Machine Tool Engineering Syllabus

Diunggah oleh

sahasanHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Machine Tool Engineering Syllabus

Diunggah oleh

sahasanHak Cipta:

Format Tersedia

WITH EFFECT FROM THE ACADEMIC YEAR 2008-2009

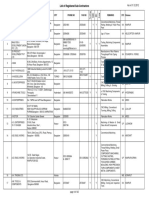

MP 303 MACHINE TOOL ENGINEERING Instruction Duration of University Examination University Examination Sessional 4 3 75 25 Periods per week Hours Marks Marks

UNIT-IV Drilling Machines: Types and constructional features, purpose and the field of application. Boring Machines: Types and constructional features, Milling machines: Classification and types, various operations on milling machines, up and down, milling. Types of milling cutters and bars. Dividing head and its application, single and differential indexing. Gear cutting machine: Methods of gear cutting, Types and classification gear hobbing and gear shaping machines, Bevel gear cutting. UNIT-V Shaping, Planning & Slotting Machines: Types, Constructional features, Types of work done on it. Quick return motion, manipulation of cutting speeds and feeds, work and tool holding devices, comparison of these machines. Grinding machines: Types, Classification. Abrasives and bonds used for grinding wheel, Selection of grinding wheel. Suggested Reading: 1. P.N.Rao Manufacturing Technology (Metal Cutting & Machine Tools), Tata McGraw Hill Book Company. 2. B.I. Juneja and Shekon, Fundamentals of Metal Cutting & Machines Tools, Wiley Eastern Ltd., 1987. 3. M.C.Shaw, Metal Cutting Principles, Clarendon Press, Oxford, 1984. 4. Hazara Choudary, Workshop Technology, Vol. II, Media Publ. New Delhi.

UNIT-I Orthogonal and oblique cutting: Cutting forces in turning, drilling, milling and grinding. Merchants analysis, Shear angle, friction angles. Experimental methods for estimation of shear angle, cutting forces and power of chips. Built up edge phenomena and its effects. Chip breakers. Sources of heat, its distribution and measurement. Different types of cutting fluids. UNIT-II Tool wear and tool life: Criteria for tool wear, flank and crater wear theories, criteria for tool life in roughing and finishing, Measurement of tool wear, Taylors tool life equation, factors effecting tool life, Machinability. Single point cutting tool design: Geometry, tool nomenclature, American, DIN, max. rake system. Interrelation between normal rake and orthogonal rake, tool signature, effect of basic tool angles on its performance. Selection of size and angles of S.I.Tools, form tools. Design feature of multi point cutting tools. UNIT-III Outline of cutting forces involved and kinematic scheme for each type of machine tool. Lathe: Types of constructional features, size of lathe, various operations that can be performed on lathe. Capstan and Turret lathes, Bar work and chunk work and tool holding devices, tool layout for typical jobs on capstan and turret lathes. Automatic and Semi Automatic Lathes: Purpose of automats and semi automats, cam drives and their types, single and multispindle automats, cycle time calculations, cam design thread production: Taps and dies, chaser, thread rolling and thread cutting machines.

OLD SYLLABUS

WITH EFFECT FROM THE ACADEMIC YEAR 2008-2009

MP 303 MACHINE TOOL ENGINEERING Instruction Duration of University Examination University Examination Sessional 4 3 75 25 Periods per week Hours Marks Marks

Boring Machines: Types and constructional features, Milling machines: Classification and types, various operations on milling machines, up and down, milling. Types of milling cutters and bars. Dividing head and its application, single and differential indexing. Gear cutting machine: Methods of gear cutting, Types and classification gear hobbing and gear shaping machines, Bevel gear cutting. UNIT-V Shaping, Planning & Slotting Machines: Types, Constructional features, Types of work done on it. Quick return motion, manipulation of cutting speeds and feeds, work and tool holding devices, comparison of these machines. Grinding machines: Types, Classification. Abrasives and bonds used for grinding wheel, Selection of grinding wheel. Suggested Reading: 1. P.N.Rao Manufacturing Technology (Metal Cutting & Machine Tools), Tata McGraw Hill Book Company. 2. B.I. Juneja and Shekon, Fundamentals of Metal Cutting & Machines Tools, Wiley Eastern Ltd., 1987. 3. M.C.Shaw, Metal Cutting Principles, Clarendon Press, Oxford, 1984. 4. Hazara Choudary, Workshop Technology, Vol. II, Media Publ. New Delhi.

UNIT-I Orthogonal and oblique cutting: Cutting forces in turning, drilling, milling and grinding. Merchants analysis, Shear angle, friction angles. Experimental methods for estimation of shear angle, cutting forces and power of chips. Built up edge phenomena and its effects. Chip breakers. Sources of heat, its distribution and measurement. Different types of cutting fluids. UNIT-II Tool wear and tool life: Criteria for tool wear, flank and crater wear theories, criteria for tool life in roughing and finishing, Measurement of tool wear, Taylors tool life equation, factors effecting tool life, Machinability. Single point cutting tool design: Geometry, tool nomenclature, American, DIN, max. rake system. Interrelation between normal rake and orthogonal rake, tool signature, effect of basic tool angles on its performance. Selection of size and angles of S.I.Tools, form tools. Design feature of multi point cutting tools. UNIT-III Outline of cutting forces involved and kinematic scheme for each type of machine tool. Lathe: Types of constructional features, size of lathe, various operations that can be performed on lathe. Capstan and Turret lathes, Bar work and chunk work and tool holding devices, thread production: Taps and dies, chaser, thread rolling and thread cutting machines. Drilling Machines: Types and constructional features, purpose and the field of application. UNIT-IV

PROPOSED SYLLABUS

Anda mungkin juga menyukai

- Machining Processes SyllabusDokumen2 halamanMachining Processes SyllabusshailkhanBelum ada peringkat

- Manufacturing Process SyllabusDokumen3 halamanManufacturing Process SyllabusRohit KumarBelum ada peringkat

- Metal Cuuting SyllabusDokumen1 halamanMetal Cuuting SyllabusAnonymous wrSPc7Bh05Belum ada peringkat

- Production TechnologyDokumen1 halamanProduction TechnologyBhavesh PipaliyaBelum ada peringkat

- Lesson Plan mp2Dokumen2 halamanLesson Plan mp2Saravanan RajendranBelum ada peringkat

- Manufacturing ProcessDokumen1 halamanManufacturing ProcessRonald Reagon20% (5)

- Manufacturing Processes - IDokumen2 halamanManufacturing Processes - Isameer_m_daniBelum ada peringkat

- JNTUK METAL CUTTING & MACHINE TOOLSDokumen2 halamanJNTUK METAL CUTTING & MACHINE TOOLSsanyasirao1Belum ada peringkat

- MCMT SyllabusDokumen3 halamanMCMT SyllabusshahazadBelum ada peringkat

- Design of Press Tools and Metal JoiningDokumen1 halamanDesign of Press Tools and Metal JoiningAdel AwnBelum ada peringkat

- Mechanical Engineering Lesson on Manufacturing TechnologyDokumen143 halamanMechanical Engineering Lesson on Manufacturing TechnologySATYAJIT BEHERABelum ada peringkat

- Syllabus For Foremen Gr. IIDokumen4 halamanSyllabus For Foremen Gr. IIMohammed AseerBelum ada peringkat

- Theory of Metal CuttingDokumen2 halamanTheory of Metal CuttingRakesh KumarBelum ada peringkat

- Metal Cutting & Machine ToolsDokumen1 halamanMetal Cutting & Machine Toolskela nBelum ada peringkat

- Metal CuttingDokumen1 halamanMetal Cuttingkela nBelum ada peringkat

- Machining Process SyllabusDokumen2 halamanMachining Process SyllabusRahul PatilBelum ada peringkat

- ProductionDokumen78 halamanProductionsreerag786Belum ada peringkat

- Mec445:Tool Design: Course ObjectivesDokumen1 halamanMec445:Tool Design: Course ObjectivesSunil SharmaBelum ada peringkat

- DETAILS OF PROGRAMME NO. 15/2011 (DECEMBER 2011Dokumen7 halamanDETAILS OF PROGRAMME NO. 15/2011 (DECEMBER 2011Ganesh MalayathBelum ada peringkat

- Manufacturing EngineeringDokumen3 halamanManufacturing EngineeringRavichandran GBelum ada peringkat

- Syllabus PDTDDokumen12 halamanSyllabus PDTDrajeshBelum ada peringkat

- MFT-2 .Two Marks With KeyDokumen13 halamanMFT-2 .Two Marks With KeySujith KumarBelum ada peringkat

- Manufacturing Process Lab IiiDokumen5 halamanManufacturing Process Lab IiiMuhammad Bilal SahiBelum ada peringkat

- Theory of Metal Cutting KTU SyllabusDokumen3 halamanTheory of Metal Cutting KTU SyllabusAron PanickerBelum ada peringkat

- Manufacturing Engineering - IIDokumen3 halamanManufacturing Engineering - IIPradip PatelBelum ada peringkat

- B.Tech. Mechanical Engineering, Third Year (6 Semester) : Sr. No. Course No. Subject L T P Hours CreditsDokumen11 halamanB.Tech. Mechanical Engineering, Third Year (6 Semester) : Sr. No. Course No. Subject L T P Hours CreditsAnkesh KapilBelum ada peringkat

- METAL CUTTING TOOL DESIGN COURSEDokumen3 halamanMETAL CUTTING TOOL DESIGN COURSEHemanth YadaBelum ada peringkat

- Metal CuttingDokumen33 halamanMetal CuttingUjjwal Katiyar100% (1)

- Machine Tools Lecture Notes-III-iDokumen74 halamanMachine Tools Lecture Notes-III-iJitendra Choudhary100% (1)

- Machine ToolsDokumen238 halamanMachine ToolsSeban AugustineBelum ada peringkat

- Syllabus For The Trade of Fitter: First Semester (Semester Code No. FTR - 01) Duration: Six Month Week Trade Theory NoDokumen8 halamanSyllabus For The Trade of Fitter: First Semester (Semester Code No. FTR - 01) Duration: Six Month Week Trade Theory NosidBelum ada peringkat

- Manufacturing Processes GuideDokumen22 halamanManufacturing Processes GuideMeer UmarBelum ada peringkat

- Tool & Die Making CoursesDokumen4 halamanTool & Die Making CoursesLoveofyouth ReddyBelum ada peringkat

- Theory of Metal CuttingDokumen237 halamanTheory of Metal CuttingnallsrajjBelum ada peringkat

- Department of Mechanical Engineering: (ACADEMIC YEAR: 2020-2021)Dokumen258 halamanDepartment of Mechanical Engineering: (ACADEMIC YEAR: 2020-2021)siddhxnt2004Belum ada peringkat

- Gujarat Technological University: Mechanical Engineering (19) SUBJECT CODE: 2161909Dokumen3 halamanGujarat Technological University: Mechanical Engineering (19) SUBJECT CODE: 2161909ShahinBelum ada peringkat

- SyllabusDokumen2 halamanSyllabuselavarasansivaBelum ada peringkat

- SPR 1301Dokumen337 halamanSPR 1301benellirider82Belum ada peringkat

- ProdDokumen9 halamanProdapi-236544093Belum ada peringkat

- Mahendra Covered TopicDokumen26 halamanMahendra Covered TopicMahendra SinghBelum ada peringkat

- Materials and MachiningDokumen116 halamanMaterials and MachiningGian RemundiniBelum ada peringkat

- Manufacturing ProcessesDokumen2 halamanManufacturing ProcessespmagrawalBelum ada peringkat

- Machine Tools Progress ReportDokumen3 halamanMachine Tools Progress Report113314Belum ada peringkat

- Aim: Study of Single Point Cutting ToolDokumen3 halamanAim: Study of Single Point Cutting Toolshailkhanna1Belum ada peringkat

- Production Technology SyllabusDokumen9 halamanProduction Technology SyllabusPankaj SharmaBelum ada peringkat

- Manufacturing Technology NotesDokumen97 halamanManufacturing Technology Notesswap1983Belum ada peringkat

- Manufacturing Technology 2Dokumen2 halamanManufacturing Technology 2msloveindia0% (2)

- Manufacturing Engineering - IDokumen3 halamanManufacturing Engineering - Ias2faasbujsacBelum ada peringkat

- Manufacturing Technology-IIDokumen70 halamanManufacturing Technology-IISaideep GhimireBelum ada peringkat

- Manufacturing Engineering IIDokumen237 halamanManufacturing Engineering IISakinala ShivaBelum ada peringkat

- Teaching Plan For - Tool Engineering T E (Mechanical) Mechanical Engineering DepartmentDokumen3 halamanTeaching Plan For - Tool Engineering T E (Mechanical) Mechanical Engineering DepartmentpatilsspBelum ada peringkat

- Machining Science: Prof. Sounak Kumar Choudhury Type of Course: Course Duration: Exam Date: 29 Mar 2020Dokumen1 halamanMachining Science: Prof. Sounak Kumar Choudhury Type of Course: Course Duration: Exam Date: 29 Mar 2020Abhishek kumarBelum ada peringkat

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionDari EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionBelum ada peringkat

- Production Technology PDFDokumen2 halamanProduction Technology PDFRamana Kumar NarsipuramBelum ada peringkat

- Traditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingDari EverandTraditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingPenilaian: 5 dari 5 bintang5/5 (2)

- Production Engineering: Jig and Tool DesignDari EverandProduction Engineering: Jig and Tool DesignPenilaian: 4 dari 5 bintang4/5 (9)

- Drop Forging, Die Sinking and Machine Forming of Steel - Modern Shop Practice, Processes, Methods, Machines, Tools and DetailsDari EverandDrop Forging, Die Sinking and Machine Forming of Steel - Modern Shop Practice, Processes, Methods, Machines, Tools and DetailsPenilaian: 5 dari 5 bintang5/5 (1)

- Sigmatube 2Dokumen2 halamanSigmatube 2Burak Mücahit YeşiltaşBelum ada peringkat

- HAL Approved Vendors PDFDokumen142 halamanHAL Approved Vendors PDFwinmanjuBelum ada peringkat

- Sheet Metal Solutions - Automating the Design ProcessDokumen16 halamanSheet Metal Solutions - Automating the Design Processrolo6945100% (1)

- Surfcam v5 Whats NewDokumen17 halamanSurfcam v5 Whats Newnnn764Belum ada peringkat

- Mastercam - X4 - Art Training TutorialDokumen28 halamanMastercam - X4 - Art Training TutorialRafael DonadioBelum ada peringkat

- CamDokumen52 halamanCamGaurav DabhekarBelum ada peringkat

- Machine Tool Design Chapter OneDokumen12 halamanMachine Tool Design Chapter Onedaggm100Belum ada peringkat

- Universidad Politecnica SalesianaDokumen4 halamanUniversidad Politecnica SalesianaDario LeicaBelum ada peringkat

- Mastercam Drilling Operations - MindworksDokumen6 halamanMastercam Drilling Operations - MindworksAntónio JesusBelum ada peringkat

- Investment Casting Design Guide PDFDokumen18 halamanInvestment Casting Design Guide PDFing_mancera100% (2)

- Electroformed Bond Hub Blades Improve Process StabilityDokumen2 halamanElectroformed Bond Hub Blades Improve Process StabilitybillalaxmanBelum ada peringkat

- Mastercam Lathe Lesson 6 CAMInstructorDokumen50 halamanMastercam Lathe Lesson 6 CAMInstructordanquinn24Belum ada peringkat

- Gv-2500 (Vtl-3200) Operation Manual 01verDokumen195 halamanGv-2500 (Vtl-3200) Operation Manual 01versunhuynhBelum ada peringkat

- Linkedin SIC Codes ListDokumen108 halamanLinkedin SIC Codes ListAnil Kumar GowdaBelum ada peringkat

- Mastercam2020 MillAdvanced TrainingTutorial SAMPLE PDFDokumen49 halamanMastercam2020 MillAdvanced TrainingTutorial SAMPLE PDFNguyen Van LyBelum ada peringkat

- User Manual of Ncstudio V15 Laser Cutting (LS3000) CNC Control System-R1Dokumen126 halamanUser Manual of Ncstudio V15 Laser Cutting (LS3000) CNC Control System-R1Ovidiu OlteanBelum ada peringkat

- Motorised Hammer Project ReportDokumen35 halamanMotorised Hammer Project ReportRaja ManeBelum ada peringkat

- VoluMill Optima Case Study - Cost Savings Using VolumillDokumen4 halamanVoluMill Optima Case Study - Cost Savings Using VolumillHighSpeedMachiningBelum ada peringkat

- Introduction Machine ToolsDokumen18 halamanIntroduction Machine ToolsMahesh JBelum ada peringkat

- Mastercam - Post-Processor Tutorial 1Dokumen40 halamanMastercam - Post-Processor Tutorial 1Edson Sawada100% (1)

- Mastercam For Solidworks® Dynamic Milling Tutorial: April 2019Dokumen98 halamanMastercam For Solidworks® Dynamic Milling Tutorial: April 2019MECHANICAL ENGINEERINGBelum ada peringkat

- Manufacturing & Production ProcessesDokumen2 halamanManufacturing & Production ProcessesPrashant GautamBelum ada peringkat

- Lab Report OnshaperDokumen10 halamanLab Report OnshaperSanatan Choudhury100% (3)

- Adobe Scan 16-Aug-2023Dokumen9 halamanAdobe Scan 16-Aug-2023danishmiddya18Belum ada peringkat

- 532 Lab 2 (Camilo)Dokumen26 halaman532 Lab 2 (Camilo)mikey shredderBelum ada peringkat

- Armar Bomba 120GDokumen25 halamanArmar Bomba 120GJuan GuzmánBelum ada peringkat

- Machine Tools Design: InstructorsDokumen31 halamanMachine Tools Design: InstructorsAladdin AdelBelum ada peringkat

- Company NamesDokumen63 halamanCompany NamesLeads guruBelum ada peringkat

- Literature Review For Designing of Portable CNC MachineDokumen3 halamanLiterature Review For Designing of Portable CNC MachineIJIRSTBelum ada peringkat

- Machine Shop TheoryDokumen1 halamanMachine Shop TheoryDaryl MadejaBelum ada peringkat