Historic Scotland Inform Guide - Care and Maintenance of Corrugated Iron

Diunggah oleh

David ConnollyHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Historic Scotland Inform Guide - Care and Maintenance of Corrugated Iron

Diunggah oleh

David ConnollyHak Cipta:

Format Tersedia

Maintenance Issues Corrosion of an experienced professional should be sought

Care and

Corrugated iron buildings are particularly Since all metals corrode, the primary problem in to ensure that this does not place undue stress on Further reading and Useful contacts

susceptible to damage from grass or other dealing with corrugated iron is attempting to slow other components. information Historic Scotland, Longmore House,

Maintenance

build up of soil / garden vegetation growing down the rate of corrosion. Corrosion can lead to Scotland’s Listed Buildings: What Listing Means Salisbury Place, Edinburgh, EH9 1SH

against the sheets and trapping moisture which coating loss, loss of structural strength or integrity, Firms experienced in the repair of traditional to Owners and Occupiers, 0131 668 8600

accelerates corrosion. A sound understanding of and serious corrosion of the iron can lead to the ironwork should be employed, but it should Historic Scotland (2006) Free publication www.historic-scotland.gov.uk

of Corrugated

the building is required. Entirely prefabricated complete loss of the sheets. be appreciated that few will have experience http://historic-scotland.gov.uk/index/

buildings may have a visible manufacturers of working with corrugated iron. Sheet metal publications/pubsforowners.htm Historic Scotland Technical Conservation

workers who are sympathetic to the historic

Iron

nameplate which could lead to a search of archive Since the sheets are not permeable to moisture, Research and Education,

catalogues for referencing. Cleaning gutters and condensation is a problem, and wetting and qualities of the material and posses a knowledge The Scottish Ironwork Foundation Conservation Bureau & Technical Enquiry

general maintenance is particularly required with drying cycles remain the primary cause of decay of how it performs may also be considered. Visit http://www.scottishironwork.org Service, 0131 668 8668

corrugated iron structures as decay can happen – internally and externally. The quality of early hs.conservation.bureau@scotland.gsi.gov.uk

quickly. Groundwater splashing onto walls also galvanising was variable. This often fails, resulting Painting INFORM; Boundary Ironwork – A guide to

accelerates decay. in an oxidised surface (rusted appearance) which Over painting sheets should follow traditional re-instatement Historic Scotland TCRE Resource Centre.

is aesthetically pleasing for many due to its natural practice. It may be possible to identify the INFORM; Iron Gates and Railings 0131 668 8642

Junction details, where ventilators and windows colouration. In many cases the rusted roofs are original paint on existing ironwork and other Historic Scotland, 2005 hs.ResourceCentre@scotland.gsi.gov.uk

etc. have been inserted are problem areas. A seen as an integral part of the rural landscape. local examples might provide an indication of the

good seal is difficult to achieve in the original Rainwater run off over the rusty sheets onto Accelerated corrosion by overlaying sheets and causing original colour. The use of red lead for roofs and Technical Advice Note 29 – Corrugated Iron and Historic Scotland TCRE Publications

construction and associated sealing materials often masonry can be a problem. Where exposed stone capillary action walls was common. This material is still available Other Ferrous Cladding Department

break down and do not perform effectively is marked in this way the staining is virtually and its use does not require statutory consent to Historic Scotland, 2004 0131 668 8638

impossible to remove. Any repairs should follow the philosophy of the use. Green and red colours were fairly commonly

Corrugated iron roofs may also be found to overlie minimum intervention necessary to reduce the applied, as were creams and browns in the Ashurst, J and Ashurst N, 1988, Practical Historic Scotland Investments and

relatively intact thatch, retained for the insulation Coating Failure loss of historic material. Wholesale dismantling twentieth century. Building Conservation; English Heritage Projects Team:

it provides, or an intact traditional cruck frame may be required for full repairs, and the services Technical Handbook. Vol. 4. Metals, Aldershot; 0131 668 8801: Fax - 0131 668 8788

Coating failure is common on galvanised

– both worthy of preservation. Corrugated iron Gower Technical Press hs.grants@scotland.gsi.gov.uk

surfaces. Effective coating requires the use of a

has been the saviour of many vernacular buildings.

mordant wash to provide a chemical etch for the

Historic Scotland Inspectorate:

primer layer, or the use of an etching primer for

Hs.inspectorate@scotland.gsi.gov.uk

galvanised surfaces. Often, neither was used.

Although there are some firms still making

corrugated iron sheets it is important to retain

the original sheets as, in many cases, the matching

profiles and sizes may be no longer available. It is

technically feasible to re-galvanise existing sheets,

and to patch repair them in some cases, although

the thin gauge of metal makes this difficult to

The House 05/08 Produced from sustainable material

achieve.

It is inadvisable to install new sheets directly

on top of existing corroding sheets. This will

trap moisture, and accelerate corrosion of the Principal author: David S Mitchell

Published by Technical Conservation, Research and Education Group, May 2008

new sheet by creating a corrosion cell. Moisture Historic Scotland, Longmore House, Salisbury Place, Edinburgh EH91SH

movement and entrapment by capillary action Tel: 0131 668 8638 Fax: 0131 668 8669

between the sheets is also likely. www.historic-scotland.gov.uk email: hs.conservation.bureau@scotland.gsi.gov.uk

Materials Coatings Construction details and techniques

Corrugated iron was patented in 1828 with A range of coatings was employed to protect Supplied in a range of sizes and profiles corrugated iron was frequently

corrugations made in flat iron sheets by passing corrugated iron from the elements. Oil (usually used for roofing and walling, and to a lesser extent for fencing and other

the thin plates through rollers to provide rigidity linseed) based paints were used extensively in innovative uses.

and additional structural strength. Until the 1920s conjunction with red lead paint, with pitch

corrugated sheets were manufactured by a broad and bitumen to a lesser extent. The galvanising

range of ironworkers in various lengths, usually up process involved the iron sheet being dipped into

to a maximum of ten feet. Sheet thickness varied a bath of molten zinc to form a protective layer

from around 0.5mm to 1.5mm depending on on the metal surface. The zinc coating chemically

the application. Galvanising of the iron with zinc protected the iron from corrosion.

became increasingly common at the end of the

19th century. There were a number of patented ‘rustless

coatings’ developed in the late nineteenth and

Sheet pitch and profiles early twentieth centuries then formed protective

oxide layers on the surface of the metal and

A wide variety of pitches was available, with Portable farm worker shed Galvanised corrugated unclimable fencing.

were often known as the Barff process after the

standard dimensions varying from 25 – 153mm.

inventor.

For domestic purposes, a 76mm (3 inch)

pitch was common. A range of profiles were

manufactured, with firms such as FW Braby

Manufacturers quickly developed other

developing their own branded lines.

Introduction components that allowed them to construct a

building from a frame and corrugated sheet.

With a pedigree of almost two hundred years This included ridging details, ventilators

corrugated iron is a much undervalued material that and windows. The retention of these pieces

was used extensively in traditional construction. is especially important as most cannot be

The material is relatively light, portable and sourced now.

its adaptability means that it was often used to

replace or cover a thatch roof, or construct a large

agricultural or industrial building. This INFORM

provides some historical background, and addresses

the physical properties of the material and its uses. It Specialist fixings were required to suit the

corrugated sheets, including hooks and bolts

also covers the conservation, repair and maintenance

(usually galvanised) with specially shaped In a prefabricated structure the corrugated sheets

of corrugated iron in a variety of situations. washers with which to effect watertight seals – were secured to an internal timber or metal frame.

particularly on varying profiles. Where these This was either left as a finished building if for

The architectural iron industry in Scotland was world leading at remain, they should be carefully saved, cleaned agricultural use, or for domestic needs internally

the end of the 19th century, and corrugated iron was extensively and set aside for reuse. insulated and covered in timber lining or plaster.

used as a construction material. Scottish firms such as Robertson

The sheet corrugations lend themselves well to

and Lister, AJ Main, and William Bain and Co developed their

lap joints, often overlapping by 150mm and by

specialism in the manufacture of iron building components and

1- 2 corrugations where sheets are adjacent. As

entire buildings using corrugated iron.

condensation was a major issue perforated sheets

were also developed.

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Guttering Design For Rainwater HarvestingDokumen22 halamanGuttering Design For Rainwater HarvestingGreen Action Sustainable Technology GroupBelum ada peringkat

- Estimation and Specificatn - ppt.20.2.18Dokumen22 halamanEstimation and Specificatn - ppt.20.2.18aparna baburaj100% (1)

- Repair of Storage ShedDokumen37 halamanRepair of Storage ShedEr Sandip SuryawanshiBelum ada peringkat

- Shristi, Farm StructureDokumen70 halamanShristi, Farm StructureShristi ShefaliBelum ada peringkat

- Garleton Castle: Southwest Lodge, Athelstaneford, East LothianDokumen123 halamanGarleton Castle: Southwest Lodge, Athelstaneford, East LothianDavid Connolly100% (1)

- BAJR Guide 31 Dig SurvivorDokumen10 halamanBAJR Guide 31 Dig SurvivorDavid Connolly100% (3)

- 26: Artefact Photography (BAJR Guide) by Lisa Jayne FisherDokumen14 halaman26: Artefact Photography (BAJR Guide) by Lisa Jayne FisherDavid Connolly100% (3)

- 29 BAJR Guide: An Introduction To Archaeological Fish RemainsDokumen9 halaman29 BAJR Guide: An Introduction To Archaeological Fish RemainsDavid Connolly88% (8)

- Painting CoefficientsDokumen2 halamanPainting CoefficientsBasanth Babu100% (6)

- Bajr Guide 32: Archaeological Illustration - Small FindsDokumen14 halamanBajr Guide 32: Archaeological Illustration - Small FindsDavid Connolly100% (1)

- Sub-Sectort Industries by ProductsDokumen9 halamanSub-Sectort Industries by ProductsAlemu Regasa100% (2)

- Structural Steel WorksDokumen85 halamanStructural Steel Workscricket reviewBelum ada peringkat

- Insurance For ArchaeologistsDokumen7 halamanInsurance For ArchaeologistsDavid ConnollyBelum ada peringkat

- Archaeology Career Advice 2013Dokumen22 halamanArchaeology Career Advice 2013David Connolly100% (1)

- Sheriffside Enclosure, East Lothian, 2012Dokumen26 halamanSheriffside Enclosure, East Lothian, 2012David ConnollyBelum ada peringkat

- Papple Cottages, East LothianDokumen31 halamanPapple Cottages, East LothiandigitalpastBelum ada peringkat

- The Templar Lodge Hotel, Gullane, East Lothian.Dokumen41 halamanThe Templar Lodge Hotel, Gullane, East Lothian.David ConnollyBelum ada peringkat

- Amisfield Walled Garden, Pineapple House - East LothianDokumen50 halamanAmisfield Walled Garden, Pineapple House - East LothianDavid ConnollyBelum ada peringkat

- Old Pentland Churchyard, MidlothianDokumen17 halamanOld Pentland Churchyard, MidlothianDavid ConnollyBelum ada peringkat

- Getting Paid On Time - A BAJR GuideDokumen29 halamanGetting Paid On Time - A BAJR GuideDavid ConnollyBelum ada peringkat

- Issue 12 May 2010 Adventures in ArchaeologyDokumen56 halamanIssue 12 May 2010 Adventures in Archaeologykcac0008Belum ada peringkat

- 13: Adventures in Archaeology August 2010 - Past HorizonsDokumen60 halaman13: Adventures in Archaeology August 2010 - Past HorizonsDavid Connolly100% (1)

- Women & Work: Sectors Pathways InitiativeDokumen1 halamanWomen & Work: Sectors Pathways InitiativeDavid ConnollyBelum ada peringkat

- Pay and Conditions For 2010 / 2011::::: April 2010Dokumen13 halamanPay and Conditions For 2010 / 2011::::: April 2010David ConnollyBelum ada peringkat

- International Archaeological Research Campaign 2010 at Marsiliana D'albegnaDokumen1 halamanInternational Archaeological Research Campaign 2010 at Marsiliana D'albegnaDavid ConnollyBelum ada peringkat

- Past Horizons Issue 10 November 2009Dokumen48 halamanPast Horizons Issue 10 November 2009David Connolly90% (10)

- Adventures in Archaeology - Past Horizons Feb 2010 - Issue 11Dokumen56 halamanAdventures in Archaeology - Past Horizons Feb 2010 - Issue 11David Connolly100% (3)

- Basic Health and Safety Advice For ArchaeologyDokumen10 halamanBasic Health and Safety Advice For ArchaeologyDavid ConnollyBelum ada peringkat

- 28 BAJR Guide: Gaining A CSCS CardDokumen14 halaman28 BAJR Guide: Gaining A CSCS CardDavid ConnollyBelum ada peringkat

- 30 BAJR Guide: Work Safe On Public Archaeology Projects: General GuidanceDokumen14 halaman30 BAJR Guide: Work Safe On Public Archaeology Projects: General GuidanceDavid Connolly81% (16)

- Getting A Job in ArchaeologyDokumen11 halamanGetting A Job in ArchaeologyDavid Connolly75% (4)

- Past Horizons Issue 9 Aug 2009Dokumen48 halamanPast Horizons Issue 9 Aug 2009David Connolly100% (6)

- Stratword SolutionDokumen1 halamanStratword SolutionDavid ConnollyBelum ada peringkat

- Treasure Trove Report 2008/2009 ScotlandDokumen42 halamanTreasure Trove Report 2008/2009 ScotlandDavid ConnollyBelum ada peringkat

- StratWord (TM) PuzzleDokumen2 halamanStratWord (TM) PuzzleDavid Connolly100% (1)

- How To Get Involved in ArchaeologyDokumen17 halamanHow To Get Involved in ArchaeologyDavid Connolly100% (13)

- Scottish Archaeology Month: 2009 Events HighlightsDokumen21 halamanScottish Archaeology Month: 2009 Events HighlightsDavid Connolly100% (1)

- Buildings SoR 2011 12Dokumen403 halamanBuildings SoR 2011 12Bhargavi BhanuBelum ada peringkat

- Group 6 - Roofing MaterialsDokumen102 halamanGroup 6 - Roofing MaterialsPercival ArcherBelum ada peringkat

- GLTRLR 10072020Dokumen110 halamanGLTRLR 10072020one formanyBelum ada peringkat

- ABC Pola QttyDokumen147 halamanABC Pola QttyELMERBelum ada peringkat

- 20' Cargo Container SpecDokumen23 halaman20' Cargo Container SpecMAYMODERN STEELBelum ada peringkat

- 3.10 Early Roofing and Roof Materials in South AustraliaDokumen45 halaman3.10 Early Roofing and Roof Materials in South AustraliaPham Ha AnBelum ada peringkat

- 20FT STANDARD DOUBLE DOOR Conex Depot Shipping Container Technical DrawingDokumen19 halaman20FT STANDARD DOUBLE DOOR Conex Depot Shipping Container Technical DrawingAlBelum ada peringkat

- New Construction Medical Building Unit Price AnalysisDokumen25 halamanNew Construction Medical Building Unit Price AnalysisYedid AmqBelum ada peringkat

- 07 Thermal Moisture ProtDokumen19 halaman07 Thermal Moisture ProtErika RafaelBelum ada peringkat

- Sea LabelDokumen65 halamanSea Labelabraham asmamawBelum ada peringkat

- Unit 1 Properties and Shape PDFDokumen9 halamanUnit 1 Properties and Shape PDFCahya pramanaBelum ada peringkat

- CGI Sheet NepalDokumen2 halamanCGI Sheet NepalSunil NepalBelum ada peringkat

- PAES 317-Metal Sheets - PlatesDokumen12 halamanPAES 317-Metal Sheets - Platesandrew cabilesBelum ada peringkat

- BD - R - ROOFING & CEILINGDokumen4 halamanBD - R - ROOFING & CEILINGMuthusamy Arumugam100% (1)

- CH 1Dokumen49 halamanCH 1Gurinder PalsinghBelum ada peringkat

- Verlegehinweise Eng Trapez Und Wellprofile 202006Dokumen20 halamanVerlegehinweise Eng Trapez Und Wellprofile 202006leogenicBelum ada peringkat

- Long Span Structures: Lattice Truss ConstructionDokumen54 halamanLong Span Structures: Lattice Truss ConstructionPreranaBelum ada peringkat

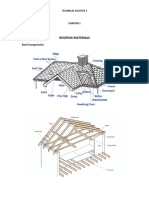

- Roofing Materials: Roof ComponentsDokumen17 halamanRoofing Materials: Roof ComponentsMero Mero100% (1)

- BS 03083-1988 (1999)Dokumen14 halamanBS 03083-1988 (1999)Chat Luong HSGBelum ada peringkat

- Truss Structure DesignDokumen32 halamanTruss Structure DesignDaanial KhanBelum ada peringkat

- Heritage Replacing Corrugated Iron RoofsDokumen9 halamanHeritage Replacing Corrugated Iron RoofsthailanBelum ada peringkat

- SOP-0005-Standard Operating (Work) Procedure - Store ManagementDokumen37 halamanSOP-0005-Standard Operating (Work) Procedure - Store Managementlelu ojhaBelum ada peringkat