Bulacan State University City of Malolos, Bulacan College of Engineering

Diunggah oleh

Kenty BoydonDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Bulacan State University City of Malolos, Bulacan College of Engineering

Diunggah oleh

Kenty BoydonHak Cipta:

Format Tersedia

BULACAN STATE UNIVERSITY CITY OF MALOLOS, BULACAN COLLEGE OF ENGINEERING

ENGINEERING MATERIALS

CHAPTER III: ALLOYING OF METALS

GROUP 2: ADRIANO, Marlon ALCANTARA, Carla Mae LIMPAHAN, Rey SALVO, Nico Bryan BSCoE 3A

Engr. Sarah M. Faustino

CHAPTER III 3.1 ALLOYS

ALLOYING OF METALS

Pure metal objects are used for good electrical and thermal conductivity and corrosion resistance. However, pure metals usually lack the strength required for structural materials. Therefore alloys are mainly used for structural materials since they can be formulated to give superior mechanical properties such as tensile strength, yield strength and hardness. However, ductility is reduced. An alloy is an intimate association of two or more component materials which form a single metallic liquid or solid that may contain metal elements or combination of metal and nonmetal elements. It is important to distinguish alloying elements from impurities. Alloying elements are added in controlled quantities to modify the properties of a material while impurities are undesirable elements that are usually carried over from some previous processes. Alloys should be completely miscible that is, components which are soluble in each other in the molten state. In any alloy, the metal with larger proportion is referred to as the parent metal or solvent, while the metal (or non-metal) present with the smaller proportion is known as the alloying component or solute.

Alloys are formed in three ways: If the alloying components in the molten solution have similar chemical properties and their atoms are of similar size, they will form a solid solution upon cooling. If the alloying components in the molten solution have different chemical properties, they may attract each other and form chemical compounds. If the alloying components are both metals, these compounds are referred to as intermetallic compounds When atoms with different chemical properties attract each other less than those with similar chemical properties, then both intermetallic compounds and solid solutions will be present at the same time. Upon cooling, they will tend to separate out to form a heterogeneous mixture.

CHAPTER III 3.2 ALLOYING ELEMENTS

ALLOYING OF METALS

Aluminum The presence of up to 1 percent aluminum in alloy steels enables them to be given a hard, wear-resistance skin by nitriding.

Chromium The presence of small amounts of chromium improves the ability of steels to respond to hardening by heat treatment. The presence of large amounts of chromium improves the corrosion resistance and heat resistance of steels. Unfortunately, the presence of chromium also promotes grain growth. It is more often associated with nickel in alloy steels because nickel tends to refine the grain structure.

CHAPTER III

ALLOYING OF METALS

Cobalt The presence of cobalt induces sluggishness into the heat treatment transformations and improves the ability of tool steels to operate at high temperatures without softening.

Copper The presence of 0.5 percent copper helps to improve the corrosion resistance of alloy steels.

CHAPTER III

ALLOYING OF METALS

Lead The presence of up to 0.2 percent lead improves the machinability of steels. Unfortunately, it also reduces the strength of the steel to which it is added.

Manganese This element is always present in steels. It improves the wear resistance of steels by spontaneously forming a hard skin when subjected to abrasion. Manganese alloy steels can also have high strength and toughness.

CHAPTER III

ALLOYING OF METALS

Molybdenum The presence of molybdenum in alloy steels raises their high-temperature creep strength, stabilizes their carbides and reduces brittleness.

Nickel The presence of nickel in alloy steels results in increased strength by grain refinement. It also improves the corrosion resistance of steels. Chromium offsets the disadvantages of nickel as an alloying element. Chromium improves the ability of the alloy to respond to heat treatment while nickel increases the strength of the alloy by grain refinement.

CHAPTER III

ALLOYING OF METALS

Phosphorus This is a residual element from the smelting (extraction) process that causes weakness in the steel. A trace of phosphorus can improve machinability and in larger quantities, can improve the fluidity of casting steels.

Silicon The presence of silicon also improves the fluidity of casting steels without the reduction of strength. It also improves the heat resistance of steels and its magnetic properties by increasing the permittivity of the alloy. Unfortunately, silicon is also a powerful graphetizer.

CHAPTER III

ALLOYING OF METALS

Sulphur This is a residual element from the smelting (extraction) process that reduces the strength and toughness of steel. It is sometimes added to low-carbon steels to improve their machinability.

Tungsten The presence of tungsten in alloy steels promotes the formation of very hard carbides and induces sluggishness into the heat-treatment transformations during hardening. It enables steels to retain their hardness at high temperatures.

CHAPTER III

ALLOYING OF METALS

Vanadium This element enhances the performance of the other alloying elements. Its effects in alloy steels are various: Promotes formation of carbides Stabilizes the martensite and improves hardenability Reduces grain growth Enhances the hot hardness of tool steels and die steels Improves the fatigue resistance of steels Improves the life of valve steels used in internal combustion engines

CHAPTER III 3.3 SOLUBILITY Example: The water is the solvent. The salt is the solute. The resulting liquid is the solution.

ALLOYING OF METALS

Solvent is a substance, usually a liquid, capable of dissolving another substance and eventually forms a solution. Solute is a substance dissolved in another substance, usually the component of a solution present in the lesser amount. It is the one being dissolved in a solution. Solution is a homogeneous mixture of two or more substances, which may be solids, liquids, gases, or a combination of these.

A solution is said to be saturated if it is combined with or containing all the solute that can normally be dissolved at a given temperature. The excess solute that will not be dissolved will remain as a residue.

CHAPTER III 3.4 SOLID SOLUTIONS

ALLOYING OF METALS

Most metals are completely and mutually soluble (they are miscible) in the liquid state that is, when they are molten.

Two Sorts of Solid Solutions: Substitutional Solid Solutions The copper-nickel alloy mentioned previously is an example of substitutional solid solutions. Insterstitial Solid Solutions It is a solid solution in which the solute atoms occupy positions between the atoms in the structure of the solvent.

Important Factors Governing the formation of Substitutional Solid Solution: Atomic Size The atoms of the solute and the solvent must be approximately the same size. If the atom diameters vary by more than 15% the formation of a substitutonal solid solutions is highly unlikely.

Electrochemical Series If there is only a small difference in charge between the alloying components then they will probably form a solid solution. Conversely, if their charges are very dissimilar they are more likely to form intermetallic compounds.

Valency A metal lower than valency is more likely to dissolve one of higher valency then the other way round, assuming the conditions stated above are also favourable.

CHAPTER III

ALLOYING OF METALS

Fig. 3.3 Substitutional Solid Solution

Fig.3.4 Interstitial Solid Solution

CHAPTER III 3.5 INTERMETALLIC COMPOUNDS

ALLOYING OF METALS

Intermetallic compounds tend to be hard and brittle and are thus less useful for engineering alloys than the tough and ductile solid solutions. Intermetallic compounds are most widely found in bearing alloys where they form hard, wear-resistant pads with a low coefficient of friction, set matrix of tough, ductile solid solution.

Fig. 3.5 Intermetallic Compounds

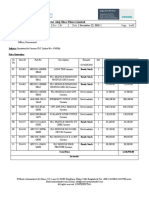

CHAPTER III 3.6 COOLING CURVES

ALLOYING OF METALS

A cooling curve is a line graph that represents the change of phase of matter, typically from a gas to a solid or a liquid to a solid. The independent variable (X-axis) is time and the dependent variable (Y-axis) is temperature.

Fig. 3.6 (a) Cooling curve for water

Fig. 3.6 (b) Cooling curve for a salt-water solution

CHAPTER III 3.7 PHASE

ALLOYING OF METALS

A portion of a system which is uniform composition and texture throughout, and which is separated from the other phases by clearly defined surfaces. Water vapor (steam). Liquid salt solution ( sodium chloride). Crystals of water (ice). Crystals of salt (sodium chloride).

When a liquid solution of two metals solidifies: Metals which are soluble in the liquid state may become totally insoluble in the solid state and separate out as grains of two pure metals. Thus there will be two phases present, with each phase consisting of many grains of the same composition. Metals which are soluble in the liquid state may remain totally soluble in the solid state resulting in a solid solution. Thus a single-phase solid solution will be present consisting of many grains of the same composition. The two metals may react together chemically to form an intermetallic compound. Again a single phase consisting of many grains of the same composition will be present.

Alloy may be built in different ways: Two pure metals existing entirely separately in the structure. In practice this is extremely rare since there is usually some solubility of one metal in another. A single solid solution of one metal dissolved in another. A mixture of two solid solutions if the metals are only partially soluble in each other. An metallic compound and a solid solution mixed together. The individual grains found in any of these phases may vary considerably in size. Some are large enough to see with the unaided eye, while others are so small that a high powered microscope is required.

CHAPTER III 3.8 ALLOY TYPES

ALLOYING OF METALS

Simple eutectic type The two components are soluble in each other in the state, but are completely insoluble in each other in the solid state.

Solid solution type The two components are completely soluble in each other both in the liquid state and in the solid state.

Combination Type The two components are completely soluble in the liquid state, but are only partially soluble in each other in the solid state. Thus this type of alloy combines some of the characteristics of both the previous types, hence the name combination type phase equilibrium diagram.

CHAPTER III

ALLOYING OF METALS 3.9 PHASE EQUILIBRIUM DIAGRAMS

The eutectic reaction is defined as follows:

This type of reaction is an invariant reaction, because it is in thermal equilibrium; another way to define this is the Gibbs free energy equals zero. Tangibly, this means the liquid and two solid solutions all coexist at the same time and are in chemical

equilibrium. There is also a thermal arrest for the duration of the reaction.

At the liquidus there is a liquid solution of molten bismuth and molten cadmium. As the solution cools to the liquidus temperature, for the alloy under consideration, crystals of pure cadmium precipitate out. This increases the concentration of bismuth and reduces the concentration of cadmium present in the remaining solution. Thus the solidification temperature is reduced to that appropriate for this new ratio of cadmium and bismuth, and further crystals of pure cadmium precipitate out. This again reduces the percentage of cadmium present in the remaining solution and solidification temperature is further reduced with more pure cadmium crystals being precipitated.

At the eutectic composition, crystals of cadmium and bismuth precipitate out simultaneously to form lamellar eutectic of the two metals.

CHAPTER III

ALLOYING OF METALS 3.10 PHASE EQUILIBRIUM DIAGRAMS (SOLID SOLUTION TYPE)

Phase equilibrium diagram is a graphic relationship between temperature and weight ratios of elements and alloys contribute to the built of the diagram.

Where phase is a uniform part of an alloy, having a certain chemical composition and structure, and which is separated from other alloy constituents by a phase boundary.

For example the salt . water solution have a four possible phases: - Water vapor (steam) - Liquid salt solution (sodium chloride in water) - Crystals of water (ice) - Crystals of salt (sodium chloride)

Alloying systems

Alloy is a metal composing of a mixture of elements. Most of alloys are composed of a base metal with small amounts of additives or alloying elements. The typical examples of alloys are steel/cast iron (iron base alloys), bronze/brass (copper base alloys), aluminum alloys, nickel base alloys, magnesium base alloys, titanium alloys. There are many types of alloying systems which they are: Binary system. It means that alloying have two metals only.

CHAPTER III

ALLOYING OF METALS

Phase Equilibrium Diagrams (Solid Solution Type):

Solid solution is a phase, where two or more elements are completely soluble in each other. Depending on the ratio of the solvent (matrix) metal atom size and solute element atom size, two types of solid solutions may be formed: substitution or interstitial.

Interstitial solid solution If the atoms of the alloying elements are considerably smaller, than the atoms of the matrix metal, interstitial solid solution forms, where the matrix solute atoms are located in the spaces between large solvent atoms. When the solubility of a solute element in interstitial solution is exceeded, a phase of intermediate compound forms. These compounds (WC, Fe3C etc.) play important role in strengthening steels and other alloys. Some substitution solid solutions may form ordered phase where ratio between concentration of matrix atoms and concentration of alloying atoms is close to simple numbers like AuCu3 and AuCu. Solid solution formation usually causes increase of electrical resistance.

CHAPTER III

ALLOYING OF METALS 3.11 PHASE EQUILIBRIUM DIAGRAM (COMBINATION OF SOLID AND EUTECTIC TYPE)

Phase equilibrium diagrams (Eutectic type): It is identical with this type of phase diagram is produced for a salt (sodium chloride) and water solution, it is total solubility of the salt in water in the liquid state and total insolubility (crystals of ice and separate crystals of salt) in the solid state. As an example of eutectic are carbon steels .

Phase equilibrium diagrams (Combination of eutectic and solid type): Many metals and non-metals are neither completely soluble other in the solid state nor are they completely insoluble. Therefore form a phase equilibrium diagram of the type shown in figure 5 system there are two solid solutions labeled and . The use of the letters , , , etc., in phase equilibrium diagrams may be defined, general, as follows: A solid solution of one component A in an excess of component B, such that A is the solute and B is the solvent, referred to as solid solution . A solid solution of the component B in an excess of the component A, so that B now becomes the solute and A becomes the solvent, referred to as solid solution . In a more complex alloy, any further solid solutions or intermetallic compounds which may be formed would be referred to subsequent letters of the Greek alphabet. That is, , , etc.

If the entire process is slow enough so that equilibrium within the crystal is maintained from the start, then diffusion will occur with copper atoms migrating into the core of the crystal and nickel atoms migrating into the case of the crystal. By the time cooling is complete, the composition should be uniform throughout with 70 % copper and 30 % nickel.

Diffusion It describes the spread of particles through random motion from regions of higher concentration to regions of lower concentration.

CHAPTER III

ALLOYING OF METALS

Crystal Growth (a) dendritic nucleus at liquidus temperature [47% Cu, 53% Ni], (b) diffusion of copper and nickel as crystal commences to grow [62% Cu, 38% Ni at 1200 C]

Example of Crystal growth:

Once diffusion is complete the rate of cooling is irrelevant. However, over-fast cooling creates stresses in the metal. On the other hand, excessively long periods of heating excessively slow cooling results in the grain growth which may improve ductility but reduce mechanical strength and may cause machining problems as the metal will tend to tear and leave a poor surface finish rather than cut cleanly.

CHAPTER III

ALLOYING OF METALS

In phase equilibrium diagrams it is always assumed that cooling will be slow enough for equilibrium to be maintained. Under production conditions in the foundry, where cooling is more rapid than the ideal, there is insufficient time for diffusion to become complete and the nickelrich core will become apparent when an etched specimen is examined under a microscope.

The core of the crystal will have the outline appearance of the initial dendrite from which the crystal has grown. The result of this more rapid cooling is called coring and, since coring leads to lack of uniformity in the structure of the metal, this adversele affects its mechanical properties.

Coring can largely be eliminated by heat treatment. The casting is heated to just below the solidus for the alloy concerned until diffusion is complete.

3.12 CORING

It happens when a heated alloy, such as a Cu-Ni system, cools in non-equilibrium conditions. This causes the exterior of the material to harden faster than the interior.

Coring causes the exterior layers to retain more of the higher melting temperature element. In this case, the dendrite arms formed from the exterior have a different composition than the alloy in the inner regions, resulting in a local compositional difference.

Anda mungkin juga menyukai

- Audi A4-7Dokumen532 halamanAudi A4-7Anonymous QRVqOsa5Belum ada peringkat

- Welding Metallurgy - Detailed PDFDokumen28 halamanWelding Metallurgy - Detailed PDFkarcoepm100% (1)

- Alloys and Types of SteelDokumen16 halamanAlloys and Types of SteelRajatBelum ada peringkat

- Aircraft Materials - Questions With AnswersDokumen21 halamanAircraft Materials - Questions With AnswersbirukBelum ada peringkat

- Code of Ethics For Civil Engineers PiceDokumen3 halamanCode of Ethics For Civil Engineers PiceEdwin Ramos Policarpio100% (3)

- Chap 07 PDFDokumen26 halamanChap 07 PDFdada jamdarBelum ada peringkat

- Austenitic Stainless SteelsDokumen20 halamanAustenitic Stainless Steelsvivekr84100% (1)

- Microstructure Study of Ferrous and Non Ferrous Alloys Under Various Compositions and Heat Treatment Conditions Lab ReportDokumen7 halamanMicrostructure Study of Ferrous and Non Ferrous Alloys Under Various Compositions and Heat Treatment Conditions Lab Reportzrro50% (4)

- Introduction of MetalsDokumen9 halamanIntroduction of MetalsmaeBelum ada peringkat

- Construction Project - Life Cycle PhasesDokumen4 halamanConstruction Project - Life Cycle Phasesaymanmomani2111Belum ada peringkat

- Eccentric FootingDokumen3 halamanEccentric FootingVarunn VelBelum ada peringkat

- Why Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksDari EverandWhy Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksBelum ada peringkat

- Structure and PropertiedDokumen43 halamanStructure and PropertiedJalaj GaurBelum ada peringkat

- Metals Used in ProsthodonticsDokumen43 halamanMetals Used in ProsthodonticsnavneetkhanBelum ada peringkat

- Amta5 1 Identifying Metals and Their Physical PropertiesDokumen104 halamanAmta5 1 Identifying Metals and Their Physical PropertiesJason Lid-ayanBelum ada peringkat

- Amta5 1 Identifying Metals and Their Physical PropertiesDokumen104 halamanAmta5 1 Identifying Metals and Their Physical PropertiesKrishnamoorthi VenkatesanBelum ada peringkat

- Mechanical Behaviour of Materials: Unit - IiiDokumen11 halamanMechanical Behaviour of Materials: Unit - IiiRemo RamBelum ada peringkat

- MS Module 2 PDFDokumen24 halamanMS Module 2 PDFChidu KBelum ada peringkat

- CHAPTER 4:solid Solution Equilibrium Phase Diagram Name:Muhammad Akmal Afiq Bin Amran MATRIK:11DKM19F1028Dokumen20 halamanCHAPTER 4:solid Solution Equilibrium Phase Diagram Name:Muhammad Akmal Afiq Bin Amran MATRIK:11DKM19F1028Muhd AriffBelum ada peringkat

- Kaduna PolytechnicsDokumen13 halamanKaduna PolytechnicsSofiyat AbdulrasakBelum ada peringkat

- Optimal Shipbuilding Technologies: Course 4Dokumen65 halamanOptimal Shipbuilding Technologies: Course 4Balis MihaiBelum ada peringkat

- Chapter 2 Alloys - 2012 - Applied Welding EngineeringDokumen5 halamanChapter 2 Alloys - 2012 - Applied Welding EngineeringJames LeonBelum ada peringkat

- Metal AlloysDokumen114 halamanMetal AlloysRudra VermaBelum ada peringkat

- Steel AlloyDokumen6 halamanSteel AlloyVishalBelum ada peringkat

- Alloys and Classification of AlloysDokumen3 halamanAlloys and Classification of AlloysFaHeem KhAnBelum ada peringkat

- Manufactured Substances in IndustryDokumen31 halamanManufactured Substances in Industryko kurikulumBelum ada peringkat

- Metals Are Combinations of Metallic ElementsDokumen4 halamanMetals Are Combinations of Metallic ElementsGuido MorlachettiBelum ada peringkat

- Properties of MetalsDokumen10 halamanProperties of MetalsKawaii SamaBelum ada peringkat

- WINSEM2018-19 CHY1701 ETH TT208 VL2018195004060 Reference Material I Alloy Coatings-1Dokumen24 halamanWINSEM2018-19 CHY1701 ETH TT208 VL2018195004060 Reference Material I Alloy Coatings-1Akshat TiwariBelum ada peringkat

- 19 Properties of MetalsDokumen110 halaman19 Properties of MetalsEvan Jared L. GalvezBelum ada peringkat

- Politecnico Di Torino - School of Architecture: SteelDokumen22 halamanPolitecnico Di Torino - School of Architecture: SteelamenrareptBelum ada peringkat

- Lab 2 MaterialDokumen22 halamanLab 2 MaterialMon LuffyBelum ada peringkat

- 4.0 Metal Alloys, Their Structure and Strengthing by Heat TreatmentDokumen33 halaman4.0 Metal Alloys, Their Structure and Strengthing by Heat TreatmentAbdul RashidBelum ada peringkat

- Lecture Three: Biomaterial Surface ChemistryDokumen12 halamanLecture Three: Biomaterial Surface Chemistryحنين حسن شعبانBelum ada peringkat

- Metals and AlloysDokumen13 halamanMetals and Alloyswoi mariaBelum ada peringkat

- Alloy TheoryDokumen3 halamanAlloy TheoryDanish Saifi100% (1)

- Further ReadingDokumen7 halamanFurther ReadingPablo PerdomoBelum ada peringkat

- Unit-3 Corrosion 1Dokumen28 halamanUnit-3 Corrosion 1N x10Belum ada peringkat

- Basic Information About Metals and AlloysDokumen7 halamanBasic Information About Metals and AlloysMahesh JingarwarBelum ada peringkat

- Dental Casting Alloys FinalDokumen175 halamanDental Casting Alloys FinalNiaz Ahammed0% (1)

- Basic Metals PDFDokumen6 halamanBasic Metals PDFTanvirBelum ada peringkat

- Study of Constituents of An AlloyDokumen18 halamanStudy of Constituents of An AlloyMohammed Anis RahmanBelum ada peringkat

- Project and Facility ManagementDokumen26 halamanProject and Facility ManagementKumaResan SubramaniamBelum ada peringkat

- HNC Unit 3 - Engineering Science LO3 - Explore The Characteristics and Properties of Engineering MaterialsDokumen7 halamanHNC Unit 3 - Engineering Science LO3 - Explore The Characteristics and Properties of Engineering MaterialsNoel JenningsBelum ada peringkat

- Lesson 3 Metals and Metal Working Processes: OverviewDokumen17 halamanLesson 3 Metals and Metal Working Processes: OverviewNadjer C. AdamBelum ada peringkat

- Revision Guidance and Check List 2022 - 2023Dokumen22 halamanRevision Guidance and Check List 2022 - 2023AlinaHlihorBelum ada peringkat

- Chemistry Notes Pt. 2Dokumen124 halamanChemistry Notes Pt. 2Blohsh KeenenBelum ada peringkat

- Final MatenggDokumen121 halamanFinal MatenggJhoven De CastroBelum ada peringkat

- Clean Steel: Part Two: AbstractDokumen4 halamanClean Steel: Part Two: AbstractdonkalonkBelum ada peringkat

- Metals 2Dokumen13 halamanMetals 2arooj anjumBelum ada peringkat

- Dental Alloys Used in ProsthodonticsDokumen11 halamanDental Alloys Used in ProsthodonticsShufeiBelum ada peringkat

- CH 4 Metals 2023Dokumen26 halamanCH 4 Metals 2023Heidi VagueBelum ada peringkat

- Pilling & Bedworth Ratio.. EmbrittlementDokumen9 halamanPilling & Bedworth Ratio.. EmbrittlementAdrian JamesBelum ada peringkat

- Alloy - WikipediaDokumen10 halamanAlloy - Wikipediaramthecharm_46098467Belum ada peringkat

- Metals: The Chemistry of Engineering Materials Lecture Notes 05 Chemistry For EngineersDokumen46 halamanMetals: The Chemistry of Engineering Materials Lecture Notes 05 Chemistry For EngineersLorielle OlivaBelum ada peringkat

- Metals: The Chemistry of Engineering Materials Lecture Notes 05 Chemistry For EngineersDokumen46 halamanMetals: The Chemistry of Engineering Materials Lecture Notes 05 Chemistry For EngineersEzriel QuantumBelum ada peringkat

- Prepared By: DR: Gehaan El-OleimyDokumen24 halamanPrepared By: DR: Gehaan El-OleimyMohammed YousriBelum ada peringkat

- Ciat II CombinedDokumen76 halamanCiat II Combinedrikiw17874Belum ada peringkat

- Unit-3 Corrosion & Its ControlDokumen29 halamanUnit-3 Corrosion & Its ControlJevaa KharthickBelum ada peringkat

- Processes Affecting Changes in PropertiesDokumen13 halamanProcesses Affecting Changes in PropertiesMark julius garciaBelum ada peringkat

- MZ FS Unit - 1Dokumen27 halamanMZ FS Unit - 1Jai KumarBelum ada peringkat

- BT4 Metal - Acdio - RSW1Dokumen29 halamanBT4 Metal - Acdio - RSW1franiancis0922Belum ada peringkat

- Importance of Porosity - Permeability Relationship in Sandstone Petrophysical PropertiesDokumen61 halamanImportance of Porosity - Permeability Relationship in Sandstone Petrophysical PropertiesjrtnBelum ada peringkat

- Bridge Over BrahmaputraDokumen38 halamanBridge Over BrahmaputraRahul DevBelum ada peringkat

- Spectroscopic Methods For Determination of DexketoprofenDokumen8 halamanSpectroscopic Methods For Determination of DexketoprofenManuel VanegasBelum ada peringkat

- TIA Guidelines SingaporeDokumen24 halamanTIA Guidelines SingaporeTahmidSaanidBelum ada peringkat

- Marking Scheme For Term 2 Trial Exam, STPM 2019 (Gbs Melaka) Section A (45 Marks)Dokumen7 halamanMarking Scheme For Term 2 Trial Exam, STPM 2019 (Gbs Melaka) Section A (45 Marks)Michelles JimBelum ada peringkat

- Design ProjectDokumen60 halamanDesign Projectmahesh warBelum ada peringkat

- School Based Management Contextualized Self Assessment and Validation Tool Region 3Dokumen29 halamanSchool Based Management Contextualized Self Assessment and Validation Tool Region 3Felisa AndamonBelum ada peringkat

- The Essence of Technology Is by No Means Anything TechnologicalDokumen22 halamanThe Essence of Technology Is by No Means Anything TechnologicalJerstine Airah SumadsadBelum ada peringkat

- Sheet-Metal Forming Processes: Group 9 PresentationDokumen90 halamanSheet-Metal Forming Processes: Group 9 PresentationjssrikantamurthyBelum ada peringkat

- Atmel 46003 SE M90E32AS DatasheetDokumen84 halamanAtmel 46003 SE M90E32AS DatasheetNagarajBelum ada peringkat

- Acoustic Glass - ENDokumen2 halamanAcoustic Glass - ENpeterandreaBelum ada peringkat

- ABS Service Data SheetDokumen32 halamanABS Service Data SheetMansur TruckingBelum ada peringkat

- Hofstede's Cultural DimensionsDokumen35 halamanHofstede's Cultural DimensionsAALIYA NASHATBelum ada peringkat

- Daftar ObatDokumen18 halamanDaftar Obatyuyun hanakoBelum ada peringkat

- Prediction of Compressive Strength of Research PaperDokumen9 halamanPrediction of Compressive Strength of Research PaperTaufik SheikhBelum ada peringkat

- Polysep... Sized For Every Application: Psg-7 Psg-15 Psg-30 Psg-60 Psg-90Dokumen1 halamanPolysep... Sized For Every Application: Psg-7 Psg-15 Psg-30 Psg-60 Psg-90Carlos JiménezBelum ada peringkat

- 2.0. Design, Protection and Sizing of Low Voltage Electrical Installations (Wiring) To IEE Wiring Regulations BS 7671 MS IEC (IEC) 60364 - 16&17.12.15Dokumen2 halaman2.0. Design, Protection and Sizing of Low Voltage Electrical Installations (Wiring) To IEE Wiring Regulations BS 7671 MS IEC (IEC) 60364 - 16&17.12.15Edison LimBelum ada peringkat

- File RecordsDokumen161 halamanFile RecordsAtharva Thite100% (2)

- Ultra Electronics Gunfire LocatorDokumen10 halamanUltra Electronics Gunfire LocatorPredatorBDU.comBelum ada peringkat

- Passage To Abstract Mathematics 1st Edition Watkins Solutions ManualDokumen25 halamanPassage To Abstract Mathematics 1st Edition Watkins Solutions ManualMichaelWilliamscnot100% (50)

- LC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Dokumen2 halamanLC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Mahadi Hassan ShemulBelum ada peringkat

- Pam8610 PDFDokumen15 halamanPam8610 PDFRaka Satria PradanaBelum ada peringkat

- Community Profile and Baseline DataDokumen7 halamanCommunity Profile and Baseline DataEJ RaveloBelum ada peringkat

- MATM1534 Main Exam 2022 PDFDokumen7 halamanMATM1534 Main Exam 2022 PDFGiftBelum ada peringkat

- English For Academic and Professional Purposes - ExamDokumen3 halamanEnglish For Academic and Professional Purposes - ExamEddie Padilla LugoBelum ada peringkat

- Static Electrification: Standard Test Method ForDokumen10 halamanStatic Electrification: Standard Test Method Forastewayb_964354182Belum ada peringkat