Confined Space Entry Procedure

Diunggah oleh

Nabeel NawazDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Confined Space Entry Procedure

Diunggah oleh

Nabeel NawazHak Cipta:

Format Tersedia

Prepared By: EFS

No.: 1 of 6 Effective Date: May, 2008 Envoy Facilitation Services (Pvt) Ltd.

Approved By:

Revision No.:

Safety, Health, and Environmental Procedures

Subject: CONFINED SPACE ENTRY PROCEDURE

1. PURPOSE

1.1

The purpose of this procedure is to provide specific instructions for safe confined space entry operations.

SCOPE

2.

2.1

This procedure is designed for Envoy Facilitation Services (Pvt) Ltd. employees and contractors whose job assignments require entering confined spaces.

RESPONSIBILITY

3.

3.1

Managers and Supervisors shall be responsible for ensuring compliance with the following procedures: 3.1.1 3.1.2 Appropriate selection concerning the use of a Company-Approved Competent Person for the job planned. Utilize a Qualified Individual to issue safe for entry permits. Any emergency exceptions to this section of the procedure shall be approved by the V.P. of Operations or his/her designated representative. 3.1.3 If an exemption to the procedure and/or work instructions is necessary, they shall approve such request ensuring that the work instructions, deviations, and exemptions are followed. Keep trained attendants on site during confined space entry, hot work, or gas-freeing activities. Ensure that individuals including contractors in the area are aware of the hazards and their responsibility to correct the hazards, and emergency procedures. Upon receipt of the Envoy Facilitation Services (Pvt) Ltd. Confined Space Entry Permit, sign his/her name to the permit to give authorization for work to be initiated. Ensure that the approved instrumentation, personal protective equipment (PPE), and operational equipment are available. Ensure employees and contract personnel understand how to notify the outside rescue service (local fire dept.) in the event of an emergency. Maintain records of Envoy Facilitation Services (Pvt) Ltd.s confined space entry permits for one year.

3.1.4 3.1.5 3.1.6

3.1.7 3.1.8 3.1.9

Safety and Environmental Procedures Subject: CONFINED SPACE ENTRY PROCEDURE

No.: Effective Date: Page: Revision No.:

2 of 6

3.1.10 Ensure that entrance openings are properly guarded to prevent an accidental fall.

3.2

Entry Attendant (Safety Watch) personnel shall: 3.2.1 3.2.2 3.2.3 3.2.4 3.2.5 Be assigned for each confined space entry. Receive training as a confined space attendant. Maintain and keep accurate account of those workers entering confined spaces. Perform no other duties that interfere with the attendants primary duties. Remain on site at the confined space area throughout the duration of the operation while the space is occupied or until the attendant is relieved properly.

3.3

Competent persons shall be: 3.3.1 3.3.2 3.3.3 3.3.4 3.3.5 3.3.6 Capable of recognizing hazards. Authorized to stop work, if such an action is warranted, and provide recommendations to supervisors. Trained as a competent person. They must also be trained in Envoy Facilitation Services (Pvt) Ltd.s Confined Space Entry Procedure. Approved as a competent person by the Safety Department. Given medical exams if exposed to carcinogens or highly toxic materials and waste on a routine basis. Required to complete the Envoy Facilitation Services (Pvt) Ltd. Confined Space Entry Permit, and/or Competent Person Log as appropriate.

3.4

The Qualified Individual shall: Any emergency exception to this section of the procedure shall be approved by the V.P. of Operations or his designated representative. 3.4.1 3.4.2 3.4.3 Have authority to stop work, if such action is warranted, and provide recommendations or requirements for supervision and re-inspection. Conduct all appropriate atmospheric testing to determine the confined space safe for entry. Ensure the appropriate systems are in place to ensure the confined space has a continuous safe environment.

3.5

The Safety Department shall develop and maintain the Confined Space Entry Procedure and maintain a current list of Envoy Facilitation Services (Pvt) Ltd.-approved competent persons. Contractor work in confined spaces

3.6

Safety and Environmental Procedures Subject: CONFINED SPACE ENTRY PROCEDURE

3.6.1

No.: Effective Date: Page: Revision No.:

3 of 6

All contractor and subcontractor employees who will enter Envoy Facilitation Services (Pvt) Ltd. equipment or jobsites/facilities to perform work in confined spaces shall be briefed on the hazards, safety rules and emergency procedures concerning those spaces.

4.

OBJECTIVE

4.1

The objective of this procedure is to identify areas of confined space hazards and provide guidelines and procedures for safe confined space entry operations.

PROCEDURE

5.

5.1

Permit-required confined spaces 5.1.1 The confined space shall be evaluated to determine if an entry permit is required. Spaces that require a permit are: 5.1.1.1 Tanks or void spaces of any kind that contain or have contained flammables, combustibles, or other chemicals. 5.1.1.2 Confined spaces where work activity will introduce flammables, combustibles, or other air contaminants, such as welding, painting, and grinding. 5.1.1.3 Confined spaces where there are mechanical hazards, such as machinery which has not been locked or tagged out. A confined space containing equipment that has been locked or tagged is not a permit-required confined space. 5.1.1.4 Storage tanks, silos, process vessels, or bins, except as noted below, adjacent to tanks that contain or have contained flammables, combustible liquids, or other toxic chemicals, shall be permit-required confined spaces. 5.1.1.5 If a space cannot be categorized in the above groups and there is any concern for safety, contact the Safety Department for assistance before entering the space. 5.1.1.6 For spaces that do not require an entry permit, see section 5.3. 5.1.2 5.1.3 A Qualified Individual must be assigned to each permit-required confined space entry and shall prepare the entry permit for that space. A Qualified Individual shall certify permit-required confined spaces as safe for entry. The Qualified Individual shall develop and post an entry permit. A competent person may perform the duties of a Qualified Individual when: 5.1.3.1 The entry is approved by the V.P. of Operations or their designated representative.

5.2

Confined Space Entry 5.2.1 All spaces shall be opened and ventilated via forced air or natural air flow and test for sufficient atmospheric oxygen levels prior to entry.

Safety and Environmental Procedures Subject: CONFINED SPACE ENTRY PROCEDURE

5.2.2

No.: Effective Date: Page: Revision No.:

4 of 6

Forced air ventilation of a confined space shall be maintained for a minimum of five (5) minutes before atmospheric testing is conducted, safe levels are confirmed, and entry is permitted. Natural ventilation of a confined space shall be maintained for a minimum of thirty (30) minutes before atmospheric testing is conducted and entry is permitted. Atmospheric testing shall be performed and documented at regular intervals to ensure safe levels of oxygen are maintained. Respiratory protection shall be made available and worn where required.

5.2.3 5.2.4 5.2.5 5.3

Non-permit confined spaces 5.3.1 There are many confined spaces where no mechanical or chemical hazard is present. There is, however, the remote possibility that oxygen deficiencies may occur. These spaces include but are not limited to mixer drums, plant mixers, and water tanks.

5.4

A pre-job safety meeting will be held with all Envoy Facilitation Services (Pvt) Ltd. and contractor personnel involved with the permit-required confined space entry.

RECORDS

6.

6.1 6.2 6.3 6.4

A copy shall be maintained at the jobsite/facility where the Confined Space Entry was made. Training records shall be maintained by Human Resources for three years. Medical records shall be maintained by the Safety Department indefinitely. Inspection records shall be maintained by managers for one year at the jobsite/facility where the Confined Space Entry was made.

FORMS

7.

7.1

8.

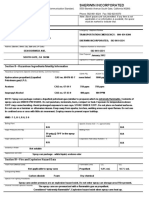

Confined Space Entry Permit

DEFINITIONS

8.1 8.2 8.3

Adjacent space - A space which borders a confined space in all directions, including all points of contact, corners, diagonals, decks, tank tops, and bulkheads. Certified marine chemist - A person possessing a current marine chemist permit issued by the National Fire Protection Association. Confined spaces - Enclosed spaces that are large enough that an employee can enter and perform assigned work, have limited means of egress, and that are not intended for continuous occupation. 8.3.1 Confined spaces are further classified as permit-required and non-permit required. Air monitoring must be performed to determine if the confined space is a permit or non-permit required confined space. For a permit-required confined space, one or more of the following apply:

Safety and Environmental Procedures Subject: CONFINED SPACE ENTRY PROCEDURE

No.: Effective Date: Page: Revision No.:

5 of 6

8.3.1.1 Flammable gas, vapors, or mist are present (LEL). 8.3.1.2 The atmospheric oxygen (O2) concentration is less than 19.5%. 8.3.1.3 Other toxic chemicals are present.

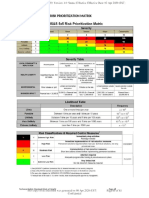

Table 1: Types of Confined Spaces and Requirements for Entry

Type of Tank Condition and/or Operations Tanks with flammables or other chemical hazards. Tanks or spaces without flammables, chemical, or mechanical hazards. Plant Mixer, Mixer Drums, water tanks Hot work inside within confined space Hot work (outside of confined spaces) Permit Yes No (b) No Yes Yes Qual. Individual Yes (a) Yes (c) Yes (d) Yes (a) Yes (a) Competent Person No No Yes No No

(a) (b) (c)

Only qualified individuals can issue an entry or hot work permit. If a qualified individual is not reasonably available, a company-approved competent person may be used. Whether such confined spaces require a permit depends upon the testing results. If the test results indicate that the space is a permit required space, a qualified individual should be called in, if possible, to issue the permit. At the direction of the manager or supervisor, these confined spaces shall be opened and "forced air" ventilated, and an entry attendant shall be assigned to the spaces prior to entry. Air monitoring shall be performed by a company-approved competent person prior to entry.

(d)

8.4

Company-approved competent person (CACP) - A person capable of recognizing and evaluating employee exposure to hazardous substances or unsafe conditions. The individual has satisfactorily completed the confined space entry training class and accompanying examination, and records have been completed for the individual and transmitted to the Safety Department. These competent persons are approved by the President, Vice President of Operations, Operations Manager, and/or Safety Officer. Cold work - Any construction, alteration or repairs that does not involve heat, fire, or sparkproducing operations. Dangerous atmosphere - An atmosphere which may expose employees to the risk of death, incapacitation, impairment of the ability to self-rescue, injury, or acute illness.

8.5 8.6

Safety and Environmental Procedures Subject: CONFINED SPACE ENTRY PROCEDURE

8.7

No.: Effective Date: Page: Revision No.:

6 of 6

Entry - An action by which a person passes through an opening into a space. Entry is considered to have occurred as soon as any part of the entrant's body breaks the plane of an opening into the space. Entry with restrictions - Entry is permitted only if engineering controls, PPE, clothing, and time limitations are specified on the permit by the certified marine chemist (not an OSHA or WISHA requirement to have certified marine chemist create permit) (hot and cold work). Hazardous substance - A substance which, by reason of being explosive, flammable, poisonous, corrosive, oxidizing, irritating or otherwise harmful, is likely to cause injury. Hot work - Any work which may produce or require flame, spark, or sufficient heat to cause auto-ignition. Examples include burning, welding, riveting, cutting, drilling, sanding, abrasive blasting, and space heating. Hot work entry permits are required. Lower explosive limit (LEL) - The minimum vapor concentration of a combustible gas or vapor in air which will ignite if an ignition source is present. The term minimum explosive concentration (MEC) is used for dusts. Not safe for workers - Denotes a space where an employee may not enter because conditions do not meet safe for workers conditions. Outside Rescue Team - The local fire department which provides service to Envoy Facilitation Services (Pvt) Ltd. equipment and/or jobsites/facilities in that area. Qualified tester - An employee who inspects and tests permit-required confined spaces prior to entry. Safe for workers - Denotes a space meeting the following requirements: 8.15.1 The oxygen content of the atmosphere is between 19.5% and 22%. 8.15.2 The concentration of flammable vapors is below 10% of the LEL. 8.15.3 Toxic materials in the atmosphere are below their respective PEL. 8.15.4 Any residues or work materials will not produce uncontrolled releases of toxic materials under existing conditions while maintained as directed.

8.8

8.9 8.10

8.11

8.12 8.13 8.14 8.15

8.16

Safe for hot work - Denotes a space in which the following conditions are met: 8.16.1 The oxygen content in the atmosphere does not exceed 22% by volume. 8.16.2 The concentration of flammable vapors in the atmosphere is less than 10% of the LEL. 8.16.3 Any residue in the space is not capable of producing an oxygen concentration in the atmosphere greater than 22% or a flammable vapor concentration greater than 10% of the LEL under existing conditions in the presence of hot work and as maintained by the Permit. 8.16.4 All adjacent spaces have been cleaned, inerted, or treated sufficiently to prevent the spread of fire.

Anda mungkin juga menyukai

- Truck, Load Handling System (LHS), W and W/O Winch, 8X8 M1120A4 NSN 2320-01-534-1872 (EIC BG7)Dokumen1.368 halamanTruck, Load Handling System (LHS), W and W/O Winch, 8X8 M1120A4 NSN 2320-01-534-1872 (EIC BG7)won kimBelum ada peringkat

- UJF-3042 Series - 6042MKII Series Maintenance Manual D501202 Ver.4.20Dokumen368 halamanUJF-3042 Series - 6042MKII Series Maintenance Manual D501202 Ver.4.20AleksandarBelum ada peringkat

- Hydro Blasting 3Dokumen6 halamanHydro Blasting 3Robinson Ysasis100% (1)

- Cms 710 01 PR 03600 Substance Abuse ProgramDokumen8 halamanCms 710 01 PR 03600 Substance Abuse Programandruta1978Belum ada peringkat

- Method Statement DPE GL1 Cooling Water Line CleaningDokumen15 halamanMethod Statement DPE GL1 Cooling Water Line CleaningDheeraj Chowdary DhanekulaBelum ada peringkat

- Guidelines in Electrical and Electronic Equipment Brand SelectionDokumen4 halamanGuidelines in Electrical and Electronic Equipment Brand SelectionJun Gonzales007Belum ada peringkat

- 059 Vacuum Truck SafetyDokumen6 halaman059 Vacuum Truck Safetyichal_zaidanBelum ada peringkat

- Copy of JSA For Cathodic Protection For Oily Water LineDokumen6 halamanCopy of JSA For Cathodic Protection For Oily Water LineMohammed Minhaj80% (5)

- Job Safety Analysis: Work Sequence Potential Hazards Recommended Action / Control MeasuresDokumen3 halamanJob Safety Analysis: Work Sequence Potential Hazards Recommended Action / Control Measuresmuhammad imtiaz100% (1)

- JSA For Manual Excavation Inside The Operation Area (Access Road)Dokumen6 halamanJSA For Manual Excavation Inside The Operation Area (Access Road)Mohammed MinhajBelum ada peringkat

- Cold Work PermitDokumen11 halamanCold Work PermitMuneeb Ur Rehman100% (1)

- JSA For Erection Modification QSTECDokumen7 halamanJSA For Erection Modification QSTECMohamed NouzerBelum ada peringkat

- Permit To Work ProceduresDokumen3 halamanPermit To Work ProceduresREBAA HatemBelum ada peringkat

- JSA For Pressure Test 2ND REVISIONDokumen10 halamanJSA For Pressure Test 2ND REVISIONMuthu AlaguRaj100% (1)

- Fall PreventionsDokumen16 halamanFall PreventionsRajesh gp100% (1)

- JHA Vessel EntryDokumen2 halamanJHA Vessel EntryRiyadh SalehBelum ada peringkat

- Hot Work Activities (Cutting)Dokumen9 halamanHot Work Activities (Cutting)Al Mughsar CompanyBelum ada peringkat

- Step Activity Potential Hazards Hazard Controls NoDokumen2 halamanStep Activity Potential Hazards Hazard Controls NoKazeneza BMBelum ada peringkat

- JHA M&F ToiletDokumen3 halamanJHA M&F ToiletBala Subra ManiamBelum ada peringkat

- Emergency Response and Contingency PlanDokumen21 halamanEmergency Response and Contingency PlanKarimo KilaniBelum ada peringkat

- Jha Confined SpaceDokumen6 halamanJha Confined SpaceArun ArunbolluBelum ada peringkat

- K013 REDA Heat Stress Plan Rev-03Dokumen18 halamanK013 REDA Heat Stress Plan Rev-03muhammadBelum ada peringkat

- Confined Space Hazard Evaluation Survey FormDokumen2 halamanConfined Space Hazard Evaluation Survey FormEdward100% (1)

- 0002 Rev 00 Jsa TR Seg Piping ErectionDokumen11 halaman0002 Rev 00 Jsa TR Seg Piping ErectionJayvee Baradas ValdezBelum ada peringkat

- Working at Height Rescue Plan: WHS-FM-008Dokumen2 halamanWorking at Height Rescue Plan: WHS-FM-008Purwo PrihartonoBelum ada peringkat

- Building De-Dusting JSADokumen3 halamanBuilding De-Dusting JSAJayesh J PillaiBelum ada peringkat

- Safe Work Method StatementDokumen2 halamanSafe Work Method StatementFrank Barnes100% (1)

- 09 JSA For Excavation and Blinding at Pump House 1 & 3Dokumen4 halaman09 JSA For Excavation and Blinding at Pump House 1 & 3Hilbrecht De Pedro100% (1)

- OB Afety NalysisDokumen5 halamanOB Afety NalysisNaveed WarraichBelum ada peringkat

- Site Specific Safety OrientationDokumen39 halamanSite Specific Safety OrientationBernard AmooBelum ada peringkat

- Working at Height Is One of The Hazardous OccupationsDokumen6 halamanWorking at Height Is One of The Hazardous OccupationsHemaBelum ada peringkat

- Scaffold CampaignDokumen9 halamanScaffold CampaignAdel SukerBelum ada peringkat

- Example JSA Job Safety AnalysisDokumen13 halamanExample JSA Job Safety AnalysisSiti MaisarahBelum ada peringkat

- Lock Out ProgramDokumen6 halamanLock Out Programsimson100% (1)

- Working at Height Rescue PlanDokumen1 halamanWorking at Height Rescue PlanAbbas AsadBelum ada peringkat

- JSA For Hydrojetting (Gun With Rigid Lance) at Jetting YardDokumen23 halamanJSA For Hydrojetting (Gun With Rigid Lance) at Jetting YardSHAH NAWAZ SAEEDBelum ada peringkat

- Jsa Bearing Replacement-OverhaulingDokumen2 halamanJsa Bearing Replacement-Overhaulingashish engineeringBelum ada peringkat

- Confined Space Entry PlansDokumen6 halamanConfined Space Entry Plansrichard100% (1)

- Ra02 - Container OffloadingDokumen3 halamanRa02 - Container OffloadingSamBelum ada peringkat

- Jsa For Choke Valve InstallationDokumen9 halamanJsa For Choke Valve InstallationjavithBelum ada peringkat

- Jsa Insulation WorkDokumen20 halamanJsa Insulation WorkazerBelum ada peringkat

- Spill Kit HandlingDokumen2 halamanSpill Kit HandlingHanan SarwarBelum ada peringkat

- Inspection Form Lockout TagoutDokumen4 halamanInspection Form Lockout TagoutCarina Kouamé100% (1)

- Confined SpaceDokumen7 halamanConfined SpacearajanchabhadBelum ada peringkat

- General Crane Operations and LiftingDokumen2 halamanGeneral Crane Operations and LiftingAhmedAmer1Belum ada peringkat

- Job Safety Analysis and Risk AssessmentDokumen9 halamanJob Safety Analysis and Risk AssessmentWK PangBelum ada peringkat

- HSEP 13 8 A1 Fall Prevention System Requirement Rev 5Dokumen5 halamanHSEP 13 8 A1 Fall Prevention System Requirement Rev 5mojgfdBelum ada peringkat

- Control Subtances Hazardous HealthDokumen8 halamanControl Subtances Hazardous HealthrslapenaBelum ada peringkat

- JHA For Positive IsolationDokumen1 halamanJHA For Positive IsolationShahid RazaBelum ada peringkat

- Confined SpaceDokumen16 halamanConfined SpaceAbdul Moeed KalsonBelum ada peringkat

- JSA For Road BarrierDokumen3 halamanJSA For Road BarrierMohammed MinhajBelum ada peringkat

- Caretaker Risk Assessment - Working at HeightDokumen8 halamanCaretaker Risk Assessment - Working at HeightLina MarcelaBelum ada peringkat

- Confined Space Entry ProcedureDokumen4 halamanConfined Space Entry Procedurerpsh90100% (1)

- Job Safety Analysis - Clinker StorageDokumen4 halamanJob Safety Analysis - Clinker StorageMohammed MinhajBelum ada peringkat

- Cold Cutting PDFDokumen9 halamanCold Cutting PDFAshraf BottaniBelum ada peringkat

- Scaffolding, Bolting Work & Working at Height at Security Building Area For Vehicle Parking ShedDokumen3 halamanScaffolding, Bolting Work & Working at Height at Security Building Area For Vehicle Parking ShedkrishnakumarBelum ada peringkat

- Confined-Space Rescue Plan 2Dokumen17 halamanConfined-Space Rescue Plan 2patrick ruwona100% (1)

- 008 JSA - Manual BoringDokumen3 halaman008 JSA - Manual BoringMohammed MinhajBelum ada peringkat

- DCL (Logo) : Hand BookDokumen16 halamanDCL (Logo) : Hand BookJahangir ShaBelum ada peringkat

- NFP0011A - Ground Disturbance ProcedureDokumen40 halamanNFP0011A - Ground Disturbance ProcedureWajdi MansourBelum ada peringkat

- IGC 1 Element 1Dokumen7 halamanIGC 1 Element 1Emmanuel ClarosBelum ada peringkat

- Confined Space ProcedureDokumen16 halamanConfined Space ProcedureRey Gaballo Jr67% (3)

- Confined Space Procedure: Last Updated: 25 June 2018Dokumen5 halamanConfined Space Procedure: Last Updated: 25 June 2018Ahmed FodaBelum ada peringkat

- Greenex Aerosol MSDSDokumen7 halamanGreenex Aerosol MSDSrkssBelum ada peringkat

- MSDS Demulsifier 334 (CL-344-L 2017) Rev 1Dokumen5 halamanMSDS Demulsifier 334 (CL-344-L 2017) Rev 1dwi ari wBelum ada peringkat

- JOB Performer: Q .1: What Is Permit?Dokumen5 halamanJOB Performer: Q .1: What Is Permit?Shahid BhattiBelum ada peringkat

- The Building and Planning Laws: Group 3Dokumen50 halamanThe Building and Planning Laws: Group 3Nesly MasarateBelum ada peringkat

- GP 24-21-Fire Hazard AnalysisDokumen46 halamanGP 24-21-Fire Hazard AnalysisErin Brady100% (1)

- Service Manual: ForewordDokumen1.324 halamanService Manual: ForewordredBelum ada peringkat

- Shops & Studio Safety Inspection Checklist: University of California, San Diego Environment, Health & SafetyDokumen6 halamanShops & Studio Safety Inspection Checklist: University of California, San Diego Environment, Health & SafetyMohamedBelum ada peringkat

- Dust Explosion Hazard AssessmentDokumen9 halamanDust Explosion Hazard AssessmentCarlos JiménezBelum ada peringkat

- Catalog Mercmaster Led Generation 3 Series Luminaires Appleton en 1732154Dokumen23 halamanCatalog Mercmaster Led Generation 3 Series Luminaires Appleton en 1732154Giuliano David Bozzo MoncadaBelum ada peringkat

- DDC Construction Safety and Health ProgramDokumen17 halamanDDC Construction Safety and Health ProgramRino BonhocBelum ada peringkat

- Refrigerator: User ManualDokumen84 halamanRefrigerator: User ManualMariana PascalauBelum ada peringkat

- Combustible Dust Report PDFDokumen37 halamanCombustible Dust Report PDFS NileshBelum ada peringkat

- BLH-SFY-Brochure V6Dokumen12 halamanBLH-SFY-Brochure V6ANDREYBelum ada peringkat

- 4F Risk and Vulnerability Checklist Rev00 070919Dokumen2 halaman4F Risk and Vulnerability Checklist Rev00 070919Matt OniaBelum ada peringkat

- D-106 (MSDS) Spray CanDokumen2 halamanD-106 (MSDS) Spray CanPubcrawlBelum ada peringkat

- Material Safety Data SheetDokumen6 halamanMaterial Safety Data Sheetonna25Belum ada peringkat

- Battery - MSDS - Stryten EnergyDokumen8 halamanBattery - MSDS - Stryten EnergyivanrrsistemasBelum ada peringkat

- Product Safety Data Sheet: 52820 Master FormDokumen4 halamanProduct Safety Data Sheet: 52820 Master FormIn liongBelum ada peringkat

- D92 PDFDokumen8 halamanD92 PDFJuan Diego ArizabalBelum ada peringkat

- PD 881Dokumen26 halamanPD 881OdyBelum ada peringkat

- Be Prepared With Lutz: Safety Is Our ConcernDokumen16 halamanBe Prepared With Lutz: Safety Is Our ConcernJhonatan QuispeBelum ada peringkat

- GGRS - RA6969Updates - JUNE 2019Dokumen96 halamanGGRS - RA6969Updates - JUNE 2019Geri-Geronimo Romero SañezBelum ada peringkat

- Omex Cat NewDokumen28 halamanOmex Cat Newbharatihk100% (1)

- Nobla enDokumen9 halamanNobla enFitri ElizabethBelum ada peringkat

- Seacare Osd-2 25 LTR MSDSDokumen11 halamanSeacare Osd-2 25 LTR MSDSMK AbouelsoudBelum ada peringkat

- D155a-5 Op PDFDokumen257 halamanD155a-5 Op PDFН.Б.Д НакBelum ada peringkat

- Fichas - Kixx HD1 CI-4 E7 15W-40 MSDSDokumen11 halamanFichas - Kixx HD1 CI-4 E7 15W-40 MSDSALEXIS SANCHEZBelum ada peringkat