Instructions

Diunggah oleh

Robelle de GuzmanDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Instructions

Diunggah oleh

Robelle de GuzmanHak Cipta:

Format Tersedia

Instructions Things You'll Need Measuring cup Fresh ginger 1 1/2 cups olive oil Oven-safe bowl

Cheese grater Unbleached cheese cloth Rubber band Funnel Vials

1 Rinse one cup of chopped fresh ginger (including the skin) and let dry for several hours. 2 Pour one 1 cups of olive oil in an oven-safe bowl. Shred the chopped ginger using a clean, dry cheese grater and transfer to the bowl. Stir the olive oil and shredded ginger. 3 Place the mixture in the oven and let it simmer under low heat (150 degrees Fahrenheit) for about two hours. 4 Cover a bowl with unbleached cheese cloth. Place a rubber band around the bowl to hold the cheese cloth in place. 5 Pour the ginger oil into the bowl. Remove the rubber band, twist the cheesecloth and squeeze the remaining oil with clean dry hands. 6 Transfer the ginger oil into vials or bottles. Use a funnel to prevent messy spills. 7 Label the bottles with the exact date when you made the ginger essential oil blend. The normal shelf life of essential oils is about six months. After this time, the ingredients begin to decompose. Store the ginger essential oils in a cool, dark place.

Simple Hydrodistillation (Lab-Scale)

Hydrodistillation is a special type of distillation (a separation process) for temperature sensitive materials like natural aromatic compounds. Many complex organic compounds tend to decompose at sustained high temperatures. Separation by normal distillation would then not be an option, so water or steam is introduced into the distillation apparatus. By adding water the boiling point of the compounds is depressed, allowing them to evaporate at lower temperatures, preferably below the temperatures at which the deterioration of the material becomes appreciable. After distillation the vapors are condensed as usual, usually yielding a two-phase system of water and the organic compounds, allowing for simple separation. Ginger boils at 256C while water boils at 100C. So, by gently heating the mixture, the most volatile component will concentrate to a greater degree in the vapor leaving the liquid. Some mixtures form azeotrope, where the mixture boils at a lower temperature than either component. A mixture of 40% ginger and 60% water boils at 80C. The mixture is put into the round bottomed flask and the fractioning column is fitted into the top. As the mixture boils, vapor rises up the column. The vapor condenses on the glass platforms, known as trays, inside the column, and conducts back down into the liquid below, refluxing distillate. The column is heated from the bottom. The hottest tray is at the bottom the coolest is at the top. At steady state conditions the vapor and liquid on each tray is at equilibrium. Only the most volatile of the vapors stays in gaseous form all the way to the top. The vapor at the top of the column then passes into the condenser, which cools it down until it liquefies. The condensate that was initially very close to the azeotrope composition becomes gradually richer in water. The process continues until all there is no more oil produced (Wikipedia, 2006). In laboratory distillation, several types of condensers are commonly found. The Liebig condenser is simply a straight tube within a water jacket, and is the simplest (and relatively least expensive) form of condenser. The Graham condenser is a spiral tube within a water jacket, and the Alhin condenser has a series of large and small constrictions on the inside tube, each increasing the surface area upon which the vapor constituents may condense. Being more complex shapes to manufacture, these latter types are also more expensive to purchase. Condensers are usually sold by the mm: 100, 200, and 400 mm are common lengths, and are connected to the other vessels with ground glass fittings (Feist, 2000).

Anda mungkin juga menyukai

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Build Your Own Garden Pond PDFDokumen10 halamanBuild Your Own Garden Pond PDFMwagaVumbiBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Proteins and Amino AcidsDokumen50 halamanProteins and Amino Acidsraddag100% (2)

- The Pneumatics Installation GuideDokumen186 halamanThe Pneumatics Installation GuideHAMIT100% (1)

- Slab Bridge DesignDokumen21 halamanSlab Bridge DesignMars Villaluna100% (2)

- ISO14001 Step by Step Guide APMM VesselsDokumen36 halamanISO14001 Step by Step Guide APMM Vesselsnasol100% (3)

- Ageing of Polymeric InsulatorsDokumen24 halamanAgeing of Polymeric Insulatorssagger09Belum ada peringkat

- ECV5701 Notes For Concrete Inspection and Assessment-1Dokumen19 halamanECV5701 Notes For Concrete Inspection and Assessment-1ahmed almhjani100% (1)

- Sebia Minicap Protein ElectrophoresisDokumen11 halamanSebia Minicap Protein ElectrophoresisMas Aditya Senaputra100% (1)

- Hoeganaes CorporationDokumen11 halamanHoeganaes CorporationjohnhenryyambaoBelum ada peringkat

- Metabolit SekunderDokumen76 halamanMetabolit SekunderCempaka Kusuma DewiBelum ada peringkat

- D4607 1378898 1 Standard Test Method For Determination of Iodine Number of Activated Carbon PDFDokumen5 halamanD4607 1378898 1 Standard Test Method For Determination of Iodine Number of Activated Carbon PDFMuthu KumarBelum ada peringkat

- Synthesis and Characterization of Cerium Oxide Nanoparticles Using Different Solvents For Electrochemical ApplicationsDokumen10 halamanSynthesis and Characterization of Cerium Oxide Nanoparticles Using Different Solvents For Electrochemical ApplicationsVengateshwaran TDBelum ada peringkat

- NEET TEst PapaerDokumen11 halamanNEET TEst PapaerBiswajit ChangkakotyBelum ada peringkat

- CHEM 160 Module 3 Resource 1Dokumen9 halamanCHEM 160 Module 3 Resource 1meyaBelum ada peringkat

- OGA - Chemical Series - Specialty Fertilizers Market Outlook 2019-2025Dokumen23 halamanOGA - Chemical Series - Specialty Fertilizers Market Outlook 2019-2025ambarish ramBelum ada peringkat

- Biochem Exam Practice QuestionsDokumen12 halamanBiochem Exam Practice Questionsihack_101Belum ada peringkat

- ChemistryDokumen6 halamanChemistryMuhammad umarBelum ada peringkat

- Isomerism: Definition-Structural Isomers: Same Molecular Formula Different Structures (Or Structural Formulae)Dokumen13 halamanIsomerism: Definition-Structural Isomers: Same Molecular Formula Different Structures (Or Structural Formulae)Trần Duy Tân100% (1)

- Bacterial ConjugationDokumen5 halamanBacterial ConjugationPrasenjit VighneBelum ada peringkat

- 0620 m23 QP 22-MinDokumen14 halaman0620 m23 QP 22-Minjelani17fBelum ada peringkat

- Numericals of ChemistryDokumen4 halamanNumericals of ChemistryAakash AkronosBelum ada peringkat

- Thermal Comparison Between Mineral Oil, Natural and Synthetic Esters at Largest Single-Phase 420 KV Green Transformer M. Cuesto, C. González-García, M. Vaquero, D. VukovicDokumen7 halamanThermal Comparison Between Mineral Oil, Natural and Synthetic Esters at Largest Single-Phase 420 KV Green Transformer M. Cuesto, C. González-García, M. Vaquero, D. VukovicSenyum Sentiasa TenangBelum ada peringkat

- Rouge Monitoring Published ND 2011 ADokumen6 halamanRouge Monitoring Published ND 2011 Agabriel silva100% (1)

- Yellow Shoulder On TomatoDokumen2 halamanYellow Shoulder On TomatoargikarBelum ada peringkat

- Different Types of ConductorsDokumen5 halamanDifferent Types of ConductorseuniczelBelum ada peringkat

- Phoenicia University Department of Engineering Faculty of Petroleum Engineering Petroleum Fluid Properties Laboratory PENG212L Dean Stark Plug SizeDokumen14 halamanPhoenicia University Department of Engineering Faculty of Petroleum Engineering Petroleum Fluid Properties Laboratory PENG212L Dean Stark Plug SizeEmanuelta NaibahoBelum ada peringkat

- Chap 03 PPTDokumen25 halamanChap 03 PPThk11813Belum ada peringkat

- 3 NsaidsDokumen23 halaman3 NsaidsHagai MagaiBelum ada peringkat

- Chemical Resistance GuideDokumen20 halamanChemical Resistance GuideDarien EdwardsBelum ada peringkat

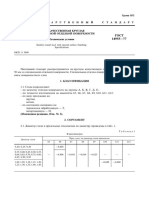

- Äèàìåòð Ñòàëè Ïðåä. Îòêë. ÏÎ Äèàìåòðó Ñòàëè Êâàëèòåòîâ h5 h11 h10 h9 h8 h7 h6 h12Dokumen7 halamanÄèàìåòð Ñòàëè Ïðåä. Îòêë. ÏÎ Äèàìåòðó Ñòàëè Êâàëèòåòîâ h5 h11 h10 h9 h8 h7 h6 h12TetianaBelum ada peringkat