187 NanoGrout EG

Diunggah oleh

Tristan Irvin AsiDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

187 NanoGrout EG

Diunggah oleh

Tristan Irvin AsiHak Cipta:

Format Tersedia

Technical Datasheet

NanoGrout EG

HIGH EARLY STRENGTH FREE FLOWING EPOXY RESIN GROUT

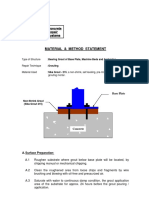

DESCRIPTION NanoGrout EG is a solvent free, three component epoxy resin grout specially designed for heavy engineering grouting of gap width 10mm to 100mm at one go. It is ready to use supplied in a pre measured kit. It is highly free flowing epoxy grout. BS 6319 : Part 2, BS 6319 : PART 3, BS 6319 : PART 7 NanoGrout EG is a high strength free flowing material with no shrinkage, and suitable for grouting where physical and chemical properties are of utmost importance. It can be used for grouting heavy machinery base plates, anchor bolts, bridge bearing, column sole plates and areas where narrow and precision grouting is required. It is used as a grout media to transfer dynamic load effectively. Solvent free and no shrinkage High physical and mechanical strength Rapid hardening and high early strength Can be used from 10mm to 100mm at one go without generating excessive exotherm. Ready to use and cost effective Curing is not affected by high humidity Impact and vibration resistant Good chemical resistant Good adhesion to all kinds of surfaces TYPICAL PROPERTIES @ 25C Component Appearance Mixed Density Pot Life Compressive Strength Bond Strength Flexural Strength Tensile Strength Application Temperature Chemical resistance SURFACE PREPARATION : Three ( Base, Hardener & Filler ) : Grey when mixed : 2.00 kg/litre : 30 - 45 minutes : 60 N/mm2 at 1 day 90 N/mm2 at 7days : > 3 N/mm2 (concrete failure) : 30 N/mm2 : 20 N/mm2 : +5 to +400C : Resisitant to general alkalies, acids, fules, oils, etc.

STANDARDS USES

ADVANTAGES

Surface preparation is important. All surfaces should be dry, clean, free from standing water, grease, curing compounds, mould oils and all loosely adhering particles. Cement laitance should be removed by mechanical means. Roughen surfaces with chipping to ensure good bonding. Steel surfaces may be grit blasted to white metal. Mix component A and B together thoroughly with a slow speed drill for 1 minute (max 400 R.P.M.). Then add component C and continue mixing until a flowing grout is achieved. A proper formwork should be constructed before grouting. Form work should be leakproof. When grouting with NanoGrout EG at underplate, base plate or

MIXING

APPLICATION

CC/NG09/Ver2/08/07

Construction Chemicals

1/2

bearing plates; ensure sufficient pressure head is maintained. Air must be allowed to escape. For large volumes, apply in layers ensuring the previous layers have hardened and cooled. When grouting under machine bases or crane rails, clearance must be available to allow the grout to flow avoiding trapping air. The operation should be continuous with a constant head. For difficult voids, a metal strap may be used to assist grout flow. Anchor bolt, dowel & starter bar holes must be dry. Use pumps or tremmie if the bolts are insitu. For bolts which will be placed into preformed holes, fill the hole with NanoGrout EG & gradually work the bolt into the grout. NOTE NanoGrout EG can be applied from 10mm to 100mm thickness at one go. Grouting more than 100mm should be done at multiple layer as per site requirement. Before going for second layer of grouting, the initial grouted layer should be hardened and cooled. Approx. 10 litre. Shelf Life 12 months from date of production, if stored properly in original unopened packing in dry conditions and away from sunlight and scorching heat. 10 litre set. Clean all equipments and tools with Conmix Cleaner. Stir Well Before Use. Gloves, goggles & organic vapour mask must be worn. Contact with skin, eyes, etc. must be avoided, if not may cause irritation. It is regarded hazardous for transportation. Do not re-use containers. To be disposed off as per local rules and regulations. Refer MSDS for detailed information.

YIELD GENERAL INFORMATION

Packaging Cleaning Note HEALTH & SAFETY PPEs Precautions Hazardous Disposal

Detailed Information TECHNICAL SERVICE

Conmix Technical services are available on request for onsite support to assist the correct use of its products.

Conmix Ltd. P.O. Box 5936 Sharjah, United Arab Emirates Tel: +971 (06) 5314155 Fax: +971 (06) 5314332 www.conmix.com CC/NG09/Ver2/08/07

Sales Office Tel: +971 (06) 5682422 Fax: +971 (06) 5681442 Email: conmix@conmix.com

Construction Chemicals

It is the customers responsibility to satisfy themselves by checking with the company that the information is still current at the time of use. The customer must be satisfied that the product is suitable for the use intended. All products comply with the properties shown on current data sheets. Conmix however do not warrant or guarantee the installation of the products as it does not have any control over installation or end use of the product. All information and in particular the recommendations relating to application and end use are given in good faith. The products are guaranteed against any defect and are manufactured and sold subject to Conmix standard terms and conditions of sale.

2/2

Anda mungkin juga menyukai

- Structural Analysis 1: Statically Determinate StructuresDari EverandStructural Analysis 1: Statically Determinate StructuresBelum ada peringkat

- Material & Method Statement: Concrete Repair SystemsDokumen3 halamanMaterial & Method Statement: Concrete Repair SystemsJuris DixonBelum ada peringkat

- AAC Block MasonaryDokumen7 halamanAAC Block MasonaryDipak ThakerBelum ada peringkat

- 6-Impact of Adhesive Thickness On The Capacity of The Surface Mounting Steel Plates Strengthening TechniqueDokumen9 halaman6-Impact of Adhesive Thickness On The Capacity of The Surface Mounting Steel Plates Strengthening TechniqueMr A. M. OlajumokeBelum ada peringkat

- Method Statement For Installation, Monitoring and Maintenance of Geotechnical InstrumentationDokumen11 halamanMethod Statement For Installation, Monitoring and Maintenance of Geotechnical InstrumentationMAYMODERN STEELBelum ada peringkat

- Workmanship On Building SitesDokumen28 halamanWorkmanship On Building SitesSa Reddi100% (1)

- Shoring and Purlins Layout PDFDokumen1 halamanShoring and Purlins Layout PDFDexter Lex F. SatanaBelum ada peringkat

- Pre U - Lox GPDokumen3 halamanPre U - Lox GPJohn Rheynor MayoBelum ada peringkat

- C8516-CLT-QMT-0003 Rev.00Inspection Checklist For Concreting WorksDokumen2 halamanC8516-CLT-QMT-0003 Rev.00Inspection Checklist For Concreting WorksJabinBelum ada peringkat

- Methodology For PQC (00) Toll Plaza L&TDokumen4 halamanMethodology For PQC (00) Toll Plaza L&TDeven PatleBelum ada peringkat

- MasterSeal 550Dokumen2 halamanMasterSeal 550Muhammad Abdul Wajid RaiBelum ada peringkat

- NanoGrout CFGDokumen3 halamanNanoGrout CFGimzee25100% (2)

- RNE Brochure (Compatibility Mode)Dokumen6 halamanRNE Brochure (Compatibility Mode)TedBelum ada peringkat

- Composite Slab Report For GIS AreaDokumen7 halamanComposite Slab Report For GIS AreaMINBelum ada peringkat

- Runway Design and Structural Design of An Airfield PavementDokumen18 halamanRunway Design and Structural Design of An Airfield PavementspruhatechBelum ada peringkat

- Isolation Valve Chamber - 900 MM Diameter PipeDokumen47 halamanIsolation Valve Chamber - 900 MM Diameter PipeAnonymous 3kDy7e100% (1)

- Nitoproof 600PFDokumen3 halamanNitoproof 600PFshyamsundar_ceBelum ada peringkat

- 0 - Sika Grout With Sikadur 732 Epoxy Bonding AgentDokumen4 halaman0 - Sika Grout With Sikadur 732 Epoxy Bonding AgentRA SamsonBelum ada peringkat

- Formwork Design For Settling TankDokumen6 halamanFormwork Design For Settling TankPartha GorainBelum ada peringkat

- DBST MSDokumen8 halamanDBST MSKrishan RodrigoBelum ada peringkat

- MS - CHRYSO Tapelastic Premia (Kalpitiya)Dokumen3 halamanMS - CHRYSO Tapelastic Premia (Kalpitiya)Kasun HewagamaBelum ada peringkat

- Datasheet File - Conbextra GPDokumen3 halamanDatasheet File - Conbextra GPmuraliBelum ada peringkat

- Procedure For Slab To SlabDokumen5 halamanProcedure For Slab To SlabKarthik Chalageri 7100% (1)

- Laying of Wet Mix RoadbaseDokumen4 halamanLaying of Wet Mix Roadbaseare_rail28100% (1)

- 01-Battery Room Ceramic Floor TilesDokumen1 halaman01-Battery Room Ceramic Floor TilesJoey RomeroBelum ada peringkat

- Gimpa Meeting Minutes For 4TH Technical MeetingDokumen3 halamanGimpa Meeting Minutes For 4TH Technical MeetingNana BarimaBelum ada peringkat

- Application of Braced and Unbraced Frame in Reinforced Concrete StructureDokumen2 halamanApplication of Braced and Unbraced Frame in Reinforced Concrete StructureNazmi DhiyauddinBelum ada peringkat

- Overhead Protection SystemsDokumen8 halamanOverhead Protection SystemsmangatamritBelum ada peringkat

- Vacuum de - Watered Flooring Method Statement: ActivitiesDokumen1 halamanVacuum de - Watered Flooring Method Statement: Activitiesவினோத் குமார்Belum ada peringkat

- Majestic True Beauty Matt: Technical Data SheetDokumen3 halamanMajestic True Beauty Matt: Technical Data SheetBilher SihombingBelum ada peringkat

- Led Light Curb Installation Instruction 2017 PDFDokumen6 halamanLed Light Curb Installation Instruction 2017 PDFFibin HaneefaBelum ada peringkat

- 10 NanoGrout SG-Anchoring Resin PDFDokumen3 halaman10 NanoGrout SG-Anchoring Resin PDFarunjacobn100% (2)

- Methodolgy of Rigid Pavement: Friday, 13 July 2012Dokumen19 halamanMethodolgy of Rigid Pavement: Friday, 13 July 2012Mac Lester MartinBelum ada peringkat

- Sikagrout - 214: High Performance, Non Shrink, Expanding Cementitious Grouting MortarDokumen3 halamanSikagrout - 214: High Performance, Non Shrink, Expanding Cementitious Grouting MortarSulaim Al KautsarBelum ada peringkat

- Method Statement For CoringDokumen4 halamanMethod Statement For CoringNasir Nagoor PitchaiBelum ada peringkat

- Controlled Low Strength MaterialDokumen4 halamanControlled Low Strength MaterialDevrim GürselBelum ada peringkat

- Method Statement Ground BeamDokumen3 halamanMethod Statement Ground Beamkoksy87Belum ada peringkat

- What Is The Fastest Broadband Internet Service in MalaysiaDokumen44 halamanWhat Is The Fastest Broadband Internet Service in MalaysiaTimothy LimBelum ada peringkat

- 7T04-CS-00-PC-011 R13 Consruction Procedure For Alloy Steel PipingDokumen9 halaman7T04-CS-00-PC-011 R13 Consruction Procedure For Alloy Steel PipingMoustafa FaresBelum ada peringkat

- MasterSeal 550Dokumen38 halamanMasterSeal 550Ahmad ElghazolyBelum ada peringkat

- Particular Specification For Reinforced Massive Concrete StructuresDokumen4 halamanParticular Specification For Reinforced Massive Concrete StructureskarfungBelum ada peringkat

- Airport Underground Electrical Duct Banks and ConduitsDokumen8 halamanAirport Underground Electrical Duct Banks and ConduitsDevrim Gürsel0% (1)

- Lintel BeamDokumen3 halamanLintel BeamJosephBelum ada peringkat

- Multifix All Mechanical Anchor - Design GuideDokumen28 halamanMultifix All Mechanical Anchor - Design GuideConstantino Ramirez (Cons)Belum ada peringkat

- Procedure For Roof Water ProofingDokumen4 halamanProcedure For Roof Water ProofingAkhilesh KumarBelum ada peringkat

- NTT-COOLING TOWER - Structural Priced BOQ R3-09-03-2021Dokumen18 halamanNTT-COOLING TOWER - Structural Priced BOQ R3-09-03-2021Corrosion Factory100% (1)

- Calculation of Decking Capacity &Dokumen9 halamanCalculation of Decking Capacity &Waqar FaziBelum ada peringkat

- Sikadur 732Dokumen2 halamanSikadur 732Hafidh Roiy100% (1)

- Sikadur 31 CFDokumen4 halamanSikadur 31 CFRonald MassoraBelum ada peringkat

- Method Statement For Core CuttingDokumen5 halamanMethod Statement For Core Cuttingahmedshah512Belum ada peringkat

- GID-253-CV-GTPP-SITE-016 Ironite IPS FlooringDokumen6 halamanGID-253-CV-GTPP-SITE-016 Ironite IPS FlooringAkash SharmaBelum ada peringkat

- Method Statement For Fabrication of Concrete StairsDokumen10 halamanMethod Statement For Fabrication of Concrete StairsDenver Vera MendozaBelum ada peringkat

- Polyseal 1PU: One Part Polyurethane Joint SealantDokumen2 halamanPolyseal 1PU: One Part Polyurethane Joint SealantVaittianathan MahavapillaiBelum ada peringkat

- ATECH-KLJ-Anchor ReportDokumen6 halamanATECH-KLJ-Anchor ReportRanjit S KashyapBelum ada peringkat

- Potable Water Thrust Blocks Construction ChecklistDokumen1 halamanPotable Water Thrust Blocks Construction ChecklistJabinBelum ada peringkat

- Apron Concrete Repair Method R01Dokumen19 halamanApron Concrete Repair Method R01ayhanarmanBelum ada peringkat

- ER420 - MS of G.I Pipe Crossing - r0Dokumen12 halamanER420 - MS of G.I Pipe Crossing - r0Wr ArBelum ada peringkat

- ConRepair 04 JurcemNonshirk GP Ed01Dokumen2 halamanConRepair 04 JurcemNonshirk GP Ed01Tuntun Tat0% (1)

- ZHJV W I Si 0167 0 A1 - Abutment Pile Cap FormworkDokumen1 halamanZHJV W I Si 0167 0 A1 - Abutment Pile Cap FormworkASAALE GLORIABelum ada peringkat

- Preprufe 300R & 160R PDFDokumen6 halamanPreprufe 300R & 160R PDForlandomcortezBelum ada peringkat

- Winter CrocFest 2017 at St. Augustine Alligator Farm - Final ReportDokumen6 halamanWinter CrocFest 2017 at St. Augustine Alligator Farm - Final ReportColette AdamsBelum ada peringkat

- Out PDFDokumen211 halamanOut PDFAbraham RojasBelum ada peringkat

- Produktkatalog SmitsvonkDokumen20 halamanProduktkatalog Smitsvonkomar alnasserBelum ada peringkat

- The Influence of Irish Monks On Merovingian Diocesan Organization-Robbins BittermannDokumen15 halamanThe Influence of Irish Monks On Merovingian Diocesan Organization-Robbins BittermanngeorgiescuBelum ada peringkat

- Pidsdps 2106Dokumen174 halamanPidsdps 2106Steven Claude TanangunanBelum ada peringkat

- Amount of Casien in Diff Samples of Milk (U)Dokumen15 halamanAmount of Casien in Diff Samples of Milk (U)VijayBelum ada peringkat

- Training For Humans Guide: FAQ's How Many Sets/reps Should I Do Per Exercise?Dokumen28 halamanTraining For Humans Guide: FAQ's How Many Sets/reps Should I Do Per Exercise?Paulo Pires100% (1)

- Fire Protection in BuildingsDokumen2 halamanFire Protection in BuildingsJames Carl AriesBelum ada peringkat

- Chapter 13 (Automatic Transmission)Dokumen26 halamanChapter 13 (Automatic Transmission)ZIBA KHADIBIBelum ada peringkat

- Sept Dec 2018 Darjeeling CoDokumen6 halamanSept Dec 2018 Darjeeling Conajihah zakariaBelum ada peringkat

- Lesson 6 - Vibration ControlDokumen62 halamanLesson 6 - Vibration ControlIzzat IkramBelum ada peringkat

- Micro Lab Midterm Study GuideDokumen15 halamanMicro Lab Midterm Study GuideYvette Salomé NievesBelum ada peringkat

- Durex 'S Marketing Strategy in VietnamDokumen45 halamanDurex 'S Marketing Strategy in VietnamPham Nguyen KhoiBelum ada peringkat

- Bachelor of Arts in Theology: Christian Apologetics/ Seventh-Day Adventist Contemporary IssuesDokumen13 halamanBachelor of Arts in Theology: Christian Apologetics/ Seventh-Day Adventist Contemporary IssuesRamel LigueBelum ada peringkat

- Caspar Hirschi - The Origins of Nationalism - An Alternative History From Ancient Rome To Early Modern Germany-Cambridge University Press (2012)Dokumen255 halamanCaspar Hirschi - The Origins of Nationalism - An Alternative History From Ancient Rome To Early Modern Germany-Cambridge University Press (2012)Roc SolàBelum ada peringkat

- Sveba Dahlen - SRP240Dokumen16 halamanSveba Dahlen - SRP240Paola MendozaBelum ada peringkat

- Dwnload Full Principles of Economics 7th Edition Frank Solutions Manual PDFDokumen35 halamanDwnload Full Principles of Economics 7th Edition Frank Solutions Manual PDFmirthafoucault100% (8)

- Bom Details FormatDokumen6 halamanBom Details FormatPrince MittalBelum ada peringkat

- Economic Review English 17-18Dokumen239 halamanEconomic Review English 17-18Shashank SinghBelum ada peringkat

- LSCM Course OutlineDokumen13 halamanLSCM Course OutlineDeep SachetiBelum ada peringkat

- Lesson 3 - ReviewerDokumen6 halamanLesson 3 - ReviewerAdrian MarananBelum ada peringkat

- An Evaluation of MGNREGA in SikkimDokumen7 halamanAn Evaluation of MGNREGA in SikkimBittu SubbaBelum ada peringkat

- IEC TC 56 Dependability PDFDokumen8 halamanIEC TC 56 Dependability PDFsaospieBelum ada peringkat

- Promotion-Mix (: Tools For IMC)Dokumen11 halamanPromotion-Mix (: Tools For IMC)Mehul RasadiyaBelum ada peringkat

- Lecture 2 Effects of Operating Conditions in VCCDokumen9 halamanLecture 2 Effects of Operating Conditions in VCCDeniell Joyce MarquezBelum ada peringkat

- Delonghi Esam Series Service Info ItalyDokumen10 halamanDelonghi Esam Series Service Info ItalyBrko BrkoskiBelum ada peringkat

- English Homework 10 Grammar Focus 2: Lecturer: Mr. Dr. H. Abdul Hamid, M.SiDokumen4 halamanEnglish Homework 10 Grammar Focus 2: Lecturer: Mr. Dr. H. Abdul Hamid, M.SiMutiara siwa UtamiBelum ada peringkat

- What Are The Spacer Bars in RC Beams - QuoraDokumen3 halamanWhat Are The Spacer Bars in RC Beams - QuoradesignBelum ada peringkat

- 15 Day Detox ChallengeDokumen84 halaman15 Day Detox ChallengeDanii Supergirl Bailey100% (4)

- Illustrating An Experiment, Outcome, Sample Space and EventDokumen9 halamanIllustrating An Experiment, Outcome, Sample Space and EventMarielle MunarBelum ada peringkat