Quiet Steel Body Panel Design With DAMP - A Custom Preprocessor Utilizing MSC-PATRAN/NASTRAN

Diunggah oleh

sfhaider1Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Quiet Steel Body Panel Design With DAMP - A Custom Preprocessor Utilizing MSC-PATRAN/NASTRAN

Diunggah oleh

sfhaider1Hak Cipta:

Format Tersedia

Quiet Steel Body Panel Design with DAMP - A Custom Preprocessor Utilizing MSC-PATRAN/NASTRAN

Lezza A. Mignery Material Sciences Corporation, Laminates and Composites Elk Grove Village, IL 600007 (847) 439-1822 x2170, lmignery@concentric.net

ABSTRACT Quiet Steel, a laminated metal, integrates vibration damping into the main structure of the vehicle. This allows for the reduction or elimination of sound absorbing materials and mastics in the conventional noise solution. With laminated metal, the result is a noise, vibration, harshness improvement without adding weight and cost. However, the marked difference between the stiff steel laminate skins and the soft laminate adhesive core requires a three-layer mesh to capture the resulting through-thickness shearing. A finite element preprocessor, DAMP, eases the design process by creating the three-layer representation, directly from a sheet metal mesh. DAMP utilizes both MSC.Patran [1] and MSC.Nastran [2] parameters in the mesh generation process. DAMP is demonstrated here with the design of a front floor panel. The laminated panel is analyzed to determine its proper gauge to maintain the stiffness of the sheet metal original. A modal test is also simulated to demonstrate the reduced vibrations associated with the Quiet Steel design.

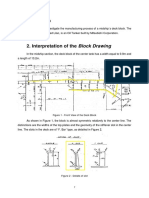

INTRODUCTION Quiet Steel is emerging as the material of choice in optimizing sound packages in automotive body applications. By adhesively bonding two flat pieces of sheet metal together in a continuous coil process, this production friendly laminate gives the automotive engineer the design flexibility of integrating vibration damping within the main structure of the vehicle. Noise transmission abatement is also available with a Quiet Steel design. Testing has shown the laminate performs as well as, or better than, a steel/mastic solution [3]. The Quiet Steel design therefore allows for the reduction or elimination of sound absorbing materials and mastics in the conventional noise solution. The bottom line advantage of using this laminate is a noise, vibration, harshness (NVH) improvement while reducing weight and cost to the vehicle. While achieving benefits in sound quality, the design analysis of these parts is challenging due to the marked difference in material properties of the laminate layers. Any analysis is difficult because, under deformation, through-thickness plane sections do not remain plane. The adhesive layer is so soft that the two layers of steel slide against each other quite readily, as shown in Figure 1. This shearing activates the main damping mechanism of the laminate. It also allows for the laminate to be formed into many complex contoured shapes. However, when modeling these materials, this deformation requires a detailed three-layer model to capture this shearing effect. To further complicate the analysis, the adhesive material properties are temperature and frequency dependent. These design challenges were the motivation for DAMP, a finite element preprocessor for designing laminated metal components. DAMP eases the design process by generating all analysis input for laminated components, allowing the engineer to concentrate more on the laminate design benefits. DAMP has been tailored to use MSC.Nastran conventional elements to describe the laminated design. It builds a three-layered element model from an original shell element MSC.Patran neutral file of the mesh. The resulting three-layer mesh can be used for any standard MSC.Nastran investigation of the part. Here, static displacements are determined to gauge an equivalent stiffness front floor panel to the steel original. The design is analyzed as connected to a rear steel floor panel. Connectivity in an assembly further demonstrates the flexibility of the laminate representation. MSC.Nastran is also used to show the greatly damped vibrations associated with the Quiet Steel design. This paper demonstrates the procedures of how a design engineer can proactively create a vibration damped noise/vibration solution, while achieving equivalent stiffness to the original solid metal design. THE FINITE ELEMENT PREPROCESSOR, DAMP Laminated metal damps vibrations by the cyclic shearing of its core adhesive layer, between the two layers of steel skins. The finite element model of a laminate design must contain all three layers of material to capture this shearing action. One of the simplest idealizations for the three layers is the offset shell element and solid element model [4] as shown in Figure 2. The offset shell elements represent the steel layers of the laminate, while the solid elements represent the core adhesive. Offset shell elements are essential 2

for the laminated metal description. MSC.Nastran was the first (of only two) finite element packages to contain offset shell elements. The offset shell elements are defined away from their mid-plane, so that they lie at the top and bottom of the adhesive core. This allows for the elimination of two rows of nodes that would normally be needed if conventional shell elements were used. In addition, the thickness of the laminated metal skins can be changed, without generating a new geometry, with the use of offset shell elements. This allows for the skin thickness of the laminate to be altered, without having to construct a new mesh. Conventional shell elements would require new grid locations to define the new mid-plane for any thickness changes. Offset shell elements require only a change of element parameters to change the skin thickness of the laminate. While this three-layer design is easy to envision for a flat part, a further challenge lies in applying the representation in a complex contoured design. This is where DAMP [5-9] becomes essential to the design process. DAMP generates all laminate parameters necessary for design. First, a conventional shell element mesh is made of the part. Next, MSC.Patran is used to orient all element normals in the same direction. Then, a MSC.Patran neutral file of the mesh is created for the design. DAMP reads in the neutral file and, essentially, duplicates each element, an adhesive layer away from their original location. DAMP converts every element into a bicubic surface, determines the local normal, and then translates the element the adhesive thickness, down this normal [8]. At this lower interface, the surfaces are intersected, so that curvature of the original design is preserved. If the elements do not intersect (due to the original curvature of the part) DAMP will expand the elements first, then translate, and try the intersection again. The two layers of surfaces are then identified as offset shell elements. The resulting two layers of shell elements are then connected with solid elements. DAMP preserves the original numbering sequence of the elements and nodal points, increasing each element and node number by a constant value to identify the new surface. This easily identifies the grids of the solid elements. Number preservation also makes applying loads, boundary conditions, and multi-point constraints easy, once they have been defined in the original model. A laminate model for a front floor pan is shown in Figure 3. The inset in Figure 3 shows the two layers of shell elements and the interconnecting solid. A consequence of the mesh is that extreme aspect ratios result for the core layer. Yet, good correlation has been achieved with experimental results [7,9]. DAMP also determines the core material properties from internal material models. The material properties of the adhesive core are temperature and frequency dependent. Core material models were determined from a standard vibrating beam test. These models can be used to determine material property estimates for static and dynamic conditions. For the stiffness calculations, a low frequency, 150 Hz, modulus is used. The low frequency mimics the static state. For the dynamic calculations, a constant modulus and material damping were identified at 250 Hz. These properties are representative of frequency ranges less than 500 Hz. All material properties were defined at room-temperature conditions. The generated finite element model and the 150 Hz material properties will be used in the following to gauge the laminated floor pan to maintain the stiffness of the original steel part. The alternate material properties at 250 Hz will be used to demonstrate the natural frequencies, mode shapes, frequency response, and damping of the laminated design. 3

DESIGNING A QUIET STEEL BODY PANEL FRONT FLOOR PAN STIFFNESS CALCULATION: The front floor pan is analyzed as part of a larger assembly that includes the rear floor pan. The full assembly is shown in Figure 4. The parts are joined together with multipoint constraints at the weld points between the two parts. These locations are indicated in the figure by small circles. The boundary of the entire floor pan is pinned in position. In addition, in order to more closely mimic the in-service condition, the floor is pinned along the regions of supporting cross members. The laminate is then analyzed to maintain the same stiffness as the original steel construction. This is done by examining the displacement due to a static load. Four loading positions were selected. These locations are indicated by the numbers in Figure 4. Having calculations at various locations gives a good representation of the local stiffness seen with the laminate construction. A 1N load is applied, equally split among four nodes, perpendicular to the surface at every location. The laminate stiffness calculations were made with the offset shell/solid model as described above. The skin thickness was varied until approximately the same displacement was given from the laminate and steel designs. Maximum displacements for each load case are given n Table 1. Also shown in the table is the resulting weight i for each panel. Some laminates are labeled not used to indicate their calculations were not necessary to judge the equivalent laminate. Table 1: Front Floor Displacements and Weights. Displ. at Displ. at Displ. at Displ. at Weight pt. 1 (mm) pt. 2 (mm) pt. 3 (mm) pt. 4 (mm) (lb) 2.00E-03 4.36E-03 3.91E-03 1.01E-02 33.63

Material

steel sheet 0.91mm (0.036") lam. skin thick. mm (in) 0.5588 (0.022) 2.59E-03 4.29E-03 4.94E-03 1.20E-02 0.5842 (0.023) 2.31E-03 3.94E-03 4.45E-03 1.08E-02 43.29 0.6096 (0.024) 2.07E-03 3.63E-03 4.02E-03 9.67E-03 0.635 (0.025) 1.86E-03 3.36E-03 3.65E-03 8.73E-03 0.6604 (0.026) 1.68E-03 3.12E-03 Not used not used Note: All laminates have steel skins and 0.0254mm (0.001) core. Displacement equivalents for 1N load are in bold. Weight of laminates is also indicated.

While each loading condition may give preference to a different thickness, viewing the results in Table 1 will show the 0.5842mm (0.023) skin thickness laminate to most closely match the stiffness of the baseline floor pan part, by providing a comparable average stiffness.

The resulting laminate thickness for equivalent stiffness is greater than the original steel thickness. This is due to the low modulus of the adhesive material at this temperature and frequency (low frequency mimics static state). The low modulus allows the layers to slide against each other, decreasing the stiffness of the laminate. If a considerable amount of welds are present, or extensive supporting structure, it may be possible to use a thinner laminate. This extra local support will not effect the damping of the laminate, unless it inhibits the overall shearing of the laminate. The design engineer will have to weigh several factors in the final gauge selection, from tooling to noise abatement. However, noise transmission abatement will benefit greater from a thicker laminate. NATURAL FREQUENCIES AND MODE SHAPES: All dynamic characteristics were determined with the boundary conditions shown in Figure 4. These conditions represent a modal test on the front and rear component, detached from other pieces, but fixed in position. The offset shell/solid model was used for the laminate as described above. Material properties for the skins of the laminate were those used for the original steel design. Material properties for the polymeric core were determined by the preprocessor at 250 Hz and 24C (75F). Ideally, the natural frequencies for the laminate design should be calculated with a modulus at that same frequency. The laminate values are then just estimates of the actual value. Table 2 gives the floor natural frequencies of the steel (0.91mm for both front and rear panels) and laminate/steel (0.5842mm - or 0.023 skins, 1.19mm total, or 0.047 total for front floor, 0.091mm steel for the rear) designs. Table 2: Natural frequencies of steel and laminate/steel floor designs (in Hz). Mode Steel Laminate/Steel 0.91mm (0.036) Laminate Front: 0.5842mm Front and Rear (0.023) skin-1.19 mm (0.047) total Steel Rear: 0.91mm (0.36) I 71.94 70.98 II 97.72 96.6 III 101.52 98.03 IV 102.55 98.76 V 104.48 102.3 VI 106.71 106.71 VII 118.3 117.52 VIII 125.23 121.45 IX 128.3 121.66 X 132.4 125.22

Selected mode shapes of the corresponding vibrations are shown in Figure 5. Mode shapes will change with other boundary conditions, or if other parts are connected to the designs. The situation here is of a modal test on the floor alone, with the components fixed in position. 5

FREQUENCY RESPONSE AND DAMPING: Frequency response calculations were done at 24C (75F) from 0 -350 Hz at 0.625 Hz increments using a modal steady state dynamics solution (SOL 111). The steel design was given a loss factor of 0.002. The laminate calculations were made with the core material properties for 250 Hz. This corresponds to the same values used in other laminate analyses [5,6]. A harmonic load was applied at location 2 in Figure 3. The acceleration was then monitored at location 3 of Figure 3. Predictions were made for the 0.91mm (0.036) steel floor and the 0.5842mm (0.023) skin laminated (1.19mm total, or 0.047) front floor, with same steel rear (0.91mm). The resulting frequency response is shown in Figure 6. As can be seen, the laminate responses are greatly damped as compared to their steel counterparts. A detailed modal analysis of this frequency response curve would give the damping of the laminate. This type of analysis could separate out the extremely damped peaks in the portions of the curve beyond 150 Hz. Simple calculations can be used to determine the level of damping in the first peak. A technique known as the 3dB method will give the level of damping [10]. The 3dB method determines the damping value, or loss factor, from a ratio of the width of the peak to the peak frequency ( f/f). The width is taken at 1/2 (~2/3) of the peak acceleration amplitude. For any steel (or any metal) design, without considering damping due to connections with other parts (system damping), the loss factor is ~0.002. If one considers system damping, a steel design has a loss factor of ~0.01. Using the 3dB method, the loss factor for the first peak (97 Hz) of the laminate design is 0.0763. A loss factor better than 0.07 is considered well damped. Beyond 150 Hz, damping will be greater than 0.1. CONCLUSIONS A finite element preprocessor, DAMP, has been presented as well as its use in designing laminated metal body parts. DAMP utilizes MSC.Nastran and MSC.Patran parameters in converting a conventional shell element model of a body panel into a three-layer, offset shell/solid mesh, representative of a laminated metal design. The resulting mesh can be used for any conventional finite element analysis available in MSC.Nastran. With this preprocessor, a Quiet Steel (vibration damped steel) floor pan was analyzed to determine the appropriate laminate gauge to maintain the stiffness of the original sheet metal design and to demonstrate its dynamic characteristics. The front floor was analyzed as connected to a steel rear floor pan. With the three-layer configuration, material properties for the laminate are defined for the base material in each layer, the adhesive core and the steel skins. Static and dynamic calculations showed the following results: To maintain equal stiffness, the 0.91mm (0.036) steel front floor pan should be replaced with a laminate constructed of equal thickness skins measuring 0.5842mm (0.023, total laminate thickness 1.19mm, or 0.047).

The natural frequencies of the equivalent stiffness laminated design are very close to the original steel design. Natural mode shapes are particular to the pinned boundary conditions applied in this analysis. The laminated frequency response curve is considerably damped as compared to the steel original. A damping value, or loss factor, of 0.076 was determined for the first peak of the frequency response curve, with values better than 0.1 for the rest of the curve. A maximum loss factor of 0.01 is available from the steel design (considering system damping). A loss factor of 0.07 is considered well damped. This implies that the laminated steel is ideal for this design application in combating noise due to vibration.

In addition, the following can be stated: Stiffness calculations were made without supporting structure in the analysis (only mimicked with pinned boundary conditions). These additions may reduce the shearing between layers of the laminate and stiffen local sections. Therefore, the gauge of the laminate here is conservative (thick). Welding will not effect the damping of the laminate, unless so much is added that it inhibits the shearing of the laminate. Dynamic analysis has shown how the laminate damps vibrations for only one set of boundary conditions. These conditions may not reflect the actual situation, but give a relative view of the laminates ability to damp vibrations.

REFERENCES 1. MSC.Patran, Version 9, The MacNeal-Schwendler Corporation. 2. MSC.Nastran, Version 70, The MacNeal-Schwendler Corporation. 3. Welch, T.E., Schwaegler, J.R., Cost and Performance Benefits for Laminated Steel Body Parts, SAE Noise and Vibration Conference, Paper No. 99NV-258, SAE, 1998. 4. Johnson, C.D., Klenholz, D.A., and Rogers, L.C., Finite Element Prediction of Damping in Beams with Constrained Viscoelastic Layers, Schock Vib. Bull, 51, 1981. 5. Mignery, L.A., Designing Body Panels with Quiet Steel and DAMP, Body Engineering Journal, Spring 2000. 6. Mignery, L.A., Designing Automotive Dash Panels with Laminated Metal, International Body Engineering Conference, SAE Paper No. 1999-01-3201, SAE, 1999.

7. Mignery, L.A., and Vydra, E.J., Vibration Analysis of Metal/Polymer/Metal Laminates Approximate versus Viscoelastic Models, SAE Noise and Vibration Conference, Paper No. 971943, SAE, 1997. 8. Mignery, L.A., Vibration Analysis of Metal/Polymer/Metal Components, Proceedings of the 1995 ASME Design Engineering Technical Conference, ASME, 1995. 9. Mignery, L.A., Designing with Metal/Polymer/Metal Composites, Proceedings of International Body Engineering Conference, IBEC 1996. 10. Nashif, A.D., Jones, D.I.G., and Henderson, J.P., Vibration Damping, John Wiley & Sons, New York, 1985.

steel

adhesive ~ 20:1 Thickness Ratio

Quiet Steel

Sheet Material

Figure 1: Through-thickness shear deformation pattern associated with the Quiet Steel , or laminated metal, design as opposed to that of a sheet material.

t/2

Offset Shell/ Solid Model

Shell Layer #1

Solid

Shell Layer #2 t/2

Figure 2: Finite element representation of laminated metal. Steel laminate skins are modeled with offset shell elements. Adhesive laminate core is modeled with solid elements.

Figure 3: Laminated mesh of front floor pan.

10

Figure 4: Loading and monitoring points for the static and frequency response analysis.

11

Figure 5: Selected mode shapes of the floor pan

12

Figure 6: Frequency response from laminate and steel front floor.

13

Anda mungkin juga menyukai

- Reinforced Concrete Buildings: Behavior and DesignDari EverandReinforced Concrete Buildings: Behavior and DesignPenilaian: 5 dari 5 bintang5/5 (1)

- 8C 2 PensoDokumen11 halaman8C 2 PensoAmirhossein AnsariBelum ada peringkat

- Etabs 11Dokumen3 halamanEtabs 11jb.dqaBelum ada peringkat

- Cold-Formed Steel Design by Spreadsheet Program: Scholars' MineDokumen19 halamanCold-Formed Steel Design by Spreadsheet Program: Scholars' MineRaineir PabiranBelum ada peringkat

- Vehicle Structure Design & Material Selection: DR Meftah HrairiDokumen19 halamanVehicle Structure Design & Material Selection: DR Meftah Hrairi'Atif AliBelum ada peringkat

- TRN Simulation Question AnswersDokumen4 halamanTRN Simulation Question AnswersCristhian Stefano Falchi PosadaBelum ada peringkat

- Cold Formed Steel Sections-LibreDokumen8 halamanCold Formed Steel Sections-LibreCernomodiac NicolaeBelum ada peringkat

- Short Proposal Finite ElementDokumen9 halamanShort Proposal Finite ElementMuhammad Ilham ZulkipllyBelum ada peringkat

- BIW Thinwall Structures PDFDokumen3 halamanBIW Thinwall Structures PDFsmani170Belum ada peringkat

- ETABS Design ProcedureDokumen10 halamanETABS Design Procedureer_rahmansBelum ada peringkat

- Thickness Determination of SMC Replacing Sheet Metals For Automobile RoofDokumen5 halamanThickness Determination of SMC Replacing Sheet Metals For Automobile Roofajaikumar ShankarBelum ada peringkat

- Finite Element Analysis of Reinforced Concrete Beams Strengthened With CFRP in FlexuralDokumen17 halamanFinite Element Analysis of Reinforced Concrete Beams Strengthened With CFRP in FlexuralZoran VasicBelum ada peringkat

- Alternative Model of The Offset Deformable BarrierDokumen8 halamanAlternative Model of The Offset Deformable Barrierkevin12rickBelum ada peringkat

- Strand7 Roofrack AssignmentDokumen17 halamanStrand7 Roofrack AssignmentJoel Forbes100% (1)

- Design Analysis Fabrication and Testing of Composite Leaf Seminar ReportDokumen26 halamanDesign Analysis Fabrication and Testing of Composite Leaf Seminar Reportyash1239100% (1)

- Fem SlabDokumen22 halamanFem SlabEfren ElegadoBelum ada peringkat

- 1027 Using Surface Elements in FE AnalysisDokumen15 halaman1027 Using Surface Elements in FE AnalysisAnonymous bVFHovBelum ada peringkat

- Experimental and Numerical Evaluation of MechanicaDokumen5 halamanExperimental and Numerical Evaluation of Mechanicabeatrice santosBelum ada peringkat

- Aluminum Metal Matrix CompositesDokumen3 halamanAluminum Metal Matrix CompositesazeemdcetBelum ada peringkat

- International Journal of Engineering Research and Development (IJERD)Dokumen8 halamanInternational Journal of Engineering Research and Development (IJERD)IJERDBelum ada peringkat

- Thin-Walled Structures: Wei Lu, Pentti M Akel Ainen, Jyri Outinen, Zhongcheng MaDokumen8 halamanThin-Walled Structures: Wei Lu, Pentti M Akel Ainen, Jyri Outinen, Zhongcheng MaPiseth HengBelum ada peringkat

- EA Flores-Johnson 2014 Numerical Investigation of The Impact Behaviour of Bioinspired Nacre-Like Aluminium Composite Plates Compos Sci Technol 96 13-22Dokumen13 halamanEA Flores-Johnson 2014 Numerical Investigation of The Impact Behaviour of Bioinspired Nacre-Like Aluminium Composite Plates Compos Sci Technol 96 13-22Sujit KumarBelum ada peringkat

- SSRN Id4163209Dokumen7 halamanSSRN Id4163209Deepak KumarBelum ada peringkat

- ZK0601249255 PDFDokumen7 halamanZK0601249255 PDFAJER JOURNALBelum ada peringkat

- Shear Wall Analysis - New Modelling, Same AnswersDokumen3 halamanShear Wall Analysis - New Modelling, Same AnswersccapotaBelum ada peringkat

- Bi Material BeamDokumen22 halamanBi Material BeamPraveen KumaarBelum ada peringkat

- Modelling and Analysis of Heavy Vehicle Chassis Frame Made by Using Carbon Fiber and Composite Material: A Comparative Study.Dokumen9 halamanModelling and Analysis of Heavy Vehicle Chassis Frame Made by Using Carbon Fiber and Composite Material: A Comparative Study.Bhimsen ShresthaBelum ada peringkat

- Design of Composite Cardan ShaftDokumen17 halamanDesign of Composite Cardan ShaftManshi AgrawalBelum ada peringkat

- Study of Finite Element Analysis Type To The Nonlinear Buckling Behavior of Cellular BeamsDokumen8 halamanStudy of Finite Element Analysis Type To The Nonlinear Buckling Behavior of Cellular BeamsCaesarAbdullahBelum ada peringkat

- Minimisation of Interlaminar Stress in Composite Wind Turbine BladesDokumen6 halamanMinimisation of Interlaminar Stress in Composite Wind Turbine Bladeslogeshboy007Belum ada peringkat

- 10 1 1 685 4139 PDFDokumen6 halaman10 1 1 685 4139 PDFOvidiu Si Roxana IvascuBelum ada peringkat

- Epstein Test MethodDokumen7 halamanEpstein Test MethodAnonymous vKD3FG6RkBelum ada peringkat

- Evolution of Texture and Microstructure During Accumulative Roll Bonding of Aluminum AA5086 AlloyDokumen13 halamanEvolution of Texture and Microstructure During Accumulative Roll Bonding of Aluminum AA5086 AlloyAmel HalimiBelum ada peringkat

- ILSSDokumen11 halamanILSSyigitilgazBelum ada peringkat

- 2002 Int Ansys ConfDokumen10 halaman2002 Int Ansys ConfjowarBelum ada peringkat

- RAM Frame - Semirigid Diaphragms FAQ - RAM - STAAD Wiki - RAM - STAAD - Bentley CommunitiesDokumen8 halamanRAM Frame - Semirigid Diaphragms FAQ - RAM - STAAD Wiki - RAM - STAAD - Bentley CommunitiesPourang EzzatfarBelum ada peringkat

- Extended Abstract 81571 PDFDokumen10 halamanExtended Abstract 81571 PDFKalyude DiógenesBelum ada peringkat

- Example 3 - S-Beam CrashDokumen13 halamanExample 3 - S-Beam CrashSanthosh LingappaBelum ada peringkat

- 167 BrotanDokumen8 halaman167 BrotanGoogle AccountBelum ada peringkat

- Heimbs 2007 Folded Sandwich Core StructuresDokumen15 halamanHeimbs 2007 Folded Sandwich Core Structuresindebtanup2443Belum ada peringkat

- Distortional BucklingDokumen16 halamanDistortional BucklingadnanmominBelum ada peringkat

- Aluminizing SiX, JMST (2009) 433Dokumen4 halamanAluminizing SiX, JMST (2009) 433Marin RomeoBelum ada peringkat

- 30 304NDokumen5 halaman30 304NJason SamuelBelum ada peringkat

- Chapter 5 - Components PropertiesDokumen47 halamanChapter 5 - Components PropertiesHamza CheemaBelum ada peringkat

- Ruukki Technical Article Local Buckling of Plates Made of High Strength Steel - AshxDokumen5 halamanRuukki Technical Article Local Buckling of Plates Made of High Strength Steel - AshxIsuru Indrajith PereraBelum ada peringkat

- Structural and Thermal Analysis of Metal - Ceramic Disk BrakeDokumen5 halamanStructural and Thermal Analysis of Metal - Ceramic Disk BrakeRavi SunnyBelum ada peringkat

- Met 56 3 4 405 408Dokumen4 halamanMet 56 3 4 405 408wendyBelum ada peringkat

- Semi-Automated Micro Assembly For Rapid Prototyping of A One DOF Surgical WristDokumen7 halamanSemi-Automated Micro Assembly For Rapid Prototyping of A One DOF Surgical WristDur MolBelum ada peringkat

- Static and Fatigue Behaviour of Hexagonal Honeycomb Cores Under In-Plane Shear LoadsDokumen19 halamanStatic and Fatigue Behaviour of Hexagonal Honeycomb Cores Under In-Plane Shear LoadsAnto PellisseryBelum ada peringkat

- PDF PDFDokumen14 halamanPDF PDFVicky VigneshBelum ada peringkat

- Design of Sports Equipment Made From Anisotropic Multilayer Composites With Stiffness Related Coupling EffectDokumen9 halamanDesign of Sports Equipment Made From Anisotropic Multilayer Composites With Stiffness Related Coupling EffectMarthaBelum ada peringkat

- Fracture Mechanics Analysis of CoatingDokumen12 halamanFracture Mechanics Analysis of CoatingBisma MasoodBelum ada peringkat

- ABSTRACT Leaf SpringDokumen7 halamanABSTRACT Leaf SpringCuGáyLâmĐồng100% (1)

- Detailed Fea of Locally Thinned Pipe Bends: Usama Abdelsalam & DK VijayDokumen9 halamanDetailed Fea of Locally Thinned Pipe Bends: Usama Abdelsalam & DK VijayAnonymous 1hOgJqwZuzBelum ada peringkat

- Figure 1 - Front View of The Deck BlockDokumen17 halamanFigure 1 - Front View of The Deck BlockAna Paula BittencourtBelum ada peringkat

- Notes in Machine Design: Insert The Title of Your Presentation HereDokumen221 halamanNotes in Machine Design: Insert The Title of Your Presentation HerePatrick MarcaidaBelum ada peringkat

- Composite Materials Note Form Nptel in PDFDokumen33 halamanComposite Materials Note Form Nptel in PDFM.Thirunavukkarasu100% (1)

- Optimization of Engine Mounting Bracket Using FEA Mr. Pramod Walunje Prof. V.K. KurkuteDokumen4 halamanOptimization of Engine Mounting Bracket Using FEA Mr. Pramod Walunje Prof. V.K. KurkuteFabian CaizaBelum ada peringkat

- SPL02090341Dokumen7 halamanSPL02090341Narasimha DvlBelum ada peringkat

- Lecture12 2019 Harmonic Potential PDFDokumen26 halamanLecture12 2019 Harmonic Potential PDFMatt AllsopBelum ada peringkat

- Mechatronics Course SyllabusDokumen17 halamanMechatronics Course Syllabusnikhilrane91_7522800Belum ada peringkat

- Reg. No.: Model ExamDokumen3 halamanReg. No.: Model ExamDamo Daran GBelum ada peringkat

- Chemistry LN 6 Quantum ChemistryDokumen25 halamanChemistry LN 6 Quantum ChemistryKaran RavalBelum ada peringkat

- RM BridgeDokumen6 halamanRM BridgeBenny Sofyan HartadiBelum ada peringkat

- PLAXIS Ground Response AnalysisDokumen46 halamanPLAXIS Ground Response AnalysisAnonymous D5s00DdUBelum ada peringkat

- What - Is - A Potentiostat PDFDokumen55 halamanWhat - Is - A Potentiostat PDFjaum_camposcosta0% (1)

- Rail Wheel Int. TOTPDokumen93 halamanRail Wheel Int. TOTPkr_abhijeet72356587100% (3)

- PH102 Course Outline 2023Dokumen9 halamanPH102 Course Outline 2023KAUSHAL KEVINBelum ada peringkat

- BNL Piping ResearchDokumen17 halamanBNL Piping ResearchaaaaBelum ada peringkat

- Honeywell Damper Selection and SizingDokumen20 halamanHoneywell Damper Selection and SizingroadiewebBelum ada peringkat

- Oau Post Utme Past Question and AnswerDokumen23 halamanOau Post Utme Past Question and AnswerFoluso Adeosun100% (1)

- G320X REV-10 Manual FormattedDokumen7 halamanG320X REV-10 Manual FormattedNghia Nguyen TrongBelum ada peringkat

- Mil Shock AnalysisDokumen48 halamanMil Shock AnalysisSotirios Margonis100% (1)

- Hysteresis Model: 5.1 GeneralDokumen21 halamanHysteresis Model: 5.1 GeneralDavidHusseyBelum ada peringkat

- Random Vibration in Patran and Classical ApproachDokumen44 halamanRandom Vibration in Patran and Classical Approachபிரபாகரன் ஆறுமுகம்Belum ada peringkat

- 1 s2.0 S2215098621000379 MainDokumen15 halaman1 s2.0 S2215098621000379 MainJackson PhinniBelum ada peringkat

- Varela (2011) - Control of Vibration Induce by People Walking On Large Span Composite Floor Decks PDFDokumen10 halamanVarela (2011) - Control of Vibration Induce by People Walking On Large Span Composite Floor Decks PDFJosé Francisco AnunciaçãoBelum ada peringkat

- General Physics LaboratoryDokumen3 halamanGeneral Physics Laboratorynameb22362Belum ada peringkat

- Liquefaction SP22Dokumen85 halamanLiquefaction SP22Soubhik MishraBelum ada peringkat

- Auto Reclosing in Transmission SystemsDokumen14 halamanAuto Reclosing in Transmission SystemsNeelakandan MasilamaniBelum ada peringkat

- Damped Harmonic Oscillator: Wednesday, 23 October 2013Dokumen9 halamanDamped Harmonic Oscillator: Wednesday, 23 October 2013MayaIsStupidBelum ada peringkat

- Dr. Mian Ashfaq Ali: Mechanical Vibrations ME-421Dokumen13 halamanDr. Mian Ashfaq Ali: Mechanical Vibrations ME-421Talha MohsinBelum ada peringkat

- Free Vibration With Coulomb Damping Examples: With Many Figures and Models From Mechanical Vibrations, S. S. RaoDokumen20 halamanFree Vibration With Coulomb Damping Examples: With Many Figures and Models From Mechanical Vibrations, S. S. RaoMihir AsharBelum ada peringkat

- AdvMath (Unit 2)Dokumen24 halamanAdvMath (Unit 2)Ivan Paul SyBelum ada peringkat

- Oscillation-Neda Razavipour (Low)Dokumen8 halamanOscillation-Neda Razavipour (Low)Informes CHINEROBelum ada peringkat

- Airplane Stability and Control Notes GATE Aerospace EngineeringDokumen31 halamanAirplane Stability and Control Notes GATE Aerospace Engineeringabrarn179208100% (4)

- Hart 1988Dokumen9 halamanHart 1988Pedro SilvaBelum ada peringkat

- Flight DynamicsDokumen13 halamanFlight Dynamics9600257003Belum ada peringkat

- Ept474 2dofDokumen118 halamanEpt474 2dofLeon OoBelum ada peringkat