3 Zone Furnace Controller

Diunggah oleh

Souvik GhoshDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

3 Zone Furnace Controller

Diunggah oleh

Souvik GhoshHak Cipta:

Format Tersedia

MEMS Sensors and Actuators Lab (MSAL)

7/2001

Standard Operating Procedure for 1200 C Box Furnace Model: BF51732BC, Manufacturer: Lindberg/Blue M

I. Safety and Precautions

1. Do not unplug the furnace. 2. Do not move the furnace. 3. Use both door handles to open and close the door vertically. 4. Do not touch the insulator on the inside chamber walls. 5. Never inhale the particles of the insulator. 6. Get MSAL Supervisor approval before putting any new material in the furnace. 7. Use a sample boat or rack compatible with your process temperature. 8. Do not touch the furnace walls when operating at high temperature. 9. Use a crucible tong to handle the sample boat or rack when the furnace is hot. 10. Turn off the furnace completely when not in use. 11. Do not change settings of the controllers other than those referred to in this SOP. For other settings inform MSAL Supervisor. 12. Close the nitrogen cylinder valve and flowmeter knob when not in use. 13. Never exceed the maximum flow of the flowmeter (13 slpm).

II. Turning on the Furnace and Running and Stopping a Stored Program

1. Turn on the furnace by means of the MAIN POWER SWITCH (located at the bottom right corner of the front panel). After a few seconds, the PV displays (red, upper displays) on both controllers show the inside chamber temperature, the SP display (green, lower display) on UP150 controller shows the initial set point of the stored program, and the SP display on UT150L controller shows the set point of the limit control. All other lamps must be off. 2. If the OUT lamp on UT150L controller is on, press and hold RESET key on UT150L controller for at least one second to turn off the OUT lamp. 3. To run a stored program, press and hold RUN key on UP150 controller for at least one second. POWER lamp (located left to MAIN POWER SWITCH) and RUN lamp turn on and the controller starts the program. 4. To stop a running program press and hold RESET key for at least one second.

III. Operating the Furnace under Nitrogen Flow

1. Make sure that the flowmeter knob is completely closed and the flowmeter floater is at rest position. 2. Open the nitrogen cylinder valve. 3. Using the flowmeter knob, adjust the floater to the desired flow.

III. Programming UP150 Controller (Program Controller)

1. Press and hold SET/ENT key for at least 3 seconds to enter the operating parameters setting mode. PRG appears on PV display and 0 on SP display. 2. Change SP display to 1 by pressing DOWN key once. The decimal point flashes. 3. Press SET/ENT key to confirm the change. 4. Press SET/ENT key once and to enter the program parameters setting mode. EV1 appears on PV display and 0 on SP display. 5. Press SET/ENT key once. AL1 appears on PV display and 9 on SP display. 6. If SP display shows a value other than 9, change it to 9 using UP/DOWN keys. When the decimal point flashes, press SET/ENT key once to confirm the change. 7. Press SET/ENT key once. A1 appears on PV display. 8. Set the SP display to alarm temperature of your process (typically 10 C higher than the highest temperature) using UP/DOWN keys. (AL1 lamp turns on when this temperature is reached.) When the decimal point flashes, press SET/ENT key once to confirm the change. 9. Press SET/ENT key several times until SSP appears on PV display. 10. Set SP display to the initial temperature set point of your process in C (typically 25 C) using UP/DOWN keys (minimum=0, maximum=1200 C). When the decimal point flashes, press SET/ENT key once to confirm the change. 11. Press SET/ENT key once. SP1 appears on PV display. 12. Set SP display to the temperature set point of the first segment of your process in C using UP/DOWN keys (minimum=0, maximum=1200 C). When the decimal point flashes, press SET/ENT key once to confirm the change. 13. Press SET/ENT key once. tM1 appears on PV display. 14. Set SP display to the time duration of the first segment of your process in hours and minutes using UP/DOWN keys (minimum=0.00, maximum=99.59 hours and minutes). When the decimal point flashes, press SET/ENT key once to confirm the change. 15. If more than one segment is needed, SP2 SP16 and tM2 tM16 can be set like steps 11 through 14. 16. If tM(n) is time duration of the last segment of your process, set tM(n+1) to oFF using UP/DOWN keys. When the decimal point flashes, press SET/ENT key once to confirm the change. 17. Press SET/ENT key once or several times until JC appears on PV display. 18. Set SP display using UP/DOWN keys to 0 for reset mode (controller shuts off its outputs at the end of the program), 1 for the hold mode (controller holds the temperature at the end of the program), and 2 for repeat mode (controller repeats the program continuously). When the decimal point flashes, press SET/ENT key once to confirm the change. 19. Press SET/ENT key once. WtZ appears on PV display. 20. Set SP display to the desired wait zone value of your process in C using UP/DOWN keys. When the decimal point flashes, press SET/ENT key once to confirm the change. (A wait zone causes the controller to stop the program clock if, at the transition from a ramp segment to a soak segment, the actual chamber temperature, PV, is not close enough to the set point. The program will continue when PV falls within the specified wait zone.) 21. Press and hold SET/ENT key for at least 3 seconds to exit the program parameters setting mode. The program is ready to run. 22. To optimize the operation of the controller, PID coefficients can be set. 22.1. Press and hold SET/ENT key for at least 3 seconds to enter the operating parameters setting mode. PRG appears on PV display and 0 on SP display. 22.2. Press SET/ENT key several times until p appears on PV display. 22.3. Change the SP display using the UP/DOWN keys according to the optimized PID coefficients table for proportional coefficient. (The table gives the PID coefficients for several temperatures. Choose a temperature closest to the highest temperature of your process.) When the decimal point flashes, press SET/ENT key once to confirm the change. 22.4. Press SET/ENT key once. I appears on PV display.

Page 1 of 2

MEMS Sensors and Actuators Lab (MSAL)

7/2001

22.5. Change the SP display using the UP/DOWN keys according to the optimized PID coefficients table for integral coefficient. When the decimal point flashes, press SET/ENT key once to confirm the change. 22.6. Press SET/ENT key once. d appears on PV display. 22.7. Change the SP display using the UP/DOWN keys according to the optimized PID coefficients table for derivative coefficient. When the decimal point flashes, press SET/ENT key once to confirm the change. 22.8. Press and hold SET/ENT key for at least 3 seconds to exit the program parameters setting mode. The program is ready to run.

IV. Programming UT150L Controller (Limit Controller)

1. Press and hold SET/ENT key for at least 3 seconds to enter the operating parameter setting mode. SP appears on PV display. 2. Change the SP display to the desired limit temperature of your process using UP/DOWN keys. (The controller shuts off the heater, EXCEEDED and OUT lamps turn on when this limit temperature is reached.) When the decimal point flashes, press SET/ENT key once to confirm the change. 3. Press SET/ENT key once. A1 appears on PV display. 4. Change the SP display to the desired alarm temperature of your process using UP/DOWN keys. (AL1 lamp turns on when this temperature is reached.) When the decimal point flashes, press SET/ENT key once to confirm the change. 5. Press SET/ENT key once. HyS appears on PV display. 6. Change the SP display to the desired hysteresis for the alarm temperature of your process using UP/DOWN keys. (EXCEEDED lamp turns off when the temperature reaches below the limit temperature by the amount of hysteresis.) When the decimal point flashes, press SET/ENT key once to confirm the change. 7. Press and hold SET/ENT key for at least 3 seconds to exit the operating parameters setting mode.

V. Monitoring the Program Status During Operation and Using Hold/Advance Functions on UP150 controller

1. When running a program, PV display always shows the chamber temperature, but SP display initially shows the target set point at the moment. The status of the running program can be monitored. 1.1. Press SET/ENT key once to see the current segment number on SP display. SEG lamp turns on in this state. 1.2. Press SET/ENT key again to see the remaining segment time on SP display. SEG lamp turns on in this state. 1.3. Press SET/ENT key again to return to he initial SP display. 2. A running program can be hold at any moment. 2.1. Press and hold SET/ENT key for at least 3 seconds. HoLd appears on PV display and oFF on SP display. 2.2. Change the SP display to on using UP/DOWN keys. When the decimal point flashes, press SET/ENT key once to confirm the change. 2.3. Press and hold SET/ENT key for at least 3 seconds to return to normal display. HLD lamp turns on. 3. To exit the hold mode: 3.1. Press and hold SET/ENT key for at least 3 seconds. HoLd appears on PV display and on on SP display. 3.2. Change the SP display to oFF using UP/DOWN keys. When the decimal point flashes, press SET/ENT key once to confirm the change. 3.3. Press and hold SET/ENT key for at least 3 seconds to return to normal display. HLD lamp turns off. 4. A running program can be advanced to the next segment at any moment. 4.1. Press and hold SET/ENT key for at least 3 seconds. HoLd appears on PV display and oFF on SP display. 4.2. Press SET/ENT key once. AdV appears on PV display and oFF on SP display. 4.2. Change the SP display to on using UP/DOWN keys. When the decimal point flashes, press SET/ENT key once to confirm the change. 4.3. Press and hold SET/ENT key for at least 3 seconds to return to initial normal display.

V. Monitoring the Limit Temperature Status During Operation on UT150L controller

1. When running a program, PV display always shows the chamber temperature, but SP display initially shows the limit temperature set point. 2. Press SET/ENT key once. PV display goes blank and SP display shows the limit temperature set point. 3. Press SET/ENT key again. tIm appears on PV display and duration time of PV maximum value appears on SP display. 4. Press SET/ENT key again. HI appears on PV display and PV maximum value appears on SP display. 5. Press SET/ENT key again to return to the initial normal display.

PV display (red) SP display (green) SEG lamp (green) AL1 lamp (red) RUN lamp (orange) HLD lamp (green) UP key (RESET key) DOWN key (RUN key) SET/ENT key

UP150 Controller Front Panel Process Value (chamber temperature), character information (parameter and error codes) Target set point, parameter values Lit when segment number or remaining segment time are displayed Lit when PV exceeds alarm temperature Lit when the operation mode is in RUN, flashed when the operation mode is in WAIT Lit when operation mode is in HOLD mode Increases a parameter value, stops a running program Decreases a parameter value, starts a program Switches the operation display, confirms data change, switches the parameters, changes controller mode

PV display (red) SP display (green) EXCEEDED lamp (green) AL1 lamp (red) OUT lamp (yellow) UP key (RESET key) DOWN key SET/ENT key

UT150L Controller Front Panel Process Value (chamber temperature), character information (parameter and error codes) Limit temperature set point, parameter values Lit while PV exceeds SP value Lit when PV exceeds alarm temperature Lit when PV exceeds SP value, goes out when confirming with RESET key Increases parameter value, puts out OUT lamp, resets PV maximum value and duration time Decreases parameter value Switches the operation display, confirms data change, switches the parameters, changes controller mode

Page 2 of 2

Anda mungkin juga menyukai

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Suzuki G13ba EnginDokumen4 halamanSuzuki G13ba EnginYoga A. Wicaksono0% (1)

- Incredible IndiaDokumen13 halamanIncredible IndiaShradha DiwanBelum ada peringkat

- Dungeon Siege Game GuideDokumen21 halamanDungeon Siege Game GuideJesse StillBelum ada peringkat

- University of Colombo Faculty of Graduate Studies: PGDBM 504 - Strategic ManagementDokumen15 halamanUniversity of Colombo Faculty of Graduate Studies: PGDBM 504 - Strategic ManagementPrasanga WdzBelum ada peringkat

- Key Responsibility AreaDokumen8 halamanKey Responsibility AreaNitin SharmaBelum ada peringkat

- Manual de Serviço PDFDokumen394 halamanManual de Serviço PDFMarcos Antonio de Souza JuniorBelum ada peringkat

- Simatic Wincc: Answers For IndustryDokumen8 halamanSimatic Wincc: Answers For IndustryAlina MirelaBelum ada peringkat

- Workshop Manual Group 21-26 - 7745282 PDFDokumen228 halamanWorkshop Manual Group 21-26 - 7745282 PDFabdelhadi houssinBelum ada peringkat

- Architectural, Museology, Urban DesignDokumen201 halamanArchitectural, Museology, Urban DesignAbby VernonBelum ada peringkat

- Eseu EnglezaDokumen1 halamanEseu EnglezaAndreea IoanaBelum ada peringkat

- Despiece Completo ThwaittesDokumen60 halamanDespiece Completo ThwaittesJuan Antonio Cano Diaz100% (1)

- Is500 PDFDokumen298 halamanIs500 PDFShekhar Srivass50% (4)

- Operation & Service Manual: Murzan IncDokumen38 halamanOperation & Service Manual: Murzan IncgokulBelum ada peringkat

- David T History Rev 26032019Dokumen18 halamanDavid T History Rev 26032019David TaleroBelum ada peringkat

- Statement of Purpose China PDFDokumen2 halamanStatement of Purpose China PDFShannon RutanBelum ada peringkat

- Honeywell Mmi 813.1 Mod 23Dokumen5 halamanHoneywell Mmi 813.1 Mod 23nestor_moBelum ada peringkat

- S7-1200 DataSheetDokumen14 halamanS7-1200 DataSheetperuhayaBelum ada peringkat

- DatasheetDokumen4 halamanDatasheetJs CameloBelum ada peringkat

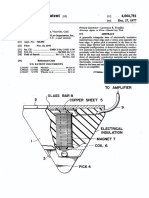

- U.S. Patent 4,064,781, Guitar Pick, Issued 1977.Dokumen3 halamanU.S. Patent 4,064,781, Guitar Pick, Issued 1977.Anonymous a7S1qyXBelum ada peringkat

- Buying Solutions' Total Cost of Ownership (TCO) CalculatorDokumen93 halamanBuying Solutions' Total Cost of Ownership (TCO) Calculatorankitch123Belum ada peringkat

- 2.1 LPC2103 Microcontroller: 2.1.1 FeaturesDokumen18 halaman2.1 LPC2103 Microcontroller: 2.1.1 FeaturesBhaskar Rao PBelum ada peringkat

- Template Extended-AbstractDokumen3 halamanTemplate Extended-AbstractGraita PurwitasariBelum ada peringkat

- All C PG and CPP Service ManualDokumen60 halamanAll C PG and CPP Service Manualhurantia100% (1)

- MailDokumen2 halamanMailSurya Ganesh SaitanaBelum ada peringkat

- Bobcat 3 Phase: Quick SpecsDokumen4 halamanBobcat 3 Phase: Quick SpecsAnonymous SDeSP1Belum ada peringkat

- Boeing Defence Australia LimitedDokumen16 halamanBoeing Defence Australia LimitedMitchBelum ada peringkat

- Denr Administrative Order (Dao) 2013-22: (Chapters 6 & 8)Dokumen24 halamanDenr Administrative Order (Dao) 2013-22: (Chapters 6 & 8)Karen Feyt Mallari100% (1)

- ASW Connection PDFDokumen7 halamanASW Connection PDFWawan SatiawanBelum ada peringkat

- R Values For Z PurlinsDokumen71 halamanR Values For Z PurlinsJohn TreffBelum ada peringkat