07 TT 02 HVT SVCs

Diunggah oleh

StevenMvuyanaDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

07 TT 02 HVT SVCs

Diunggah oleh

StevenMvuyanaHak Cipta:

Format Tersedia

TRANSMISSION AND DISTRIBUTION

SVCs - the regulators to maximise Africas power systems

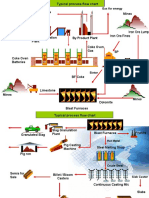

by Dale Pudney, High Voltage Technology, and Dr. Pat Naidoo, Pat Naidoo Consulting Engineers The strength of electrical power systems is defined by the fault level which is determined by the investment in power generation. Many of the developing countries in Africa have small generation facilities such as small hydro and diesel driven turbines. With a low fault level, the resulting power system is weak and this deters new economic investments in mining and industries. Using a Static Var Compensator [SVC], mining and industrial customers with modern technology loads can continue to couple with weak power systems. SVCs regulates each phase of the three phase power system and restores full balance to the power system. A new cost effective method is presented for customer connections without the need for more investment in expensive power generation. HVT have noticed a significant increase in demand for SVCs in recent times as mining and minerals processing companies are embarking on new and expansion projects; while the transmission networks cannot supply the new loads. SVCs provide voltage stability and the dynamic reactive power required to enable maximum power transfer in the existing transmission networks. SVCs projects are normally orders of magnitude cheaper and faster than the alternative of installing new transmission capacity. The mechanics of SVCs SVCs traditionally comprise a combination of breaker switched fixed capacitor banks that provide the capacitive reactive power and Thyristor Controlled Reactors (TCR) that provide the dynamically controlled inductive reactive power ( Fig. 1). By controlling the firing angle on the thyristors, (Fig. 2) the current flowing in the TCR is rapidly controlled. The thyristors are very fast acting, which means that the reactive power output of the TCR can be changed in less than a cycle. A downside of the operation of the thyristors is the introduction of harmonic currents into the system. The fixed capacitors are designed to absorb the harmonic currents [called the harmonic filter]. Thus the SVC does not introduce unacceptable harmonic levels into the network. If an SVC needs to be variable from +20 Mvar inductive to -30 Mvar capacitive, the SVC would probably comprise harmonic filters with a combined output of 30 Mvar to produce the capacitive output and a TCR of 50 Mvar inductive. The TCR output is changed by operation of the thyristors from 0 to 50 Mvar. When the output of the TCR is zero, the output of the SVC is -30 Mvar capacitive. When the

Fig. 1: Typical SVC arrangement.

Fig. 2: Thyristor firing angle.

Fig. 3: Voltage problems without SVC.

energize - September 2011 - Page 37

TRANSMISSION AND DISTRIBUTION

amount of reactive power supply for the reactive demand of the load. Hence reactive power is not required from the utility; maximizing the capacity utilisation of the transmission network. During fault conditions, the reactive output is increased immediately (sub 1 cycle) to support the voltage during the fault. The degree of compensation is determined by the series impedance between the point of fault and the position of the SVC. After the fault, the output of the SVC changes rapidly to damp the oscillations. During low load or voltage surges, the output of the SVC goes inductive to reduce the voltages. Benefits of SVCs SVCs are used to improve the power and voltage quality with rapidly varying loads. Economic benefits of this include:

Fig. 4: Voltage profile improvement with SVC.

Increasing the productivity of arc furnaces by increasing the voltage across the electrodes and shortening the heating cycle. Productivity is typically increased by 8 10%. Improved voltage stability also reduces the wear on electrodes and furnace lining, heat loss and increases the lifespan of the equipment. Payback periods of installing an SVC on an arc furnace are typically less than two years. Enabling increased power transfer in weak transmission systems. SVCs are normally installed within 12 months much shorter than lead times to new transmission capacity and much cheaper. Enabling large machines to operate in islanded systems with generation (renewable energy) matched to the steady state power requirements of the loads.

Fig. 5: Voltage profile with high duty switches.

output of the TCR is 50 Mvar, the output of the SVC is 20 Mvar inductive. And the SVC can operate at any point in between. Where SVCs are needed SVCs are typically needed where there is a rapidly varying load, and especially rapidly varying reactive power loads such as:

Long lines/weak systems: where the transmission capacity is limited and voltage collapse occurs when the load increases too much. At times of no load, the voltage rises due to the Ferranti effect. During and after faults, voltage variations are exaggerated due to the higher system impedance of weak systems. Small generation systems, such as wind turbines, small hydro power, etc.: where the machines often can't generate the high reactive power demand required for short durations by large machines (especially when the generation size is matched to the steady state demand of the load).

SVCs for wind farms Windfarms typically operate within a wide range of wind speeds which poses a problem for generating power at a constant frequency and rate. Different manufacturers have different solutions to this problem, but wind farms typically need some form of reactive power compensation to meet the power factor and power quality requirements. Although a cheap way of managing reactive power, capacitor bank switching using bang-bang control also results in an immediate, abrupt step-change in the voltage on the grid or the bus to which they are connected. The step-change instantaneously increases the torque, or twisting force, on a wind turbine gearbox, which is analogous to banging on it with a sledge hammer. The variable nature of wind generation itself often triggers an extremely high number of the very switching events that hammer the gearboxes. Like all induction motors, induction-type wind turbines absorb reactive power off of the grid in

Arc furnaces: where the loads var y dynamically due to uneven arc between the electrodes in the furnace. This results in unbalance between the phases and reduces the efficiency and causes overheating, noise, torque pulses and speed pulses in three phase motors used on the furnaces. Voltage variations also increase electrode consumption, heat loss and wear of the furnace lining. Mining loads: such as large mills, winders, etc., where the reactive power at start-up and acceleration is often orders of magnitude higher than the steady state active power, for short times. In particular large mines in remote areas of Africa often require SVC systems to ensure that the transmission systems are able to deliver the power required. Traction loads: normally fed from large single phase systems introducing unbalance into the 3-phase system.

With long lines, weak systems and variable loads the following scenarios can be expected:

No load conditions the voltage at the end of the line rises due to the Ferranti effect. Full load conditions the voltage collapses because of excessive volt drops along the line. During fault conditions the fault currents cause significant voltage dips After fault conditions the voltage oscillates during recovery

With an SVC in circuit, the steady state operation of the SVC outputs the required energize - September 2011 - Page 38

TRANSMISSION AND DISTRIBUTION

with dependable and affordable products. We bring you the cutting edge technology from the factory of the world.

We have established relationships with Chinese SVC OEMs who have aggressive and flexible expansion plans. China has the world's second largest power system [now surging to 950 GW and just behind the USA at 1100 GW]. This market is served by Chinese manufacturers of high quality and world class technology. Previously all of this capacity was consumed in the Chinese market, but these manufacturers are now looking for export markets as well. We will ensure skills transfer into the local market with enabling local support and service for the local SVC market. Skills transfer from the OEM to HVT was one of the criteria used to select the OEM. We will custom integrate the best technology choices from a range of global OEMs. By integrating primary equipment from suppliers such as capacitors from Cooper Power Systems, reactors from Trench and specialized SVC technology from NR Electric, HVT has been able to offer the market world class SVCs at a much more affordable price. We pride ourselves in full customer service from pre sales to after sales support; always ensuring peak product performance at all times.

Fig. 6: Variable shunt reactor.

amounts that fluctuate with the speed at which the wind drives the turbines. This, in turn, causes an unacceptably large voltage drop at or near the wind farm interconnection point with the grid. So, if this reactive power is generated by capacitor banks at the wind farm, it's not uncommon for a site to experience a hundred or more switching events a day. Poor per formance of wind turbines is directly associated with gearbox failures. The repairs contribute to long periods of unavailability of the wind machine; further compounding its natural, low load factor, energy production. This makes dynamically variable reactive power compensation, such as an SVC, beneficial for the power quality requirements of wind farms. Alternatives to SVCs There exists an old perception that SVC's are expensive and other alternatives are much cheaper. We need to take full life cycle costing into consideration rather than a once off capital payment. For example, we have the choice of switched harmonic filters for arc furnaces. Switched harmonic filters for arc furnaces A number of arc furnace customers have installed harmonic filters with high switching duty capable vacuum switches, which can typically do about 60 000 operations. The switches switch the filter banks in during the furnace cycle (typically around one hour) and out while the furnace is out (typically around 15 min). The furnace can do around 20 cycles per day which means that the switches should last between 8 and 12 years. The result of using high switching duty switches means that the voltage profile is raised during furnace operation, which assists to increase the productivity of the furnace. However, the filter bank is not switched out immediately

after the furnace stops operating; normally there is a delay of about one minute. There is a significant voltage rise during this delay, which must be maintained below the allowable voltage limits; this limitation therefore limits the amount of reactive power compensation that can be applied to the furnace to improve the voltage and thereby the productivity. The voltage profile shown in Fig. 5 reflects the typical effect of high duty switches used to switch filter banks on a furnace supply. The furnaces and all equipment connected to the same busbars would be detrimentally affected by this voltage fluctuation; affecting their own life, productivity and reliability. An SVC which changes its reactive power output dynamically and smoothly would overcome this problem. Wind farms Where the fast response of an SVC is not required, a Variable Shunt Reactor (VSR) may provide an acceptable solution, such as the one depicted in Fig. 6. This can be used where varying reactive power is required, but the variation of the load or generation is not fast as is the case with wind farms. The VSR varies the output of the reactor by varying the inductance of the reactor achieved through mechanically adjusting the air gaps of its magnetic circuit. Hence the variation is achieved without the introduction of harmonic currents, but the changes are much slower about five minuts from minimum to maximum power. Affordability of SVCs The perception that SVCs are expensive is misleading. HVT has opened market opportunities and will continuously promote customer satisfaction and delight energize - September 2011 - Page 40

Conclusion Africa has an abundance of low cost, renewable energy resources. Africa is also endowed with natural mineral wealth. As the global economy recovers, and the demand for minerals improves, more intensive loads will be installed initially on Africa's weak transmission systems. SVCs are the ideal technology to bridge the power systems gaps for the present day loads and to continue into the future as part of the Flexible Alternating Current Transmission Systems [FACTS] support for growing AC networks and interconnections. SVC's provide both a contribution to power systems stability with quality voltages and will maximise the AC power system power transfer capacity. High Voltage Technology will give the customer the competitive edge by providing SVC's that are affordable and reliable; with full professional engineering back up for pre and after sales service inclusive of customer staff training and development. High Voltage Technology brings a new paradigm in the SVC supplier market in full support of Africa's economic growth and development. Contact Dale Pudney, High Voltage Technology, Tel 012 666-9358, dale@hvt.co.za

Anda mungkin juga menyukai

- Static Var Compensator: Rongxin Power Electronic Co., LTDDokumen17 halamanStatic Var Compensator: Rongxin Power Electronic Co., LTDSteven Leif EsselBelum ada peringkat

- Group 7 SVC and StatcomDokumen15 halamanGroup 7 SVC and Statcomhamza mandlwiBelum ada peringkat

- 716 - UniGear ZS2 With VD4 05Dokumen6 halaman716 - UniGear ZS2 With VD4 05srmohapatra5086Belum ada peringkat

- 7-1 (Combined Bending and Axial Load)Dokumen10 halaman7-1 (Combined Bending and Axial Load)Ruben Ham Caba HizukaBelum ada peringkat

- DRAFT User Guide PDFDokumen363 halamanDRAFT User Guide PDFRobles Dresch100% (1)

- Lec 12 Design of An EAFDokumen14 halamanLec 12 Design of An EAFSakunaPappu100% (1)

- Impact of Artificial Intelligence, and The Fourth Industrial Revolution On Business SuccessDokumen1.026 halamanImpact of Artificial Intelligence, and The Fourth Industrial Revolution On Business SuccessMEKamilBelum ada peringkat

- Comparative Study of Different Facility LayoutDokumen27 halamanComparative Study of Different Facility LayoutAmee Thakkar ParekhBelum ada peringkat

- Project Planning: CIS 375 Bruce R. Maxim UM-DearbornDokumen17 halamanProject Planning: CIS 375 Bruce R. Maxim UM-DearbornSolomon W. DemissieBelum ada peringkat

- Üretim Akış Şeması Ve Nihai Ürünler IngDokumen8 halamanÜretim Akış Şeması Ve Nihai Ürünler IngtalhadikenBelum ada peringkat

- Classification of CostDokumen33 halamanClassification of CostGeet SharmaBelum ada peringkat

- Green Steel & Its Production Technologies: Aditya Shankar Routray ROLL NO-26614 REGD NO-0701105140Dokumen28 halamanGreen Steel & Its Production Technologies: Aditya Shankar Routray ROLL NO-26614 REGD NO-0701105140Aditya ShankarBelum ada peringkat

- Leanix - Agile Enterprise Architecture FrameworkDokumen1 halamanLeanix - Agile Enterprise Architecture FrameworkPaul Vintimilla CarrascoBelum ada peringkat

- Case Study in Industrialized Building System (IBS)Dokumen17 halamanCase Study in Industrialized Building System (IBS)Mohamed A. SattiBelum ada peringkat

- Note CHP 4 Material Science 281 Uitm Em110Dokumen52 halamanNote CHP 4 Material Science 281 Uitm Em110bino_ryeBelum ada peringkat

- ZVEI Positionspapier MES Prerequisite For Digital Operation and Production ManagementDokumen24 halamanZVEI Positionspapier MES Prerequisite For Digital Operation and Production ManagementengacostaBelum ada peringkat

- Vacuum DegasserDokumen6 halamanVacuum Degasserreza haghjooBelum ada peringkat

- Unit-VDokumen164 halamanUnit-VPoreddy vineelaBelum ada peringkat

- 10.1007@978 3 030 31019 6 PDFDokumen784 halaman10.1007@978 3 030 31019 6 PDFHAROLD FABIAN MURCIA MORENO100% (1)

- Sap DesignDokumen1 halamanSap DesignCIVIL100Belum ada peringkat

- النماذج المستخدمة في إدارة استبدال الأصول الثابتة 355-375Dokumen537 halamanالنماذج المستخدمة في إدارة استبدال الأصول الثابتة 355-375Ammar AlsafadiBelum ada peringkat

- Nippon Imp Diagramas de FlujoDokumen4 halamanNippon Imp Diagramas de FlujodiegoBelum ada peringkat

- Formato de EvaluaciónDokumen34 halamanFormato de EvaluaciónSergio LandinBelum ada peringkat

- Project SchedulingDokumen17 halamanProject SchedulingSolomon W. DemissieBelum ada peringkat

- What Is HIPOT Testing (Dielectric Strength Test) - EEPDokumen7 halamanWhat Is HIPOT Testing (Dielectric Strength Test) - EEPmahmoud fawzyBelum ada peringkat

- 3.problems SVC - Static Var or SolvedDokumen19 halaman3.problems SVC - Static Var or Solvedgonfree100% (1)

- 00 Practice 2 Bridge CraneDokumen14 halaman00 Practice 2 Bridge CraneMarco NeveBelum ada peringkat

- LCL Filter 2Dokumen5 halamanLCL Filter 2Hasib PeyalBelum ada peringkat

- Smart Plant Enterprise For Owner OperatorsDokumen12 halamanSmart Plant Enterprise For Owner Operatorsthawatchai11222512Belum ada peringkat

- Capacitive Voltage Transformers (CVT) For HV Measurements - EEPDokumen8 halamanCapacitive Voltage Transformers (CVT) For HV Measurements - EEPNeelakandan MasilamaniBelum ada peringkat

- Symmetrical Faults Part I PDFDokumen39 halamanSymmetrical Faults Part I PDFGunjan lalakiya100% (2)

- Aistech 2012 - Modernization and Upgrade of A Static Var Compensator For An Electric Arc Furnace ApplicationDokumen7 halamanAistech 2012 - Modernization and Upgrade of A Static Var Compensator For An Electric Arc Furnace ApplicationRamin GoudarziBelum ada peringkat

- Application of Measuring Gas Flow in The DowncomerDokumen4 halamanApplication of Measuring Gas Flow in The DowncomerAhmad NilBelum ada peringkat

- Break Even Analysis in ProductionDokumen17 halamanBreak Even Analysis in Productionyashwant4043994Belum ada peringkat

- Mini Peoject - SMDokumen9 halamanMini Peoject - SMRajat GuptaBelum ada peringkat

- Engineering Discipline Document Title: List of Common Engineering DeliverablesDokumen2 halamanEngineering Discipline Document Title: List of Common Engineering DeliverablesAngling DharmaBelum ada peringkat

- Battery Types Used For Auxiliary Power Supply in Substations and Power PlantsDokumen8 halamanBattery Types Used For Auxiliary Power Supply in Substations and Power PlantsTigrilloBelum ada peringkat

- Hbi Use in FoundryDokumen3 halamanHbi Use in Foundryravikataria02Belum ada peringkat

- 1RN4 WL OperatingInstructions EN PDFDokumen214 halaman1RN4 WL OperatingInstructions EN PDFZegh FatehBelum ada peringkat

- SVC Abb Case StudyDokumen2 halamanSVC Abb Case StudybhsujanBelum ada peringkat

- Roadmap I4Dokumen138 halamanRoadmap I4RESHMABelum ada peringkat

- Capacity Control of Centrifugal Compressor: By: Raghda AhmedDokumen15 halamanCapacity Control of Centrifugal Compressor: By: Raghda AhmedMostafa HosnyBelum ada peringkat

- Short Circuit Fault Calculator V62Dokumen11 halamanShort Circuit Fault Calculator V62Arif KhanBelum ada peringkat

- How To Read A Fan CurveDokumen13 halamanHow To Read A Fan CurveMuhammad Amin HunzaiBelum ada peringkat

- Defining Size and Location of Capacitor in Electrical System 1Dokumen7 halamanDefining Size and Location of Capacitor in Electrical System 1Prince BlissfulBelum ada peringkat

- Obo PNK PDFDokumen26 halamanObo PNK PDFJanko GardaševićBelum ada peringkat

- Flow ChartDokumen2 halamanFlow ChartVc ShekharBelum ada peringkat

- SRX11838 Engineers Handbooks ACI AISC 16Dokumen194 halamanSRX11838 Engineers Handbooks ACI AISC 16AntonBelum ada peringkat

- QoneDokumen3 halamanQoneHv TopBelum ada peringkat

- PESTEL Analysis of TATA SteelDokumen3 halamanPESTEL Analysis of TATA SteelSaurabhkumar SinghBelum ada peringkat

- Applications of Computational Intelligence PDFDokumen279 halamanApplications of Computational Intelligence PDFYisela MayorgaBelum ada peringkat

- Eur Steel Scrap SpecDokumen6 halamanEur Steel Scrap SpecGabriel CaraveteanuBelum ada peringkat

- Classification of Electrical System According To Neutral DistributionDokumen36 halamanClassification of Electrical System According To Neutral DistributionMohammedSaadaniHassaniBelum ada peringkat

- Classification of FACTSDokumen8 halamanClassification of FACTSEngr Imtiaz Hussain GilaniBelum ada peringkat

- Table 2.5 Loading For Building Frames and Support Columns: II. Crane Loads Metal Building Systems ManualDokumen6 halamanTable 2.5 Loading For Building Frames and Support Columns: II. Crane Loads Metal Building Systems ManualtuansteelsBelum ada peringkat

- 3D Photovoltaic Devices Complete Self-Assessment GuideDari Everand3D Photovoltaic Devices Complete Self-Assessment GuideBelum ada peringkat

- Automatic Power Factor Controlling PanelDokumen15 halamanAutomatic Power Factor Controlling PanelheruvalaBelum ada peringkat

- 03MC0132 Rev. 00Dokumen11 halaman03MC0132 Rev. 0089deveshBelum ada peringkat

- Modeling and Control of A Cascaded-Multilevel Converter Based StatcomDokumen72 halamanModeling and Control of A Cascaded-Multilevel Converter Based StatcomShareef KhanBelum ada peringkat

- Coren Write UpDokumen20 halamanCoren Write UpBabatunde MartinsBelum ada peringkat

- Multicast Routing Protocols in Wireless Sensor Networks (WSNS)Dokumen9 halamanMulticast Routing Protocols in Wireless Sensor Networks (WSNS)Journal of Computing100% (1)

- Generator Protection - 7UM85 - Technical DataDokumen42 halamanGenerator Protection - 7UM85 - Technical DataDoan Anh TuanBelum ada peringkat

- CS-C12BKPG Cu-2c24bkp5gDokumen70 halamanCS-C12BKPG Cu-2c24bkp5gDũng LêBelum ada peringkat

- QuestionnaireDokumen4 halamanQuestionnaireBishu BiswasBelum ada peringkat

- ATM - PPT - de Guzman Aladin Quinola PascuaDokumen25 halamanATM - PPT - de Guzman Aladin Quinola PascuaJohn Michael Gaoiran GajotanBelum ada peringkat

- Mk10E Brochure - English PDFDokumen2 halamanMk10E Brochure - English PDFmatthewivanBelum ada peringkat

- PROJECT NAME: Construction of 380/33kV SWPC 3A BSP: S.No. Item Description Name of Supplier FAT RemarksDokumen2 halamanPROJECT NAME: Construction of 380/33kV SWPC 3A BSP: S.No. Item Description Name of Supplier FAT RemarksshahzebBelum ada peringkat

- Maytec-HT-08 Maytec Generell BrochureDokumen6 halamanMaytec-HT-08 Maytec Generell BrochurezhiqianxuBelum ada peringkat

- Connecting To The Internet With Pico WDokumen30 halamanConnecting To The Internet With Pico WKnut BoergeBelum ada peringkat

- CareerCentre Resume and Cover Letter Toolkit - UofTDokumen32 halamanCareerCentre Resume and Cover Letter Toolkit - UofTMallikaShakyaBelum ada peringkat

- Cisco IOS For DummiesDokumen29 halamanCisco IOS For DummiesGary LuBelum ada peringkat

- OxBlue Enhanced Security Monitoring Brochure 0 01Dokumen3 halamanOxBlue Enhanced Security Monitoring Brochure 0 01jhBelum ada peringkat

- How To Use NUCLEO-F401RE and MbedDokumen14 halamanHow To Use NUCLEO-F401RE and MbedmavisXzeref 17Belum ada peringkat

- Per 01a - Cargo Pumproom Entry PermitDokumen3 halamanPer 01a - Cargo Pumproom Entry PermitRajesh NairBelum ada peringkat

- Modeling and Simulation in XENDEE: IEEE 34 Node Test FeederDokumen12 halamanModeling and Simulation in XENDEE: IEEE 34 Node Test Feedercarlos cervantesBelum ada peringkat

- PI Calliope SQN3223 3 20160205 Web PDFDokumen2 halamanPI Calliope SQN3223 3 20160205 Web PDFrqueirosBelum ada peringkat

- IT Module 4Dokumen2 halamanIT Module 4Crizele Joy LagudaBelum ada peringkat

- Spencer Kane Kennelly, Exp. Associate: Data Standardization and Master/Reference Data ManagementDokumen1 halamanSpencer Kane Kennelly, Exp. Associate: Data Standardization and Master/Reference Data ManagementArjun GhattamneniBelum ada peringkat

- Alexa Howell: EducationDokumen1 halamanAlexa Howell: EducationAlexaBelum ada peringkat

- As 2159 2009 Piling Design and InstallationDokumen9 halamanAs 2159 2009 Piling Design and InstallationKinson LowBelum ada peringkat

- Windows Processor Requirements Windows 11 Supported AMD Processors - Microsoft DocsDokumen1 halamanWindows Processor Requirements Windows 11 Supported AMD Processors - Microsoft DocscursantcataBelum ada peringkat

- UNIX PermissionsDokumen4 halamanUNIX PermissionsIngiaBelum ada peringkat

- The Systems Life Cycle - Form 5Dokumen14 halamanThe Systems Life Cycle - Form 5Hatz ProBelum ada peringkat

- Dse E800 Data Sheet PDFDokumen2 halamanDse E800 Data Sheet PDFbagusBelum ada peringkat

- Introduction of CENTUM VP R6 RS R4 FullDokumen98 halamanIntroduction of CENTUM VP R6 RS R4 FullmohamedfaizykaBelum ada peringkat

- WDG 4Dokumen2 halamanWDG 4Anonymous rNLEUdBelum ada peringkat

- Nursing InformaticsDokumen7 halamanNursing Informaticsapi-19880840100% (1)

- Get More From Your: MIRO Power Quality Logger and Analyser Starter KitsDokumen5 halamanGet More From Your: MIRO Power Quality Logger and Analyser Starter Kitsjobpei2Belum ada peringkat

- Veko Brand VFD Inverter Basic Default Settings and Adjusting InstructionsDokumen4 halamanVeko Brand VFD Inverter Basic Default Settings and Adjusting InstructionsNuhj OsohcidBelum ada peringkat

- Lab ManualDokumen10 halamanLab ManualtheBelum ada peringkat