Process Verification Audit Checklist

Diunggah oleh

riki3xHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Process Verification Audit Checklist

Diunggah oleh

riki3xHak Cipta:

Format Tersedia

John Deere Process Verification Audit - Instructions

Background

This on-site audit is intended for parts with a high level of criticality to determine the effectiveness and conformance of process controls when performing work for John Deere. The work performed can include manufacturing operations at a John Deere or supplier' facility, or operations sub-contracted (sub-tier). This audit may also be performed on similar parts when the work has not yet been sourced, or when preparing for full production. It is intended to be conducted by John Deere personnel familiar with the requirements of the JDSG223 Supplier Quality Manual, the requirements of the selected parts, and processes used in manufacturing the selected parts. This audit is not intended to cover the supplier's or John Deere's entire quality system. To conduct a thorough review of the supplier's quality system, an audit must be conducted an using the JDS-G223 Supplier Quality System Audit Questionnaire and led by a qualified Lead Auditor. A review of John Deere's quality system is conducted with internal audits by trained auditors or consultants. The lead auditor and team members must be qualified to conduct a Process Verification Audit.

Instructions

Prior to the on-site audit, review the most recent part specifications (drawing) and Control Plan on file for relevance, design level, and date. Also, review any other pertinent data or documents, such as key characteristics, Gage R&R studies, capability study information, Materials Engineering report / material certification, inspection data, FMEAs, internal and external failure data, and/or the supplier's internal procedures. Schedule the on-site audit with the part manufacturer at a time when the identified parts are being produced with the processes to be audited, and when manufacturing personnel are available to help guide the audit. The on-site audit is led by a qualified John Deere auditor trained in the Process Verification Audit process, and who is familiar with quality processes and tools. The audit team should have representatives who are familiar with the processes and parts being audited. The audit sequence should follow the order of the steps of the process. Score each question on the checklist with a whole number from 1 to 3, with 3 being the highest possible score. If the question is not applicable, select NA in the scoring field. NA questions are excluded from the final score Total Point and Percentage calculations. Scoring definitions are on the checklist. Up to five part numbers or families may be audited per worksheet. When all the questions are scored, a total score and percentage is automatically calculated. To display scores to the supplier, you may want to group the data by selecting "1" in the top left corner of the spreadsheet. This will hide the comment fields. Select "2" to display the comments. Non-conformances (all questions scored as 1) require corrective action. List the corrective action request description and other follow-up actions in the Audit Summary and Corrective Action section. Enter corrective action requests into NCCA. Document the NCCA number on the audit report.

Data Storage

After completing the audit report, please send it to your division quality audit system coordinator to file in Supplier Evaluation Tracking system located in JD Supply Network. Delete the audit instructions and change history prior to filing the audit. Completed audits can be viewed in Supplier Evaluation Tracking at this link: http://www.90.deere.com/suppmgmt/business_processes/strategic_sourcing_process/tools/supplier_evaluation _tracking/supplier_evaluation_tracking_index.htm

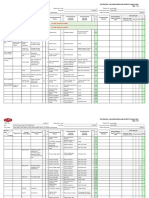

John Deere Process Verification Audit - Checklist

Supplier Name: Supplier Number: Supplier Address: Supplier Phone Number: Supplier E-Mail: Audit Team Leader: Reason for Audit: Date of Last John Deere Assessment or Survey (if any): Process(es) / Product(s) Audited: Note: Secure copy of certification(s) if not provided in advance Quality System Certification, Registrar, and Date of Certificate Expiration (ISO, ISO/TS, etc.): Environmental System Certification, Registrar & Date of Expiration (ISO 14001): Health & Safety System Certification, Registrar & Date of Expiration (ISO 18001): Supplier Fax Number: Audit Team Members: Survey Date(s): Supplier Contact(s):

Audit Summary and Corrective Action

Total Audit Points: Audit Summary: 0 Total Possible Points: 0 Percent: NOT SCORED

Corrective Action Required (if any):

NCCA #(s):

GENERAL SCORING CRITERIA Rating Does Not Apply Does Not Comply 2 Needs Improvement 3 Score ** NA 1 Ability to meet requirement in question: Requirement is not applicable. Requirement is not met or partially met. There is no evidence of implementation or documentation, or major inconsistencies in implementation or documentation (major non-conformance). Requirement is met but there are minor inconsistencies in implementation or documentation, or is in the early phases and only preliminary evidence of implementation effectiveness exists. Requirement is met, effectively implemented, and fully documented. Corrective Action No action required Requires Corrective Action Request (CAR), Document in NCCA Opportunity for Improvement. Recommend CAR, but not required No action required

Complies

** A supplier must have a score of 2 or greater on each of the questions to be acceptable.

93339247.xls.ms_office

Page 2 of 5

Print Date: 4/18/2012

John Deere Process Verification Audit - Checklist

Supplier Name: Survey Date(s): Score each question using a 1 to 3 point scale, where 3 is the best possible score. Input NA for non-applicable questions.

Process Verification Audit Checklist

Part Number(s) or Families:

A.

#

1

Document Control

Question

Is the part print to the current Revision Level? Comments: Are the Control Plan documents being used up-to-date? Comments: If the Control Plan at the supplier is not the same version as the one at John Deere, was the change process followed per JDS-G223? Comments: a Do the process control documents adequately address all process parameters and product characteristics? b Are the Product and Process Key Characteristics known, visible, and is there a documented control plan in place to continuously monitor the process control and capability? c If the part has Key Characteristics, have a Gage R&R and capability study been performed? d If the key characteristic has a Cpk < 1.33, does the Control Plan follow the requirements of the Continuous Process Monitoring Matrix? e Are cleanliness requirements documented on the Control Plan? Comments: Are the Process flow diagrams, PFMEAs, Capability Studies, and Gage R&Rs controlled and up-to-date? Comments: Are other pertinent process control documents up-to-date? (Examples: process sheets, inspection and test instructions, standard operating procedures, preventive maintenance instructions) Comments: Are Suppliers' (sub-tier) documentation of the above (questions 1-6) for key characteristics controlled and up-to-date? Comments: Are computer programs used in the manufacturing process secure, controlled and backed up? (Examples: CNC & PLC programs). Comments:

Score

B. Material and Process Control

9 a Is the Control Plan applied at each operation and being followed, from incoming material to shipping? b Is the frequency of inspection being performed as described in the Control Plan? c Are the inspection method and equipment being used as described in the Control Plan? d Do the operator instructions reflect the requirements of the Control Plan? Comments: 10 Do the sample size, frequency and sampling method take into account the sources of variation? (Examples: multiple machines or fixtures for same characteristic, multi-cavity molds for the same part, and changes over time, like tool wear and environment) Comments:

93339247.xls.ms_office

Page 3 of 5

Print Date: 4/18/2012

John Deere Process Verification Audit - Checklist

Supplier Name:

11 Are other pertinent process control documents in place and being followed? (Examples: process sheets, inspection & test instructions, standard operating procedures, preventive maintenance instructions) Comments: Is inspection data retained and stored appropriately? Comments: Are instructions included for packaging to protect the parts (both in-process & final) from damage & contamination, & are they followed? Comments: Are operators properly trained to perform their operations? Are appropriate personnel properly trained for performing work involving key product and process characteristics (especially for special processes)? Comments:

Survey Date(s):

12

13

14

C. Tools/Gages

15 Is there an understanding of which tools/gages are needed for each operation, and are the needed tools/gages at the work station? Comments: Are any tools/gages being used or needed but not called out? Comments: Does the operator understand the proper use of the tools/gages and is he/she using them properly? Comments: Is equipment, including tooling, properly maintained? Comments: Are all the gages calibrated and records retained? Comments: Do Gage R&R studies have acceptable results? Comments:

16

17

18

19

20

D. Corrective Action

21 Is the Reaction Plan listed on the Control Plan effective & being followed? Comments: Is there an adequate process for isolation & control of non-conforming material (inc. Customer Notification) & is it being followed? Comments: Is an effective closed-loop corrective action process, including identification of root causes, fully implemented? Does the supplier use NCCA, as appropriate? Comments:

22

23

E.

24

Change Control

What is the change control process, and is it effective? (All part and process documentation, including Control Plans, must be updated.) Comments: Are Change Control Procedures followed in accordance with JDS-G223 (Supplier Change Request)? Does this include applicable sub-tier suppliers? Comments:

25

F.

Scoring Summary Total Points 96 Maximum Points Possible Percent of Total Points Available (NA questions are excluded.)

93339247.xls.ms_office Page 4 of 5

0 0%

0 0%

0 0%

0 0%

0 0%

Print Date: 4/18/2012

John Deere Process Verification Audit - Change History

Date Division Who Made Changes Reason for Change 6-May-06 Ag Mark Pershing Proposed Form 28-Aug-07 Ag, C&F, Mark Pershing, Marilyn Adopted by Enterprise Team C&CE, Dumolien, Daryl Fortin, JDPS Gary Watson, Dan Falkenstein, Todd Herzog, Theodore Tyler

93339247.xls.ms_office

Page 5 of 5

Print Date: 4/18/2012

Anda mungkin juga menyukai

- Stalcop Llc. Supplier Audit Form: Page 1 of 12Dokumen12 halamanStalcop Llc. Supplier Audit Form: Page 1 of 12ArdiFebriansyahBelum ada peringkat

- Manufacturing Process Audit ChecklistDokumen4 halamanManufacturing Process Audit Checklistgksp100% (4)

- 2 Run at Rate ProcedureDokumen7 halaman2 Run at Rate ProcedureiandriiBelum ada peringkat

- Manufacturing Process Audit Excel FormDokumen2 halamanManufacturing Process Audit Excel FormTri Hdyvtdt100% (1)

- Manufacturing Process Audit Checklist: Reference DocumentsDokumen4 halamanManufacturing Process Audit Checklist: Reference DocumentsAri Rosyadi100% (1)

- 8D Corrective Actions Report SummaryDokumen2 halaman8D Corrective Actions Report Summarynantha74Belum ada peringkat

- 10 Steps To Conduct A DFMEADokumen5 halaman10 Steps To Conduct A DFMEAkirthi83Belum ada peringkat

- QAF12 Process Audit Rev 09Dokumen4 halamanQAF12 Process Audit Rev 09ukavathekarBelum ada peringkat

- Improve Process Definitions to Pass Stage 1 AuditDokumen48 halamanImprove Process Definitions to Pass Stage 1 Audittehky63Belum ada peringkat

- Quality & Industrial Performance: Supply Chain ManagementDokumen50 halamanQuality & Industrial Performance: Supply Chain Managementshivashankar hrBelum ada peringkat

- Abnormal Situation Record for Manufacturing ChangesDokumen2 halamanAbnormal Situation Record for Manufacturing ChangesPk NimiwalBelum ada peringkat

- GP-9 Process Control Plan Audit Summary SheetDokumen5 halamanGP-9 Process Control Plan Audit Summary SheetAsifBelum ada peringkat

- C8 TurtleDiagramCustomerFeedbackProcess顾客反馈过程乌龟图 EnDokumen1 halamanC8 TurtleDiagramCustomerFeedbackProcess顾客反馈过程乌龟图 EnBAlaBelum ada peringkat

- PFMEA Audit ChecklistDokumen2 halamanPFMEA Audit Checklistadnans100% (3)

- Deptwise IATF RequirementDokumen3 halamanDeptwise IATF RequirementShaili SharmaBelum ada peringkat

- How To Use The Audit Program Manager: List The Processes/functional AreasDokumen25 halamanHow To Use The Audit Program Manager: List The Processes/functional AreasAliBelum ada peringkat

- Procedure For Ppap: Input / Output DiagramDokumen5 halamanProcedure For Ppap: Input / Output DiagrammuthuselvanBelum ada peringkat

- Excel Tool Process Audit Services VDA 6.3 2016 en V1.0Dokumen12 halamanExcel Tool Process Audit Services VDA 6.3 2016 en V1.0Roberto Barbosa100% (1)

- Apqp - DR SHFTDokumen60 halamanApqp - DR SHFTrajesh5000100% (2)

- Process & Product AuditDokumen17 halamanProcess & Product AuditPrakash kumarTripathiBelum ada peringkat

- Meenakshi Molding Private Limited Process FMEA: Form No - FM/7.1/01/09Dokumen4 halamanMeenakshi Molding Private Limited Process FMEA: Form No - FM/7.1/01/09ilaya rajaBelum ada peringkat

- Vendor PPAP Readiness for MEMBER EXTENSION LONGITUDINAL FRONT LH/RHDokumen39 halamanVendor PPAP Readiness for MEMBER EXTENSION LONGITUDINAL FRONT LH/RHSanjay KumarBelum ada peringkat

- Layered AuditDokumen2 halamanLayered AuditJohn Hall100% (2)

- VDA FMEA TemplateDokumen53 halamanVDA FMEA Templatewatna0% (2)

- Supplier Audit Details and Problem Solving Effectiveness ReviewDokumen14 halamanSupplier Audit Details and Problem Solving Effectiveness ReviewDuho ConsultoresBelum ada peringkat

- Layer Process AuditDokumen8 halamanLayer Process AuditR JBelum ada peringkat

- Trainer Manual Internal Quality AuditDokumen28 halamanTrainer Manual Internal Quality AuditmonetteBelum ada peringkat

- Pfmea - Aiag-VdaDokumen108 halamanPfmea - Aiag-VdaGLAUCIO DOS SANTOS SILVABelum ada peringkat

- Supplier Audit Check SheetDokumen5 halamanSupplier Audit Check SheetMotive Post100% (2)

- 8D ReportDokumen2 halaman8D Reportgatofelix1980100% (1)

- VM Checklist - Manufacturing: Peracha Engineering CoDokumen2 halamanVM Checklist - Manufacturing: Peracha Engineering CoPeracha EngineeringBelum ada peringkat

- Supplier Incident Analysis: Claim NoDokumen10 halamanSupplier Incident Analysis: Claim Nonitin pendharkarBelum ada peringkat

- Sop-Special Characteristics IdentificationDokumen3 halamanSop-Special Characteristics IdentificationSaravana kumar NagarajanBelum ada peringkat

- ISO 9001 Quality Procedure Context of the OrganizationDokumen1 halamanISO 9001 Quality Procedure Context of the OrganizationKarim HakimBelum ada peringkat

- Product liability principles and product safetyDokumen3 halamanProduct liability principles and product safetyepimenta_24Belum ada peringkat

- Product Audit Checklist SEODokumen1 halamanProduct Audit Checklist SEORoy PhanBelum ada peringkat

- Layered Audit Check SheetsDokumen5 halamanLayered Audit Check Sheetsdeepak sharmaBelum ada peringkat

- QSP-10 Change Control Rev 02Dokumen4 halamanQSP-10 Change Control Rev 02ukavathekarBelum ada peringkat

- CD6 Prototype Control PlanDokumen3 halamanCD6 Prototype Control Planmpedraza-1Belum ada peringkat

- Prad Automotive Supplier Audit ChecklistDokumen5 halamanPrad Automotive Supplier Audit ChecklistvishvendanBelum ada peringkat

- Production Process Audit ChecklistDokumen2 halamanProduction Process Audit Checklistprofmlocampo100% (5)

- 6 PFMEA & Control Plan 1 of 7Dokumen8 halaman6 PFMEA & Control Plan 1 of 7P G Suman100% (1)

- SQAM-2019 VolvoGroupDokumen52 halamanSQAM-2019 VolvoGroupJanBelum ada peringkat

- Quality ToolDokumen7 halamanQuality ToolAhmed M. HashimBelum ada peringkat

- ISO/TS16949-Self Audit ChecklistDokumen14 halamanISO/TS16949-Self Audit ChecklistBharathBelum ada peringkat

- PFD - Fmea - CPDokumen5 halamanPFD - Fmea - CPNagarajanBelum ada peringkat

- 10.roles, Responsibilities, Authority & AccountabilityDokumen13 halaman10.roles, Responsibilities, Authority & AccountabilitymuthuselvanBelum ada peringkat

- Corrective ActionDokumen18 halamanCorrective ActionDayanand PaiBelum ada peringkat

- CD6 Prototype PFMEADokumen4 halamanCD6 Prototype PFMEAmpedraza-1Belum ada peringkat

- SAFE LAUNCH - Process Description and Information: 1. ObjectiveDokumen3 halamanSAFE LAUNCH - Process Description and Information: 1. ObjectiveSushil Kumar100% (2)

- Layered Audit ChecklistDokumen4 halamanLayered Audit ChecklistNavnath TamhaneBelum ada peringkat

- PPAP FundamentalsDokumen21 halamanPPAP FundamentalsRajdeep SinghBelum ada peringkat

- Apqp - Layered Process Audit-1594636097 SAMPLE 4Dokumen9 halamanApqp - Layered Process Audit-1594636097 SAMPLE 4ubraghuBelum ada peringkat

- GMs Drill Deep Read Across MatrixDokumen10 halamanGMs Drill Deep Read Across MatrixJohn Oo100% (1)

- Transitioning to IATF-16949:2016Dokumen39 halamanTransitioning to IATF-16949:2016Joseph StephenBelum ada peringkat

- Centurion Power Cables (P) LTD.: 1.0 PurposeDokumen4 halamanCenturion Power Cables (P) LTD.: 1.0 PurposetriveshBelum ada peringkat

- IATF - International Automotive Task ForceDokumen10 halamanIATF - International Automotive Task ForceBeli NovareseBelum ada peringkat

- Control Plan Audit FormDokumen2 halamanControl Plan Audit Formdpcastilla50% (2)

- 04 Turtle DiagramsDokumen1 halaman04 Turtle Diagramsabhisheksen.asindBelum ada peringkat

- Assessing Gross Efficiency and Propelling Efficiency in Swimming Paola Zamparo Department of Neurological Sciences, Faculty of Exercise and Sport Sciences, University of Verona, Verona, ItalyDokumen4 halamanAssessing Gross Efficiency and Propelling Efficiency in Swimming Paola Zamparo Department of Neurological Sciences, Faculty of Exercise and Sport Sciences, University of Verona, Verona, ItalyVijay KumarBelum ada peringkat

- Lecture 4Dokumen25 halamanLecture 4ptnyagortey91Belum ada peringkat

- Irctc Tour May 2023Dokumen6 halamanIrctc Tour May 2023Mysa ChakrapaniBelum ada peringkat

- Vidura College Marketing AnalysisDokumen24 halamanVidura College Marketing Analysiskingcoconut kingcoconutBelum ada peringkat

- Cisco CMTS Feature GuideDokumen756 halamanCisco CMTS Feature GuideEzequiel Mariano DaoudBelum ada peringkat

- EE290 Practice 3Dokumen4 halamanEE290 Practice 3olgaBelum ada peringkat

- IMT Ghaziabad PGDM Timetable Term II 2020Dokumen22 halamanIMT Ghaziabad PGDM Timetable Term II 2020Ved JhingranBelum ada peringkat

- Basic Five Creative ArtsDokumen4 halamanBasic Five Creative Artsprincedonkor177Belum ada peringkat

- Cells in The Urine SedimentDokumen3 halamanCells in The Urine SedimentTaufan LutfiBelum ada peringkat

- National Advisory Committee For AeronauticsDokumen36 halamanNational Advisory Committee For AeronauticsSamuel ChristioBelum ada peringkat

- EnerSys Global Leader in Industrial BatteriesDokumen32 halamanEnerSys Global Leader in Industrial BatteriesAshredBelum ada peringkat

- 2016 Mustang WiringDokumen9 halaman2016 Mustang WiringRuben TeixeiraBelum ada peringkat

- Recycle Used Motor Oil With Tongrui PurifiersDokumen12 halamanRecycle Used Motor Oil With Tongrui PurifiersRégis Ongollo100% (1)

- Planview Innovation Management Maturity Model PDFDokumen1 halamanPlanview Innovation Management Maturity Model PDFMiguel Alfonso Mercado GarcíaBelum ada peringkat

- SYNOPSIS - Impact of GST On Small Traders!Dokumen21 halamanSYNOPSIS - Impact of GST On Small Traders!Laxmi PriyaBelum ada peringkat

- Brain, Behavior, and Immunity: Alok Kumar, David J. LoaneDokumen11 halamanBrain, Behavior, and Immunity: Alok Kumar, David J. LoaneRinaldy TejaBelum ada peringkat

- Emergency Room Delivery RecordDokumen7 halamanEmergency Room Delivery RecordMariel VillamorBelum ada peringkat

- Operation Manual: Auto Lensmeter Plm-8000Dokumen39 halamanOperation Manual: Auto Lensmeter Plm-8000Wilson CepedaBelum ada peringkat

- ROPE TENSIONER Product-Catalog-2019Dokumen178 halamanROPE TENSIONER Product-Catalog-2019jeedanBelum ada peringkat

- Desert Power India 2050Dokumen231 halamanDesert Power India 2050suraj jhaBelum ada peringkat

- Optimization of The Spray-Drying Process For Developing Guava Powder Using Response Surface MethodologyDokumen7 halamanOptimization of The Spray-Drying Process For Developing Guava Powder Using Response Surface MethodologyDr-Paras PorwalBelum ada peringkat

- Driving Continuous Improvement by Developing and Leveraging Lean Key Performance IndicatorsDokumen10 halamanDriving Continuous Improvement by Developing and Leveraging Lean Key Performance IndicatorskellendadBelum ada peringkat

- Modified Release Drug ProductsDokumen58 halamanModified Release Drug Productsmailtorubal2573100% (2)

- Term Sheet: Original Borrowers) Material Subsidiaries/jurisdiction) )Dokumen16 halamanTerm Sheet: Original Borrowers) Material Subsidiaries/jurisdiction) )spachecofdz0% (1)

- Supreme Court rules stabilization fees not trust fundsDokumen8 halamanSupreme Court rules stabilization fees not trust fundsNadzlah BandilaBelum ada peringkat

- Newcomers Guide To The Canadian Job MarketDokumen47 halamanNewcomers Guide To The Canadian Job MarketSS NairBelum ada peringkat

- Major Bank Performance IndicatorsDokumen35 halamanMajor Bank Performance IndicatorsAshish MehraBelum ada peringkat

- 10 Slides For A Perfect Startup Pitch DeckDokumen6 halaman10 Slides For A Perfect Startup Pitch DeckZakky AzhariBelum ada peringkat

- SEO Design ExamplesDokumen10 halamanSEO Design ExamplesAnonymous YDwBCtsBelum ada peringkat

- Modul-Document Control Training - Agus F - 12 Juli 2023 Rev1Dokumen34 halamanModul-Document Control Training - Agus F - 12 Juli 2023 Rev1vanesaBelum ada peringkat