AFIADORA DE BROCAS - Manual de Instrução

Diunggah oleh

lccortesDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

AFIADORA DE BROCAS - Manual de Instrução

Diunggah oleh

lccortesHak Cipta:

Format Tersedia

2009/02

DRILL GRINDER &

END MILL RE- SHARPENER

EASY FAST PRECI SI ON

Easy t o operat e, no experi ence requi red f or gri nd a preci si on dri l l .

DRI LL GRI NDER

EDG- 213N

( 2mm- 13mm)

END MILL

RE-SHARPENER

EMG- 413

( 4mm- 13mm) SG DRI LL GRI NDER

EDSG- 313

( 3mm- 13mm)

END MILL

RE-SHARPENER

EMG- 1225

( 12mm- 25mm)

DRI LL GRI NDER

EDG- 1226N

( 12mm- 26mm)

1

DRILL GRINDER

(EASY FAST PRECISION)

10 Seconds f or gri nd a preci si on dri l l i n a expert er

EDG- 1226N

( 12mm- 26mm)

15pcs ER Col l et

CBN Wheel

12pcs ER Col l et

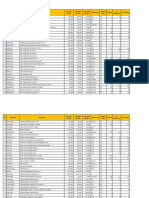

Model No. EDG-213N

Capacity 2mm ~ 13mm

Drill Angle 90 ~ 135

Grinding Wheel CBN#200(For Hss Drill )

Motor 1/3HP 250W

Power Supply AC110V / AC220V Single Phase

R.P.M 5500 R.P.M.

Weight 8.5kg

Standard Accessories

ER collets 2mm ~ 13mm(12pcs)

CBN Wheel #2001pc(For Hss drill)

Hexagon Wrench 4mm1pc 5mm1pc

Option Accessories

Order No. Description

EDG-213N-1D SDC Wheel #400( For Carbide drill )

EDG-213N-1C CBN Wheel #200( For HSS drill )

EDG-213N-2C

CBN Wheel #400

(For HSS drill under 5mm )

Model No. EDG-1226N

Capacity 12mm ~ 26mm

Drill Angle 90 ~ 135

Grinding Wheel CBN#150(For Hss Drill )

Motor 1/2HP 450W

Power Supply AC110V / AC220V Single Phase

R.P.M 4500 R.P.M.

Weight 26kg

Standard Accessories

ER collets 12mm ~ 26mm(15pcs)

CBN Wheel#1501pc(For Hss drill)

Hexagon Wrench 4mm1pc 6mm1pc

Option Accessories

Order No. Description

EDG-1226N-1D SDC Wheel #200( For Carbide drill )

EDG-1226N-1C CBN Wheel #150( For HSS drill )

Col l et Hol der : bear i ng assembl ed

( Mor e easy & conveni ent f or t i ght i ng)

Gr i ndi ng Base : bear i ng assembl ed

(More preci si on and st abl e f or gri ndi ng)

NEW Desi gn

Easy to operate, no experience required for grind a precision drill.

EDG- 213N

( 2mm- 13mm)

2

1.Set up the drill to the collet holder.

Follow up the Steps I,2,3,4 for set up the drill to the collet holder

. ( without tighting ) ***as shown on diagram #1

2.Set up the diameter of dril

Turn right the scale annulus to be "0" position

Adjust the scale to meet the diameter of the drill.

***as shown on diagram #2

3.Set up the drill to the grinding

position

Insert the collet holder with drill and turn right,

then tight the drill by collet holder for set up the

grinding position. ***as shown on diagram #3

Attn : The scale annulus maybe not exact for

the drill diameter, because of used drill

or different model of drill any how, please

always check the center edge of drill must

be parallel with the gap of " Collet Holder"

***as shown on the right diagram.

4.Grind the drill tip

Turn on the power of the grinder.

Insert the collet holder with drill and push to

the grinding wheel slowly, then move left and right repeatedly

to sharpen the drill until the grinding sound disappeared.

Take out the collet holder with drill and change to the other

side to grind again in same way as above mentioned.

***as shown on diagram #4

5.Center Point Grinding Base adjusting

Adjust the center point grinding base to the suitable position.

Turn right for bigger, turn left for smaller.

***as shown on diagram #5

6 . Grind the center point of drill

Insert the collet holder with drill and push to the grinding

wheel slowly, then move Ieft and right repeatedly to grind the

center point of drill until the grinding sound disappeared .

Take out the collet holder with drill and change to the other

side to grind again in same way as above mentioned.

***as shown on diagram #6

The center point suitable for soft materials such as

copper, aluminum, plastic.. .etc.

The center point suitable for general materials such

as iron, general steel and brass. ..etc.

The center point suitable for hard steels . . .etc hard

materials.

***Please clean the grinding chip often for avoid the chip scrape to the grinding base and

keep using life.

OPERATIONS

1.

3

4

1 2

2.

3.

4.

5.

6.

3

Set t i ng( dr i l l ) base

CBN Wheel

11pcs ER col l et

Model No. EDSG-313 Motor 200W

Capacity 3mm ~ 13mm R.P.M. 4500 R.P.M.

Drill Angle 135 Weight 12.8 kg

Power

Supply

AC110V / AC220V Single Phase

50Hz/60Hz

Grinding

Wheel

CBN#250

Standard Accessories

ER collets 3mm ~ 13mm (11pcs)

CBN Wheel#2501pc and #4001pc(For Hss drill)

Hexagon Wrench 4mm1 pc, 5mm1 pc

Col l et Hol der : bear i ng assembl ed

( Mor e easy & conveni ent f or t i ght i ng)

NEW Desi gn

This machine is guaranteed for one year under normal operating

(expendable parts and wheels are exceptions)

EDSG- 313

( 3mm- 13mm)

GR DRILL GRINDER

(EASY FAST PRECISION)

Easy to operate, no experience required for grind a precision drill.

4

1. Set up the drill to the collet holder.

Follow up the steps 1,2,3,4 for set up the drill to the collet

holder. (without tightening) ***as shown on diagram #1

2. Set up the diameter of drill

Turn right the scale annulus to be "0" position

Adjust the scale to meet the diameter of the

drill.

***as shown on diagram #2

3. Set up the drill to the grinding position.

Insert the collet holder with drill and turn right,

then tighten the drill by collet holder for set up

the grinding position. ***as shown on diagram #3

Attn : The scale annulus maybe not exact for

the drill diameter, because of used drill or

different model of drill. Any how, please

always make sure the center edge of drill

must be parallel with the gap of "Collet

Holder" ***as shown on the right diagram

4. Adjust the center point of drill and width

of trimming angle.

Confrm the drill diameter frst and check the

suggested trimming angle (See trimming

angle table at right side). Loosen the second

fxed hole, then loosen the frst fxed hole.

Set the scale to the required diameter (scale

gauge measuring same as caliper's). Reverse

steps to tighten the fxed holes to grind.

Adjust the center point to the suitable

position. Turn right for bigger, turn left for

smaller. ***as shown on diagram #4

5. Grind the center point of drill

Insert the collet holder with drill and push to

the grinding wheel slightly to grind the center point of drill until

the grinding sound disappeared.

Take out the collet holder with drill and change to the other

side to grind again in same way as above mentioned.

***as shown on diagram #5

6. Grind the secondary clearance angle of drill

Insert the collet holder with drill to the secondary clearance

angle grinding port and push to the grinding wheel slowly to

grind the secondary clearance angle of drill until the grinding

sound disappeared.

Take out the collet holder with drill and change to the other

side to grind again in same way as above

mentioned.

Adjust the end gash to the suitable position.

Turn right for smaller, turn left for bigger.

***as shown on diagram #6

7. Grind the end gash of drill

Insert the collet holder with drill to the end gash grinding port

and push to the grinding wheel slowly to grind the end gash

until the grinding sound disappeared.

Take out the collet holder with drill and change to the other

side to grind again in same way as above mentioned.

***as shown on diagram #7

Note: Please always clean the grinding dust after grinding and

do maintenance to avoid the dust scrape the grinding

base, and to extend the usage life.

Do not keep the motor run continuously over 1 hour.

OPERATIONS

TYPE

Trimming

angle(mm)

3mm 0.50

4mm 0.50

5mm 0.75

6mm 1.00

7mm 1.25

8mm 1.50

9mm 2.00

10mm 2.00

11mm 2.25

12mm 2.50

13mm 2.50

Trimming angle

table

1.

3

4

1 2

2.

3.

4.

5.

6.

7.

width of trimming angle

adjust scale

center point adjust hole

First fxed hole

Second fxed hole

Adjust End gash

5

6 pcs ER collets

2 pcs collet holders

10 pcs ER collets

2 pcs collet holders

SDC Wheel for4mm-5mm

2 pcs SDC Wheels included

SDC Wheel for 6mm-13mm SDC Wheel for4mm-5mm

EMG- 1225

( 12mm- 25mm)

EMG- 413

( 4mm- 13mm)

For 2,3, and 4 flutes END MILL

2 pcs SDC Wheels included (For carbide End Mill only)

END MILL RE-SHARPENER

(EASY FAST PRECISION)

6

4mm 5mm 6mm 7mm 8mm

9mm 10mm 11mm 12mm 13mm

12mm 16mm 18mm 20mm 22mm 25mm

EMG-413-1D

or

EMG-413-1C

EMG-413-2D

or

EMG-413-2C

for 3 futes End Mill for 2 and 4 futes End Mill

Order No.

EMG-1225-H1 EMG-1225-H2

collets Holder

for 3 futes End Mill for 2 and 4 futes End Mill

Order No.

EMG-413-H1 EMG-413-H2

Order No. EMG-1225ER

ER

collets

Order No. EMG-413ER

EMG-1225-1C EMG-1225-1D

SDC and CBN Wheel

Model NO.

EMG-413 EMG-1225

Capacity 4mm - 13mm 12mm - 25mm

Drill Angle

6 20 30

Grinding

Wheel

SDC Wheel #300 for4mm-5mm CBN #150x1PC

SDC Wheel #300/#120 for6mm-

13mm

SDC #150x1PC

Motor 3/4 HP 450W 1000W

R.P.M. 6000 R.P.M. 4300 R.P.M.

Power

Supply

AC110V or AC220V Single Phase

Weight 17 KGS 31 KGS

Standard Accessories

Model NO. EMG-413 EMG-1225

ER collets 4mm - 13mm 10pcs 12mm - 25mm 6pcs

SDC Wheel #300 1pcs (4mm--5mm) CBN #150x1PC

SDC Wheel #300 #120 1pcs (6mm--13mm) SDC #150x1PC

Collet Holder 1pc(for 2 and 4 futes End Mill)

1pc(for 2 and 4 futes End

Mill)

Collet Holder 1pc(for 3 futes End Mill) 1pc(for 3 futes End Mill)

Hexagon

Wrench

4mm 1pc 4mm 1pc

Option Accessories

Model NO. Description

EMG-413-1D SDC Wheel #300 (for 4mm-5mm)

EMG-413-2D SDC Wheel #300/#120 (for 6mm-13mm)

EMG-413-1C SBN Wheel #300 (for 4mm-5mm)

EMG-413-2C SBN Wheel #300/#120 (for 6mm-13mm)

EMG-1225-1D SDC Wheel #150

EMG-1225-1C SBN Wheel #150

***SDC Wheel for carbide End Mill.

***CBN Wheel for HSS End Mill.

END MILL RE-SHARPENER

(EASY FAST PRECISION)

EARTH-CHAIN ENTERPRISE Co.,Ltd.

43546551() No.551, Sec, 1, Gangbu Rd., Wu-Chi, Taichung 43546, Taiwan

Tel:+886-4-2630-3737 Fax:+886-4-2630-3636 E-mail:ece.richard@msa.hinet.net

www. eart h- chai n. com. t w

OUR OTHER PRODUCTS SYSTEM

magnetIc products omer that morks.

EEPM-TA EEPM-SL

EEPM-V2 EEPM-CIRS EEPM-CIRR

EEPM-V4 EEPM-CIT2F EEPM-CIT4F

-

Electro-Permanent Magnetic Chuck-Workholder System

magnetIc products omer that morks.

MagVise Clamping System

magnetIc products omer that morks.

MagVise Clamping System

magnetIc products omer that morks.

!

EEPM-IT Series

Can do 5 side machining in traditional Milling Machine

Electro-Permanent Magnetic Index Table

magnetIc products omer that morks.

Universal Arm Indicator Stand

magnetIc products omer that morks.

Permanent Lifting Magnets

magnetIc products omer that morks.

EMG-1225

EMG-413

2, 3, 4

10 pcs ER

2 pcs

SDC (4mm-5mm) SDC (6mm-13mm)

2 pcs SDC ()

6 pcs ER

2 pcs

SDC (4mm-5mm)

2 pcs SDC

(4mm-13mm)

(12mm-25mm)

END MILL Re-sharpener

magnetIc products omer that morks.

2 1 3

4

Anda mungkin juga menyukai

- Krenov SawhorseDokumen4 halamanKrenov SawhorseNaomi Weiss92% (13)

- Solaredge Monitoring Portal User GuideDokumen23 halamanSolaredge Monitoring Portal User GuidethegoodpatriotBelum ada peringkat

- Operating Manual: ZAY7032FG ZAY7040FG ZAY7045FG Bench Milling&Drilling MachineDokumen23 halamanOperating Manual: ZAY7032FG ZAY7040FG ZAY7045FG Bench Milling&Drilling MachineLucas QuinteroBelum ada peringkat

- Work HoldingDokumen5 halamanWork HoldingBalvinder Uday BudaniaBelum ada peringkat

- Using Caterpillar Replacement Thread Inserts (0676) : Instrucción EspecialDokumen9 halamanUsing Caterpillar Replacement Thread Inserts (0676) : Instrucción EspecialMiguel Gutierrez50% (2)

- Catalogue Complet 2013 PDFDokumen591 halamanCatalogue Complet 2013 PDFvisibilart100% (1)

- Table of Contents Microscope ManualDokumen39 halamanTable of Contents Microscope ManualAgus Salim DarmaBelum ada peringkat

- Gun Drill Sharpening Fixture - LIT-079Dokumen2 halamanGun Drill Sharpening Fixture - LIT-079Ron Biggs100% (1)

- Veritas MkII Honing GuideDokumen12 halamanVeritas MkII Honing Guidejb71xxBelum ada peringkat

- 13 Tool Cutter GrinderDokumen26 halaman13 Tool Cutter GrinderAnonymous ITnkbIEFBelum ada peringkat

- C9 - GrindingDokumen7 halamanC9 - GrindingHans PinonBelum ada peringkat

- Workshop Manual: Department of Mechanical EngineeringDokumen82 halamanWorkshop Manual: Department of Mechanical Engineeringdoggie on streetBelum ada peringkat

- Lathe Alignment: by Tubal CainDokumen7 halamanLathe Alignment: by Tubal CainmarkschooleyBelum ada peringkat

- Engraving Tools Catalog: Quality Cutting Tools and Resharpening Service For The Engraving and Sign Making IndustriesDokumen8 halamanEngraving Tools Catalog: Quality Cutting Tools and Resharpening Service For The Engraving and Sign Making IndustriesCristian FuentesBelum ada peringkat

- Pc. Tap and Die Set: Operator'S ManualDokumen8 halamanPc. Tap and Die Set: Operator'S Manualvirk_70Belum ada peringkat

- Stacking Tool InstructionsDokumen8 halamanStacking Tool InstructionsSonia SantamaríaBelum ada peringkat

- Work Sharp Tool Sharpener WS2000Dokumen31 halamanWork Sharp Tool Sharpener WS2000ottuserBelum ada peringkat

- Radio Club G5RV Presentation 002Dokumen25 halamanRadio Club G5RV Presentation 002golf1rvdBelum ada peringkat

- Quansheng Uv k5 Two Way RadioDokumen12 halamanQuansheng Uv k5 Two Way Radioairbus75Belum ada peringkat

- NanoVNA-F V2 Quick Start Guide - For Firmware v0.1.0Dokumen1 halamanNanoVNA-F V2 Quick Start Guide - For Firmware v0.1.0Sasha PkhidenkoBelum ada peringkat

- Smart Cities: A Review On Electric Vehicles: Technologies and ChallengesDokumen33 halamanSmart Cities: A Review On Electric Vehicles: Technologies and ChallengesAhmad RabayaBelum ada peringkat

- Design of A Bearingless BLDC MotorDokumen6 halamanDesign of A Bearingless BLDC MotorTien Dung TranBelum ada peringkat

- Grinding Wheel Specification PDFDokumen17 halamanGrinding Wheel Specification PDFPENONVVBelum ada peringkat

- Spring Loaded GraverDokumen1 halamanSpring Loaded GraverGeo CpBelum ada peringkat

- Lesson 6 AntennaDokumen27 halamanLesson 6 AntennaShylaja HalageriBelum ada peringkat

- Olympus Microscope Maintenance Guide 2020Dokumen12 halamanOlympus Microscope Maintenance Guide 2020csc palakkuttyBelum ada peringkat

- Antennas & Their Associated PatternsDokumen45 halamanAntennas & Their Associated PatternsTrần Châu ThôngBelum ada peringkat

- Intellibox Basic Manual65060-01eDokumen68 halamanIntellibox Basic Manual65060-01eΝίκος ΜπούλιαρηςBelum ada peringkat

- Tips for Capturing High-Quality Digital Microscope ImagesDokumen4 halamanTips for Capturing High-Quality Digital Microscope ImagesAida LizethBelum ada peringkat

- NL Maritime News 31-May-13Dokumen5 halamanNL Maritime News 31-May-13vu2jabBelum ada peringkat

- Microscope: Greek Instrument Microscopy MicroscopicDokumen9 halamanMicroscope: Greek Instrument Microscopy MicroscopicBrian Lester Llanos DeeBelum ada peringkat

- Chapter 2-5 Peatland Rhizopods: Peatlands Taxa: SphagnumDokumen22 halamanChapter 2-5 Peatland Rhizopods: Peatlands Taxa: SphagnumJose Facundo Ortega OrizBelum ada peringkat

- Inverted microscope for cell culture observationDokumen7 halamanInverted microscope for cell culture observationRudra MouryaBelum ada peringkat

- Just Like Clockwork: A Clock Project ReportDokumen8 halamanJust Like Clockwork: A Clock Project Reportapi-421395581Belum ada peringkat

- Titanium DRILLINGDokumen50 halamanTitanium DRILLINGDome StoiBelum ada peringkat

- Sinowon 3D Video Measuring Machine VMM-P Operation ManualDokumen12 halamanSinowon 3D Video Measuring Machine VMM-P Operation ManualJohnny DaiBelum ada peringkat

- D STAR System IntroductionDokumen6 halamanD STAR System IntroductionRu RickjamesBelum ada peringkat

- Microscopic Measurements Laboratory Activity: Background InformationDokumen4 halamanMicroscopic Measurements Laboratory Activity: Background InformationPaige EvansBelum ada peringkat

- Comparison MicoscopeDokumen10 halamanComparison MicoscopeSwati V NairBelum ada peringkat

- Geometry and Types of Twist Drills and Drilling MachinesDokumen15 halamanGeometry and Types of Twist Drills and Drilling Machinesbest4reverBelum ada peringkat

- How To Use Micrometer On Microscopes: Biology 1Dokumen7 halamanHow To Use Micrometer On Microscopes: Biology 1Rakeesh VeeraBelum ada peringkat

- Micro precision grinding wheel types and tool sharpening anglesDokumen29 halamanMicro precision grinding wheel types and tool sharpening anglesAzmi MustafaBelum ada peringkat

- Spanners and WrenchesDokumen4 halamanSpanners and WrenchesYounes BarakaBelum ada peringkat

- The Swiss Watch Parts Distributors Catalog - September 2010Dokumen63 halamanThe Swiss Watch Parts Distributors Catalog - September 2010watchparts100% (1)

- DIN 69871 enDokumen69 halamanDIN 69871 enalphatoolsBelum ada peringkat

- Broaches - Basic CharacteristicDokumen5 halamanBroaches - Basic CharacteristicDhan CBelum ada peringkat

- Cowells Manuals PDFDokumen16 halamanCowells Manuals PDFpedjaBelum ada peringkat

- Pivot Replacement: ChecklistDokumen7 halamanPivot Replacement: Checklistottershaw57Belum ada peringkat

- Grinding WheelsDokumen26 halamanGrinding Wheelsznovak77Belum ada peringkat

- Christopher Jobson Clock RestorerDokumen2 halamanChristopher Jobson Clock RestorerTommy JobsonBelum ada peringkat

- Benchworking StudyDokumen100 halamanBenchworking StudyBrianRuaroBelum ada peringkat

- AO 820 Microtome PDFDokumen8 halamanAO 820 Microtome PDFalmutazimBelum ada peringkat

- 2016 Endmills and Drills Metric InchDokumen396 halaman2016 Endmills and Drills Metric InchyoungkyBelum ada peringkat

- Group: Preparations of Microscope SlidesDokumen16 halamanGroup: Preparations of Microscope SlidesNova Jane EdradBelum ada peringkat

- Power Tools For WatchmakersDokumen10 halamanPower Tools For Watchmakersshe56421gaBelum ada peringkat

- Four Facet Drill Grinding JigDokumen20 halamanFour Facet Drill Grinding Jigian_newBelum ada peringkat

- Turbine BladeDokumen27 halamanTurbine BladesrtanandBelum ada peringkat

- Indexing and Dividing Head OperationsDokumen55 halamanIndexing and Dividing Head OperationsShrinivas BhatBelum ada peringkat

- Lathe Accessories Price List: P/N Description WT Price P/N Description WT PriceDokumen2 halamanLathe Accessories Price List: P/N Description WT Price P/N Description WT PriceAnonymous hos8odBelum ada peringkat

- 90-1 Rotary Table GuideDokumen5 halaman90-1 Rotary Table GuidehdquanBelum ada peringkat

- Bench Milling Drilling Machine ManualDokumen22 halamanBench Milling Drilling Machine ManualAnonymous Cx74V6ntI80% (1)

- RaiseBoringUsersManual PDFDokumen40 halamanRaiseBoringUsersManual PDFJhonatanLiCuadradoBelum ada peringkat

- Raise Boring Heads: User ManualDokumen40 halamanRaise Boring Heads: User ManualMaykol Ken Hasaki MaselBelum ada peringkat

- 21 Catalog Krisbow9 Wood Working RevisiDokumen8 halaman21 Catalog Krisbow9 Wood Working RevisiEnrique da MattaBelum ada peringkat

- Publication PDFDokumen244 halamanPublication PDF37thorBelum ada peringkat

- Chapter 22-Machining Operations IDokumen79 halamanChapter 22-Machining Operations Iasifayaz120Belum ada peringkat

- Lathe Modelling 2Dokumen2 halamanLathe Modelling 2cesargramcko100% (1)

- Carpentry ToolsDokumen2 halamanCarpentry ToolsJill Catherine CabanaBelum ada peringkat

- ShopNotes #01 (Vol. 01) - Shop Built Router Table - TextDokumen38 halamanShopNotes #01 (Vol. 01) - Shop Built Router Table - TextJustin SBelum ada peringkat

- (INGCO) 17 April 2023 Stock ReportDokumen16 halaman(INGCO) 17 April 2023 Stock ReportMandiri JayaBelum ada peringkat

- The Overnigth Cure)Dokumen68 halamanThe Overnigth Cure)RODOLFO FERNANDEZBelum ada peringkat

- Circular Saw Grinding Machines Complete RangeDokumen24 halamanCircular Saw Grinding Machines Complete RangeAttila PolacsekBelum ada peringkat

- Universiti Tun Hussein Onn Malaysia Centre For Diploma StudiesDokumen11 halamanUniversiti Tun Hussein Onn Malaysia Centre For Diploma StudiesMuhammad Hazeeq Hilman Bin RosliBelum ada peringkat

- Kids in the Shop: Shaker Step Stool BuildDokumen5 halamanKids in the Shop: Shaker Step Stool BuildwillBelum ada peringkat

- Miter Shooting BoardDokumen1 halamanMiter Shooting BoardRod HyattBelum ada peringkat

- Features: TC-MS 2112 TDokumen2 halamanFeatures: TC-MS 2112 TAlain Alcázar GarcíaBelum ada peringkat

- Router Table Fence Building PlansDokumen11 halamanRouter Table Fence Building Plansleo100% (2)

- Third Quarter Lesson 2 - Classification of ToolsDokumen94 halamanThird Quarter Lesson 2 - Classification of ToolsNova GarciaBelum ada peringkat

- Tools Used in CarpentryDokumen7 halamanTools Used in CarpentryUstat kaurBelum ada peringkat

- Cutting A Bridle JointDokumen6 halamanCutting A Bridle JointMario BerronesBelum ada peringkat

- Granberg Precision Grinder G1012XT ManualDokumen2 halamanGranberg Precision Grinder G1012XT ManualAnonymous GtkD9AEJqeBelum ada peringkat

- Stock Gin Engineers April 2010Dokumen80 halamanStock Gin Engineers April 2010rachelibdBelum ada peringkat

- Making Window Sash F HB LekeDokumen6 halamanMaking Window Sash F HB LekeStephen Sutcliffe100% (1)

- Borehole Status.Dokumen7 halamanBorehole Status.deepak925Belum ada peringkat

- Making A Cross Match Punch: Tool Tip..Dokumen2 halamanMaking A Cross Match Punch: Tool Tip..Olindo D'AndreaBelum ada peringkat

- Machine Woodworking 1Dokumen4 halamanMachine Woodworking 1Kunbi Santos-ArinzeBelum ada peringkat

- KTA Spindle ToolingDokumen12 halamanKTA Spindle ToolingFelipe LipertBelum ada peringkat

- CFS - File 5-3-15Dokumen13 halamanCFS - File 5-3-15Andri aryanataBelum ada peringkat

- Opc Antena Kelompok 1 FixDokumen1 halamanOpc Antena Kelompok 1 FixChandra DesparajaBelum ada peringkat

- Woodworking Crafts February 2018Dokumen92 halamanWoodworking Crafts February 2018edgar velasco50% (2)