IMO Resolution 1053 (27) - IOPP - R

Diunggah oleh

hlekakisDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

IMO Resolution 1053 (27) - IOPP - R

Diunggah oleh

hlekakisHak Cipta:

Format Tersedia

A/27/Res.1053 Page 127 (OIn) 1.3.

5 For the oil pollution prevention the completion of the intermediate survey should consist of: after a satisfactory survey, endorsing the International Oil Pollution Prevention Certificate; if a survey shows that the condition of a ship or its equipment is unsatisfactory; see part "General", section 4.8. Renewal surveys see part "General" section 4.5 For oil pollution prevention the examination of current certificates and other records should consist of: the provisions of (OA) 1.2.1, except for the validity of the International Oil Pollution Prevention Certificate; verifying that, if applicable, the 15ppm bilge alarm has been calibrated by the manufacturer or a person authorized by the manufacturer and that a valid calibration certificate is available on board18. For oil pollution prevention the examination of current certificates and other records for tankers should additionally consist of: the provisions of (OA) 1.2.2; verifying that, if applicable, the oil discharge monitoring equipment has been calibrated and that a valid calibration certificate is available on board19. For oil pollution prevention the renewal survey should consist of: the provisions of (OIn) 1.3.3; confirming, if necessary by simulated test or equivalent, the satisfactory operation of the oily-water separating equipment or oil filtering equipment (MARPOL 90/04 Annex I reg.14); confirming, if necessary by simulated test or equivalent, the satisfactory operation of the oil discharge monitoring and control system, including where practicable the automatic and manual operation of the means provided to stop the discharge of effluent (MARPOL 90/04 Annex I reg.31); confirming the satisfactory operation of the alarm for the oil filtering system (MARPOL 90/04 Annex I reg.14); confirming the satisfactory operation of homogenizers, sludge incinerators or other recognized means for the control of sludge when the size of oil residue (sludge) tank is approved on the basis of such installations (MARPOL 90/04 Annex I reg.12).

(OIn) 1.3.5.1 (OIn) 1.3.5.2

(OR) (OR)

1.4 1.4.1

(OR)

1.4.1.1

(OR)

1.4.1.2

(OR)

1.4.2

(OR) (OR)

1.4.2.1 1.4.2.2

(OR) (OR) (OR)

1.4.3 1.4.3.1 1.4.3.2

(OR)

1.4.3.3

(OR)

1.4.3.4

(OR)

1.4.3.5

18 19

For installations complying with resolution MEPC.107(49). For installations complying with resolution MEPC.108(49).

I:\ASSEMBLY\27\RES\1053.doc

A 27/Res.1053 Page 128 (OR) 1.4.4 For oil pollution prevention the renewal survey of the additional requirements for oil tankers should consist of: the provisions of (OIn) 1.3.4; confirming that the arrangements of slop tanks or cargo tanks designated as slop tanks and associated piping systems are satisfactory (MARPOL 90/04 Annex I regs.29 and 34); confirming, if necessary by simulated test or equivalent, the satisfactory operation of the oil discharge monitoring and control system and its associated equipment, including the oil/water interface detectors (MARPOL 90/04 Annex I regs.31 and 32); confirming that the arrangements of pumps, pipes and valves are in accordance with the requirements for SBT systems (MARPOL 90/04 Annex I reg.18); confirming that the arrangements of pumps, pipes and valves are in accordance with the Revised Specifications for Oil Tankers with Dedicated Clean Ballast Tanks (MARPOL 90/04 Annex I reg.18); confirming that the crude oil washing system is in accordance with the requirements for such systems (MARPOL 90/04 Annex I reg.33) and, in particular: carrying out pressure testing of the crude oil washing system to at least the working pressure; examining the cargo tanks for the express purpose of verifying the continued effectiveness of the installed crude oil washing and stripping systems; examining internally, when fitted, the isolation valves for any steam heaters; verifying, by internal tank inspection or by another alternative method acceptable to the Administration, the effectiveness of the crude oil washing system. If the tank cannot be gas-freed for the safe entry of the surveyor, an internal inspection should not be conducted. An acceptable alternative would be satisfactory results during the surveys required by (OA) 1.2.4.9 (MARPOL 90/04 Annex I reg.33); confirming that there is no leakage from those ballast pipelines passing through cargo tanks and those cargo pipelines passing through ballast tanks (MARPOL 90/04 Annex I regs.18 and 33); confirming that the pumping, piping and discharge arrangements are satisfactory (MARPOL 90/04 Annex I reg.30) and, in particular: confirming that the piping systems associated with the discharge of dirty ballast water or oil contaminated water are satisfactory;

(OR) (OR)

1.4.4.1 1.4.4.2

(OR)

1.4.4.3

(OR)

1.4.4.4

(OR)

1.4.4.5

(OR)

1.4.4.6

(OR)

1.4.4.6.1

(OR)

1.4.4.6.2

(OR)

1.4.4.6.3

(OR)

1.4.4.7

(OR)

1.4.4.8

(OR) (OR)

1.4.4.9 1.4.4.9.1

I:\ASSEMBLY\27\RES\1053.doc

A/27/Res.1053 Page 129 (OR) 1.4.4.9.2 confirming that the means of draining cargo pumps and cargo lines, including the stripping device and the connections for pumping to the slop or cargo tanks or ashore are satisfactory; confirming that the arrangements for the part flow system, where fitted, are satisfactory; confirming that closing devices installed in the cargo transfer system and cargo piping as appropriate are satisfactory (MARPOL 90/04 Annex I regs.23 and 26); confirming, as appropriate and as practicable, that the arrangements for the prevention of oil pollution in the event of collision or stranding are satisfactory (MARPOL 73/78/90 Annex I regs.19 to 22); confirming for oil tankers of 5,000 tonnes deadweight and above that arrangements are in place to provide prompt access to shore based damage stability and residual structural strength computerized calculation programs (MARPOL 90/04 Annex I reg.37.4). For oil pollution prevention the completion of the renewal survey should consist of: after a satisfactory survey, issuing the International Oil Pollution Prevention Certificate. GUIDELINES FOR SURVEYS FOR THE INTERNATIONAL POLLUTION PREVENTION CERTIFICATE FOR THE CARRIAGE OF NOXIOUS LIQUID SUBSTANCES IN BULK Initial surveys see part General section 4.1 For the carriage of noxious liquid substances in bulk the examination of plans and designs (as applicable to the cargoes the ship is to be certified to carry) should consist of: drawing up the list of noxious liquid substances it is proposed the ship will be certified to carry (MARPOL 90/04 Annex II reg.6); examining the pumping system (MARPOL 90/04 Annex II reg.12); examining the stripping system (MARPOL 90/04 Annex II reg.12); examining the tank washing system and equipment (MARPOL 90/04 Annex II reg.14 and App.4); examining the underwater discharge arrangements (MARPOL 90/04 Annex II reg.12); examining the ventilation equipment for (MARPOL 90/04 Annex II reg.13 and App.7); residue removal

(OR)

1.4.4.9.3

(OR)

1.4.4.10

(OR)

1.4.4.11

(OR)

1.4.4.12

(OR)

1.4.5

(OR)

1.4.5.1

(N)

(NI) (NI)

2.1 2.1.1

(NI)

2.1.1.1

(NI) (NI) (NI)

2.1.1.2 2.1.1.3 2.1.1.4

(NI)

2.1.1.5

(NI)

2.1.1.6

(NI)

2.1.1.7

examining the heating system for solidifying and high viscosity substances (MARPOL 90/04 Annex II reg.14 and App.4);

I:\ASSEMBLY\27\RES\1053.doc

Anda mungkin juga menyukai

- Marine and Offshore Pumping and Piping SystemsDari EverandMarine and Offshore Pumping and Piping SystemsPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Checklist For The Renewal Survey of Iopp Certificate PDFDokumen8 halamanChecklist For The Renewal Survey of Iopp Certificate PDFAnita GangzBelum ada peringkat

- Checklist For The Renewal Survey of Iopp CertificateDokumen8 halamanChecklist For The Renewal Survey of Iopp CertificateMohd ShajiBelum ada peringkat

- Annex 14 RESOLUTION MEPC.108 (49) Adopted On 18 July 2003Dokumen41 halamanAnnex 14 RESOLUTION MEPC.108 (49) Adopted On 18 July 2003Reet DeolBelum ada peringkat

- ODMEDokumen42 halamanODMEThirawat Thitisitthikorn100% (2)

- A.496 (12) - Guidelines and Specifications For Oil Discharge Monitoring and Control Systems For Oil TankersDokumen13 halamanA.496 (12) - Guidelines and Specifications For Oil Discharge Monitoring and Control Systems For Oil Tankersimgesu tahtaBelum ada peringkat

- Report On The Surveys Concerning International Oil Pollution Prevention CertificateDokumen3 halamanReport On The Surveys Concerning International Oil Pollution Prevention CertificateSUNILBelum ada peringkat

- 4704 Part 6 Rev8Dokumen3 halaman4704 Part 6 Rev8Tammam HassanBelum ada peringkat

- Mepc 321Dokumen13 halamanMepc 321Fragkiskos ZouridakisBelum ada peringkat

- 4704 Part 7 (Rev.7)Dokumen6 halaman4704 Part 7 (Rev.7)Jagjit SinghBelum ada peringkat

- P01 2017 OilPolPrev FormDokumen4 halamanP01 2017 OilPolPrev FormMade PutraBelum ada peringkat

- Annex 14 RESOLUTION MEPC.108 (49) Adopted On 18 July 2003Dokumen41 halamanAnnex 14 RESOLUTION MEPC.108 (49) Adopted On 18 July 2003Amit PandeyBelum ada peringkat

- DNVPS Fuel Testing Procedures Part 2Dokumen18 halamanDNVPS Fuel Testing Procedures Part 2KaiBelum ada peringkat

- Crude Oil Washing (Cow)Dokumen60 halamanCrude Oil Washing (Cow)Prashanth Arumugam100% (2)

- Viking Marpoil ODMEDokumen93 halamanViking Marpoil ODMEajshsu56820% (1)

- IOPP FORM B - Vessel Preparation ChecklistDokumen4 halamanIOPP FORM B - Vessel Preparation ChecklistvagGS1150Belum ada peringkat

- Oil Record Book TrainingDokumen102 halamanOil Record Book Trainingyjbsfz5ny6100% (1)

- 4704 Part 7 Rev9Dokumen6 halaman4704 Part 7 Rev9Tammam HassanBelum ada peringkat

- Open Loop-3-5Dokumen3 halamanOpen Loop-3-5galin8575Belum ada peringkat

- F10marine Inert Gas SystemDokumen16 halamanF10marine Inert Gas SystemNitish KumarBelum ada peringkat

- Regulation 17 - Oil Record Book, Part I (Machinery Space Operations)Dokumen2 halamanRegulation 17 - Oil Record Book, Part I (Machinery Space Operations)Prizam 2021Belum ada peringkat

- Mepc 181Dokumen9 halamanMepc 181Gabriel Elano CostaBelum ada peringkat

- Group 4 LODokumen8 halamanGroup 4 LOKaruro SanBelum ada peringkat

- Cow PDFDokumen34 halamanCow PDFarunrai78Belum ada peringkat

- Uts II Msi 2016310008 Suciyanti Ikhlasul PratiwiDokumen28 halamanUts II Msi 2016310008 Suciyanti Ikhlasul Pratiwisuci yantiBelum ada peringkat

- Jan 2012 To Aug 2014 Ques and Ans SafetyDokumen224 halamanJan 2012 To Aug 2014 Ques and Ans SafetyAnonymous E33XbE100% (2)

- Differnce Between 107 (49) & 60Dokumen4 halamanDiffernce Between 107 (49) & 60MannMannBelum ada peringkat

- Week 7 Mandatory Regulations Annex 1Dokumen39 halamanWeek 7 Mandatory Regulations Annex 1Justin CaliguiaBelum ada peringkat

- ODME RequirementDokumen2 halamanODME Requirementssabih75Belum ada peringkat

- 4 Albert Embankment London Se1 7Sr Telephone: 020 7587 3152 Fax: 020 7587 3210Dokumen9 halaman4 Albert Embankment London Se1 7Sr Telephone: 020 7587 3152 Fax: 020 7587 3210Amir SoleimanyBelum ada peringkat

- Regulation 12:-Ozone Depleting Substances (ODS) : A. Verify VOC Return System Certification and BDokumen47 halamanRegulation 12:-Ozone Depleting Substances (ODS) : A. Verify VOC Return System Certification and BParesh Redkar100% (1)

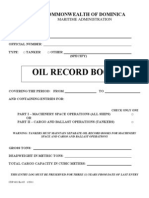

- Oil Record Book InstructionsDokumen6 halamanOil Record Book InstructionsNamal Fernando100% (1)

- Paris MoU - Annex 10Dokumen3 halamanParis MoU - Annex 10Pavel BelousBelum ada peringkat

- Huatai Insurance Agency Consultant Service LTD Circular PNI2001Dokumen15 halamanHuatai Insurance Agency Consultant Service LTD Circular PNI2001cong binh trang100% (1)

- Shanghai MSA Guidelines On Supervision and Administration of ECA During Interim Period 1Dokumen23 halamanShanghai MSA Guidelines On Supervision and Administration of ECA During Interim Period 1omkarBelum ada peringkat

- ORB Guidelines Ver 20110811Dokumen16 halamanORB Guidelines Ver 20110811Ivan Maltsev100% (2)

- Crude Oil Washing SystemDokumen96 halamanCrude Oil Washing SystemMoBelum ada peringkat

- COE LUISA-Oil Pollution Prevention, Type A Annual-Requirements-SignedDokumen1 halamanCOE LUISA-Oil Pollution Prevention, Type A Annual-Requirements-SignedNavo MareBelum ada peringkat

- Oil Record Book: Commonwealth of DominicaDokumen76 halamanOil Record Book: Commonwealth of DominicaNarendra ChitturiBelum ada peringkat

- A 586Dokumen65 halamanA 586Oscar Sacases PlanasBelum ada peringkat

- Petroleum Safety Measures Transportation of Petroleum by Pipelines Regulation 1985Dokumen7 halamanPetroleum Safety Measures Transportation of Petroleum by Pipelines Regulation 1985Sherry AbeBelum ada peringkat

- Sample VOC PlanDokumen18 halamanSample VOC PlanbharatBelum ada peringkat

- Surveys & CertificationDokumen15 halamanSurveys & CertificationNisha100% (1)

- Standard Rules For PVR Stage IIDokumen4 halamanStandard Rules For PVR Stage IIRafael Ubillus GuzmanBelum ada peringkat

- Marpol Annex I Chapter IDokumen23 halamanMarpol Annex I Chapter Iaika hartiniBelum ada peringkat

- Propac: Flushing Procedure For Hydraulic Piping, Tubing & HoseDokumen4 halamanPropac: Flushing Procedure For Hydraulic Piping, Tubing & HoseClaudio Hernández PobleteBelum ada peringkat

- Resolution MEPC 107Dokumen33 halamanResolution MEPC 107rakis9069Belum ada peringkat

- MSC.1/Circ.1328 11 June 2009Dokumen11 halamanMSC.1/Circ.1328 11 June 2009Viddhesh ManjrekarBelum ada peringkat

- Annnex 1 NoteDokumen12 halamanAnnnex 1 Notealfa89pBelum ada peringkat

- Amsa-228 2023Dokumen36 halamanAmsa-228 2023pattuabinBelum ada peringkat

- Orb Guidelines - LatestDokumen20 halamanOrb Guidelines - Latestsarkarraktim94Belum ada peringkat

- Training Material 126 Company Guidance For Recording Operations in The Oil Record Book PDFDokumen37 halamanTraining Material 126 Company Guidance For Recording Operations in The Oil Record Book PDFkurupath100% (1)

- BunkerDokumen3 halamanBunkerAhmed AL BatalBelum ada peringkat

- Shipping PresentationDokumen43 halamanShipping PresentationDebabrata BandyopadhyayBelum ada peringkat

- Oil Record Book InstructionsDokumen3 halamanOil Record Book InstructionsRutvikBelum ada peringkat

- Mepc 108Dokumen41 halamanMepc 108Dario RomeoBelum ada peringkat

- Interpretations of MarpolDokumen15 halamanInterpretations of Marpolgreatenick.nbBelum ada peringkat

- FAR-AMT 2021: Federal Aviation Regulations for Aviation Maintenance TechniciansDari EverandFAR-AMT 2021: Federal Aviation Regulations for Aviation Maintenance TechniciansPenilaian: 5 dari 5 bintang5/5 (2)

- 1.yes Bank: Human Capital Initiatives of A Startup in The Indian Banking IndustryDokumen10 halaman1.yes Bank: Human Capital Initiatives of A Startup in The Indian Banking IndustryManvi JainBelum ada peringkat

- Ethods For Mitigation of Voltage Fluctuation Effects: Publication No Cu0208 Issue Date: November 2014Dokumen5 halamanEthods For Mitigation of Voltage Fluctuation Effects: Publication No Cu0208 Issue Date: November 2014Camilo CortesBelum ada peringkat

- History of HypnosisDokumen3 halamanHistory of Hypnosisbutterfly975k100% (1)

- CCNA - Access List QuestionsDokumen3 halamanCCNA - Access List QuestionsBaaska214Belum ada peringkat

- Chopra Scm5 Ch13Dokumen58 halamanChopra Scm5 Ch13Faried Putra SandiantoBelum ada peringkat

- 103096-CG9-20AD IIDokumen30 halaman103096-CG9-20AD IICristian Eduardo Chavez GallardoBelum ada peringkat

- Electrical Design Checklist v1.2Dokumen39 halamanElectrical Design Checklist v1.2huangjlBelum ada peringkat

- VCEguide 300-360Dokumen25 halamanVCEguide 300-360olam batorBelum ada peringkat

- VW Piezometer Input Calculation Sheet V1.1Dokumen5 halamanVW Piezometer Input Calculation Sheet V1.1Gauri 'tika' Kartika100% (1)

- Facility Details On DataCenterDokumen26 halamanFacility Details On DataCenterishtiaqkhurshid470Belum ada peringkat

- Improvements in Offshore Pipeline Cathodic ProtectionDokumen6 halamanImprovements in Offshore Pipeline Cathodic ProtectionEddy Norman Benites DelgadoBelum ada peringkat

- 10 A103 SiteDokumen112 halaman10 A103 SiteGovindaraju HSBelum ada peringkat

- 3600 2 TX All Rounder Rotary Brochure India enDokumen2 halaman3600 2 TX All Rounder Rotary Brochure India ensaravananknpcBelum ada peringkat

- Ga AsDokumen7 halamanGa Aspippo pappiBelum ada peringkat

- Automotive Engg. & TechnologyDokumen15 halamanAutomotive Engg. & TechnologysayuuishotBelum ada peringkat

- CBB Exam Preparation CourseDokumen2 halamanCBB Exam Preparation CourseaadmaadmBelum ada peringkat

- Surveyor C.VDokumen2 halamanSurveyor C.VMasood Shabbir Khan Niazi100% (1)

- Solenoid ValvesDokumen23 halamanSolenoid ValvesmcsecBelum ada peringkat

- SRX5400-SRX5800 Services Gateway DSDokumen12 halamanSRX5400-SRX5800 Services Gateway DSAnonymous rSFHGQIBdFBelum ada peringkat

- 28L059 PDFDokumen9 halaman28L059 PDFone_blanche6175Belum ada peringkat

- Your Profile 16personalitiesDokumen3 halamanYour Profile 16personalitiesapi-583293897Belum ada peringkat

- Xpulse200t Manual de PartesDokumen92 halamanXpulse200t Manual de PartesAthiq Nehman100% (2)

- Value Creation Through Project Risk ManagementDokumen19 halamanValue Creation Through Project Risk ManagementMatt SlowikowskiBelum ada peringkat

- KEDA Quotation of 2 3 4 Inch Mini Gold DredgerDokumen3 halamanKEDA Quotation of 2 3 4 Inch Mini Gold DredgerShane CapstickBelum ada peringkat

- Rigmaster 304 Stainless Steel Fluorescent LuminairesDokumen2 halamanRigmaster 304 Stainless Steel Fluorescent LuminairesErikaGaitanGonzalezBelum ada peringkat

- Aspect Oriented ArchitectureDokumen43 halamanAspect Oriented ArchitectureerzhanbaiBelum ada peringkat

- Hyperloop 170201003657Dokumen29 halamanHyperloop 170201003657RafaelLazoPomaBelum ada peringkat

- Flight Training Instruction: Naval Air Training CommandDokumen174 halamanFlight Training Instruction: Naval Air Training CommandITLHAPN100% (1)

- 9A01304 Fluid MechanicsDokumen4 halaman9A01304 Fluid MechanicssivabharathamurthyBelum ada peringkat

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Dokumen2 halamanIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)AmriteshbhaskarBelum ada peringkat