MCBR1010 Magic Chef 24

Diunggah oleh

Laurie SpryDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

MCBR1010 Magic Chef 24

Diunggah oleh

Laurie SpryHak Cipta:

Format Tersedia

MCBR1010 SERIES SERVICE MANUAL

PREPARED BY:280W item group

Hefei Meiling Company Ltd.Aug,2006

CATALOGUE 1. 2. 3. 4. PRODUCT BRIEF 3 COOLING SYSTEM

6

CONTROLING SYSTEM 8 EXPLODE VIEW

11

CHAPTER 1 PRODUCT BRIEF

This product is a newly developed frost-free refrigerator of our company. The product's external appearance is special and decent sculpting. It is the whole box hull structure, poured foam behind, ensured foamed layer thickness equality. So the heat preservation function is more excellent It is the whole foamed door structure, designed to a thin door gasket structure that can keep cold air effect better and with maximum limit attain economy energy effect. In the frozen room door racks are used that it can enlarge the storage space and increment to store. In the refrigerate room can rack is used that it can easily store and take to take to easily pull a soft beverage product such as can. In the cold system wings slice type evaporate is used that it

can spread hot efficiency increment and make cold effectively. Control the system accords with American UL safe attestation request, you can trust an usage please. Structure sketch plan and main parts name of that product

1.FREEZER

BIN

2.REFRIGERATOR 4.FREEZER

BIN

3.CAN DISPENSER 5.FREEZER TEMPERATURE CONTROL KNOB 7.LAMP COVER COVER

SHELF

6.REFRIGERATOR TEMPERATURE CONTROL KNOB 8.REFRIGERATOR 10.CRISPER SHELF

9.CRISPER

11.LEVELING LEGS

The chapter 2 colding system

Colding system principle diagram

Explain:

refrigerant

processing left condenser connect pipe

Compress

Suction pipe

right condenser

Evaporator

connect pipe

Capillary pipe

filter

anti-coagulate pipe

Two, function parameter form

Technology parameter BCD-280W

Electric shock classification of I protection aganist Total capacity(L) 280

Effective cubage refrigoratorL 72 (L) VoltageV FrequencyHz Total input powerW Defrost powerW Electricity consumption KW.h/24h Refrigerant and inject amount weightKg R134a /103g 64 Freezen L 208 115 60 130 200 1.05

Figure dimensionwidthdepth 6006701545 height mmmmmm

Three, break down analysis: refrigerate room isnt cool or is cool not better Break down analysis: 1)the fan is bad or there is the stopper and its rotate speed is much low(it is much more possibility in after two kind.) 2)Refrigerator air road is not free so that breeze is much little or not. 3)Frost on the evaporate is thick ,or the ice is much more(see a behind reason analysis)so that refrigerator room is not cold or cold much better. 4)Refrigerant lacks or leaks 5)The compressor doesn't operate or is bad(see a behind reason analysis). 6) The door is not closed completely or the door gasket does not seal properly. 7)Too much food is stored so that cool air dosent flow much better. The frozen room room isnt cool or is cool not better Break down analysis: 1) the fan is bad or there is the stopper and its rotate speed is

much low(it is much more possibility in after two kind.) 2) Refrigerant lacks or leaks 3) Frost on the evaporate is thick ,or the ice is much more(see a behind reason analysis)so that refrigerator room is not cold or cold much better. 4) The compressor doesn't operate or is bad(see a behind reason analysis). 5) Too much food is stored so that cool air dosent flow much better. Frost on the evaporate thick or the ice much more Break down analysis: Frost on the evaporate thick 1) The door gasket does not seal properly so that the compressor doesn't shut down 2) Door is opened too frequently and much water in the foods is placed refrigerator. 3)The defrost timer doesnt operate properly. 4)The temperature fuse doesnt operate properly. 5)The electrical connection doesnt operate properly. The ice block up: There is much water in the system.There need replace a new filter The compressor doesn't shut down

Break down analysis: 1) The door is not closed completely or the door gasket does not seal properly. 2) The electrical connection doesnt operate properly. 3) The temperature fuse doesnt operate properly. 4) the fan is bad or there is the stopper and its rotate speed is much low The compressor doesn't start Break down analysis: 1) The electrical connection doesnt operate properly. 2) The starter is bad. 3) The temperature fuse is bad Noise abnormality Break down analysis: In the normal circumstance, compressor is operating and fan blade is operating,which cause noises. But sometimes noises isnt normal ,reason is: Check if the compressor is installed properly? Check if interference happens which the fan blade with surroundings the structure

Control system 1. Electricity principle diagram

2.Defrost work principle It is time to begin from last defrost period,defrost timer port 3 and 4 are connected, the compressor begins to operate, between the compressor is operated ,the same time the motor of the defrost timer is operated,when it 16 hours that is the time of the compressor s operated ,under the drive of defrost timer motor defrost timer port 3 and 2 are connected ,the compressor is stopped and auto-defrost is processed. After getting in to auto-defrost, because the temperature of the evaporator surface is low, over-temerature control of heater is connected and defrost timer motor is stopped, defrost heater is operated.When the temperature of cool evaporator is rised to about 8 , over-temerature control of heater isnt

connected and defrost timer is stopped. The defrost timer motor is processed after about 7 minutes under the drive of defrost timer motor defrost timer port 3 and 2 are connected

again,and it is time to end of defrost period, and the compressor is operated.Such as goes round and round. 3. Electric appliances part of easy troubled detailed statement 3. Parts easy to damage

NO 1 2 3

NAME lamp defrost heater over-temerature control of heater

4 5 6 7 8

thermal cutoff fan motor defrost timer thermostat compressor

4.wiring diagram

Product Explosive View

BOM

Model: MCBR1010GS/S/W

Page 1

Model: MCBR1010GS/S/W

Page 2

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5783)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Tech ME007 PDFDokumen12 halamanTech ME007 PDFfredniels100% (2)

- Ibraheem Gaffar 124002 PDFDokumen65 halamanIbraheem Gaffar 124002 PDFSriram ramsBelum ada peringkat

- Samsung LN (32,40,46) A550p3r Chassis N43a SMDokumen152 halamanSamsung LN (32,40,46) A550p3r Chassis N43a SMAnthony GonzalesBelum ada peringkat

- PLC Programming and Control ManualDokumen59 halamanPLC Programming and Control Manualyourwish1992Belum ada peringkat

- Advantages of Automatic Switching System Over The Manual ExchangesDokumen9 halamanAdvantages of Automatic Switching System Over The Manual ExchangesWodari HelenaBelum ada peringkat

- Simotics HV TN H Compact Catalog d84 1 2019 enDokumen128 halamanSimotics HV TN H Compact Catalog d84 1 2019 enSergio MolinaBelum ada peringkat

- ZXSDR R8862A Product DescriptionDokumen26 halamanZXSDR R8862A Product DescriptionPissu PusaBelum ada peringkat

- To Study, Analyse and Implement MPPT PandO Based Photovoltaic PV System Using PID ControllerDokumen4 halamanTo Study, Analyse and Implement MPPT PandO Based Photovoltaic PV System Using PID ControllerEditor IJTSRDBelum ada peringkat

- Whirlpool Aws 63013Dokumen33 halamanWhirlpool Aws 63013criksuu_795296388Belum ada peringkat

- KN61000 4 2정전기방전내성시험방법Dokumen36 halamanKN61000 4 2정전기방전내성시험방법조성철Belum ada peringkat

- FPD 1361 Ea4Dokumen12 halamanFPD 1361 Ea4Moe LattBelum ada peringkat

- MA8692 Supplement EU MLDokumen4 halamanMA8692 Supplement EU MLMaxsilva85Belum ada peringkat

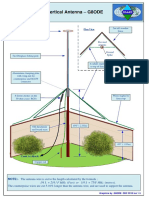

- 20m Elevated Vertical Antenna DesignDokumen5 halaman20m Elevated Vertical Antenna Designleonardo_manzanoBelum ada peringkat

- Sinusoidal Response of Series Circuits - GATE Study Material in PDFDokumen11 halamanSinusoidal Response of Series Circuits - GATE Study Material in PDFSupriya Santre100% (1)

- Skin Effect Is The Tendency of AnDokumen3 halamanSkin Effect Is The Tendency of AnDr-Ali AlbakryBelum ada peringkat

- TeledexDokumen2 halamanTeledexsatriaBelum ada peringkat

- Intellivision A/V Mod Installation Guide: Important Note!Dokumen8 halamanIntellivision A/V Mod Installation Guide: Important Note!Alex FratelliBelum ada peringkat

- Counting SensorDokumen2 halamanCounting Sensorzheng zhengBelum ada peringkat

- Diagnostic Methods of Oil Immersed TransformersDokumen13 halamanDiagnostic Methods of Oil Immersed Transformerskrmurali2000100% (1)

- Causes and Effects of Single-Phasing Induction MotorsDokumen8 halamanCauses and Effects of Single-Phasing Induction MotorsvenugopalBelum ada peringkat

- Electronics Projects Petrol Bunk Automation With Prepaid Cards and GSM CommunicationDokumen5 halamanElectronics Projects Petrol Bunk Automation With Prepaid Cards and GSM CommunicationannzeraBelum ada peringkat

- AN296097 Hall Effect System With Two Linear Sensor ICsDokumen8 halamanAN296097 Hall Effect System With Two Linear Sensor ICsAryan MahajanBelum ada peringkat

- Rectangular To Circular Waveguide TransitionsDokumen2 halamanRectangular To Circular Waveguide TransitionsAntonio P. Souza JuniorBelum ada peringkat

- Port Splitters: Installation InstructionsDokumen24 halamanPort Splitters: Installation InstructionsJosep Alexander Gutierrez ReyesBelum ada peringkat

- MICROCONTROLLER NOTES Unit 6Dokumen13 halamanMICROCONTROLLER NOTES Unit 6SOMESH B SBelum ada peringkat

- SSP 664 Audi A8 Type 4N Electrics and Electronics PDFDokumen112 halamanSSP 664 Audi A8 Type 4N Electrics and Electronics PDFbanelab100% (2)

- LTE Principle and LTE PlanningDokumen70 halamanLTE Principle and LTE PlanningShain SalimBelum ada peringkat

- Introduction To Power System ProtectionDokumen33 halamanIntroduction To Power System ProtectionputrasejahtraBelum ada peringkat

- Technical Instruction F-50L Compressor Unit - SM - CD32ZZ-227 - TDokumen38 halamanTechnical Instruction F-50L Compressor Unit - SM - CD32ZZ-227 - Teyad.marji1990Belum ada peringkat

- Understanding Video RAM Memory BandwidthDokumen1 halamanUnderstanding Video RAM Memory BandwidthHarish MahadevanBelum ada peringkat