V450-650 PFC UNIT Instructions Manual (May-04)

Diunggah oleh

EddyHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

V450-650 PFC UNIT Instructions Manual (May-04)

Diunggah oleh

EddyHak Cipta:

Format Tersedia

Instructions valid only for units with S. No.

xxxx1800 or higher (disregard the first four digits)

I NSTRUCTIONS AND USER MANUAL I NSTRUCTIONS AND USER MANUAL

Reactive Power Controllers type 450 and 650

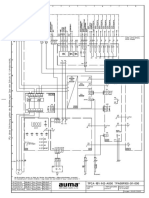

2.2 REAR PANEL AND WIRING DIAGRAM

TEMPERATURE SENSOR

Instructions valid only for units with S. No. xxxx1800 or higher (please watch at the note on the back of this flyer)

Thank you for your choosing our automatic Power Factor Controllers that represent the ultimate development in this field. Our PF controllers are the result of long-standing expertise and know-how in PF correction applied to the latest FLASH microprocessor technology ensuring ultra high-speed data processing and hence the execution of sophisticated algorithms and mathematical functions with highest dependability and greatest functionality. PF adjustment is achieved by continuos metering of the reactive power absorbed by the load and through the connection/disconnection of capacitor banks in order to maintain the target PF. Sophisticated alarm and control functions ensure protection of capacitor banks against abnormal or particularly severe working conditions such as harmonic currents, resonance, high mains voltage and high temperature. Correct compensation is also monitored and signalled when improper.

SUPPLY VOLTAGE SELECTOR Type S. No. DATA LABEL (side) POWER SUPPLY (115-120V / 230-240V)

92

TYPE 450

PANEL CUT (mm)

1.0

WARNING

This Power Factor Controller has been designed, constructed and tested in compliance with IEC 255-5 Standards and left the production factory in perfect condition both from the points of view of quality and safety. In order to maintain these conditions and to ensure safe operation, the user must follow carefully the instructions and the markings given in this Instructions Manual.

MAINS SUPPLY

1.1

PRELIMINARY INSPECTION

The units are packed in strong cardboard boxes designed to tolerate normal transport and handling conditions but they cannot be exposed to water or humidity. When receiving the units, inspect the external packaging immediately and check any for visible damage or signs of humidity; if any of these should be found, immediately raise a claim for damages with the carrier. In case of visible damage to the units, precautions must be taken to prevent its accidental use or installation; contact supplier for inspection / repair / replacement.

L1 L2 L3 N

F1 - F2 = 1A - 500V F3 - F4 = 2A - 250V F5 = 10A - 250V R = Discharge Resistor

TO OTHER CONTACTORS

LOAD

1.2

ENVIRONMENTAL WORKING CONDITIONS

The unit shall be installed indoors in non-aggressive atmosphere and shall be protected against accidental shocks, heat sources, direct sun radiation, corrosive liquids or substances. The ambient temperature (taking into account the Dt of the cabinet, too) shall not exceed the limits specified for this unit; relative humidity shall not exceed the limits specified and under no circumstances should condensation occur.

TEMPERATURE SENSOR

1.3

WIRING

138

SUPPLY VOLTAGE SELECTOR

Before actual connection ensure that the mains voltage and auxiliary voltage match those admitted by the unit.

1.4

SAFETY

PANEL CUT (mm)

Installation and maintenance of this unit shall be carried out by suitably trained personnel only. Before carrying out any operation on its connections, the unit must be disconnected from all power sources for at least three minutes in order to allow complete discharge of inner capacitors. The controller is connected to a Current Transformer; do not unplug the CT connections before making sure that all loads are switched off or make sure that the CT output is short-circuited. Failure to do so may cause dangerous over voltages. Before accessing the controllers terminals use a voltmeter to ensure that no dangerous voltage is present.

TYPE 650

POWER SUPPLY (115-120V / 230-240V)

1.5

WAREHOUSING

MAINS SUPPLY

TO OTHER CONTACTORS

LOAD

Warehousing must take place in a dry and adequately ventilated environment, free from dust and free from liquid or chemical substances likely to be aggressive to metal parts; temperature and humidity shall not exceed the working limits prescribed for the units. Avoid over stacking units or placing heavy weights on the cartons, as they are likely to damage packing and units.

L1 L2 L3 N

F1 - F2 = 1A - 500V F3 - F4 = 2A - 250V F5 = 10A - 250V R = Discharge Resistor

1.6

PACKAGING DISPOSAL

Materials used for packaging are all non-toxic and recyclable and, when removed, shall not be thrown away but re-used or conveniently disposed of as industrial waste by specialised companies according to local rules and regulations.

2.0 2.1

DESCRIPTION FRONT PANEL

1 2 3 4

3.0 3.1

WIRING AND CONNECTIONS GENERAL

1 Capacitor bank indicators

POWER FACTOR CONTROLLER

2 Alarm state indicator

1 4 2 5 3 6

SELECT ALARM

0.98

PF

1 UN PROG AUTO MAN 1 MAN 2 MODE

16 15 14

V

Dkvar

THC%

6 7

4 Readings display 5 PROG indicators 6 Man2 MODE indicator 7 Man1 MODE indicator

Type 450

3 Fan state indicator

wiring identification of terminals. Please refer tosure thatdiagrams (par. 2.2) forapplied are compatible with those of the controller. the signals/voltages Always make shall be foreseen as shown in the wiring diagram and namely: fuses Protective F1 - F2: 1A-500V, F3-F4: 2A-250V, F5: 10A- 250V The use of fuses in the current signal path is prohibited.

450

8 9

3.2

POWER SUPPLY CONNECTION

13

SELECT MODE

10

12

11 4 16 15 14 13 5

A separate auxiliary power supply is required for controller energisation Rear voltage selector - type 450: terminals 5-6 Use 1,5 mm2 stranded cables = 230 240 V - type 650: terminals 6-7 Use 1,5 mm2 stranded cables = 115 120 V Check the rear voltage selector combination to match actual supply voltage prior to connection. Depending upon the jumpers combination, the supply voltage may be 230240V or 115120V. If a modification is required pull out the jumpers (located underneath the rear panel) and reinsert them into the proper pin combination as shown in the figure.

8 Auto MODE indicator 9 UP key

3.3

8

VOLTAGE SIGNAL CONNECTION CURRENT TRANSFORMER (CT) CONNECTION AND INSTALLATION

Connect terminals 1-2 to phase L2(S) and L3 (T) of the three-phase mains. Use 1,5mm2 stranded cables.

POWER FACTOR CONTROLLER

3.4

10 DOWN key 11 MODE key 12 SELECT key 13 C reading/alarm indicator 14 THC% reading/alarm indicator

1

PF

10 11 12

ALARM

3 2

650

Type 650

0.98

Dkvar

AUTO

THC% C

1 UN

MAN 1 MAN 2 MODE

7 6

SELECT

PROG

SELECT

MODE

15 Dkvar reading/alarm indicator 16 V reading/alarm indicator

12 9 10 11

Connect terminals 3-4 (K-L) to the secondary of a current transformer (CT) having a 5A secondary rating. The CT primary rating shall be sized for the maximum current absorbed by the load (generally, 2030% higher than the maximum load current)) but anyway higher than the overall current absorbed by the PF correction equipment. If the distance between the CT and the controller is 3-4 m. use a 5VA CT and 2,5 mm2 stranded cables. For longer distances use a 10VA CT and 4-6 mm2 stranded cables. A class 1 CT is recommended for greater metering accuracy. Terminal 3 (K) must be grounded by using same or higher size cables. Pay close attention to the CT installation point along the line; its correct location is essential for the controller to work properly and the following instructions shall be carefully followed: The CT must be situated UPSTREAM ALL LOADS i.e. at a point in the network where the circulating current is the one of the load including that of the capacitors; for example, at mains input of the LV-MCB. The CT must be situated in the L1 ( R ) phase. CT orientation (polarisation) is irrelevant because a wrong CT orientation or CT leads swapping is automatically compensated by the controller.

138

DATA LABEL

92

3.5

SUMMATING TRANSFORMERS

4.4

TEST WITH NO LOAD

If 2 or more CTs are used (for instance, in the case of systems with two or more transformers in parallel) the connection of the CTs to the controller shall be made through a 5A Summating Transformer providing as many inlets as CTs are being used. The following instructions must be carefully observed: All the CTs used shall have the same primary and the same secondary values. All the CTs must be situated on the SAME reference PHASE and their secondary must be connected to the Summating Transformer in the same DIRECTION. When programming the CT CURRENT VALUE in the BASIC SET-UP, consider the summation of the primary ratings. Example: three 500/5 CTs = one virtual CT rated 3x500 = 1500A

Press the MODE key once until the MAN1 indicator is lit then press the UP key in order to connect one or more banks. After the banks have actually been connected, press the MODE key again to return to the AUTO mode; the display will show a capacitive PF ( -- sign before the reading) and all banks will be disconnected. The flashing of the MAN1 led indicator signals an attempt to reconnect a temporarily suspended bank until reconnection delay time has elapsed.

5.0 5.1

OPERATING THE CONTROLLER OPERATING MODES

3.6

CT AND VT ON HIGH VOLTAGE SIDE

Should the PFC equipment operate on the LV side but the control signals need to be taken from the HT side, it will become necessary for the CT and VT (PT, potential transformer) to be both installed on the HT side in order to avoid likely phase rotations. The VT (PT) secondary value shall not be lower than 100V. NB: In order for the controller to work properly, it shall be programmed to take into account a coefficient as per ADVANCED PROGRAMMING section (step P15 for type 450 or step P14 for type 650).

By pressing the MODE key, three distinct operating modes may be selected in sequence. Automatic Mode (AUTO) yellow (AUTO) indicator on This is the normal operating mode; the controller automatically connects/disconnects the capacitor banks in order to achieve the Target PF. The AUTO indicator flashes (and bank connection is temporarily suspended), if bank reconnection delay time is not yet elapsed.

3.7

CONTROLLER ENERGISATION

Energise the controller. The display and all led indicators (except the banks ones) turn on for 2 sec. then: the AUTO (automatic)) operating mode will be started the AUTO led indicator will go on the PF reading will appear on the display When started for the first time, the controller operates on the basis of factory pre-set parameters. Refer to following paragraphs to adapt pre-settings to actual installation parameters.

Manual Mode 1 (MAN1) red (MAN 1) indicator on Pressing the UP / DOWN keys enables the manual connection/disconnection of capacitor banks. The banks are connected progressively (summation). The MAN1 indicator flashes (and bank connection is temporarily suspended), if bank reconnection delay time has not yet elapsed. Manual Mode 2 (MAN2) red (MAN2) indicator on Earlier connected banks, if any, are automatically released in rapid sequence. Pressing the UP key enables the manual connection of one bank and disconnection of bank connected earlier. The banks are therefore connected individually. The MAN2 indicator flashes (and bank connection is temporarily suspended), if bank reconnection delay time has not yet elapsed.

4.0 4.1

FAST START-UP BASIC SET UP PROGRAMMING

In order to operate correctly, the controller requires the entry of only two basic parameters i.e. CT Primary Current and Target PF. Being self-determined, the traditional C/K setting is no longer required. Press the MODE key for approx. 4 sec to enter into the BASIC SET-UP procedure. - the (PROG) indicators will signal the parameter to be programmed. - the display will show parameter values. Use the UP / DOWN keys to increase/decrease the value; - single pressure for single variations, steady key pressure for increasingly faster variations. When the desired value is reached, press the SELECT key to confirm & store setting and to proceed to the following step.

For banks safety, the Manual mode selection is disabled in case of alarm for Over-V, THC% and over-C. The (Dkvar) alarm instead has no influence on this selection. When selected, a manual operating mode is maintained until a different selection is made. In case of power supply failure, however, the controller resets and, on power return automatically restarts in the AUTO mode.

5.2

READINGS

When operating in the AUTO mode, the three-digit display provides 5 readings that may be scrolled by pressing the SELECT key. The parameter displayed is identified by the corresponding led indicator:

CT PRIMARY CURRENT (flashing indicator, steady + indicators) Enter the value of the CT primary in Amps. The admitted range is 5 to 12.000 A in steps of 5. Values up to 995 A are shown as Amps, values above 1.000 are shown as kAmps. (example: 2.50 = 2500 A) TARGET PF (simultaneous flashing + + indicators) Enter the value of the Power Factor required (Target PF). The admitted range is 0.50 (ind.) to -.50 (cap.) in steps of 0.01; the - sign stands for Capacitive (leading) value.

Power Factor default reading (all indicators off) This is the reading normally displayed and/or that automatically returns if no key is pressed for 30 sec. This reading refers to the PF metered at CT installation point. The sign appears for capacitive (leading) PF Mains voltage in Volt-rms (V) indicator on This reading refers to mains input voltage (L2-L3 reading) Reactive power in Kvar-rms (Dkvar) indicator on This reading indicates the reactive power missing to reach Target PF or exceeding Target PF - steady Dkvar indicator = INDUCTIVE reading = kvar missing to Target PF. - flashing Dkvar indicator = CAPACITIVE reading = kvar exceeding the Target PF. Example: 12,5 on display + steady Dkvar indicator = 12,5 kvar are missing to reach the Target PF Current (harmonics) overload THC %-rms (THC%) indicator on This reading indicates the likely % overload of current generated by harmonics circulating on capacitors with respect to capacitors rated current at capacitors rated voltage [100 * (I-In ) / In ]. The reading is zero when below or equal to capacitors In (rated current). Ex.1: "15" stands for a 15% current overload i.e. the current circulating on capacitors is 115%In. Ex.2: "100" stands for a 100% current overload i.e. the current circulating on capacitors is 200%In. Ex.3: "200" stands for a 200% current overload i.e. the current circulating on capacitors is 300%In. NB: In case of choke-protected capacitor banks, this reading may be unrealistic because it is always calculated according to a THC likely to circulate on capacitors WITHOUT chokes.

When the above programming is completed, press the MODE key to exit set-up mode and to return to AUTO operating mode. If no key is pressed for 30 sec., exit and return to AUTO operating mode is automatic. NB: Exit from set-up is possible at any point by pressing the MODE key however, it should be carefully noted that: - any variations in parameter value will be retained and stored ONLY when the SELECT key is pressed - when exiting the set-up procedure, care should be taken to confirm the modified value with the SELECT key before exiting otherwise the controller retains the value displayed before modification.

4.2

CHECK SET-UP ENTRIES

We recommend checking the SET-UP entries in order to avoid problems generated by incorrect programming: - Press the MODE key for approx. 4 sec. - Press the SELECT key to scroll the stored values. - Press the MODE key to exit. The controller is now ready to operate on the basis of CT value and Target PF entered into the BASIC SET-UP. Warning The controller operation is also based on additional factory-set working parameters - like switch ON-OFF-delay intervals, alarm thresholds and delays, output contacts, etc. - that are factory preprogrammed according to general use criteria. If the controller is already integrated into a PFC cabinet these values should have already been programmed by the manufacturer of the cabinet. Operating the controller at this stage implies the acceptance by the user of these additional settings. It is otherwise essential to make sure that they are compatible with PFC equipment design and with mains system destination. Refer to the ADVANCED PROGRAMMING section for alteration, if necessary.

Temperature in C. (C) indicator on This reading indicates the temperature inside the cabinet. NB: the reading is blanked ( is shown on the display) during the first 25-30 minutes from controller energisation i.e. during the warm-up time that this reading requires in order to become realistic.

5.3

UUU AAA

OTHER INDICATIONS DISPLAYED

= no voltage signal is detected at terminals 1-2 = the current signal input (CT output) is below 0,05 A

The following messages may temporarily appear on display depending on circumstances

AL(14) = alarm condition and alarm identification number = reading temporarily not available

5.4

ALARM FUNCTIONS

The controller is equipped with 4 sophisticated alarm functions designed for PFC equipment protection whenever operation takes place in the AUTO mode and in any of the MAN operating modes.

4.3

TEST WITH INDUCTIVE LOAD

Turn on the equipments General Switch, and make sure that there is an inductive load (for example, motors) sufficient for the Controller to be started (current signal should be greater than 0,05A). All the indicators (except those related to capacitor banks) and all the Display segments light up for approx. 2 sec.; the controller then sets itself to AUTO mode and actual PF reading is displayed. The capacitor banks needed to compensate the load are switched on with the programmed interval until the target PF is reached; the display shows the PF improvement at each bank switch-on. If all the wiring has been properly done and the whole system works correctly it will be noticed that the Controller connects the capacitor banks as the load increases and disconnects them as it decreases. With no load, all banks will automatically be disconnected.

Over-voltage Low-PF Over-current Over-temperature

(V) (Dkvar) (THC%) (C)

High mains voltage level (non temporary) Low PF output (non temporary) Harmonics overload (over-current) on capacitors. High inner cabinet temperature

NB: The controller is normally delivered with all 4 alarms enabled. In specific cases or for reasons related to PFC equipment design however, some of the alarms could be purposely disabled. For example, THC% alarm disabled in equipment with capacitors protected by chokes.

5.5

ALARM INDICATION AND EFFECTS

When one alarm trips: the ALARM and the PARAMETER led indicators flash the alarm CODE and the reading of parameter under alarm appear alternately on the display the alarm output contact (where applicable) closes - type 450: terminals 14-15 (unless the output is otherwise programmed) - type 650: terminals 23-24 (dedicated output) An automatic release of capacitor banks may take place depending on alarm severity and on alarm set-points.

Common Programming

CODE Parameter & description 1st Remarks Min-Max step default new 0.5500 0.5 0.5

The Alarm identification codes, the parameters, their triggering points and the effects generated by each alarm are the following: AL1 Over-V Set points Effect: Low-PF Set points Effect: AL3 THC% Set points Effect: Over C Set points Effect: High mains voltage Threshold and delay: as programmed All banks are disconnected following the switch-off interval Banks reconnection is prevented as long as the alarm persists. PF outside ind-cap range Threshold and delay: as programmed. Automatically disabled in case of small powers (< 66% of 1st bank power). Display of alarm state only + alarm output contact closing (where applicable). This alarm does not interfere with normal PF regulation process. Harmonic over-current Threshold: as programmed; delay: Instantaneous All banks are rapidly disconnected (one bank every 2 sec.) High cabinet temperature Threshold: as programmed; delay: instantaneous All banks are disconnected following the switch-off interval. Banks reconnection is prevented as long as the alarm persists.

AL2

AL4

In case of multiple alarm condition, the one detected first is triggered.

5.6

ALARM END

Once the alarm condition ceases, the controller automatically restores its normal operation; banks reconnection takes place gradually, after the re-connection delay time and following the controller switch-on routines.

5.7

NO-VOLT RELEASE

An automatic no-volt control device instantly releases all capacitor banks in case of auxiliary power supply interruption above 20 ms. in order to protect capacitors against improper manoeuvres. Banks re-connection is automatic at mains return and after banks' reconnection delay time.

5.8

FAN CONTROL

A relay output is available for control of an external cooling fan. The output contact closes when the inner cabinet temperature exceeds the pre-set fan control threshold and the corresponding led indicator goes on. Fan control is active only if at least one bank is connected. type 450:the output contact (terminals 14-15) operates for fan control only if programmed for this purpose. Refer to Advanced Programming (step P12-P13) for further details. type 650:the output contact (term.21-22) is dedicated to fan control. See also Advanced Programming (step P12).

flashing led (kvar) P01 Power of capacitor bank The entry required is 1st bank rated kvar at capacitors rated voltage; if capacitors rated voltage is higher than actual mains voltage, the controller will calculate the actual kvar output according to actual mains voltage Kvar decimals are shown up to 100 kvar, kvar integers above P02 Capacitors rated voltage flashing led (Volt) The entry required is the capacitors rated voltage P03 Switch-ON interval (seconds) For normal application, this is generally set between 20 and 40 sec. Shorter intervals increase no. of manoeuvres and will cause faster contactors wear out P04 Switch-OFF interval (seconds) This is generally set to the same value as Switch-ON interval P05 Reconnection delay time (second) It prevents reconnection of any bank prior to an adequate rest time to allow proper capacitors discharge. The value depends upon the discharge resistors (generally 3 times the switch-on interval if banks are equipped with quickdischarge resistors) A "0" entry disables this function P06 Over-voltage Alarm threshold (Volt) This value depends primarily upon the rated voltage of capacitors used A "0" entry disables this alarm P07 Over-voltage Alarm delay time (minutes) The delay time depends upon the time that capacitors can tolerate the programmed over-voltage. However the delay time should be long enough to avoid undesired tripping due to short duration over-voltage. P08 Low-PF Alarm threshold (PF) This set point is symmetrical in order to detect PF irregularities both on inductive and capacitive quadrant. It must be set to a value lower than Target PF (usually 5% lower). Example: a 0.88 setting triggers when actual PF is outside the 0.88(ind) -.88(cap) range. A "0" entry disables this alarm P09 Low-PF Alarm delay time (minutes) This generally set to a time sufficiently long to allow the indication of actual PFC equipment failure or malfunction P10 THC% harmonic over-current Alarm threshold (%) This is the value triggering banks switch-off in case of harmonics overload. The value is determined primarily by the capacitors characteristics. Its expressed in %, which refers to capacitors rated current (In). Example: 25 = 25% = current threshold set at 1,25 In. A "0" entry disables this alarm P11 Over-Temperature Alarm threshold (C) Max. temperature causing automatic banks switch off. Its value depends primarily on capacitors temperature class A "0" entry disables this alarm

0999 2250

1 1

400 (u 415) (u .....)

20

2250 0250

1 1

20 60

0995 1250

5 1

450 60

01.00

0.01 0.86

1250 0200

1 1

60 25

060

50

6.0

ADVANCED PROGRAMMING

Specific programming for type 450 only

P12 Contact output destination (terminals 14-15) (choice) FA / AL FA It programs the relay output to trigger for Fan Control (FA) or Alarm (AL) P13 Fan-control temperature threshold (C) 060 1 35 Cooling fan start-up temperature. NB: active only if P12 is set to FA (fan). Its normally set to 35C. Lower values are likely to cause fan over-work and reduction of its life A "0" entry disables this function P14 Number of Banks (depending upon on-board outputs) (number) 14 1 4 In case of unused outputs, it allows to program the no. of 16 1 6 controller outputs according to the actual no. of capacitor banks P15 VT(PT) coefficient (number) 1.009.99 0.01 1.00 Voltage coefficient for measurement via VT-Potential Transformer. This value is the ratio between LV side voltage and VT secondary voltage. Example: 415V LV mains, /100V VT. The value to set is 415/100 = 4.15

Several working parameters are programmable in order to adapt the controller to most diversified PFC equipment design and field applications. The Advanced Programming procedure described in this chapter enables the customisation of these parameters to suit ones own requirements. Warning This section covers a programming area that could potentially generate sever damage to equipment and persons if operated by unauthorised persons. We decline all responsibility connected with inadequate settings or improper alteration of these values.

6.1

ACCESSING ADVANCED PROGRAMMING

For safety reasons, access to this programming mode from the AUTO mode takes place in 2 steps: (a) Press the MODE key for approx. 4 sec. to enter the BASIC SET-UP mode - the PROG indicator flashes; the PROG indicators are steadily lit (b) Press the SELECT key for approx. 4 sec. to enter the ADVANCED PROGRAMMING mode - all the PROG indicators are steadily lit - the display shows a Pxx code to indicate the Parameter Number that can be programmed (c) Refer to the following paragraphs for actual alteration/programming of parameters.

Specific programming for type 650 only

P12 Fan-control temperature threshold (C) 060 1 35 Cooling fan start-up temperature. Its normally set to 35C. Lower values are likely to cause fan over-work and reduction of its life. A "0" entry disables this function P13 Number of Banks (depending upon on-board outputs) (number) 16 1 6 In case of unused outputs, it allows to program the no. of 112 1 12 controller outputs according to the actual no. of capacitor banks P14 VT (PT) coefficient (number) 1.009.99 0.01 1.00 Voltage coefficient for measurement via VT-Potential Transformer. This value is the ratio between LV side voltage and VT secondary voltage. Example: 415V LV mains, /100V VT. The value to set is 415/100 = 4.15 IMPORTANT: when the CT is placed on the HT side, the CT value entry in the BASIC SET UP needs to be reprogrammed to be: actual CT primary value multiplied by HT / LT ratio. Example: 20.000 / 415V system, 50/5 CT placed on HT side. The correct CT entry is: 50*(20.000/415)=2409,6; round up to 2410; the value to set is 2,41 (kA)

6.2

PROGRAMMING KEYS

UP / DOWN keys: to increase/decrease the value displayed to confirm & store the value displayed and/or to pass on to following parameter. SELECT key: MODE key: to exit ADVANCED PROGRAMMING and return to the AUTO mode. An automatic exit will also take place if no key is pressed for 30 sec. NB: Exit the ADVANCED PROGRAMMING mode is possible at any point by pressing the MODE key. However: Variation of parameter value is retained and stored ONLY when the SELECT key is pressed when exiting the programming procedure, make sure to confirm the modified value with the SELECT key before exiting, otherwise the controller will retain the value displayed before modification.

6.3

Min-Max step default new

PARAMETERS DESCRIPTION

admitted range of values; a 0 setting disables the parameter. minimum variation (resolution) factory pre-programmed value according to general use criteria. for annotation of new setting(s) if different from default setting(s)

In case of alteration of the default values, we recommend noting down in the NEW column the unit Serial No. and the new setting(s) for future reference.

6.4

ALARMS DISABLING

The Alarms can be individually disabled by setting their minimum value to zero as per Parameters description table above. In such cases, the associated delay time setting (where foreseen) may be skipped because it has no influence whatever on its value.

NOTES

Controller type : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5

CHECKING THE ADVANCED PROGRAMMING ENTRIES

S. No. : ....................................................................

In order to check the settings stored in the memory, start from the AUTO mode and proceed as follows: (1) Press the MODE key for approx. 4 sec. to enter the BASIC SET-UP mode (2) Press the SELECT key for approx. 4 sec. to enter the ADVANCED PROGRAMMING mode: - all 3 PROG indicators are steadily lit - display shows P01 code to indicate the first parameter SELECT key to scroll parameter codes (3) Press the UP key once only to display actual setting (one pressure only will not change - press the the value) - press the SELECT key to pass onto the next parameter (4) Press the MODE key at any point to exit.

7.0

TECHNICAL SPECIFICATIONS

100690 Vrms 50 / 60 Hz self-determined < 0,1 VA 230240V, 115120V 10% 3VA (type 450) 4 VA (type 650) 5A via external ../5A CT < 0,4 VA (sinusoidal) 5,5 A 100 mA 5/5 A 12.000/5 A Automatic compensation Automatic 0,50 Ind. / 0,50 Cap. PF, V, kvar, THC%, C 4 or 6 (type 450) 1-4, 1-6 (type 450) 6 or 12 (type 650) 1-6, 1-12 (type 650) 2250 sec 2250 sec 0250 sec 0 690 Vac 1240 min. 0 1 PF 1240 min. 0 200 % 060 C 060 C > 20 ms -10 +55 C RH < 90% (non condensing) 2000V for 1 min. IP54 (front panel), IP 20 rear panel self extinguishing plastic (UL94 V0) flush mount with 4 self-blocking slide holders 2,5 mm2 screw terminals 96x96x50 mm (type 450) 144x144x50 mm (type 650) 92x92 mm (type 450) 0,450 kg (type 450) 137x137 mm (type 650) 0,680 kg (type 650) self adapting (1.1.1.1.. - 1.1.2.2.. - 1.2.2.2.. - 1.2.3.3.. - 1.2.3.4.. - 1.2.4.8.. - etc.)

Instructions valid only for units with S.No. xxxx 1800 or higher (Disregard the initial 4 digits. Consider only the last 4 digits)

Voltage input Frequency Voltage input burden Power supply (selectable) Power supply consumption Current input Current input burden (at 5 A) Max. current input Minimum current input CT range. CT orientation C/K adjustment PF adjustment Readings Outputs (steps) Outputs programming Output contact rating Switch-on interval Switch-off interval Reconnection delay time Switching sequence Alarms Over-Voltage alarm Over-Voltage alarm delay Low-PF alarm Low-PF alarm delay Over-Current (harmonics) alarm Over-Temperature alarm for fan activation for equipment switch-off Low-volt release Working temperature range Relative humidity Insulation voltage Protection degree Casing Installation Connection Size (DIN 43700) Panel cut Weight

The following space is left empty for notes and remarks

(>4 kV insulation) 1.250 VA - 250 Vac

Your Distributor

CE compliance - Ref. standards: EN50081-2 EN55011 EN55014 EN50082-2 ENV50140 ENV 50204 EN 61000-4-8 EN 61000-4-2 EN61000-4-4

8.0

ELECTROMAGNETIC COMPATIBILITY

This unit has been verified for compliance with European regulations for EMC (Electromagnetic compatibility) and bears the CE marking to this effect.

While all care was taken to ensure that the information contained in this manual is correct, no responsibility can be accepted for any inaccuracy. We reserve the right to modify the information herein contained at any moment without prior notice. We decline all responsibility in the event of any unsuitable or incorrect use of the product and cannot be held liable for any direct, indirect or ensuing damage.

450-650 UK manual 0504

Anda mungkin juga menyukai

- 110/30 kV transformer specsDokumen3 halaman110/30 kV transformer specsamulya00428Belum ada peringkat

- Chroma - PV Inverter (PCS) - White - Paper - v1Dokumen31 halamanChroma - PV Inverter (PCS) - White - Paper - v1Rafik Cherni100% (1)

- MES114 Modules: Logic Input / Output ModulesDokumen1 halamanMES114 Modules: Logic Input / Output ModulestuanudinBelum ada peringkat

- D000011316 E850 Tech Data SheetDokumen10 halamanD000011316 E850 Tech Data SheetstrahinjaBelum ada peringkat

- Grundfos RSI: AC Drives Installation and Operating InstructionsDokumen100 halamanGrundfos RSI: AC Drives Installation and Operating InstructionsGuillermo FuentesBelum ada peringkat

- NANJING REL ManualDokumen470 halamanNANJING REL Manualajeez86Belum ada peringkat

- L170R41 eDokumen142 halamanL170R41 eJairo Morales100% (2)

- Grid AIS L3 FKG1N 0132 2016 - 07 EN - Lo PDFDokumen2 halamanGrid AIS L3 FKG1N 0132 2016 - 07 EN - Lo PDFDoan Anh TuanBelum ada peringkat

- Product Manual For The 4-Quadrant-/ Combi Meter LZQJ in Accordance With VDEW-Specifications 2.1Dokumen101 halamanProduct Manual For The 4-Quadrant-/ Combi Meter LZQJ in Accordance With VDEW-Specifications 2.1manset tjbtbBelum ada peringkat

- Arc Sensor User Manual: MN026008ENDokumen12 halamanArc Sensor User Manual: MN026008ENRoberto Patricio Llanquiman MuñosBelum ada peringkat

- MFM 10-1 Mobile Fault LocatorDokumen3 halamanMFM 10-1 Mobile Fault Locatormanish100% (1)

- Application: Heat-Shrinkable Three Core Xlpe Straight Joint Up To 36 KVDokumen2 halamanApplication: Heat-Shrinkable Three Core Xlpe Straight Joint Up To 36 KVHồ ThànhBelum ada peringkat

- IM30AP Manual - en 01111 PDFDokumen32 halamanIM30AP Manual - en 01111 PDFAbdulhameed AlqadreeBelum ada peringkat

- REM615Dokumen2 halamanREM615anksyete50% (2)

- Tavrida ElectricDokumen42 halamanTavrida ElectricmmmindasBelum ada peringkat

- Configure analog inputs on ABB RTU560Dokumen7 halamanConfigure analog inputs on ABB RTU560TalibBelum ada peringkat

- Sm1223 CadDokumen1 halamanSm1223 CadYEINER HERNAN ACUÑA VEGABelum ada peringkat

- GD5000 Inverter Operation ManualDokumen242 halamanGD5000 Inverter Operation Manualpradeepfriday13Belum ada peringkat

- 36 KV, 2500A, 31.5 Ka Medium Voltage, Arc-Proof Switchgear: Unigear Zs2Dokumen2 halaman36 KV, 2500A, 31.5 Ka Medium Voltage, Arc-Proof Switchgear: Unigear Zs2KekKangLoong100% (1)

- Presenatation Regulateur de TensionDokumen36 halamanPresenatation Regulateur de TensionDjebien Ahmed Abu Abderrahim100% (1)

- Altivar 18Dokumen35 halamanAltivar 18veroljubdjBelum ada peringkat

- Sm34 Controller WSNMPDokumen2 halamanSm34 Controller WSNMPBraian AvellaBelum ada peringkat

- f0253805 Vacutap VM enDokumen10 halamanf0253805 Vacutap VM enhardian syaputraBelum ada peringkat

- XRIO Converter Manual AREVA P443 P445 ENU TU2.22 V1.000Dokumen13 halamanXRIO Converter Manual AREVA P443 P445 ENU TU2.22 V1.000Sakthi MuruganBelum ada peringkat

- P50 Agile: GE Grid SolutionsDokumen288 halamanP50 Agile: GE Grid Solutionsnurahmat57Belum ada peringkat

- 11-Zinc Ribbon For HT CrossingsDokumen6 halaman11-Zinc Ribbon For HT Crossingsmansih457Belum ada peringkat

- Rcm14-03 Ac/Dc Residual Current Monitor: Making Electricity Safer by DesignDokumen2 halamanRcm14-03 Ac/Dc Residual Current Monitor: Making Electricity Safer by DesignAli Lakrakbi100% (1)

- DILO SF6 Catalogue 2021 ENDokumen214 halamanDILO SF6 Catalogue 2021 ENBadraa BatorgilBelum ada peringkat

- EcodialAdvanceCalculation HelpDokumen33 halamanEcodialAdvanceCalculation HelpChàng NgốcBelum ada peringkat

- Gutor PXW AC UPS System 5 220 KVApdfDokumen2 halamanGutor PXW AC UPS System 5 220 KVApdfFELIXDEJBelum ada peringkat

- Okken Brochure 2016Dokumen14 halamanOkken Brochure 2016nooruddinkhan1Belum ada peringkat

- Elster Alpha A1800 Installation InstructionsDokumen12 halamanElster Alpha A1800 Installation InstructionsArivazhagan AdhikesavanBelum ada peringkat

- KELAR POWER GEAR MOTOR SPECIFICATIONSDokumen2 halamanKELAR POWER GEAR MOTOR SPECIFICATIONSHeber Alejandro Gahona JeriaBelum ada peringkat

- P127 OrderForm - V20 - 062017Dokumen8 halamanP127 OrderForm - V20 - 062017tandin.t6393Belum ada peringkat

- Operation Manual for Fully Automatic Capacitance and Loss Factor Measuring Bridges Type 2816 and 2818Dokumen151 halamanOperation Manual for Fully Automatic Capacitance and Loss Factor Measuring Bridges Type 2816 and 2818mikrurkBelum ada peringkat

- 110V Battery & Battery Charger Sizing Calculation For Payra 132/11Kv (Ais) Grid SubstationDokumen32 halaman110V Battery & Battery Charger Sizing Calculation For Payra 132/11Kv (Ais) Grid Substationarafin100% (1)

- Sizing Conductors and Selecting Protection Devices: Power Guide 2009 / Book 04Dokumen71 halamanSizing Conductors and Selecting Protection Devices: Power Guide 2009 / Book 04Omar SaidiBelum ada peringkat

- External CT Usage-EOCRDokumen3 halamanExternal CT Usage-EOCRNaveen GuptaBelum ada peringkat

- ETS-50-00 Outdoor AIS AC Substation Common Conditions and Technical RequirementsDokumen8 halamanETS-50-00 Outdoor AIS AC Substation Common Conditions and Technical Requirementsraghavendran raghuBelum ada peringkat

- Schneider Electric P3U30 LED labels printoutDokumen2 halamanSchneider Electric P3U30 LED labels printoutPeter Paul Condinato100% (1)

- N100-Hyundai Brochure 2Dokumen28 halamanN100-Hyundai Brochure 2herororoBelum ada peringkat

- Ahmed Kamouche Electrical Engineer Resume-2Dokumen2 halamanAhmed Kamouche Electrical Engineer Resume-2Ahmed KamoucheBelum ada peringkat

- GCB - Hec 3-6.emergancy Spare Parts and Comp.V1Dokumen18 halamanGCB - Hec 3-6.emergancy Spare Parts and Comp.V1Fabyano BrittoBelum ada peringkat

- Air Circuit Breakers Technical SpecsDokumen28 halamanAir Circuit Breakers Technical SpecsDerargh100% (1)

- Magel IsDokumen162 halamanMagel Issalmo83:18Belum ada peringkat

- See-Electrical Free v8r2 UsDokumen65 halamanSee-Electrical Free v8r2 UsOng MatBelum ada peringkat

- TDR9000 QuickStartGuide PDFDokumen2 halamanTDR9000 QuickStartGuide PDFmiamor$44Belum ada peringkat

- Catalogo Contactores en Vacio MitsubichiDokumen16 halamanCatalogo Contactores en Vacio MitsubichiWalter CataldoBelum ada peringkat

- ADVC2-1186 USB Connection PDFDokumen4 halamanADVC2-1186 USB Connection PDFPeri Edison GurusingaBelum ada peringkat

- Sdmo V500C2Dokumen5 halamanSdmo V500C2ChristopheBelum ada peringkat

- Gutor TechnologyDokumen2 halamanGutor TechnologyFELIXDEJBelum ada peringkat

- CTA Remote Excel File LoaderDokumen58 halamanCTA Remote Excel File LoaderAkbar SyawaludinBelum ada peringkat

- CSC-211 Multifunction Protection IED Product Guide - V1.10Dokumen87 halamanCSC-211 Multifunction Protection IED Product Guide - V1.10erec87Belum ada peringkat

- Acs580mv Catalog 3bht490775r0001 en RevbDokumen28 halamanAcs580mv Catalog 3bht490775r0001 en RevbRadu BabauBelum ada peringkat

- QJ71C24N PDFDokumen358 halamanQJ71C24N PDFalbertoBelum ada peringkat

- Fault, Protection and Failure Indications in PSE Soft StarterDokumen5 halamanFault, Protection and Failure Indications in PSE Soft StartermichaelBelum ada peringkat

- GE FKG1N - Brochure-EnDokumen2 halamanGE FKG1N - Brochure-EnHassan_haBelum ada peringkat

- Computer Methods in Power Systems Analysis with MATLABDari EverandComputer Methods in Power Systems Analysis with MATLABBelum ada peringkat

- Handbook UPS PDFDokumen52 halamanHandbook UPS PDFJoni EfwanBelum ada peringkat

- Wiring DiagramDokumen28 halamanWiring DiagramAbdulSattarBelum ada peringkat

- Lec.01 - Building Design Concept - SE Sponsor 2021Dokumen20 halamanLec.01 - Building Design Concept - SE Sponsor 2021moosuhaibBelum ada peringkat

- Documents For Working - AmpleforthDokumen70 halamanDocuments For Working - AmpleforthSpontan GezginBelum ada peringkat

- 06 Main Medium-Voltage-Fuses PDFDokumen22 halaman06 Main Medium-Voltage-Fuses PDFCarlos Cordero HerreraBelum ada peringkat

- Simulation of Parallel Resonance Condition in ElectricalDokumen6 halamanSimulation of Parallel Resonance Condition in ElectricalyaoBelum ada peringkat

- User's Manual: Powersim IncDokumen317 halamanUser's Manual: Powersim IncNOURDINE EZZALMADIBelum ada peringkat

- PGK70 HB ManualDokumen34 halamanPGK70 HB ManualAlan Gallagher100% (1)

- LAB 06 To Make The Three Phase Transformer Connections ( - Y, - , Y-, Y-Y) and Verify The Line and Phase Voltages and CurrentsDokumen5 halamanLAB 06 To Make The Three Phase Transformer Connections ( - Y, - , Y-, Y-Y) and Verify The Line and Phase Voltages and CurrentsMuhammad MashamBelum ada peringkat

- Sizing of Instrument Transformer For 66 KV Ukai Left Branch Canal (LBC) Lift Irrigation SchemeDokumen36 halamanSizing of Instrument Transformer For 66 KV Ukai Left Branch Canal (LBC) Lift Irrigation SchemeSumitBelum ada peringkat

- Vacon NXP Grid Converter Application Manual DPD01599B UKDokumen138 halamanVacon NXP Grid Converter Application Manual DPD01599B UKTrung NguyenBelum ada peringkat

- Mitigate Voltage FluctuationsDokumen5 halamanMitigate Voltage FluctuationsCamilo CortesBelum ada peringkat

- Comments On HT & LT SLDDokumen3 halamanComments On HT & LT SLDNaveen NagisettiBelum ada peringkat

- A 25 KW Industrial Prototype Wireless Electric Vehicle ChargerDokumen6 halamanA 25 KW Industrial Prototype Wireless Electric Vehicle Chargerabhinandan.kumarBelum ada peringkat

- DOE Guidelines On Energy Conserving Design of Buildings v2020Dokumen74 halamanDOE Guidelines On Energy Conserving Design of Buildings v2020Dominic Vincent Ver100% (1)

- Supape 10VSCATR06-EDokumen25 halamanSupape 10VSCATR06-EmaggamBelum ada peringkat

- Smart SubstationDokumen34 halamanSmart Substationsrkhan55Belum ada peringkat

- PTW 6.0 EnhancementsDokumen36 halamanPTW 6.0 EnhancementsBreno AlmeidaBelum ada peringkat

- Tutorial Pse - 2012-2013Dokumen23 halamanTutorial Pse - 2012-2013Mahesh SinghBelum ada peringkat

- Step Down Transformer Class 12 Physics ProjectDokumen10 halamanStep Down Transformer Class 12 Physics Projectloveguru062006Belum ada peringkat

- Construction of Transmission LinesDokumen36 halamanConstruction of Transmission Linesಶ್ರೀಕಾಂತ್ ತಿಪ್ಪೇರುದ್ರಪ್ಪ100% (1)

- EZ-THUMP™ Series: Portable Fault Location SystemsDokumen2 halamanEZ-THUMP™ Series: Portable Fault Location Systemsriyad abdulhafeedBelum ada peringkat

- B Power Packs Control SensorsDokumen2 halamanB Power Packs Control SensorsRobertBelum ada peringkat

- ABB TPU5 Indoor Current Transformers - CT - MV Medium Voltage 13 - 8KV 17 - 5KVDokumen8 halamanABB TPU5 Indoor Current Transformers - CT - MV Medium Voltage 13 - 8KV 17 - 5KVMANUEL JESÚS GÓMEZ GARCÍABelum ada peringkat

- Full Wave Rectifier Micro Project ReportDokumen14 halamanFull Wave Rectifier Micro Project Reportmohit moreBelum ada peringkat

- TManual Chapter 01Dokumen23 halamanTManual Chapter 01abhayambujBelum ada peringkat

- AN555Dokumen38 halamanAN555Hernan Ortiz EnamoradoBelum ada peringkat

- ResumeDokumen4 halamanResumePratik JenaBelum ada peringkat

- Magnetic Circuits Explained in 40 CharactersDokumen71 halamanMagnetic Circuits Explained in 40 CharactersSanthosh PBelum ada peringkat

- Transformer Design Module 2 NewDokumen17 halamanTransformer Design Module 2 NewRajath SuryaBelum ada peringkat

- Southern Electric Power Distribution Long Term Development Statement Parts 1 and 2Dokumen40 halamanSouthern Electric Power Distribution Long Term Development Statement Parts 1 and 2Christos ApostolopoulosBelum ada peringkat

- Schneider Electric LT6 Protection Intelligence Combined Catalog 9110CT9702Dokumen24 halamanSchneider Electric LT6 Protection Intelligence Combined Catalog 9110CT9702Igidio PedroBelum ada peringkat