can be identifies.

5.5

Resources Identification of resources is integral part of planning and scheduling is the most essential part of the basic requirement in undertaking Out of Pit Crushing and Conveyor System Project in particular and in all jobs in general. Resources means, the materials, labour and equipment needed to perform Out of Pit Crushing and Conveyor System Project.

6 6.1

PREPARATION WORK Checking of Tracking Conveyor Erection Drawings This has to be done by the Construction Manager, Field Engineer, Superintendent and Supervisor to determine the correct resources needed to perform the job.

6.2

Checking of Client Supplied Material and Equipment Checking and inspection of the materials and equipment including the spare parts is to be done by the material control. He will make sure that all materials, equipment and spare parts received from FLSmidth, conform to the quantity and the specifications started in the packing list or shipping.

6.3

Checking of Erection Materials, Equipment, Tools and Machinery In the early stage of planning, these resources had been already identified. The schedule of mobilization is as planed schedule made by the Construction Manager and Engineer.

6.4

Checking of Labour Labour requirement for every stage of erection job is prepared by the Chief Engineer and his erection team, which is in accordance to their planning.

PRELIMINARY Document Number OPCC-90-RIG-0003

METHOD OF WORK INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 7 of 11

TRACKING CONVEYOR ERECTION SEQUENCE

It is assumed in this procedure that before starting the erection of the Tracking Conveyor, the supporting structure were already erected and checked by others and clearance to proceed with the Tracking Conveyor system erection had been obtained. The following sequences are for reference only. During actual field assembly, refer to lifting procedure and erection drawing (Rigging plan). 7.1 Preparation Make sure the job site in a safe condition for the installation work, in accordance with the requirements of Health Safety Environment department. Prepare equipment and materials that will be done. All equipment in good condition. In accordance with the Safety Equipment Checklist. All man power associated with lifting and installation job, certainly in good health. Make sure if the main frame for support of Tracking Conveyor in ready for supporting. Make sure that if the Crawler Crane 120 tons in good condition. In accordance with the results inspection crane safety checklist. This use for main crane for lifting. Ensure the use of 20 millimetre thick steel plate to the floor where the position of crawler cranes for work.

PRELIMINARY Document Number OPCC-90-RIG-0003

METHOD OF WORK INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 8 of 11

7.2 7.2.1

Step of Works Unload the Tracking Conveyor from Landing Craft Tank to Jetty Land Yard

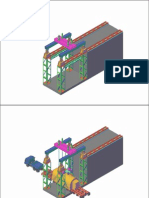

Figure 1

PRELIMINARY Document Number OPCC-90-RIG-0003

METHOD OF WORK INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 9 of 11

These activities: Mengeluarkan Tracking Conveyor dari Landing Craft Tank, menggunakan Multi Axel. 1. Jacking up Tracking Conveyor sehingga Multi Axel dapat masuk kebawah-nya. 2. Turunkan Jack up, sehingga beban Tracking Conveyor berpindah dari elephant foot. 3. Kunci Tracking Conveyor ke Multi Axel menggunakan sling dan lever block.

7.2.2

Delivered the Tracking Conveyor from Landing Craft Tank to project area

Figure 2

These activities: 1. Multi Axel bergerak dengan dengan kecepatan 20km/jam, dari jetty tujuan site project. 2. Sesuai dengan standard safety PT Adaro, maka Multi Axel mendapat pengawalan di depan dan di belakang-nya.

PRELIMINARY Document Number OPCC-90-RIG-0003

METHOD OF WORK INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 10 of 11

7.2.3

Placed Object on the Work Floor

Figure 3

These activities: 1. Connected lifting tool to Tracking Conveyor. 2. Lift object until 1 meter up to multi axel. 3. Multi Axel bergerak menjauhi lokasi.

PRELIMINARY Document Number OPCC-90-RIG-0003

METHOD OF WORK INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 11 of 11

7.2.4

Object on Position

Figure 4

These activities: 1. Turunkan Tracking Conveyor secara perlahan, sehingga mencapai tujuan. 2. Rigger and Fitter are positioning the Tracking Conveyor to target placement. 3. After the Tracking Conveyors are in correct position, connected it by using bolts and nuts are recommended. Strengthen all the connector. 4. Make sure the Tracking Conveyors have been strong enough to stand alone. Refer to lifting safety checklist. 5. Disconnect all the connectors to the Tracking Conveyor crane. 6. Crane left the job site. 7. Welcome to the Quality Control to do the inspection.

PRELIMINARY Document Number OPCC-90-RIG-0003

JOB SAFETY ASSESSMENT PROCEDURE INSTALLING

TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 1 of 10

CHAPTER 2

PRELIMINARY Document Number OPCC-90-RIG-0003

JOB SAFETY ASSESSMENT PROCEDURE INSTALLING

TRACKING CONVEYOR

TABLE OF CONTENT

Rev. : A 29 July 2011 Page 2 of 10

TABLE OF CONTENT .................................................................................................................. 2 1 2 3 GENERAL ............................................................................................................................. 3 DEFINITIONS ....................................................................................................................... 3 RESPONSIBILITIES ............................................................................................................. 4 3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8 3.9 3.10 4 MANAGERS ................................................................................................................... 4 SUPERVISORS ............................................................................................................. 4 RESPONSIBLE OFFICER ............................................................................................. 4 PERMIT AUTHORISER ................................................................................................. 5 PERMIT HOLDER .......................................................................................................... 5 TEAM MEMBERS (WORKERS PERFORMING THE TASK) ........................................ 5 SAFETY ADVISOR AND TRAINING IMPROVEMENT COORDINATOR ...................... 5 SHIFT SUPERVISOR .................................................................................................... 6 SAFETY REPRESENTATIVES ...................................................................................... 6 COMPLIANCE TEAM ................................................................................................. 6

JOB SAFETY ANALYSIS (JSA) PROCESS ......................................................................... 6 4.1 PROCESS STEP DETAILS ........................................................................................... 7

NOTICE .............................................................................................................................. 10

PRELIMINARY Document Number OPCC-90-RIG-0003

JOB SAFETY ASSESSMENT PROCEDURE INSTALLING

TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 3 of 10

GENERAL This document applies to all employees and Contractors of Wijya Karya, and full compliance is required by 29 July 2011, in the erection of Tracking Conveyor at Out of Pit Crushing and Conveyor System Project.

DEFINITIONS Task A segment of work that requires a set of specific and distinct actions, which has a definable goal or outcome. Job A specific task that is performed in a particular location. A jobs hazards are a combination of the task hazards and the work area hazards. Minor Job A task of negligible risk (typically a single step) that is planned to be performed in a work area such that it: does not involve moving off a walkway, is within handrails, does not have the potential to make contact with moving parts or hazardous substances (i.e. no additional PPE), does not require isolations, and Does not require additional support equipment (e.g. ladder, scaffolding, harness). For example: Opening or closing a Valve. Visual inspection of equipment. Lubrication. Plant cleaning, where no isolation is required. Non-intrusive condition monitoring etc.

JSA

Job Safety Analysis is a structured risk assessment used for tasks of substantial size; ideally developed by those conducting the work.

TBRA

Team Based Risk Assessment. A risk assessment structured that is used for complex and high hazard situations on work.

Standard Procedure

A document, which contains detailed instruction regarding a

particular task (routine or non-routine) and will over time, come to

PRELIMINARY Document Number OPCC-90-RIG-0003

JOB SAFETY ASSESSMENT PROCEDURE INSTALLING

TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 4 of 10

contain a risk assessment document (where there is any risk other than negligible). The types of Standard Procedures include: Standard Operating Procedure held in Document Management System. Standard Maintenance Procedure / PMs / Work Orders that are used on a scheduled or as needed basis.

A personal safety check, completed by an individual, and which identifies hazards and encourages review of risks before carrying out a task.

3 3.1

RESPONSIBILITIES MANAGERS Managers shall ensure compliance with this guide manual within their area of responsibility

3.2

SUPERVISORS Supervisors shall: 1. Ensure their personnel are competent in basic risk assessments and comply with the requirements of this guide manual. 2. Ensure all tasks are risk assessed in accordance with this guide manual. 3. Authorise JSAs that are used to create or revise Standard Procedures.

3.3

RESPONSIBLE OFFICER The Responsible Officer (RO) shall: 1. Ensure Contractors have an adequate risk assessment in accordance with this guide manual. 2. Review and endorse (by signature) all JSAs, Standard Procedure or other generic risk assessments to be used. This task-based risk document is then supplemented by risk assessing the hazards associated with the work environment just prior to the work by: a. updating the JSA b. working under a new Work Permit

PRELIMINARY Document Number OPCC-90-RIG-0003

JOB SAFETY ASSESSMENT PROCEDURE INSTALLING

TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 5 of 10

3.4

PERMIT AUTHORISER The Permit Authoriser shall: 1. Ensure risk assessment for the task is adequate before authorizing the Work Permit. 2. Understand the hazards and controls that have been put in place to minimize the risk of incidents. 3. Discuss additional area specific hazards and controls with the Permit Holder as identified on the new Work Permit or ensure that these are identified by Take 5 or revised JSA.

3.5

PERMIT HOLDER The Permit Holder shall: 1. Ensure the appropriate level of risk assessment for the type of job is completed. 2. Walk through the work area escorted by an operational person if they are not familiar with the hazards and layout. 3. Ensure all hazard controls are maintained during the task and personnel working on the task follow the requirements of all the risk management documentation: Standard Procedures (SOPs, PMs, Work Orders), JSA, Work Permit

3.6

TEAM MEMBERS (WORKERS PERFORMING THE TASK) The Team Members shall: 1. Participate in developing risk assessment or read, review and include any additional risk controls to existing JSA / Standard Procedure / Work Permit. 2. Understand the hazards and controls that have been put in place to minimize the risk of incidents and their responsibility in maintaining those hazard controls. 3. Where a JSA risk assessment is used, write the date, their name and sign onto the document before commencing the task every day / shift they are on that task to indicate their acceptance to work in line with the risk assessments on the job.

3.7

SAFETY ADVISOR AND TRAINING IMPROVEMENT COORDINATOR The Safety Advisor and Training Improvement Coordinator shall: 1. Provide support to all aspects of the risk assessment process. 2. Audit risk assessments in their area of responsibility to ensure compliance with this guide manual. 3. Facilitate JSAs is being absorbed into Standard Procedures.

PRELIMINARY Document Number OPCC-90-RIG-0003

JOB SAFETY ASSESSMENT PROCEDURE INSTALLING

TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 6 of 10

4. Deliver Basic Risk Assessment training sessions. 5. Approve use of a contractors own format of risk assessment (Safety Advisor and Shift Supervisors only). 3.8 SHIFT SUPERVISOR The Shift Supervisor shall: 1. Approve use of a contractors own format of risk assessment outside of normal working hours. 3.9 SAFETY REPRESENTATIVES The Safety Representatives shall: 1. Facilitate and support the JSA process for their area of responsibility. 3.10 COMPLIANCE TEAM The Compliance Team shall: 1. Verify the implementation of this guide manual by: a. Review of documentation. b. Interview of personnel.

JOB SAFETY ANALYSIS (JSA) PROCESS

There are eight (8) steps in preparing a JSA as follows.

Step 1 Select the job to be analyzed Step 2 Using the JSA worksheet, break down the job into logical steps and in the correct sequence that the work will be carried out Step 3 Identify all the hazards in each step Step 4 Develop Hazard Controls required Step 5 Measure the Residual Risk Step 6 Sign JSA Acknowledgement Sheet Step 7 Review and Update the JSA Step 8 File the JSA

PRELIMINARY Document Number OPCC-90-RIG-0003

JOB SAFETY ASSESSMENT PROCEDURE INSTALLING

TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 7 of 10

4.1

PROCESS STEP DETAILS 1. Select the job to be analysed. 2. Using the JSA worksheet, break down the job into logical steps and in the correct sequence that the work will be carried out. 3. Identify all the hazards in each step. This can be done by: a. Reviewing the listing of hazards on the JSA worksheet itself. b. Considering any additional hazards that may arise. c. Considering pollution of the environment, competency of workers, fitness issues, fatigue of workers, simultaneous operations in the area and other personnel in the area and damage to equipment. 4. Develop Hazard Controls required When determining hazard control measures use the following preferred order of controls: a. Elimination of the hazard. b. Substitution with a less hazardous process or substance. c. Engineering controls (guarding, interlocks, mechanical aids, barriers). d. Administration controls (operating or maintenance procedures, JSA, reducing exposure time). e. PPE Personal Protective Equipment (refer checklist on front of JSA form). 5. Measure the Residual Risk In order to check that the hazards have been sufficiently controlled by the actions nominated, it is a requirement to assess the residual risk that exists with the controls in place. Risk is the combination of the likelihood of an incident resulting from a hazard and the potential consequences if it occurs. Refer Table 2. Consequence is the outcome that can be reasonably expected, refer Table 1. Likelihood is how possible it is for the incident to occur, refer Table 1.

PRELIMINARY Document Number OPCC-90-RIG-0003

JOB SAFETY ASSESSMENT PROCEDURE INSTALLING

TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 8 of 10

CONSEQUENCE Insignificant Minor Moderate Major Catastrophic

DESCRIPTION Injury / Illness Minor Injury / Illness Medical Treatment Injury / Illness Restricted Duties Injury / Illness Lost Time Injury / Illness Fatality or Permanent Disability Injury / Illness .. RISK RANK E H M L Environment Little or no environmental impact Small and/or localized impact Substantial environmental impact Serious environmental impact Widespread environmental impact

LIKELIHOOD Rare Unlikely Possible Likely Almost certain

DESCRIPTION Only by exception Could occur at some stage Might occur at some time Will probably occur Is expected to occur

IMPACT Extreme risk High risk Medium risk Low risk

Table 1 JSA Risk Assessment: Consequence, Likelihood and Risk Ranking Definitions

a. Once the reasonable consequence and likelihood of each potential unwanted event is determined, the risk can be ranked using the Risk Matrix below and recorded on the JSA Worksheet LIKELIHOOD Rare Unlikely Possible Likely Almost certain CONSEQUENCE Insignificant L L L M H Minor L L M H H Moderate M M H H E Major H H E E E Catastrophic H E E E E

Table 2 JSA Risk Matrix: Likelihood versus Consequence

PRELIMINARY Document Number OPCC-90-RIG-0003

JOB SAFETY ASSESSMENT PROCEDURE INSTALLING

TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 9 of 10

b. The risk ranking is then used to determine those risks that have an acceptable level of risk i.e. are controlled. c. An Extreme risk outcome is not acceptable and the job cannot commence. Risk rank scores of Extreme require additional risk reduction strategies to be implemented. Risk rank scores of High need to be highlighted to both the workers in the team and the Permit Authorizer. d. Responsible Officers shall be made aware of any High risk work planned by the Contractors. e. Potential work that results in an Extreme risk ranking shall not go ahead. Additional hazard controls need to be implemented. If these are not known to those planning to undertake the work, an additional risk assessment tool is required, such as Team Based Risk Assessment. The Business Unit Manager (or their designate) shall authorize the outcome of the TBRA as it relates to the planned work.

6. Sign JSA Acknowledgement Sheet Construction Manager, Safety Manager and Rigging Supervisor, shall sign the JSA Acknowledgement Sheet to confirm that they have read and understood the risk reduction measures specified in the JSA. This is done every day that the work is being progressed under the JSA. This is completed after revalidation of the Work Permit by the Permit Authorizer and briefing by the Permit Holder to their team on any changed conditions. The person in charge of a job, signs to endorse the JSA as appropriate for the task, on the day of the task. 7. Review and Update the JSA The JSA is to be reviewed and updated whenever there are changes to the job or the hazards and controls required. This may trigger changes to the Standard Procedure. 8. File the JSA

PRELIMINARY Document Number OPCC-90-RIG-0003

JOB SAFETY ASSESSMENT PROCEDURE INSTALLING

TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 10 of 10

There is no regulatory requirement to retain a completed JSA unless there has been an incident on that task and then it forms part of the investigation documents. The only exception to this is confined space activities where JSAs shall be retained for 5 years as required under legislation.

As a business decision, once the JSA has been used on the task, the JSA is to be retained as a controlled document in CSBPs Document Management System for future reference. Refer to Section 10: JSAs and Standard Procedures for further details 5 NOTICE

The other things which not be coverage and included in this regulation will be added and described in the other documents.

PRELIMINARY

Document Number OPCC-90-RIG-0003

SAFE WORK METHOD STATEMENT INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 1 of 8

CHAPTER 3

PRELIMINARY

Document Number OPCC-90-RIG-0003

SAFE WORK METHOD STATEMENT INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 2 of 8

Work activity: Project: Prepared by: Name: Gunawan, H HaGun Reviewed and Approved by: Name: HaGun Gunawan Hg Gunawan, H HaGun Gunawan Date safe work method prepared: 29 July 2011 Signature: Signature:

Location: Project No.:

ITP Reference: SWMS No.:

Position: Rigging Engineer Project Engineer

Name:

Signature:

Position:

Position

Date:

Date work to be commenced:

PRELIMINARY

Document Number OPCC-90-RIG-0003

SAFE WORK METHOD STATEMENT INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 3 of 8

Action before work commences: All Wijaya Karya inductions complete. Client Liaison Coordinator advised (if applicable). Warning signage for overhead electrical power to be placed on every mast and gantry. Work method shall be explained to all personnel participating in the task prior to the commencement of the activity, all personnel to sign the Work Method Statement. Daily Pre-start meetings to be undertaken and recorded. Daily plant pre-start checklist completed. All personnel advised of first aid location.

Action during work: All PPE must be correctly worn at all times. Work site to be kept clean and tidy at all times. Safety Pins to be installed on all Quick Hitch attachments. Regular review and assessment of controls shall be carried out. Positive communication shall be established with the crane operator using 2-way radios or precise hand signals. When issued all work to adhere to SCA conditions Action after works is complete: All plant to be securely locked up at conclusion of each workday. All tools and equipment to be cleaned, and securely stored away at conclusion of each workday. Work area to be kept clean and tidy. All gates to be locked after all personnel have exited. Personnel qualification & experience required: Crane Operators, Riggers, Protection Officer, Supervisors, Labourers Engineering details/certificates authority approval required: Lifting Assembly to be fully certified.

PRELIMINARY

Document Number OPCC-90-RIG-0003

SAFE WORK METHOD STATEMENT INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 4 of 8

Supervision: Foreman, Protection Officer Plant, equipment & materials to be used and the maintenance checks to be completed: Crawler crane 120 ton, trailers,

Permits e.g., confined spaces, hot work etc: Environmental Permits, Cultural Heritage Areas plan. Warning signs and control measures: Clear zones are to be established around the crane and where the Tracking Conveyor will be lowered on the piers. All loads are to be lifted and slung by a Qualified Rigger or Dogman. Spotter present when working close to the track (overhead power lines). All lifting equipment must be checked and tagged current. Warning signage for overhead electrical power to be placed on every mast and gantry. Lift plan to be provide before commencement works and approved.

Training and Instruction: All Operators and Riggers must be suitably trained and carryall relevant certificates. Tool Box on Safe Work Method, Daily Pre-start Brief. Legislation, codes of practice, standards applicable: AS 2550 - 1 Cranes Safe Use General Required AS 2550 - 5 Cranes Safe Use Mobile & Vehicle AS 2550 - 6 Cranes Safe Use - Guided St & Ret App AS 2550 - 10 Cranes Safe Use EWPs AS 1891 3 Industrial Fall Arrest Devices Crane Book by Crane Vendor

Personal protective equipment requirements: PPE according to the Wijaya Karya standard.

List of attachments (e.g. material safety data sheets, diagrams etc): Lind ores SWMS: Lifting and positioning of Tracking Conveyor units onto that position.

PRELIMINARY

Document Number OPCC-90-RIG-0003

SAFE WORK METHOD STATEMENT INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 5 of 8

How severely could it hurt someone or how ill could it make someone? Kill or cause permanent disability or ill health Long term illness or serious injury Medical attention and several days off work First aid needed

How likely is it to occur? Very likely Could happen any time 1/H Likely Could happen sometime 1/H Unlikely Could happen but very rarely 1/H Very unlikely Could happen, but probably never will 2/M

1/H

1/H

2/M

2/M

1/H 2/M

2/M 2/M

2/M 3/L

3/L 3/L

PRELIMINARY

Document Number OPCC-90-RIG-0003

SAFE WORK METHOD STATEMENT INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 6 of 8

ITEM

WHAT ARE THE BASIC STEPS

POTENTIAL HAZARDS

(What may cause an injury/illness to occur)

RISK HAZARD CONTROLS RANKING (What controls can be put in place to prevent an injury/illness) 1(H), 2(M), N.B. Control measures must not raise or create an increased risk or 3(L) All work group to be made aware of scope of works Ticketed/certified personnel to carry out pre start check

WHO WILL ENSURE THAT THIS IS DONE

Daily Pre-Start Safety Brief

Plant in unsafe condition causing slips trips, falls Plant failure Electro conduction

All personal

Daily Pre-Start Plant Check

Plant Operators

Start up plant Position Crawler crane 120 ton in accordance with PT Wijaya Karya Safe Work Method Statement Load required amount of counter weights onto crawler crane, install and secure weights in accordance with PT Wijaya Karya Safe Work Method Statement Check all lifting equipment. Raise crane boom to a safe radius. Check all motions, limits and operation of controls in accordance with PT Wijaya

Plant Operators

Wika Personnel

Wika Personnel

Wika Personnel

PRELIMINARY

Document Number OPCC-90-RIG-0003

SAFE WORK METHOD STATEMENT INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 7 of 8

Karya Safe Work Method Statement Position elastomeric bearings on new piers (off scaffolding next to blade piers) Limb injuries Fall from scaffolding Ensure appropriate care is taken. Ensure good manual handling techniques are employed and work process communicated to workers. Ensure workers are wearing safety harnesses attached to horizontal safety bar (edge protection) of scaffold

Wika Personnel

Lift Tracking Conveyors, attach specified tag line & static line and place Tracking Conveyors on piers in accordance with PT Wijaya Karya Safe Work Method Statement Remove lifting chains from Tracking Conveyor Repeat steps 7-9 until all 2 Tracking Conveyors have been placed Collision with personnel, structures etc. Limb injuries Ensure appropriate care is taken while operating plant and adequate safety distance is adhered while moving vehicles. Shutdown plant in accordance with manufacturer's recommendations and/or specifications. Fall from Tracking Conveyor Ensure dogman is wearing safety harness attached to static line on Tracking Conveyor.

Wika Personnel

Wika Personnel

10

Wika Personnel

11

Move plant to a designated shutdown area at the conclusion of each work day

Operators

PRELIMINARY

Document Number OPCC-90-RIG-0003

SAFE WORK METHOD STATEMENT INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 8 of 8

12 Move temporary fencing back to original position

Limb injuries from poor manual handling

Ensure good manual handling techniques are employed and communicated to all workers

Foreman

PRELIMINARY

RISK MANAGEMENT SAFE WORK METHOD STATEMENT (SWMS) INSTALLING

Rev. : A 29 July 2011 Page 1 of 7

Document Number OPCC-90-RIG-0003

TRACKING CONVEYOR

CHAPTER 4

PRELIMINARY

RISK MANAGEMENT SAFE WORK METHOD STATEMENT (SWMS) INSTALLING

Rev. : A 29 July 2011 Page 2 of 7

Document Number OPCC-90-RIG-0003

TRACKING CONVEYOR

COMPANY NAME: Work Activity: Lifting TRACKING CONVEYOR Principal Contractor: H Gunawan SWMS number: WIKA-OPCCRESORCES: Equipment Used:

PROJECT: Developed by: Approved by: Position: Date:

Trades Involved: Riggers. Crane Operators Relevant certificates of competency and General Induction certificate. Pink card. Maintenance checks: Current lifting chain test certificates, all crane log books to be up to date. Materials used: Rigging equipment, Appropriate warning signs & Barricade tape. Relevant tag line. Relevant Personnel Protection Equipment required: Hard hats. Steel caped safety boots, Harness with double lanyard, eye and sun protection. High vies clothing or vests, Gloves. LIST THE RELEVANT OHS ACT and REGULATIONS: AS 2550 - 1 Cranes Safe Use General Required AS 2550 - 5 Cranes Safe Use Mobile & Vehicle AS 2550 - 6 Cranes Safe Use - Guided St & Ret App AS 2550 - 10 Cranes Safe Use EWPs AS 1891 3 Industrial Fall Arrest Devices .

LIST THE RELEVANT CODES OF PRACTICE APPLICABLE TO YOUR WORK:

PRELIMINARY

RISK MANAGEMENT SAFE WORK METHOD STATEMENT (SWMS) INSTALLING

Rev. : A 29 July 2011 Page 3 of 7

Document Number OPCC-90-RIG-0003

TRACKING CONVEYOR

CONSEQUENCE

PROBABILITY

Toolbox meeting and signing of JSA in relation to the unloading and positioning of Tracking Conveyor units. Boom configuration Weight of load being lifted Tracking Conveyor units. Radius required: 8.00m. Boom length: 24.4m. Crawler crane 120 ton Note; weight of lifting hook, lifting equipment and spreader to be in overall weight.

Not understanding the job in hand

Ensure all personnel involved in the unloading and positioning of Tracking Conveyor understand procedure and sign SWMS

RANKING

JOB STEP Break the job down into Steps (where practical in sequence)

POTENTIAL HAZARDS Identify the Hazards associated with each step. Examine each to find possibilities that could lead to an incident involving injury. Equipment damage or environmental harm.

EXISTING CONTROLS List the existing controls we currently have in place to address the identified hazard for each job step Conduct a risk assessment utilising the attached Matrix

ADDITIONAL CONTROLS If the risk rating is too high add additional controls and nominate Person/s Responsible.

PERSON/S RESPONSIBLE

All work to carry out by qualified personnel. No unauthorised personnel permitted in the work area. Wika personnel to clearly identify all potential underground and over head hazards and services in relation to work and access areas of crawler cranes and relevant transport.

Wika personnel

Use of relevant PPE equipment and up to date

Equipment failure Personnel injury crushing and pinch

Ensure that all personnel are trained and competent in the

PPE required; eye protection, safety boots,

Wika personnel

PRELIMINARY

RISK MANAGEMENT SAFE WORK METHOD STATEMENT (SWMS) INSTALLING

Rev. : A 29 July 2011 Page 4 of 7

Document Number OPCC-90-RIG-0003

TRACKING CONVEYOR

Pink card

points. Back strain, Muscular injuries, and falling objects.

relevant use of PPE. Ensure all relevant PPE equipment is used at all times. Harnesses are to be worn and lanyards attached at heights greater than 2m or in the event of no edge protection or risk of falling exists.

Establish exclusion zone.

Falling objects and protection of site personnel and public.

All loads to be contained within exclusion zone Wika to notify of required exclusion zone and notify site personnel of work activity. Exclusions zones to be barricaded of using appropriate signage & barricading tape to ensure an exclusion zone is set.

sun protection, hard hats, and harness with double layer high vis vests and cover all. All personnel working on ground and round plant or machinery are to wear high vis clothing or vests. All personnel to comply with Pink card induction requirements. Ensure that all WIKA personnel are conversant with WIKA safe working policies No unauthorised access will be permitted into areas during the rigging and derigging of the Crawler crane 120 ton. If access is required during the lifting of units, Wika personnel are to be notified of access. All loads are to be slung and directed by a qualified rigger or Dogman. Ensure that all Wika personnel are conversant with Wika safe working

Wika personnel

Manual handling

Back strain, Muscular injuries

Seek assistance if required, use correct manual handling techniques.

Wika personnel

PRELIMINARY

RISK MANAGEMENT SAFE WORK METHOD STATEMENT (SWMS) INSTALLING

Rev. : A 29 July 2011 Page 5 of 7

Document Number OPCC-90-RIG-0003

TRACKING CONVEYOR

policies. Organize communication Communications Failure to understand directions All two way radios to be tested before starting. Riggers to carry or have access to fresh battery when required, whistle to be used in the event of radio failure. An audible wind speed indicator is installed to indicate if wind speed is too great to continue lifts safely, Operator to monitor conditions and to notify relevant supervisors. Wika personnel to clearly identify all potential underground and over head hazards and services in relation to work and access areas of crawler cranes and relevant transport. Wika personnel

Establish Crawler crane 120 ton at required radius from centre of rift on head stocks.

Ground failure, Structural failure, and personnel injury.

Crane to be set up as per manufactures specifications. Riggers to observe position of boom at all times when working in close proximity to overhead obstructions.

Wika personnel

Crane counters weight radius and clearance.

Impact of counter weight resulting in load swing or sling breakage and catastrophic load fall. Crane base tracks sink resulting in uneven lift, load shift and excess boom stress and collapses. Mechanical Failure, Personal injury, sling breaks, load drops, and boom collapses.

Check swing radius and clearances.

Ground conditions.

Check all lifting gear and relevant equipment on Crawler crane 120 ton required for lift being performed

Ground compaction report to be supplied before the setting up of crawler crane, use steel ground pads under crane tracks. All lifting equipment must be checked and tagged current. Any faults must be reported immediately to site supervisor. All loads are to slung and directed by a qualified rigger

Any lifting equipment that has been supplied by other parties is to be compatible for required lifts and to be of Australian Standards and have required test

Wika personnel

PRELIMINARY

RISK MANAGEMENT SAFE WORK METHOD STATEMENT (SWMS) INSTALLING

Rev. : A 29 July 2011 Page 6 of 7

Document Number OPCC-90-RIG-0003

TRACKING CONVEYOR

Attach lifting equipment to required lift as per manufactures specified lifting points on tracking conveyor.

Structural failure, personnel injury, and inclement weather conditions. Load Falls from height.

or dogman Ensure all personnel involved in the lifting of the tracking conveyor understand the procedure and sign SWMS. Harnesses are to be worn and lanyards attached at heights greater than 2m or in the event of no edge protection or risk of falling exists.

certificates. All loads are to be slung and directed by a qualified rigger. All work to be carried out by qualified personnel. No unauthorised personnel permitted in the work area or access onto crane. Lugs on tracking conveyor have been engineered to withstand the required weights that are required for the lift being performed

Wika personnel

Lugs on units not suitable to take the weight of the load on the lift being performed.

In the event of any deviation from this Safe Work Method Statement

Stop all work activities

Hold a toolbox meeting record and adjust SWMS variations

To be authorised by Wika safety representative

Wika personnel

PRELIMINARY

RISK MANAGEMENT SAFE WORK METHOD STATEMENT (SWMS) INSTALLING

Rev. : A 29 July 2011 Page 7 of 7

Document Number OPCC-90-RIG-0003

TRACKING CONVEYOR

THIS SWYIS HAS BEEN DEVELOPED THROUGH CONSULTATIONS WITH LCR EMPLOYEES AND HAS BEEN READ AND UNDERSTOOD THEN SIGNED BY ALL EMPLOYEES INVOLVED WITH THIS ACTIVITY NAME SIGNATURE NAME SIGNATURE

. PERSONNEL QUALIFICATIONS AND EXPERIENCE REQUIRED TO COMPLETE THE TASK: SPECIFIC TRAINING REQUIRED TO COMPLETE THIS TASK: APPROVALS:

12

11

10

PROJECT

OUT OF PIT CRUSHING AND CONVEYING (OPCC) SYSTEMS

RIGGING PLAN Tracking Conveyor

OWNER

PT ADARO INDONESIA, Tbk

Menara Karya, 23rd Floor Jalan H.R. Rasuna Said Block X-5, Kav. 1-2 Jakarta 12950, Indonesia Phone: +6221-521-1265

CONTRACTOR

FLSmidth Indonesia

Gedung BRI II, 21st floor, Suite # 2101 Jalan Jendral Sudirman Kav. 44-46 Jakarta 10210, Indonesia Tel +62 21 251 27 38/2739 Fax +62 21 251 27 40

A

PT WIJAYA KARYA (Persero), Tbk

Jl. DI Panjaitan Kav 9 Jakarta 13340 Phone : (62-21) 819 2808, 850 8640, 850 8650 Fax : (62-21) 856 4463, 819 1235

DRAWING NUMBER :

12 11 10 9 8 7 6 5 4 3 2 1

12

11

10

NOTES:

REMARK: -. All dimension in millimeters

H

RIGGING DEPARTMENT

ANALYZE AND PLANED ACTIVITY FOR LIFTING AND ERECTION WORK

START

DATA MATERIAL 1. DIMENSION 2. WEIGHT

7.

REFERENCE 1. RIGGING BOOK 2. EQUIPMENT MANUAL 3. ASME B30.5-2004 Mobil & Locomotive cranes 4. ASME B30.6-2003 Derrick 5. ASME B30.10-1999 Hook 6. ASME B30.21-2005 manually lever operated hoist ASME B30.24-2003 Safety standard for cranes,derrick, hoist, jacks, and Sling 8. ASME B30.26-2004 Rigging Hardware 9. BS EN 5973 Scaffolding 10. Australian Standard, AS 3569--1989, Wire ropes 11. Australian Standard, AS 2759--1985, Wire ropes

E For Information For Review For Approval For Release For As-Built

NEED DUO CRANE No

D

Yes

DRAWN CHKD APRD BP APRD DATE DATE DATE DATE D REFERENCE DRAWINGS DWG NO. OWNER TITLE

TAILING DESIGN

REV.

DATE

DESCRIPTION REVISIONS

MONO CRANE

Risk

JOB SAFETY ANALISYS Safe

CONTRACTOR

RIGGING PLAN

ACTION

CORE

NON

EQUIP ITEM NO : ISSUE PURPOSE :

LIFECYCLE CODE : A OR B RESULT CODE : C, B, A

CONTROL

B

NEXT STATUS : FA, FR, RE, AB RESUBMISSION DATE : NEXT SUBMISSION DATE: RESPONSIBLE DEPT. / PERSON :

B

Final Inspection by WIKA Yes Prepare Final Report for ApprovaL Handover FINISH

No

REVIEW DATE :

C: ACCEPTED WITHOUT COMMENTS B: ACCEPTED WITH COMMENTS A: DOCUMENT TO BE REVISED AND REISSUED

Approval or review hereunder shall not be construed to relieve Vendor / Subcontractor of his responsibilities and liability under the Contract

AREA TYPE PAGE

: OUT OF PIT CRUSHING AND CONVEYING : TRACKING CONVEYOR : 01 / 14

DETAIL : RIGGING PLAN

DWG NO :

DATE

DRAWN CHECKED ENGINEER APPROVED

FILE NAME:

OPCC-90-RIG-0003

INITIALS

Hg HaGun Gunawan H SUKMA ARI

SIGN.

SCALE

1:1

SIZE A4 REV. 00 1

12

11

10

12

11

10

NOTES:

REMARK: -. All dimension in millimeters

H H

RIGGING PROCEDURE

G

01. OBJECTIVE

Rigging Study of install Tracking Conveyor.

02. SCOPE OF APPLICATION

Rigging study is describe the guidelines and operating step of lifting Tracking Conveyor.

F F

03. REFERENCE

1. PT WIJAYA KARYA RIGGING DEPARTMENT REFERENCE

04. EQUIPMENT

E

No 01 02

Equipment CRAWLER CRANE Multi Axel

Qty 1 unit 1 unit

Capacities 120 ton 100 ton

Remark New New

REV.

E For Information For Review For Approval For Release For As-Built

05. RIGGING TOOLS

D

DATE

DESCRIPTION REVISIONS

DRAWN CHKD APRD BP APRD DATE DATE DATE DATE D

No 01 02 03

Equipment Wire Sling 2.5 inch x 8.500m Omega Type Shackle Chain BLock

Qty 4 pcs 4 pcs 2 pcs

Capacities 47.7 ton 50 ton 50 ton

Remark

REFERENCE DRAWINGS DWG NO. OWNER

TITLE

06. SAFETY REQUIREMENTS

No 01 02 Equipment Safety Barricade Red White Safety Cone Qty 77 mtr 7 pcs

CONTRACTOR C

CORE

NON

EQUIP ITEM NO : ISSUE PURPOSE :

LIFECYCLE CODE : A OR B RESULT CODE : C, B, A NEXT STATUS : FA, FR, RE, AB RESUBMISSION DATE : NEXT SUBMISSION DATE:

RESPONSIBLE DEPT. / PERSON : REVIEW DATE :

C: ACCEPTED WITHOUT COMMENTS B: ACCEPTED WITH COMMENTS A: DOCUMENT TO BE REVISED AND REISSUED

Approval or review hereunder shall not be construed to relieve Vendor / Subcontractor of his responsibilities and liability under the Contract

AREA TYPE PAGE

A

: OUT OF PIT CRUSHING AND CONVEYING : TRACKING CONVEYOR : 02 / 14

DETAIL : RIGGING PLAN

DWG NO :

DATE

DRAWN CHECKED ENGINEER APPROVED

FILE NAME:

OPCC-90-RIG-0003

INITIALS

Hg HaGun Gunawan H SUKMA ARI

SIGN.

SCALE

1:1

SIZE A4 REV. 00 1

12

11

10

12

11

10

NOTES:

REMARK: -. All dimension in millimeters

H

Apron Feeder INSTALLATION

LAY DOWN ACTIVITY START Moving Preparation by Rigger Crew

Move Tracking Conveyor by Trailer to Site

PREPARING ACTIVITY IN SITE

Control Position of Tracking Conveyor to be Lifted by Rigging Supervisor

Cleaning Tracking Conveyor

E For Information For Review For Approval For Release For As-Built

Inspection Quality by QC & Safety Yes Connected all Sling for Lifting

No

DRAWN CHKD APRD BP APRD DATE DATE DATE DATE D REFERENCE DRAWINGS DWG NO. OWNER TITLE

REV.

DATE

DESCRIPTION REVISIONS

ERECTION ACTIVITY

Lifting Tracking Conveyor by Crawler Crane to Target Elevation From ELev. 0.000

CONTRACTOR C

CORE

NON

EQUIP ITEM NO : ISSUE PURPOSE :

LIFECYCLE CODE : A OR B RESULT CODE : C, B, A NEXT STATUS : FA, FR, RE, AB RESUBMISSION DATE : NEXT SUBMISSION DATE:

Connected Tracking Conveyor to Foundation

RESPONSIBLE DEPT. / PERSON : REVIEW DATE :

C: ACCEPTED WITHOUT COMMENTS B: ACCEPTED WITH COMMENTS A: DOCUMENT TO BE REVISED AND REISSUED

Approval or review hereunder shall not be construed to relieve Vendor / Subcontractor of his responsibilities and liability under the Contract

Object on Target Position

A

AREA TYPE PAGE

: OUT OF PIT CRUSHING AND CONVEYING : TRACKING CONVEYOR : 03 / 14

DETAIL : RIGGING PLAN

DWG NO :

OPCC-90-RIG-0003

INITIALS

Hg HaGun Gunawan H SUKMA ARI

FINISH

12 11 10 9 8 7 6 5 4 3

DATE

DRAWN CHECKED ENGINEER APPROVED

FILE NAME:

SIGN.

SCALE

1:1

SIZE A4 REV. 00 1

12

11

10

NOTES:

REMARK: -. All dimension in millimeters

H H

E For Information For Review For Approval For Release For As-Built

REV.

DATE

DESCRIPTION REVISIONS

DRAWN CHKD APRD BP APRD DATE DATE DATE DATE D

D REFERENCE DRAWINGS DWG NO. OWNER TITLE

CONTRACTOR C C

CORE

NON

EQUIP ITEM NO : ISSUE PURPOSE :

LIFECYCLE CODE : A OR B RESULT CODE : C, B, A NEXT STATUS : FA, FR, RE, AB RESUBMISSION DATE : NEXT SUBMISSION DATE:

B

RESPONSIBLE DEPT. / PERSON : REVIEW DATE :

C: ACCEPTED WITHOUT COMMENTS B: ACCEPTED WITH COMMENTS A: DOCUMENT TO BE REVISED AND REISSUED

Approval or review hereunder shall not be construed to relieve Vendor / Subcontractor of his responsibilities and liability under the Contract

AREA TYPE PAGE

A

: OUT OF PIT CRUSHING AND CONVEYING : TRACKING CONVEYOR : 03 / 14

DETAIL : RIGGING PLAN

DWG NO :

DATE

DRAWN CHECKED ENGINEER APPROVED

FILE NAME:

OPCC-90-RIG-0003

INITIALS

Hg HaGun Gunawan H SUKMA ARI

SIGN.

SCALE

1:700

SIZE A4 REV. 00 1

12

11

10

12

11

10

NOTES:

REMARK: -. All dimension in millimeters

H H

E For Information For Review For Approval For Release For As-Built

REV.

DATE

DESCRIPTION REVISIONS

DRAWN CHKD APRD BP APRD DATE DATE DATE DATE D

D REFERENCE DRAWINGS DWG NO. OWNER TITLE

CONTRACTOR C C

CORE

NON

EQUIP ITEM NO : ISSUE PURPOSE :

LIFECYCLE CODE : A OR B RESULT CODE : C, B, A NEXT STATUS : FA, FR, RE, AB RESUBMISSION DATE : NEXT SUBMISSION DATE:

B

RESPONSIBLE DEPT. / PERSON : REVIEW DATE :

C: ACCEPTED WITHOUT COMMENTS B: ACCEPTED WITH COMMENTS A: DOCUMENT TO BE REVISED AND REISSUED

Approval or review hereunder shall not be construed to relieve Vendor / Subcontractor of his responsibilities and liability under the Contract

AREA TYPE PAGE

A

: OUT OF PIT CRUSHING AND CONVEYING : TRACKING CONVEYOR : 03 / 14

DETAIL : RIGGING PLAN

DWG NO :

DATE

DRAWN CHECKED ENGINEER APPROVED

FILE NAME:

OPCC-90-RIG-0003

INITIALS

Hg HaGun Gunawan H SUKMA ARI

SIGN.

SCALE

1:1000

SIZE A4 REV. 00 1

12

11

10

12

11

10

NOTES:

REMARK: -. All dimension in millimeters

H H

E For Information For Review For Approval For Release For As-Built

REV.

DATE

DESCRIPTION REVISIONS

DRAWN CHKD APRD BP APRD DATE DATE DATE DATE D

D REFERENCE DRAWINGS DWG NO. OWNER TITLE

CONTRACTOR C C

CORE

NON

EQUIP ITEM NO : ISSUE PURPOSE :

LIFECYCLE CODE : A OR B RESULT CODE : C, B, A NEXT STATUS : FA, FR, RE, AB RESUBMISSION DATE : NEXT SUBMISSION DATE:

B

RESPONSIBLE DEPT. / PERSON : REVIEW DATE :

C: ACCEPTED WITHOUT COMMENTS B: ACCEPTED WITH COMMENTS A: DOCUMENT TO BE REVISED AND REISSUED

Approval or review hereunder shall not be construed to relieve Vendor / Subcontractor of his responsibilities and liability under the Contract

AREA TYPE PAGE

A

: OUT OF PIT CRUSHING AND CONVEYING : TRACKING CONVEYOR : 03 / 14

DETAIL : RIGGING PLAN

DWG NO :

DATE

DRAWN CHECKED ENGINEER APPROVED

FILE NAME:

OPCC-90-RIG-0003

INITIALS

Hg HaGun Gunawan H SUKMA ARI

SIGN.

SCALE

1:200

SIZE A4 REV. 00 1

12

11

10

12

11

10

NOTES:

REMARK: -. All dimension in millimeters

H H

E For Information For Review For Approval For Release For As-Built

REV.

DATE

DESCRIPTION REVISIONS

DRAWN CHKD APRD BP APRD DATE DATE DATE DATE D

D REFERENCE DRAWINGS DWG NO. OWNER TITLE

CONTRACTOR C C

CORE

NON

EQUIP ITEM NO : ISSUE PURPOSE :

LIFECYCLE CODE : A OR B RESULT CODE : C, B, A NEXT STATUS : FA, FR, RE, AB RESUBMISSION DATE : NEXT SUBMISSION DATE:

B

RESPONSIBLE DEPT. / PERSON : REVIEW DATE :

C: ACCEPTED WITHOUT COMMENTS B: ACCEPTED WITH COMMENTS A: DOCUMENT TO BE REVISED AND REISSUED

Approval or review hereunder shall not be construed to relieve Vendor / Subcontractor of his responsibilities and liability under the Contract

AREA TYPE PAGE

A

: OUT OF PIT CRUSHING AND CONVEYING : TRACKING CONVEYOR : 03 / 14

DETAIL : RIGGING PLAN

DWG NO :

DATE

DRAWN CHECKED ENGINEER APPROVED

FILE NAME:

OPCC-90-RIG-0003

INITIALS

Hg HaGun Gunawan H SUKMA ARI

SIGN.

SCALE

1:250

SIZE A4 REV. 00 1

12

11

10

12

11

10

NOTES:

REMARK: -. All dimension in millimeters

H H

E For Information For Review For Approval For Release For As-Built

REV.

DATE

DESCRIPTION REVISIONS

DRAWN CHKD APRD BP APRD DATE DATE DATE DATE D

D REFERENCE DRAWINGS DWG NO. OWNER TITLE

CONTRACTOR C C

CORE

NON

EQUIP ITEM NO : ISSUE PURPOSE :

LIFECYCLE CODE : A OR B RESULT CODE : C, B, A NEXT STATUS : FA, FR, RE, AB RESUBMISSION DATE : NEXT SUBMISSION DATE:

B

RESPONSIBLE DEPT. / PERSON : REVIEW DATE :

C: ACCEPTED WITHOUT COMMENTS B: ACCEPTED WITH COMMENTS A: DOCUMENT TO BE REVISED AND REISSUED

Approval or review hereunder shall not be construed to relieve Vendor / Subcontractor of his responsibilities and liability under the Contract

AREA TYPE PAGE

A

: OUT OF PIT CRUSHING AND CONVEYING : TRACKING CONVEYOR : 03 / 14

DETAIL : RIGGING PLAN

DWG NO :

DATE

DRAWN CHECKED ENGINEER APPROVED

FILE NAME:

OPCC-90-RIG-0003

INITIALS

Hg HaGun Gunawan H SUKMA ARI

SIGN.

SCALE

1:500

SIZE A4 REV. 00 1

12

11

10

PRELIMINARY Document Number OPCC-90-RIG-0003

RIGGING TOOLS INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 1 of 4

CHAPTER 6

PRELIMINARY Document Number OPCC-90-RIG-0003

RIGGING TOOLS INSTALLING TRACKING CONVEYOR

TABLE OF CONTENT

Rev. : A 29 July 2011 Page 2 of 4

TABLE OF CONTENT .................................................................................................................. 2 1 2 3 WORKING LOAD LIMIT - 1770 GRADE W.R.C. .................................................................. 3 GRADE 'S' SHACKLES ........................................................................................................ 3 3G Industrial Chain Block - 20 tonne Capacity ........................................................... 4

PRELIMINARY Document Number OPCC-90-RIG-0003

RIGGING TOOLS INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 3 of 4

WORKING LOAD LIMIT - 1770 GRADE W.R.C.

DIRECT LOADED CHOKE HITCH 2-LEG ASSEMBLY 4-LEG ASSEMBLY

METHOD OF LOADING Round Rect. load Included angle a Loading factor Nominal rope dia. Working Load Limit -- tonnes mm 52 56 60 33.0 38.0 44.0 25.0 29.0 33.0 16.6 19.2 22.0 63.8 74.0 84.8 61.1 70.8 81.2 57.0 66.0 76.0 47.0 54.0 62.0 33.0 38.0 44.0 61.1 70.8 81.2 57.0 66.0 76.0 47.0 54.0 62.0 33.0 122.2 114.6 93.6 66.1 38.0 141.6 132.6 108.3 76.6 44.0 161.5 152.3 124.4 88.0 1.00 x 0.95 0.75 x 0.95 0.50 x 0.95 load Angle a is between opposite legs Rigid load 30 1.93 x 0.95 45 1.85 x 0.95 60 1.73 x 0.95 90 1.41 x 0.95 120 45 1.00 x 0.95 1.85 x 0.95 60 1.73 x 0.95 90 1.41 x 0.95 Flexible load 120 45 1.00 x 0.95 3.70 x 0.95 60 3.46 x 0.95 90 2.83 x 0.95 120 2.00 x 0.95

GRADE 'S' SHACKLES

WORKING LOAD LIMIT DIA BOW DIA PIN INSIDE WIDTH INSIDE LENGTH CHAIN TYPE ANCHOR TYPE WIDTH OF BOW APPROX. WEIGHT EACH

D metric tons mm

d mm

a mm

C mm

C mm

2r mm

in kgs SCREW PIN SAFETY PIN

35 42.5 55

50 57 65

57 65 70

83 95 105

171 190 203

197 222 254

146 160 185

18.85 26.06 37.86

20.65 29.01 41.05

PRELIMINARY Document Number OPCC-90-RIG-0003

RIGGING TOOLS INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 4 of 4

3G Industrial Chain Block - 20 tonne Capacity

Product Code Rated Capacity Colour Code Standard Lift Falls of Chain Efforts to lift full load Net Weight 500706M 20 tonne Orange 6m 8 45kg 252kg

Hand Chain Overhauled 2 x 308m to lift load one metre Load Chain diameter Clearance Dimensions A (Headroom) B (Width) C (Depth) D (Diameter) Hook opening (upper) Hook opening (lower) 1060 240 210 218 75 75 10mm

PRELIMINARY Document Number OPCC-90-RIG-0003

CRITICAL LIFT WORKSHEET INSTALLING

TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 1 of 6

CHAPTER 7

PRELIMINARY Document Number OPCC-90-RIG-0003

CRITICAL LIFT WORKSHEET INSTALLING

TRACKING CONVEYOR

TABLE OF CONTENT

Rev. : A 29 July 2011 Page 2 of 6

TABLE OF CONTENT .................................................................................................................. 2 CRITICAL LIFT WORKSHEET ..................................................................................................... 3

PRELIMINARY Document Number OPCC-90-RIG-0003

CRITICAL LIFT WORKSHEET INSTALLING

TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 3 of 6

CRITICAL LIFT WORKSHEET Title: Project: Description: Jobsite Address: Customer: Lift Plan Drawings and Load Placement Drawing attached? Notes: P.O./ Contract#: YES / NO Date: Job Number:

Crane Information Manufacturer: Model: Serial #:

Lift Information Crane Radius: Crane Capacity at Radius: Capacity at Pick Point: Capacity at Set Point: Notes:

Notes:

Crane Configuration Crane Carrier: Counterweigh: Chart Capacity: Main Boom Length: Boom Sections:

Load Configuration Net Load Weight Description: Dimensions: Load Weight: Rigging Weight:

PRELIMINARY Document Number OPCC-90-RIG-0003

CRITICAL LIFT WORKSHEET INSTALLING

TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 4 of 6

Parts of Line: Line Size: Capacity of Line @ Parts: Radius: Boom Angle: Tip Height: Jib Used? Jib: Jib offsets: Jib Angle from Ground: Ground Bearing Pressure (Worst Case):

Hook Weight: Block Weight: Load Line Weight: Hook Height: Sling Length: Sling Angle: Sling Equipment #:

Sling Type:

Spreader Bar #: Spreader Bar Capacity: Hook Block:

Setup Information Crane Setup (Over Rear)

Shackle Type: Shackle Qty: Shackle Capacity

Setup Distance Mat Used? Mat dimensions: Ground Bearing Pressure Below Mat: Notes:

Additional Rigging Additional Rigging Capacity: % of Chart Capacity Chart Capacity Deduction Deduct Capacity Notes:

Not for construction use. For pre-planning only.

PRELIMINARY Document Number OPCC-90-RIG-0003

CRITICAL LIFT WORKSHEET INSTALLING

TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 5 of 6

Title: Project: Notes:

Date: Job Number: Notes:

Pre-Lift Checklist Crane Operator: Signalperson Assigned: Communication Method: Crane Inspected by Operator? Rigging Inspected? All Permits Obtained? Are weather conditions OK? Wind OK? Are there Power Lines? Is Operators Certification Card current? Is area OK for entry and exit of jobsite? YES / NO YES / NO YES / NO YES / NO YES / NO YES / NO YES / NO YES / NO Name: Name:

PRELIMINARY Document Number OPCC-90-RIG-0003

CRITICAL LIFT WORKSHEET INSTALLING

TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 6 of 6

Has a pre-lift meeting between operator, signalperson, supervisor, and any and all other persons occurred? Other Considerations:

YES / NO

Signatures

Engineer: Supervisor: Operator: Client: Not for construction use. For pre-planning only.

PRELIMINARY Document Number OPCC-90-RIG-0003

LIFT STUDY INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 1 of 12

CHAPTER 8

PRELIMINARY Document Number OPCC-90-RIG-0003

LIFT STUDY INSTALLING TRACKING CONVEYOR

TABLE OF CONTENT

Rev. : A 29 July 2011 Page 2 of 12

TABLE OF CONTENT .................................................................................................................. 2 1 2 3 4 LIFT PLAN METHOD AND PROCEDURE ........................................................................ 3 PERSONNEL - EQUIPMENT LIST ..................................................................................... 4 RIGGING/SLINGING EQUIPMENT LIST ............................................................................. 5 CRANE LOAD CHART ......................................................................................................... 6 4.1 5 6 7 8 Hydraulic Crawler Crane 120 ton ................................................................................... 6

RIGGING/SLINGING DIAGRAM ........................................................................................ 6 PLANNING PROCESS CHECK LIST ................................................................................... 9 OPERATIONAL PROGRESS - CHECK LIST..................................................................... 10 MAIN SPECIFICATION ...................................................................................................... 11 8.1 Crawler Crane Capacities 120 ton (Model: 7120-1F) ................................................... 11

LANDFILL - CHECK LIST ................................................................................................... 12

PRELIMINARY Document Number OPCC-90-RIG-0003

LIFT STUDY INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 3 of 12

LIFT PLAN METHOD AND PROCEDURE Job No.: Phone:

Customer: Customer Contact: Project Title: Project Address:

Commencement Date: Completion Date:

Task Description Crawler Crane 120 tons used to lift of TRACKING CONVEYOR to position while installing.

Load Description

Dimensions:

Weight Load: Weight Distribution: Equal

Lift Equipment:

Total:

Centre of Gravity:

Prepared by: Gunawan, H

Supervisor / Controller: HaGun

Date

Issued to:

Date

PRELIMINARY Document Number OPCC-90-RIG-0003

LIFT STUDY INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 4 of 12

PERSONNEL - EQUIPMENT LIST

Personnel Name Classification Crane Operator Rigger Cart Number

Cranes Unit No Make Capacity Plan Reg No. Inspect Proposed Boom Date CWT Jib Hook Max SWL Load Share

Length Length Riving

Transport Unit No. Prime Mover Trailer Reg No. Inspect Date Max Load Cap Proposed Load

Other:

Prepared by: Gunawan, H

Supervisor / Controller: HaGun

Date

Issued to:

Date

PRELIMINARY Document Number OPCC-90-RIG-0003

LIFT STUDY INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 5 of 12

RIGGING/SLINGING EQUIPMENT LIST

Chains Lift Point No Diameter Length SWL Inspected Load Share Details

Slings Lift Point No Diameter Length SWL Inspected Load Share Details

Shackles Lift Point No Size SWL Inspected Load Share Details

Other Lifting Beams, Spreader, Equal sling Sheaves, etc. Lift Point No Description SWL Inspected Load Share Details

Prepared by: Gunawan, H

Supervisor / Controller: HaGun

Date

Issued to:

Date

PRELIMINARY Document Number OPCC-90-RIG-0003

LIFT STUDY INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 6 of 12

4 4.1

CRANE LOAD CHART Hydraulic Crawler Crane 120 ton

RIGGING/SLINGING DIAGRAM

Sketch the Load and mark: Nominated Lift Points, Weight at each Lift Point, Centre of Gravity, Load Sharing Calculation, and Rigging Arrangement.

PRELIMINARY Document Number OPCC-90-RIG-0003

LIFT STUDY INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 7 of 12

PRELIMINARY Document Number OPCC-90-RIG-0003

LIFT STUDY INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 8 of 12

Prepared by: Gunawan, H

Supervisor / Controller: HaGun

Date

Issued to:

Date

PRELIMINARY Document Number OPCC-90-RIG-0003

LIFT STUDY INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 9 of 12

6 Item

PLANNING PROCESS CHECK LIST Checked

Access on site is suitable for cranes and transport vehicles Cranes standing and working area is level. compacted and suitable for assembly Outrigger point loadings calculated Outrigger packing identified and prepared to suit ground conditions Adequate and suitable area identified to unload, assemble, handle and store the load All overhead obstructions, power wires, structures etc, identified and controlled All underground obstructions, pipes drains, manholes etc, identified and controlled All permits, authorities, etc, identified and organised Methods are designed and implemented to control unauthorised entry of others Barriers, barricades, signage. warning lights, etc, identified and prepared Scaffold, ladders, access platforms, to all work areas identified and prepared Communication and control methods established and instructed Clearances for tail swing, boom operation and load movement are confirmed All appropriate P.P.E. is identified and provided All hazards are identified and control measures prepared All necessary information and instruction is given to all persons involved The supervisor or lift controller is identified to all persons involved All arrangements are confirmed with the customer representative

Prepared by: Gunawan, H

Supervisor / Controller: HaGun

Date

Issued to:

Date

PRELIMINARY Document Number OPCC-90-RIG-0003

LIFT STUDY INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 10 of 12

7 Item

OPERATIONAL PROGRESS - CHECK LIST Checked

Personnel On arrival at site all personnel are briefed and delegated particular tasks The site area is cleared of all persons and equipment not involved Barricades, signage warning devices installed Access to work areas installed - P.P.E. Control measures applied to hazardous areas or situations CRANES Crane/s positioned in accordance with plan, radius and S.W.L. confirmed Outrigger packing positioned, outrigger beams extended, outrigger jacks extended Crane jacked level, locking pins and devices fitted, as per crane manual

Boom assembled or extended to required length, pins, wedges, safety devices etc., fitted

Counterweight fitted, hooks revved, bolts, pins, wedges, safety devices etc. fitted Boom erected, brakes, pawls, lock outs, weigh gauges, etc. tested Tail swing and boom clearances confirmed, communications system tested LOAD Item is positioned or assembled, supported and brace, in a safe stable manner Rigging/Slinging is fitted, protection for gear installed as per plan Load is lifted clear of ground, slinging checked, outriggers checked Observance for hazards is made, confirmation to proceed is given Load is lifted and placed in final position and safely secure Rigging / Slinging equipment disconnected and lowered to ground MOVE OUT All equipment is safely dis-assembled, stowed loaded and tied on transport Cranes are prepared for travel in accordance with manuals and permits Inspection made to ensure no hazards remain as a result of activity All personnel and equipment depart from site in a safe. orderly manner Prepared by: Gunawan, H Supervisor / Controller: HaGun Issued to: Date Date

PRELIMINARY Document Number OPCC-90-RIG-0003

LIFT STUDY INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 11 of 12

8 8.1

MAIN SPECIFICATION Crawler Crane Capacities 120 ton (Model: 7120-1F)

PRELIMINARY Document Number OPCC-90-RIG-0003

LIFT STUDY INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 12 of 12

LANDFILL - CHECK LIST Checked

ITEM Are all surface encumbrances that may create a hazard re-moved or supported? Have all underground utility installation been located? Are employees exposed to vehicular traffic wearing warning vests made of reflector zed or high visibility material? Is a warning system such as barricades, hand or mechanical signals or stop logs used when mobile equipment approaches the edge of the excavation? Is there Settlement (Low spots) in the ground? Are there Cracks in the ground? Is there Erosion in the ground? Are there Alternative Cover (armoured rock, concrete, etc.) in the ground? Whether the soil has a horizontal surface?

Prepared by: Gunawan, H

Supervisor / Controller: HaGun

Date

Issued to:

Date

PRELIMINARY Document Number OPCC-90-RIG-0003

CRANE STUDY INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 1 of 15

CHAPTER 9

PRELIMINARY Document Number OPCC-90-RIG-0003

CRANE STUDY INSTALLING TRACKING CONVEYOR

TABLE OF CONTENT

Rev. : A 29 July 2011 Page 2 of 15

TABLE OF CONTENT .................................................................................................................. 2 1 HYDRAULIC CRAWLER CRANE Model: 7120-1F .............................................................. 3 1.1 1.2 1.3 1.4 1.5 1.6 1.7 2 CONFIGURATION ......................................................................................................... 4 SPECIFICATIONS ......................................................................................................... 5 GENERAL DIMENSIONS .............................................................................................. 7 BOOM AND JIB ARRANGEMENTS .............................................................................. 8 WORKING RANGES AND LIFTING CAPACITIES ...................................................... 10 CRANE BOOM LIFTING CAPACITY ........................................................................... 11 PARTS AND ATTACHMENTS ..................................................................................... 12

ACTUAL CONDITION......................................................................................................... 14

PRELIMINARY Document Number OPCC-90-RIG-0003

CRANE STUDY INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 3 of 15

HYDRAULIC CRAWLER CRANE Model: 7120-1F

PRELIMINARY Document Number OPCC-90-RIG-0003

CRANE STUDY INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 4 of 15

1.1

CONFIGURATION

PRELIMINARY Document Number OPCC-90-RIG-0003

CRANE STUDY INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 5 of 15

1.2

SPECIFICATIONS

PRELIMINARY Document Number OPCC-90-RIG-0003

CRANE STUDY INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 6 of 15

PRELIMINARY Document Number OPCC-90-RIG-0003

CRANE STUDY INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 7 of 15

1.3

GENERAL DIMENSIONS

PRELIMINARY Document Number OPCC-90-RIG-0003

CRANE STUDY INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 8 of 15

1.4

BOOM AND JIB ARRANGEMENTS

PRELIMINARY Document Number OPCC-90-RIG-0003

CRANE STUDY INSTALLING TRACKING CONVEYOR

Rev. : A 29 July 2011 Page 9 of 15

PRELIMINARY Document Number OPCC-90-RIG-0003