William G. Proud Et Al - Diagnostic Techniques in Deflagration and Detonation Studies

Diunggah oleh

Ghoree23456Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

William G. Proud Et Al - Diagnostic Techniques in Deflagration and Detonation Studies

Diunggah oleh

Ghoree23456Hak Cipta:

Format Tersedia

New Trends in Research of Energetic Materials, Czech Republic, 2010

[Content]

Diagnostic techniques in deflagration and detonation studies

William G. Proud*, David M. Williamson, John E. Field, and Stephen M. Walley

Cavendish Laboratory, University of Cambridge, Cambridge, United Kingdom * currently at - Institute of Shock Physics, Imperial College London, United Kingdom wgp1000@cam.ac.uk Abstract: Advances in a number of experimental, high-speed techniques have been used to explore the processes occurring within energetic materials. This review describes techniques used to study a wide range of processes: hot-spot formation, ignition thresholds, deflagration, sensitivity and finally the detonation process. As this is a wide field the focus will be on small-scale experiments and quantitative studies. It is important that such studies are linked to predictive models, which inform the experimental design process. The stimuli range includes, thermal ignition, drop-weight, Hopkinson Bar and Plate Impact studies. Studies made with inert simulants are also included as these are important in differentiating between reactive response and purely mechanical behaviour. Keywords: high-speed; quantitative; experimental; diagnostic; characterisation

Introduction

Energetic materials are characterized by high energy-release rates that result in phase transformation, rapid temperature rises and mechanical or other work. These dramatic changes take place on sub-millisecond to sub-nanosecond timescales making them difficult to study using standard techniques. For many years, studies tended to focus on post-reaction effects, e.g. the size of craters in metal blocks, ignition thresholds, the impulse given to pendulums. The value of these studies should not be under estimated as they form the basis of this field of study. However, the interpretation of these results was wide and the resulting theories reflect the limited understanding of the high-speed processes. Industrialization and increased use of explosives resulted in a number of unfortunate explosive accidents and poisonings [1]. Legislation was imposed which required the reduction in risk to property and people. This drove the development of a series of qualification and classification techniques to address the variety of common hazard scenarios [2]. These also served the purpose of producing a series of reference scales that allowed the broad comparison of data from different sources. With increased emphasis on factors such as environmental issues, safety and handling and reliability, modeling has become a major area of development: the promise of wide applicability, prediction of material properties and the description of whole systems. However, accurate prediction requires good knowledge of fundamental behaviour and well-controlled validation experiments. This drives increased interest in physical understanding of the reaction processes. While many of these properties and trends are present in legally required qualification studies, often it is in the presence of complicating factors. The advent of modern data capture techniques has allowed increased physical understanding and the ability to study effects that have previously been masked. A range of small-scale

21

New Trends in Research of Energetic Materials, Czech Republic, 2010

[Content]

tests and techniques have been developed to isolate particular processes, both to populate and validate predictive models. High-speed data capture has made nanosecond time-resolved data increasingly common, advances in opto-engineering have produced cameras and lasers which operate at speeds and sensitivities not possible a few decades ago [e.g. 3]. In this paper a number of techniques will be discussed which give an overview of some important material parameters and processes. It should be emphasized that this is not an exhaustive account nor are the techniques applicable in all cases; however, they do show that to study these systems there is a need for simple, well-controlled stimuli, giving clear results. In many cases these studies show the importance of previously unknown or secondary processes, resulting in much improved understanding and another cycle of development.

High Strain Rate Regimes

The range of strain rates, along with the corresponding techniques is listed in Table 1. A review on these techniques applied to a wide range of materials has been published by the authors elsewhere [4]. In this review the techniques will be discussed specifically in relation to energetic materials; drop weight studies are generally conducted with respect to ignition levels, Hopkinson bar studies with relation to accident and impact scenarios, while plate impact probes the region leading to detonation. The main effect of increasing the strain rate is that the transient stress levels increase and the sudden delivery of energy allows processes with high activation energies to be accessed. Processes, which operate on long time scales, e.g. thermal diffusion, which are significant under quasi-static loading, do not have time to occur. It is generally found that yield and fracture stresses increase with increasing strain rate [5]. The increase in failure stress is very marked at strain rates above 103 s-1 and the effect of inertia becomes significant. Ultimately the response changes from one where the sample can be assumed to be in stress equilibrium to one of a wave with associated 1-D strain moves so quickly that the material does not have time to move laterally, as seen in shock waves.

Table 1: High Strain Rate Regimes and the Associated Equipment.

Strain rate 10-6 10-2 10+2 10+3 10+2 10+3

Equipment Instron Drop weight Hopkinson bars

Stimulus duration 100s of seconds 10s milliseconds 100s microseconds

10+4 10+5 10+3 10+6 10+5 10+8

Miniature Hopkinson bar Taylor impact Plate impact

10s microseconds 10s microseconds microseconds

Comment Quasi-static loading Generally used to determine impact ignition thresholds Compression, tension and torsion loading. Extensively used for PBX formulations. Constitutive models. For fine grain materials or single crystals. Generally metals Sometimes used for metal jacketed energetic samples Pressures and durations similar to that of gap tests. Laser driven flier plates have submicrosecond duration highintensity shocks

22

New Trends in Research of Energetic Materials, Czech Republic, 2010

[Content]

Techniques and Diagnostics

3.1 Quasi-static techniques

Quasi-static loading and standard property determination form the bedrock of all material characterization. Properties traditionally determined are density, thermal capacity and conductivity, melting points, ignition temperature, spectroscopic signatures, molecular and crystal structure. Advances in x-ray techniques and especially tomography have allowed the internal structure of composites and crystals to be determined in a non-destructive fashion [6]. Atomic force microscopy allows chemical composition, crystal hardness, facet variation to be seen at a nanometer level [7] while environmental scanning electron microscopy gives insight to the crystal scale variation to be observed. Many high rate studies are rationalized by reference to these properties, which need to be determined experimentally they are not always simple to predict e.g. the theoretical maximum density of a polymer-bonded explosive. X-ray diffraction, over a range of sample temperatures, allows the structure to be determined in a series of sequential experiments. It has been widely confirmed that crystal orientation is significant in defining material sensitivity through the crystal structure and the crystallographic slip planes. Temperature controlled x-ray diffraction has been useful in showing the sensitivity of molecular and crystal-cell properties, estimating the heat capacity and highlighting a wide range of phenomena, phase transitions, the movement of water of crystallization and ultimately when long-range order breaks down and the material decomposes [8]. Figure 1(a) shows the structure of copper(II) styphnate tetrahydrate, while figure 1(b) shows the temperature variation of the crystal parameters. The crystal expands in a regular fashion until ~300K. Above this, the crystal structure starts to break down as initially the water of crystallization moves out of the structure. This is rapidly followed by bulk breakdown of the material. For this material, this shows the limitation of its practical use, but also it indicates the fundamental cause of the marked change in the crystal structure.

(a) (b) Figure 1. (a) Crystal structure and (b) crystal parameters of copper(II) styphnate tetrahydrate. Taken from [8]

Moving beyond the crystal to consider polymer bonded systems much effort has been directed into understanding the movement of cracks through the system [9-12]. For polymerbonded systems, fractures, which move within the polymer binder alone, are considered important in weakening the material but are not obviously related to increased ignition sensitivity. Cracks which move through the energetic crystals opening up an interface where crystal fragments can the rub together and become hot are a more obvious route to increased sensitivity.

23

New Trends in Research of Energetic Materials, Czech Republic, 2010

[Content]

The use of data from moir interferometry or image correlation, in combination with micromechanical models, has shown the importance of the marked strain rate behaviour of polymers. Polymers become harder and more crystal-like with small downward changes in temperature or increases in strain rate [12]. The adhesive strength between crystal and binder is very important in the strain localization process [11].

3.2 Deflagration to Detonation Studies

The localisation of energy into small regions of an energetic material to produce hot spots has been widely studied and reported [13, 14]. Several mechanisms, e.g. void collapse, have been identified as important in this process. These mechanisms tend to act simultaneously and so it is sometimes difficult to identify which is the most important. However, once a sufficient number of hot spots have been produced by heating or impact, deflagration will start to spread. The dynamics of this process can be studied in a number of ways; one way is to use high-speed photography and combine this with other techniques. Amongst the simplest experiments are those, which use metal cylinders as shown in figure 2. The channel along the centre of the cylinder had a diameter of 5 mm and varied in length between 70 and 100 mm (total length 100 - 130mm). Initial analysis of what had occurred while reaction had taken place in a column was performed by a system of post-mortem examinations. Test shots were carried out using cylinders made of copper, steel and brass. It was found that copper cylinders gave the best record of the event that had taken place. Brass proved too brittle to survive a detonation in one piece and steel although providing some record of the event did not distort in the ductile manner of copper and as such provided a less clear picture of the processes that had occurred.

(a) (b) Figure 2. Cylinders for use in (a) post-mortem type experiments (b) photographic study of DDT. Taken from [15] Plastics such as polycarbonate and polymethylmethacrylate (PMMA) were not tried as it had been shown [15] that the level of confinement offered by these materials was insufficient to withstand the sustained pressures required for a DDT event in PETN or RDX. In experiments where a photographic record of the events was required, it was necessary to use a confinement that afforded direct optical access to the charge whilst retaining the pressure levels of the simple metal confinement. The confinement shown in figure 2(b) was developed by Luebcke [16] based on previous designs by researchers such as Korotkov [17] and Griffiths and Groocock [18]. The confinements used consisted of sections of square steel bar with a 5 mm channel drilled along the centre for the charge and a 1 mm wide polycarbonate window laid into the steel. The window af-

24

New Trends in Research of Energetic Materials, Czech Republic, 2010

[Content]

fords an optical viewing point whilst being thin enough that the level of confinement afforded by the steel is not overly compromised. The length of the charges used varied from 45 to 80 mm depending on the nature of the event that was being investigated. The explosive charges were pressed incrementally using a hydraulic press. Care was taken to ensure that the height of each individual increment never exceeded more than half of the diameter of the column. Charges below densities of 50% of theoretical maximum density (TMD) were also incrementally pressed. A system whereby static weights were placed on top of the pressing rod was used in these cases. A pyrotechnic was used to ignite the columns of explosive. The pyrotechnic was ignited using a nichrome wire through which was passed an electrical current. The mixture consisted of 80% potassium dichromate and 20% boron as developed by Dickson [19]. It has the advantage of producing few gaseous products, so little prepressurisation of the charge occurs. The burning temperature is far higher than the ignition temperature of the materials used in the charges. The pyrotechnic was tamped in order to ensure as few gas pockets as possible so as to reduce rapid expansion during reaction. The pyrotechnic was added after the main charge had been pressed into the column. Finally a small conical aluminium piece was placed around the electrical wires and pushed into the confinement to reduce rearward venting of the charge to a minimum. As a result pressure generated during the early stages of reaction could be sustained. Often, a thin piece of copper foil was placed between the pyrotechnic charge and the explosive charge. This was done in order to prevent light emitted during the slow burning of the pyrotechnic charge from being transmitted down the column to the optical fibres and as a result prematurely triggering the experimental diagnostics. The brass tube into which the pyrotechnic charge was placed also acts as a light stop as well as an easy check on the amount of pyrotechnic that is used. The type of data recorded from this experiment is shown in figure 3. A full description of the processes can be found in the papers of Gifford [20-22]. However, the streak image shows convective burning B, the step from deflagration to detonation D and the movement of the waves including a retonation wave F. Addition of high-speed thermocouples [21] to the system allowed the internal states at point along the column to be known prior to detonation.

Figure 3. Normal or type I DDT event in ultrafine PETN. Taken from [21]

3.3 Drop Weight Studies

A standard technique for sensitivity studies, the drop-weight is a system that allows long, low-level pressure pulses to be applied to small samples. In combination with high-speed photography, photodiodes and stress transducers it is a powerful system for both qualitative and quantitative analysis of material response. The standard way of analyzing the output of a drop weight assumes the weight behaves as a rigid body and hence that one can simply apply Newtons laws of motion. This is used in determining the calibration of a drop weight force transducer dynamically, by directly relating the

25

New Trends in Research of Energetic Materials, Czech Republic, 2010

[Content]

measured force both to the deceleration of the weight also to position. A typical signal from a calibration experiment is presented in figure 4.

Figure 4. Typical output from a drop-weight stress transducer used in these studies. Taken from [4]

Figure 5. The ignition under impact of a thermite composition. Taken from [31]

In practice, the output signal from a drop weight machine often has oscillations comparable in size to the signal produced by the mechanical resistance of the specimen. This is particularly true if the drop weight itself is instrumented, e.g. with accelerometers. The reason is that impact excites the weight below its resonance frequency [23]. Elastic waves, therefore, reverberate around inside until the momenta of the constituent parts of the weight have been reversed. Rebound then occurs and the specimen is unloaded. Recent work [24] has demonstrated that it is possible to obtain high quality data from such machines either by the use of a momentum trap in the weight, if the weight itself has to be instrumented [25] or by careful design of a separate force transducer placed below the specimen e.g. in [26,27]. One modification to the drop weight apparatus, which has proved invaluable in the elucidation of explosives ignition mechanisms, is to machine a light-path through the weight and to perform the deformation between transparent glass anvils [14, 2831]. This allows the event to be captured using high-speed photography. An example of a classic high-speed photographic sequences obtained using this apparatus is given in Fig. 5.

3.4 Second Harmonic Generation

In a recent paper the use one of the more unusual optical properties of HMX to probe the ignition process [32]. The relatively new technique of Second Harmonic Generation (SHG) was used to study the phase transition in HMX by many authors in the late 1990s [3336] A second harmonic is generated when intense radiation is incident on molecular crystals with appropriate symmetry properties. -HMX, the chair configuration, is a centrosymmetric molecule and as such is forbidden by its symmetry from generating second harmonics. However, -HMX, a boat configuration, has no centre of inversion and generates second harmonics very efficiently. For these second-order processes to be observable the incident radiation needs to be very intense and so a laser is required. In order to produce second harmonics near the peak sensitivity of the high-speed cameras, a Nd:YAG, (YAG = yttrium aluminum garnet) laser operating at 1064 nm was used to irradiate the sample allowing the detection of the second harmonic at 532 nm (green). This technique can be applied in a transparent anvil drop

26

New Trends in Research of Energetic Materials, Czech Republic, 2010

[Content]

weight apparatus. The second harmonic generation is near instantaneous process and so a 9 ns laser pulse, can a probe for -HMX during impact. The apparatus allowed separate light paths for the laser light to travel to the sample and for the visible light (both light from reaction and SHG) to travel from the sample to the cameras. A diagram of the drop weight setup is shown in Figure 6.

Figure 6. Drop weight modified to detect SHG in HMX crystals during impact. Taken from [32]

Figure 7. Four images showing SHG. The field of view of each image is 10 mm wide. All of the images have enhanced and reversed contrast (black indicates the presence of SHG). Taken from [32]

The cameras used were Imacons 790 and 792, and a notch filter in front of one of them was used to isolate SHG, while the other followed the visible light from reaction. A drop height of 39 cm was used, giving an impact velocity of 2.75 m s-1. The height was chosen as the lowest at which the sample would reliably ignite on impact. The stress-time output was a half sinusoid with a peak pressure of 107 Pa and duration of the order of 104 s. A light gate broken by the falling drop weight just before impact was used to trigger the diagnostics, and a photodiode monitored the time of ignition relative to that time reference. While precise impact times are not known for individual experiments, the photodiode gave a good reference as to when reaction began. The system was such that one frame on the filtered camera coincided with the laser pulse. The visible light camera was set to record a sequence starting just before the laser pulse. Each pulse deposited 0.8 J of energy over an 8 mm diameter spot. The sensitivity of the system to the presence of -HMX, in the sample bulk, was shown by using -HMX pellets converted to -HMX through selective heating. SHG was clearly visible whether the phase regions were on the top or the bottom of the pellet and so -HMX at any depth in the sample could be detected with excellent spatial resolution in pellets up to 1 mm thick. The time delay between the trigger provided by a light gate broken by the falling drop weight and the laser pulse was varied, in order to probe for -HMX throughout the impact. Selected images showing SHG are presented in Fig. 7. The images showed the second harmonic in narrow regions of the sample. In the experiments all the impacted pellets reacted but no HMX was observed any earlier than 13 s before ignition. This implies that any transition to the phase occurs late in the reaction sequence. It could be the case that either the -HMX region grows rapidly before ignition or that after ignition the higher temperature of the burning material converts the rest of the sample before it is completely consumed.

27

New Trends in Research of Energetic Materials, Czech Republic, 2010

[Content]

In earlier research, Field [37] saw localized heating along lines and at their junctions and attributed this to shear band formation. It appears that the heating on impact is sufficient to cause conversion to phase under these stress conditions before ignition, the patches of HMX observed were small (1 mm across) and very localized. After ignition, larger patches (3 mm across) of -HMX were seen before the sample was completely consumed.

3.5 Digital Speckle Photography

Hopkinson bars are used to probe rates of 102 104 s-1. This is an important region in strain rate characterization as here the dynamic strength of the material increases dramatically. Rate sensitive materials, e.g. many polymers, become very brittle in this strain-rate regime . A fuller description of these techniques can be found in [4]. In general the output of Hopkinson Bar studies takes the form of stress-strain curves (figure 8). However, this is based on assumptions about sample integrity, no cracking, and homogenous material flow. For polymer-bonded explosives (PBXs), this may not be the case [38]. It is important to measure the movement of the sample during the test procedure in order to ensure the results are valid. To do this, a technique called digital speckle photography was developed. This is a method that, in broad terms, compares the movement of random patterns, either naturally present, as in the case of large grain-size PBXs, or painted onto the surface. In the study summarized here samples of an inert PBX simulant, a polymer-bonded sugar (PBS), were sprayed with a dilute solution of silver dag, to give a fine, silver speckle pattern. High-speed photographs were taken using an Ultra-8 camera, and analyzed using software described in [39, 40]. The procedure is described in more detail in [41] and the result shown in figure 9. Measurements of the specimen diameter during the experiments was also obtained by measuring the shadow cast by the specimen, which for an opaque un-cracked specimen with a smooth surface is the same as the specimens load bearing diameter.

Figure 8. Stress-strain curves for PBS9501 at three Hopkinson bar strain rates. Taken from [40]

Figure 9. Evolution of displacement at 1420 s-1. Exposure time 2 s, frame times shown relative to arrival of stress wave.

Figure 10. Stress-time plot for the specimen of PBS 9501 in Fig. 9. Photographs in 2 are indicated by crosses.

The evolution of displacement on the surface of a typical specimen, relative to the undeformed frame, is given in figure 9. The arrow on the frame at 24 s shows the onset of strain localization, before surface cracks are visible in the next frame. Comparison to the stressstrain curve in figure 10 shows that the first sign of localization corresponds to the peak stress. This means that that localization, or cracking, precedes strain softening in this material.

28

New Trends in Research of Energetic Materials, Czech Republic, 2010

[Content]

The speckle data were, where possible, also used to calculate global surface strain fields in the specimens in longitudinal and radial directions, not shown, and thus apparent Poissons ratio at different strains, figure 12. The line laser output was used successfully to calculate the radial strain of a number of specimens. The scatter between specimens is shown neatly in figure 11, where two experiments at the same strain rate give overlapping longitudinal, but very different radial, strain time curves. Figure 12 shows the results of calculations of apparent Poissons ratio, defined as radial strain divided by longitudinal strain, from 6 experiments, compared to those from the speckle analysis and a typical stress-strain curve. The small strain Poissons ratio, calculated from ultrasonic measurements, is ~0.30. The figure shows that the values calculated from speckle data are consistently below those of the line laser.

Figure 11. Comparison of apparent Poissons ratios from line laser and speckle (3 specimens) to the small strain Poissons ratio (X) and a typical stress-strain curve. Taken from [40]

Figure 12. Comparison of longitudinal strains from the standard Hopkinson bar analysis to radial strains from the line laser for two specimens.

Figure 13. Comparison of stress-strain curves calculated assuming volume conservation in the specimen, and using the apparent Poissons ratio.

Overall these measurements show during deformation the early onset of specimen fractures, which produce pockets of material and of air: the area of the specimen is not the same as the load bearing area of material. Therefore, the true stress in the material may be better represented by assuming volume conservation in the material not volume conservation of the specimen. To measure volume conservation in this way would require significant technique development in dynamic tomography for example. Therefore, a true understanding of the physical behaviour of the material will require a more complete evaluation. However, it is encouraging to note that, as shown in figure 13, because the key features of the mechanical behaviour occur at small strains, the difference between the stress-strain curve calculated assuming volume conservation, and that calculated using the line laser measurement of specimen radius shows less scatter than that between different specimens.

3.6 Digital Speckle Radiography

Digital Speckle Radiography (DSR) is equivalent to Digital Speckle Photography (DSP) [42] in that the technique relies upon the cross-correlation of image subsections. However, DSR makes use of X-ray images and the placing of a lightly populated, <30%, layer of X-ray opaque particles. The benefit of DSR over DSP is that it allows for the measurement of the in-

29

New Trends in Research of Energetic Materials, Czech Republic, 2010

[Content]

ternal deformations of optically opaque materials. The use of short duration of flash X-rays, 70 ns, is ideal for freezing fast processes such as those that occur in ballistic impact [43]. Here the DSR technique has been applied to a series of experiments designed to simulate the effects of setback and set-forward upon the explosive fill of modern munitions [44]. That is, the high inertial forces exerted during gun launch (setback) and impact/penetration (set forward). An inert polymer bonded explosive simulant, a PBS, based on granulated sugar in a hydroxy-terminated polybutadiene (HTPB) matrix, was designed to mimic the fillings of gunlaunched energetics. The speckle field was created within the target samples by the seeding of lead particles within a central plane perpendicular to X-ray axis and parallel to the impact axis. The lead particles were 500 m in size and the coverage was approximately 20 % by area. The X-ray system used was a Scandiflash 150 keV unit producing a flash of x-rays in a 70 ns pulse. The X-rays impinged upon medical grade intensifier screens and film, which was subsequently digitally scanned. The targets were shock-loaded by plate impact [45] of polycarbonate. Additionally, an experiment was performed in which the sample was doubly shocked, first by polycarbonate and then by copper a few microseconds later. Double shock scenarios have important implications for explosive initiation [46]. Experimental parameters are velocity at impact and time delay between impact and triggering the flash X-ray system. Figure 14 shows the X-ray image which captures the shock-loading process. The projectile has just begun to penetrate the target. Also visible in the image is a fiducial speckle field which is used to remove any rigid body motions introduced during the scanning process. This is done by fitting planes to the u- and v-components of displacement in the fiducial region and subtracting these from the total displacements measured from the film. Also visible is the silhouette of a UK 1 pence piece, which acts as a scale bar (diameter 20.32 mm).

Figure 14: Flash X-ray of Figure 15: u-component data Figure 16: v-component data impact experiment Projectile from plate impact experiment. from plate impact experiment. traveling left to right. Taken from [44] In the analysis, the u-axis is parallel to the projectile axis, and the v-axis is perpendicular. Figure 15 shows the u-component of displacement obtained from the DSR analysis within the target area, the shock wave is clearly visible. The curved nature of the shock front is due to the lateral release of material from a shocked to an unshocked state. The lateral release waves originate from the radial edges of the plate projectile where the material is no longer loaded uniaxially, and will eventually negate the propagating shock wave. Information about the lateral release is contained within the v-component data, figure 16. It should be remembered that

30

New Trends in Research of Energetic Materials, Czech Republic, 2010

[Content]

the data in figures 15 and 16 represent the 2-dimensional displacement fields within the plane of the lead seeded layer, and that the target response is really 3-dimensional in nature. From spatial shift of the parallel displacement curves reported in [44], and knowledge of the time delays between the experiments, estimates can be made of the shock wave speeds: 1.6 km s-1 at for an impact at 300 m s-1. A second series of experiments showed a shock speed of 2.4 km s-1 for an impact at 600 m s-1. This data can also be used to determine the strain associated with the shock: 4.0 0.1 % for an impact at 300 m s-1 and 7.3 0.1 % for an impact at 600 m s-1. By using a composite impactor it was possible to put a stepped shock wave through the target. The displacement shown in figure 17, displays this. Region I is unshocked material. Region II is material subject to shock loading by polycarbonate: the strain in this region is 5.5 0.1 %. Region III is material subject to double shock loading, first by polycarbonate and then copper: the strain in this region is 60 5 %. This data has been used both to populate and validate material models.

Figure 17. Displacement measured in PBS material subject to a stepped shock wave.

3.7 Small Scale Gap Test

In the last two examples, shock waves will be considered; a detonation is by definition a reactive shock wave. These examples are complementary. In the small-scale gap test a shock impinges onto a column of energetic material, while in the cylinder test an energetic material pushes on an inert surround cylinder of inert material. The gap test is a shock sensitivity technique in which a sample of the material of interest is placed in contact with a barrier. On the other side of the barrier an explosive charge is detonated. The shock from the charge moves trough the barrier, losing energy as it goes, and, ultimately passes into the test material. The thicker the barrier, the more the pulse from the charge is reduced and the lower the shock felt by the sample. Experiments are repeated with different barrier or gap thicknesses until a 50:50, or other probability, go: no-go threshold is established. In this study small samples were used [47]. The test samples were pressed into PMMA holders. The cylindrical holders were 25 mm long, 25 mm in diameter with a central bore of 5 mm. The columns were incrementally pressed with a step height of 0.5 mm to give a very homogeneous column. A variety of pressing densities were studied from 60% - 90%. The holders were then placed in the arrangement as shown in figure 18. The holder has a PMMA gap placed above it and a C8 detonator placed on top. The assembly was placed in an armoured box fitted with an observation window. The camera was triggered by a fibre optic that was fitted near the end of the detonator on top of the gap plate. When light was detected from this source, the camera was triggered. At the lower end of the gap arrangement, was a brass witness

31

New Trends in Research of Energetic Materials, Czech Republic, 2010

[Content]

plate. All contacting surfaces were coated in a thin layer of silicone grease in order to allow good acoustic transmission between the layers. The streak records from a series of experiments on 90% TMD PETN presented in figure 19. The PETN had an ultrafine grain size. The gaps were 3.51, 3.63, 3.67 and 3.71 mm. It can be seen that in the top image the detonation is slightly overdriven and was prompt i.e. at the top of the column. The detonation speed then settled down within 5 mm in the column length. In the second image, there is a slight hooking at the top of the column. This is due to the detonation not starting at the top of the column but rather a short distance down it. At 3.67 mm the hooking is severe and the detonation wave breaks out about 8 mm down the column. Finally at 3.71 mm there is no light associated with the detonation process. The brass witness plate dented in the area exposed to the explosive column indicating a detonation pressure in all cases except 3.71 mm. For 3.71 mm, only a small dent was seen indicating the more modest pressure associated with deflagration. A similar series of results was obtained for conventional grain size material where the gap thickness for failure was shown to be 5.54 mm of PMMA. In a final series of experiments, Dynasen PVDF gauges [48] were placed between a gap plate and a block of PMMA 100 mm square and 25 mm thick. The output from a PVDF gauge is shown in figure 20. The output voltage can be converted to stress. For the 5.54 mm gap used in the experiment here this corresponded to a stress level of 2.1 GPa. For a PMMA thickness of 3.67 mm, the stress level was of the order 4.1 GPa. It should be pointed out that the PVDF gauge is recording the stress for several microseconds, much longer than it takes detonation to start.

Figure 18. Experimental arrangements. Top, for gap test, Bottom, for PVDF gauge study

Figure 20. PVDF Output from a gauge separated by 5.54 mm PMMA gap from a C8 detonator.

Figure 19. Streak records of fine-grained PETN 90% TMD. Variation in gap thickness; top - 3.53 mm, second 3.63 mm, third 3.67 mm, bottom 3.71 mm

32

New Trends in Research of Energetic Materials, Czech Republic, 2010

[Content]

3.8 The Cylinder Test

The cylinder test is used to measure detonation performance. In concept it has a very simple geometry: a tube filled with explosive. The material is detonated and, if possible, the deformation of the tube is measured and then related to the detonation pressure and velocity. High-speed recording systems, such as streak photography, allow the rate of expansion of the cylinder to be measured relatively straightforwardly. However, if the aim is to track gradual changes in detonation behaviour of a system, due to the presence of additives, especially in the width of the detonation front, this requires a more time-resolved technique. In this case streak photography was supplemented by the used of velocity interferometer (VISAR) [49]. In this study it was used to look at the effect of aluminium added to sensitized nitromethane [50]. In these experiments the streak camera recorded the radial expansion of the cylinder while the particle velocity-time history of the outer surface of the cylinder during detonation was determined using VISAR. It is important that the surface is not polished to an optical finish because such a finish is unlikely to be preserved at the high stress and strains associated with the cylinder test. Barker et al. developed this technique in the late 60s and early 70s [49]. The reflected laser light is captured and split into two beams, one of which is passed through a glass cylinder known as an etalon. Because the refractive index of glass is larger than that of air, the light in this beam is slowed down and hence delayed with respect to the other beam, which passes through air. If the target is stationary, the interference pattern will not change with time when the two beams are recombined. For an accelerating target, however, the reflected beam will be Doppler shifted. The time resolution of the VISAR data is 2 ns and the noise on the photo-multiplier produces an error of 5 %. Copper cylinder expansion tests were carried out on nitromethane / aluminium (NM/Al) compositions containing 20, 30, 40, 50 and 60% by weight aluminium. The NM used was Analar grade and the aluminium particles were spherical, with a mean size of 10.5m. The mixtures were prepared by adding 5% by weight of polyethylene oxide to the NM to thicken it, thus helping suspend the aluminium, then adding the appropriate percentage of aluminium. The copper cylinders (304mm long, 25.4mm ID with a wall thickness of 2.6mm) were mounted vertically, sealed at the bottom end and initiated by a small booster pellet at the top. The overall expansion was viewed with a Cordin-132 streak camera writing at 5.999 mm/s. An argon flash bomb and diffusing screen were used to provide backlighting. There was a decrease in expansion speed as the particle loading density was increased with a marked change between 40% and 50% as shown in figure 22. The accuracy of measurement of the initial expansion phase is limited by the resolution of the film. Analysis of the VISAR traces gave the velocity histories shown in figure 23. The traces are offset for clarity. The velocity history in these traces tends to flatten after 10 s but this is due to the loss in sensitivity when the fibre is close to the expanding copper surface. The initial acceleration can be seen to take the form of a series of steps. These are due to the reflection of waves within the copper cylinder. This can be explained with reference to figure 24. The detonation of the NM/Al mix causes the cylinder to expand. A shock wave is sent from the inner wall to the outer wall of the cylinder. This reflects at the outer wall as a release, which moves back towards the centre of the tube. When it reaches the centre it is reflected as compression due to the sustained pressure of the detonation products. Overall, the outer wall of the cylinder accelerates as a series of steps. The cylinder walls become thinner, ultimately shredding into fragments. This effect tends to obscure the step-like structure at later times. Hence the system with the most rapid expansion shows the least resolution of the steps while the highest loading of Al caused the most easily resolved steps. While the VISAR data measure the rapid acceleration of the outer surface of the copper cylinder in the first few microseconds, the steps are not seen in the resulting streak displace33

New Trends in Research of Energetic Materials, Czech Republic, 2010

[Content]

ment history. Part of the reason for this is that the stepped region corresponds to the first 2 s of the process, where the displacements are very small. From this simple analysis it can be seen that while the streak camera system is excellent for large displacements it would be difficult to capture the detail of the early acceleration using such a system. The displacements measured using the streak and VISAR can be combined as shown in figure 25.

Figure 21. The experimental set-up

Figure 24. Schematic of deformation of the copper cylinder.

Figure 22. Streak camera records. Cylinder expansion radius time plots for various percentages mass fractions of 10.5 m Al in nitromethane.

Figure 25. Combined VISAR (solid) and streak (dashed) records for 60% Al loading

Figure 23. Velocity histories from VISAR for the loading densities studied

34

New Trends in Research of Energetic Materials, Czech Republic, 2010

[Content]

4.

Conclusions

While the above series of examples shows a wide range of techniques applied to energetic systems, ranging from low to high velocity impact, it is for from exhaustive. However, it is possible to draw some simple conclusions. Keeping experimental geometries and interfaces as simple as possible is useful as it allows data to be extracted with limited recourse to complex analysis. Attention to pressing, the use of small increments gives a marked reduction in error bars which allows other processes to be more clearly observed. In energetic materials, it has been known for over 50 years that ignition and initiation are multi-variable processes and so experimental design is of paramount importance. In some cases like HMX, the specific crystal properties allow second harmonic generation to be used to look at the ignition process. While many of the techniques listed can involve complex equipment, some advances, like the use of line lasers to monitor material expansion can be done with modest resources. Finally, the desired output from the study is important, where it is a legal requirement, variation in procedure may invalidate the results. However, if it is a study to evaluate material properties, experiments can be adapted to lead to new data, which can reveal the complexity of reactive materials.

5.

Acknowledgements

The authors acknowledge a large number of colleagues, students and collaborators, who have supported and developed the techniques in this review. Amongst these Drs. P. Dickson, P.J. Rae, S.G. Grantham, C.R. Siviour, H.T. Goldrein, D.J. Chapman, M.J. Gifford, P.E. Luebcke, H. Czerski contributed significantly to many of the techniques. The late Dr. Avik Chakravarty made a singularly effective contribution to the small-scale gap test. Many technicians have provided indispensable assistance over the years, D. Johnson, R. Marrah, R. Flaxman, K. Fagan, and others in the Cavendish Laboratory Workshop. EPSRC supported the high-speed cameras. QinetiQ, [dstl], Orica, AWE, MoD, provided the support for much of this research. The UK-E consortia, supported by MoD, provided the framework for much of the recent energetic materials research. Finally, I.G. Cullis, A. Cumming, P. Gould, P. Collins, P.D. Church, D. Mullenger, P. Haskins, M. Cook, I. Kirby, M. Braithwaite, P. Collins, S. Wortley, R. Govier all provided stimulus, guidance and much discussion. This long list is not exhaustive and the author (WGP) apologises for any omissions.

6.

[1]

References

Santis L D, A summary of transportation incidents and accidents involving Class 1 materials from 1993 to 1998 in the United States. Proc, 26th Ann. Conf. on Explosives and Blasting Technique. Vol. 1. Cleveland, OH, International Society of Explosives Engineers: 123-132. 2000 Deschambault EJ, Relationships between UN transportation tests and NATO SsD 1.2.3 and IM tests. Proc. 37th Int. Ann. Conf. of Institut fr Chemische Technologie. Karlsruhe, Germany: paper 68. 2006 Smith GW, Riches MJ, Huxford RB Smith PA, Seymour CLG, and Bell JD, Ultra: A new approach to ultrahigh-speed framing cameras. Proc. SPIE 4183: 105-118. 2001 Field JE, Walley SM, Proud, WG, Goldrein, HT, and Siviour, CR, Review of experimental techniques for high rate deformation and shock studies. International Journal of Impact Engineering 30 725-775. 2004 Meyers, MA, Dynamic Behavior of Materials. New York, Wiley Interscience. 1994 Greenaway MW, Laity PR and Pelikan V, X-ray microtomography of sugar and HMX granular beds undergoing compaction. Shock Compression of Condensed Matter - 2005.

[2]

[3] [4]

[5] [6]

35

New Trends in Research of Energetic Materials, Czech Republic, 2010

[Content]

[7] [8]

[9] [10]

[11]

[12]

[13] [14] [15] [16]

[17]

[18] [19] [20] [21]

[22] [23] [24] [25]

M. D. Furnish, M. Elert, T. P. Russell and C. T. White eds. Melville, NY, American Institute of Physics: 1279-1282. 2006 Proud WG, Palmer SJP, Field JE, Kennedy G and Lewis A, AFM studies of PBX systems. Thermochim. Acta 384: 245-251. 2002 Collins AL, Cole JM, Angliss TJP, Proud WG, A parametric study into the thermal properties of copper(II) styphnate tetrahydrate using single-crystal X-ray diffraction. Proc. 40th Int. Ann. Conf. of the Institut fr Chemische Technologie. Karlsruhe, Germany, Institut fr Chemische Technologie: paper 63. 2009 Lewis, AL and Goldrein, HT, Strain measurement techniques in explosives. Strain 40: 33-37. 2004 Williamson DM, Palmer, SJP, et al. Fracture studies of PBX simulant materials. Shock Compression of Condensed Matter - 2005. M. D. Furnish, M. Elert, T. P. Russell and C. T. White eds. Melville, NY, American Institute of Physics: 829-832. 2006 Williamson DM, Palmer SJP, Proud WG, and Govier R, Thermodynamic work of adhesion between HMX and a UK PBX system. Shock Compression of Condensed Matter 2009. M. L. Elert, W. T. Buttler, M. D. Furnish, W. W. Anderson and W. G. Proud eds. Melville, NY, American Institute of Physics: 478-481. 2009 Williamson DM, Siviour CR, Proud WG, Palmer SJP, Govier R, Ellis K, Blackwell P, Leppard C, (Temperature-time response of a polymer bonded explosive in compression (EDC37). J. Phys. D: Appl. Phys. 41: 085404. 2008 Bowden, FP and Yoffe, AD, Initiation and Growth of Explosion in Liquids and Solids Cambridge, Cambridge University Press. 1952 (republ. 1985). Field JE, Swallowe GM, Heavens SN. Ignition mechanisms of explosives during mechanical deformation. Proc R Soc Lond A;382:23144. 1982 Luebcke, PE The deflagration-to-detonation transition in granular secondary explosives, PhD Thesis, Cambridge. 1995 Luebcke PE, Dickson PM, and Field JE, An experimental study of the deflagration to detonation transition in granular secondary explosives. Proc. R. Soc. Lond. A 448: 439448 1995 Korotkov AI, Sulimov AA, Obmenin AV, Dubovitskii VF, and Kurkin AI, Transition from combustion to detonation in porous explosives. Combust. Explos. Shock Waves 5: 216-222. 1969 Griffiths N and Groocock JM, The burning to detonation of solid explosives. J. Chem. Soc. 11: 4154-4162 1960 Dickson PM, and Field JE, Initiation and propagation in primary explosives. Proc. R. Soc. Lond. A 441: 359-375. 1993 Gifford MJ, Proud WG, Field JE, Development of a method for quantification of hotspots. Thermochimica Acta, Vol. 384 pp. 285-290. 2002 Gifford MJ, Proud WG and Field JE, Observations on type II deflagration-to-detonation transitions. Shock Compression of Condensed Matter - 2001. M. D. Furnish, N. N. Thadhani and Y. Horie eds. Melville, NY, American Institute of Physics: 878-881. 2002 Gifford MJ, Luebcke PE and Field JE, A new mechanism for deflagration-to-detonation in porous granular explosives. J. Appl. Phys. 86: 1749-1753. 1999 Pope PH, Dynamic compression of metals and explosives. PhD thesis, University of Cambridge, 1985. Follansbee PS, Regazzoni G, Kocks UF, The transition to drag controlled deformation in copper at high strain rates. Inst Phys Conf Ser;70:7180. 1984 Swallowe GM, Lee SF. A study of the mechanical properties of PMMA and PS at strain rates of 104 to 103 s-1 over the temperature range 293363 K. J Phys IV France;110:338. 2003

36

New Trends in Research of Energetic Materials, Czech Republic, 2010

[Content]

[26] Radford DD, Walley SM, Church P, Field JE. Dynamic upsetting and failure of metal cylinders: experiments and analysis. J Phys IV France;110:2638. 2003 [27] Meyer, LW, Material behaviour at high strain rates, Proc. 1st Int. Conf. on High Speed Forming, ed. M. Kleiner publ. Dortmund, Germany, University of Dortmund, pp. 33-43, 2004 [28] Heavens SN, Field JE. The ignition of a thin layer of explosive by impact. Proc R Soc Lond A;338:7793. 1974 [29] Field JE, Bourne NK, Palmer SJP, Walley SM. Hot-spot ignition mechanisms for explosives and propellants. Philos Trans R Soc Lond A;339:26983. 1992 [30] Walley SM, Field JE, Palmer SJP. Impact sensitivity of propellants. Proc R Soc Lond A;438:57183. 1992 [31] Walley SM, Balzer JE, Proud WG, Field JE. Response of thermites to dynamic high pressure and shear. Proc R Soc Lond A;456:1483503. 2000 [32] Czerski H, Greenaway MW, Proud WG, and Field JE, - phase transition during drop weight impact on HMX. J. Appl. Phys. 96: 4131-4134. 2004 [33] Henson BF, Asay BW, Sander, Son S, Robinson, and Dickson PM, Dynamic measurement of the HMX - phase transition by second harmonic generation. Phys. Rev. Letts 82: 1213-1216. 1999 [34] Saw CK, Kinetics of HMX and phase transitions: Effects of particle size at elevated temperature. Proc. Twelfth International Detonation Symposium. Arlington, VA, Office of Naval Research: 70-76. 2002 [35] Smilowitz L, Henson BF, Asay BW, Dickson PM and Robinson, Kinetics of the phase transition in PBX 9501. Shock Compression of Condensed Matter - 2001. M. D. Furnish, N. N. Thadhani and Y. Horie eds. Melville, NY, American Institute of Physics: 1077-1080. 2002 [36] Smilowitz L, Henson BF, Asay BW, and Dickson PM, The phase transition in the energetic nitramine ocathydro-1,3,5,7-tetranitro-1,3,5,7-tetrazocine: Kinetics. J. Chem. Phys. 117: 3789-3798. 2002 [37] Field JE, Bourne NK, Palmer SJP, Walley SM, Hot-Spot Ignition Mechanisms for Explosives and Propellants, Phil. Trans. R Soc. Lond. A,Vol. 339, No. 1654, Energetic Materials, pp. 269-283, 1992 [38] Walley SM, Siviour CR, Drodge DR and Williamson DM, High-rate mechanical properties of energetic materials, JOM J. Minerals Metals Materials Soc. 62(1) 31-34, 2010 [39] Sjdahl, M, Electronic speckle photography: Increased accuracy by non-integral pixel shifting. Appl. Opt., 33, pp. 6667-6673. 1994 [40] Sjdahl M and Benckert LR, Electronic speckle photography: Analysis of an algorithm giving the displacement with subpixel accuracy. Appl. Opt., pp. 2278-2284. 1993 [41] Siviour CR, Grantham SG, Williamson DM, Proud, WG, Walley SM, and Field JE, High resolution optical analysis of dynamic experiments on PBXs. Proc. 7th Seminar on New Trends in Research of Energetic Materials. J. Vgenknecht. Pardubice, Czech Republic, University of Pardubice: 277-284 2004 [42] Sjdahl M., Electronic speckle photography applied to in-plane deformation and strain field measurements. PhD thesis, Lule University of Technology, Lule, Sweden. 1995 [43] Grantham SG, Goldrein, HT, Proud WG, and Field JE, Digital speckle radiography a new ballistic measurment technique. Imaging Science J. 51 175-186. 2003 [44] Church P, Townsley R, Bezance T, Proud B, Grantham S, Bourne N, and Millet J, Simulation of precise setforward and setback experiments. International Journal of Imapact Engineering 32 80-91. 2005 [45] Bourne NK, Rosenberg Z, Johnson DJ, Field JE, Timbs AE, and Flaxman RP, Design and construction of the UK plate impact facility. Meas Sci Technol 6 1462-1470. 1995

37

New Trends in Research of Energetic Materials, Czech Republic, 2010

[Content]

[46] Gustavsen RL, Sheffield SA, Alcon RR, Winter RE, Taylor P, and Salisbury DA, Double shock initiation of the HMX based explosive EDC-37. In Proceedings of the 12th APS Topical Meeting on Shock Compression of Condensed Matter 2001 (Edited by Furnish/Thadhani/Horie) pp. 999-1002. (The American Institute of Physics, New York). 2002 [47] Chakravarty A, Gifford MJ, Greenaway MW, Proud WG and Field JE, Factors affecting shock sensitivity of energetic materials. 12th APS Topical Meeting on Shock Compression of Condensed Matter 2001. M. D. Furnish, N. N. Thadhani and Y. Horie eds. Melville, NY, American Institute of Physics: 1007-1010. 2002 [48] Bauer, F. Advances in piezoelectric PVDF shock compression sensors: Applications to HE studies. Proc. 25th Int. Pyrotechnics Seminar. Saint Aubin, France, Association Franaise de Pyrotechnie: 28-37. 1999 [49] Barker, LM and Hollenbach, RE, Laser interferometer for measuring high velocities of any reflecting surface." J. Appl. Phys. 43: 4669-4675. 1972 [50] Proud, WG, Field, JE, Milne A, Longbottom AW, Haskins PJ, Briggs RI and Cook MD, The detonation of NM/Al mixtures. Proc. Fifth Int. Symp. on High Dynamic Pressures. Vol. 1. Paris, France, Commissariat l'Energie Atomique: 135-141. 2003

38

Anda mungkin juga menyukai

- William P. Walters - Explosive Loading of Metals and Related TopicsDokumen134 halamanWilliam P. Walters - Explosive Loading of Metals and Related TopicsGhoree23456Belum ada peringkat

- William P. Walters and Stanley K. Golatski - Hemispherical and Conical Shaped-Charge Liner Collapse and Jet FormationDokumen48 halamanWilliam P. Walters and Stanley K. Golatski - Hemispherical and Conical Shaped-Charge Liner Collapse and Jet FormationGhoree23456Belum ada peringkat

- Hanwei He and Shouya Jia - Direct Electrodeposition of Cu-Ni-W Alloys For The Liners For Shaped ChargesDokumen4 halamanHanwei He and Shouya Jia - Direct Electrodeposition of Cu-Ni-W Alloys For The Liners For Shaped ChargesGhoree23456Belum ada peringkat

- Ai-Ling Fan Et Al - Comparison of Microstructures in Electroformed and Spin-Formed Copper Liners of Shaped Charge Undergone High-Strain-Rate DeformationDokumen4 halamanAi-Ling Fan Et Al - Comparison of Microstructures in Electroformed and Spin-Formed Copper Liners of Shaped Charge Undergone High-Strain-Rate DeformationGhoree23456Belum ada peringkat

- IMP1Dokumen6 halamanIMP1api-3762972Belum ada peringkat

- Sorin Bastea - Transport Properties of Fluid Mixtures at High Pressures and Temperatures. Application To The Detonation of Products of HMXDokumen9 halamanSorin Bastea - Transport Properties of Fluid Mixtures at High Pressures and Temperatures. Application To The Detonation of Products of HMXGhoree23456Belum ada peringkat

- I.Horsfall, E.Petrou and S.M.Champion - Shaped Charge Attack of Spaced and Composite ArmourDokumen8 halamanI.Horsfall, E.Petrou and S.M.Champion - Shaped Charge Attack of Spaced and Composite ArmourGhoree23456Belum ada peringkat

- R.L. Summers, W.P. Walters and R.D. Dick - The Behavior of Shaped Charges With Open-Poled Hemispherical LinersDokumen142 halamanR.L. Summers, W.P. Walters and R.D. Dick - The Behavior of Shaped Charges With Open-Poled Hemispherical LinersGhoree23456Belum ada peringkat

- C. G. Fountzoulas Et Al - A Computational Study of Laminate Transparent Armor Impacted by FSPDokumen14 halamanC. G. Fountzoulas Et Al - A Computational Study of Laminate Transparent Armor Impacted by FSPGhoree23456Belum ada peringkat

- JJ. Morrison, PF Mahoney and T. Hodgetts - Shaped Charges and Explosively Formed Penetrators: Background For CliniciansDokumen4 halamanJJ. Morrison, PF Mahoney and T. Hodgetts - Shaped Charges and Explosively Formed Penetrators: Background For CliniciansGhoree23456100% (1)

- Manfred Held - Liners For Shaped ChargesDokumen7 halamanManfred Held - Liners For Shaped ChargesGhoree23456Belum ada peringkat

- Alistair Doig - Some Metallurgical Aspects of Shaped Charge LinersDokumen3 halamanAlistair Doig - Some Metallurgical Aspects of Shaped Charge LinersGhoree23456Belum ada peringkat

- M.F. Gogulya Et Al - Detonation Performance of Aluminized Compositions Based On BTNENDokumen10 halamanM.F. Gogulya Et Al - Detonation Performance of Aluminized Compositions Based On BTNENGhoree23456Belum ada peringkat

- Manfred Held - Liners For Shaped ChargesDokumen1 halamanManfred Held - Liners For Shaped ChargesGhoree23456Belum ada peringkat

- Jason C. Gilliam and Darin L. Kielsmeier - Multi-Purpose Single Initiated Tandem WarheadDokumen6 halamanJason C. Gilliam and Darin L. Kielsmeier - Multi-Purpose Single Initiated Tandem WarheadGhoree23456Belum ada peringkat

- Klaus Lindstadt and Manfred Klare - Tandem Warhead With Secondary ProjectileDokumen5 halamanKlaus Lindstadt and Manfred Klare - Tandem Warhead With Secondary ProjectileGhoree23456Belum ada peringkat

- Arnold S. Klein - Bounding Anti-Tank/Anti-Vehicle WeaponDokumen9 halamanArnold S. Klein - Bounding Anti-Tank/Anti-Vehicle WeaponGhoree23456Belum ada peringkat

- A.V. Fedorov, T.A. Khmel and Yu.V. Kratova - Numerical Modeling of Detonation Propagation in Gas-Particle Mixtures in The Duct With A Cross-Sectional BreakdownDokumen9 halamanA.V. Fedorov, T.A. Khmel and Yu.V. Kratova - Numerical Modeling of Detonation Propagation in Gas-Particle Mixtures in The Duct With A Cross-Sectional BreakdownGhoree23456Belum ada peringkat

- Ernest L. Baker Et Al - High Explosive Assembly For Projecting High Velocity Long RodsDokumen8 halamanErnest L. Baker Et Al - High Explosive Assembly For Projecting High Velocity Long RodsGhoree23456Belum ada peringkat

- C. Needham - The Influence of Delayed Energy Release in Aluminized ExplosivesDokumen1 halamanC. Needham - The Influence of Delayed Energy Release in Aluminized ExplosivesGhoree23456Belum ada peringkat

- J.B.W. Borgers and J. Vantomme - Towards A Parametric Model of A Planar Blast Wave Created With Detonating CordDokumen1 halamanJ.B.W. Borgers and J. Vantomme - Towards A Parametric Model of A Planar Blast Wave Created With Detonating CordGhoree23456Belum ada peringkat

- R. C. Ripley Et Al - Explosion Performance of Aluminized TNT in A ChamberDokumen1 halamanR. C. Ripley Et Al - Explosion Performance of Aluminized TNT in A ChamberNikeShoxxxBelum ada peringkat

- Ian A. Johnston - The Noble-Abel Equation of State: Thermodynamic Derivations For Ballistics ModellingDokumen24 halamanIan A. Johnston - The Noble-Abel Equation of State: Thermodynamic Derivations For Ballistics ModellingGhoree23456Belum ada peringkat

- D. Frost and F. Zhang - The Nature of Heterogeneous Blast ExplosivesDokumen1 halamanD. Frost and F. Zhang - The Nature of Heterogeneous Blast ExplosivesGhoree23456Belum ada peringkat

- M. Lombardini and D. I. Pullin - Small-Amplitude Perturbations in The Three-Dimensional Cylindrical Richtmyer-Meshkov InstabilityDokumen18 halamanM. Lombardini and D. I. Pullin - Small-Amplitude Perturbations in The Three-Dimensional Cylindrical Richtmyer-Meshkov InstabilityGhoree23456Belum ada peringkat

- A. L. Kuhl - A Baroclinic Model of Turbulent Dusty FlowsDokumen58 halamanA. L. Kuhl - A Baroclinic Model of Turbulent Dusty FlowsGhoree23456Belum ada peringkat

- Svend Tollak Munkejord and Mikael Papin - The Effect of Interfacial Pressure in The Discrete - Equation Multiphase ModelDokumen34 halamanSvend Tollak Munkejord and Mikael Papin - The Effect of Interfacial Pressure in The Discrete - Equation Multiphase ModelGhoree23456Belum ada peringkat

- Alistair Doig - Some Metallurgical Aspects of Shaped Charge LinersDokumen3 halamanAlistair Doig - Some Metallurgical Aspects of Shaped Charge LinersGhoree23456Belum ada peringkat

- V. Tanguay Et Al - Reaction of Metal Particles in Gas-Phase Detonation ProductsDokumen16 halamanV. Tanguay Et Al - Reaction of Metal Particles in Gas-Phase Detonation ProductsGhoree23456Belum ada peringkat

- Fan Zhang, Paul A. Thibault and Rick Link - Shock Interaction With Solid Particles in Condensed Matter and Related Momentum TransferDokumen23 halamanFan Zhang, Paul A. Thibault and Rick Link - Shock Interaction With Solid Particles in Condensed Matter and Related Momentum TransferGhoree23456Belum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- ثرموداينمكDokumen10 halamanثرموداينمكabdcivilBelum ada peringkat

- PDL FOR Emergency Procedure Guide - 170713 PDFDokumen2 halamanPDL FOR Emergency Procedure Guide - 170713 PDFmalisolangiBelum ada peringkat

- Combustion Instability Vortex SheddingDokumen16 halamanCombustion Instability Vortex Sheddingflowh_Belum ada peringkat

- Pamphlet of Bower-Barff ProcessDokumen68 halamanPamphlet of Bower-Barff ProcessJeric_QBelum ada peringkat

- 3516ta Ulb Tech DataDokumen4 halaman3516ta Ulb Tech Datactopher63Belum ada peringkat

- CB MFG ProcessDokumen35 halamanCB MFG ProcessChinmoy DholeBelum ada peringkat

- Citroen Bosch Hdi Edc15c2 Injection System and Particle FilterDokumen155 halamanCitroen Bosch Hdi Edc15c2 Injection System and Particle FilterJose Ramón Orenes ClementeBelum ada peringkat

- Properties and Reaction of Methyl BenzeneDokumen21 halamanProperties and Reaction of Methyl Benzeneoasis_dessert100% (2)

- Gek97310 File0024Dokumen32 halamanGek97310 File0024URIONA RUBEN100% (2)

- CWI Product Information Bulletin - Natural Gas Engine Oils - April 2018Dokumen2 halamanCWI Product Information Bulletin - Natural Gas Engine Oils - April 2018roger gonzales hoyosBelum ada peringkat

- Oil Gas Boilers For Medium and High OutputDokumen70 halamanOil Gas Boilers For Medium and High OutputMihaela BuciucBelum ada peringkat

- Fuel Induction Techniques For A H Y D R O G E N Operated EngineDokumen10 halamanFuel Induction Techniques For A H Y D R O G E N Operated Engineshivang36Belum ada peringkat

- Chemistry Notes (Organic Chem)Dokumen6 halamanChemistry Notes (Organic Chem)Teo Jia Ming NickolasBelum ada peringkat

- Otto and Diesel CyclesDokumen16 halamanOtto and Diesel CyclesYogaisan RamasawmyBelum ada peringkat

- Disaster Readiness and Risk Reduction Exam for Mabilbila Integrated SchoolDokumen5 halamanDisaster Readiness and Risk Reduction Exam for Mabilbila Integrated SchoolFRECY LOPEZBelum ada peringkat

- Environmental Crisis Causes and ManifestationsDokumen26 halamanEnvironmental Crisis Causes and Manifestationsबाजीराव सिंघम0% (1)

- Literature Review: Forced Draft and Induced Draft FansDokumen6 halamanLiterature Review: Forced Draft and Induced Draft FansAlif Nur FirdausBelum ada peringkat

- Cdi 106 ModuleDokumen6 halamanCdi 106 ModuleFrancheska Kate LabiosBelum ada peringkat

- Advanced Bright Stock SDSDokumen7 halamanAdvanced Bright Stock SDSmishal123456Belum ada peringkat

- Msds Colazoline o (16 Section)Dokumen6 halamanMsds Colazoline o (16 Section)mndmattBelum ada peringkat

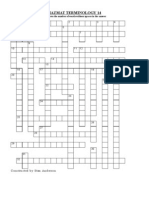

- Hazmat Terminology 14: in Clues, The Following ( - Words) Indicates The Number of Words Without Spaces in The AnswerDokumen5 halamanHazmat Terminology 14: in Clues, The Following ( - Words) Indicates The Number of Words Without Spaces in The AnswerFire LibraryBelum ada peringkat

- CAT - C13 (Prefix LEE) .LEE1-840Dokumen13 halamanCAT - C13 (Prefix LEE) .LEE1-840Phil B.Belum ada peringkat

- CHAPTER-6 CombustionDokumen6 halamanCHAPTER-6 CombustionAkshara ChawlaBelum ada peringkat

- What Is The Differences Between Gas Turbine and A Steam TurbineDokumen1 halamanWhat Is The Differences Between Gas Turbine and A Steam TurbineGourav ChoudhuriBelum ada peringkat

- AG° calculations for argon combustion reactionDokumen2 halamanAG° calculations for argon combustion reactionPhillip BurgessBelum ada peringkat

- Furnace & Ovens WP (Original)Dokumen38 halamanFurnace & Ovens WP (Original)Mumahmmad Rizwan RBelum ada peringkat

- Steam Generation - Distribution 2023Dokumen64 halamanSteam Generation - Distribution 2023Aaqil cassimBelum ada peringkat

- FM Global - Fire Suppression Physics For Sprinkler ProtectionDokumen14 halamanFM Global - Fire Suppression Physics For Sprinkler ProtectionChidi Henry100% (1)

- Wartsila 50 DF Dual Fuel Engine Reference For LNGC 04 01 07 PPTDokumen47 halamanWartsila 50 DF Dual Fuel Engine Reference For LNGC 04 01 07 PPTEDDIN1960100% (3)

- 9701 w12 QP 23Dokumen12 halaman9701 w12 QP 23poliuytrewqBelum ada peringkat