Timber Examples - Tedds

Diunggah oleh

Tom KwoDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Timber Examples - Tedds

Diunggah oleh

Tom KwoHak Cipta:

Format Tersedia

Project

Job no.

TCI

Calcs for

Start page no./Revision

1

Calcs by Calcs date Checked by Checked date Approved by Approved date

18/04/2012

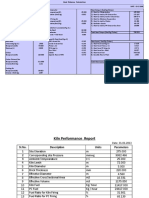

GLULAM BEAM ANALYSIS & DESIGN TO AS1720.1-2010

TEDDS calculation version 1.5.01

mm A

4600 1

Unfactored Loads 1.250 Permanent Live

Self weight included

0.0 mm A 4600 1 B

Load Envelope - Com bination 1 3.000

0.0 mm A 4600 1 B

Load Com bination 1 (show n in proportion)

Live

Permanent

mm A

4600 1

kNm 0.0

Bending Mom ent Envelope

9.2 11.945 mm A 11.9 4600 1

Project

Job no.

TCI

Calcs for

Start page no./Revision

2

Calcs by Calcs date Checked by Checked date Approved by Approved date

18/04/2012

kN 8.847

Shear Force Envelope 8.8 6.5 1.1

0.0

-9.239 mm A 4600 1

-9.2 B

Applied loading Beam loads Permanent self weight of beam 1 Permanent full UDL 0.750 kN/m Live full UDL 0.500 kN/m Permanent point load 1.250 kN at 1200 mm Live point load 1.000 kN at 1200 mm Permanent point load 1.250 kN at 2400 mm Live point load 1.000 kN at 2400 mm Permanent point load 1.250 kN at 3600 mm Live point load 1.000 kN at 3600 mm Load combinations Load combination 1 Support A Span 1 Support B Permanent 1.20 Live 1.50 Permanent 1.20 Live 1.50 Permanent 1.20 Live 1.50 Analysis results Maximum moment; Design moment; Maximum shear; Design shear; Total load on member; Reactions at support A; Unfactored permanent load reaction at support A; Unfactored live load reaction at support A; Reactions at support B; Unfactored permanent load reaction at support B; Unfactored live load reaction at support B; M max = 11.945 kNm; M min = 0.000 kNm M = max(abs(M max ),abs(M min )) = 11.945 kNm V max = 8.847 kN; V min = -9.239 kN V = max(abs(V max ),abs(V min )) = 9.239 kN W tot = 18.086 kN R A_max = 8.847 kN; R A_Permanent = 4.142 kN R A_Live = 2.585 kN R B_max = 9.239 kN; R B_Permanent = 4.305 kN R B_Live = 2.715 kN R B_min = 9.239 kN R A_min = 8.847 kN

315

135 100

Project

Job no.

TCI

Calcs for

Start page no./Revision

3

Calcs by Calcs date Checked by Checked date Approved by Approved date

Y Glulam section details Breadth of glulam section; Depth of glulam section; Number of glulam sections in member; Overall breadth of glulam member; Glulam strength grade - Table 7.1; Strength group - Table 2.3(A); Member details Load duration - cl.2.4.1; Length of bearing; Section properties Cross sectional area of member; Section modulus; Second moment of area; Radius of gyration;

18/04/2012

b = 135 mm d = 315 mm N=1 b b = N b = 135 mm GL8 SD4

Long-term L b = 100 mm A = N b d = 42525 mm 2 Z x = N b d 2 / 6 = 2232562 mm 3 Z y = d (N b) 2 / 6 = 956812 mm 3 Ix = N b d 3 / 12 = 351628594 mm 4 Iy = d (N b)3 / 12 = 64584844 mm 4 r x = (Ix / A) = 90.9 mm r y = (I y / A) = 39.0 mm

Modification factors Duration of load factor for strength - Table 2.3; Moisture condition factor - cl.2.4.2.3; Temperature factor - cl.2.4.3; Length and position of bearing factor - Table 2.6; Strength sharing factor - cl.7.4.3; Temporary design action ratio; Material constant - exp.E2(1); Distance between discrete lateral restraints; Major axis slenderness coefficient - cl.3.2.3.2(b); Major axis bending stability factor - exp.3.2(10); Minor axis slenderness coefficient - cl.3.2.3.2 (c); Minor axis bending stability factor - cl.3.2.4; Bearing strength - cl.3.2.6 Capacity factor - Table 2.1; Bearing area for loading perpendicular to grain; p = 0.95 A p = N b L b = 13500 mm 2 N p = p k 1 k 4 k 6 k 7 f'p A p = 174.420 kN PASS - Design capacity in bearing perpendicular to the grain exceeds design bearing load Bending strength - cl.3.2.1 Capacity factor - Table 2.1; Design capacity in bending - cl.3.2(2); b = 0.95 M = b k 1 k 4 k 6 k 9 k 12bx f'b Z x = 32.238 kNm PASS - Design capacity in bending exceeds design bending moment Flexural shear strength - cl.3.2.5 Capacity factor - Table 2.1; Shear plane area; Design shear capacity - exp.3.2(14); s = 0.95 A s = N b d 2 / 3 = 28350 mm 2 V = s k 1 k 4 k 6 f's A s = 79.720 kN k 1 = 0.80 k 4 = 1.00 k 6 = 1.00 k 7 = 1.00 k 9 = 1.00 r = 0.25 b = 14.71 (E / f'b) -0.480 r -0.061 = 0.88 L ay = 1200 mm; S 1 = 0.00 k 12bx = 1.00 S 2 = 0.00 k 12by = 1.00 L ay / d < 64 [N b / ( b d)]2

Design capacity in bearing perpendicular to grain - exp.3.2(16)

Project

Job no.

TCI

Calcs for

Start page no./Revision

4

Calcs by Calcs date Checked by Checked date Approved by Approved date

18/04/2012 PASS - Design shear capacity exceeds design shear force

Deflection - AS/NZS 1170.0 Deflection limit - Table C1; Deflection due to permanent load; Deflection due to imposed load; Load factor - Table 4.1; Creep factor (Long-term); Total deflection; lim = min(14 mm, 0.004 L s1 ) = 14.000 mm G = 4.499 mm Q = 2.898 mm = 0.7 j2 = 1.850 tot = j2 [ G + Q ] = 12.075 mm PASS - Total deflection is less than the deflection limit

Project

Job no.

TCI

Calcs for

Start page no./Revision

1

Calcs by Calcs date Checked by Checked date Approved by Approved date

18/04/2012

TIMBER BEAM ANALYSIS & DESIGN TO AS1720.1-2010

TEDDS calculation version 1.5.01

mm A

3000 1

Unfactored Loads 2.500 Permanent Live

Self weight included

0.0 mm A 3000 1 B

Load Envelope - Com bination 1 5.302

0.0 mm A 3000 1 B

Load Com bination 1 (show n in proportion)

Live

Permanent

mm A

3000 1

kNm 0.0

Bending Mom ent Envelope

5.965 mm A

6.0 3000 1

Project

Job no.

TCI

Calcs for

Start page no./Revision

2

Calcs by Calcs date Checked by Checked date Approved by Approved date

18/04/2012

kN 7.953

Shear Force Envelope 8.0

0.0

-7.953 mm A 3000 1

-8.0 B

Applied loading Beam loads Permanent self weight of beam 1 Permanent full UDL 2.500 kN/m Live full UDL 1.450 kN/m Load combinations Load combination 1 Support A Span 1 Support B Permanent 1.20 Live 1.50 Permanent 1.20 Live 1.50 Permanent 1.20 Live 1.50 Analysis results Maximum moment; Design moment; Maximum shear; Design shear; Total load on member; Reactions at support A; Unfactored permanent load reaction at support A; Unfactored live load reaction at support A; Reactions at support B; Unfactored permanent load reaction at support B; Unfactored live load reaction at support B; M max = 5.965 kNm; M min = 0.000 kNm M = max(abs(M max ),abs(M min )) = 5.965 kNm V max = 7.953 kN; V min = -7.953 kN V = max(abs(V max ),abs(V min )) = 7.953 kN W tot = 15.906 kN R A_max = 7.953 kN; R A_Permanent = 3.909 kN R A_Live = 2.175 kN R B_max = 7.953 kN; R B_Permanent = 3.909 kN R B_Live = 2.175 kN R A_min = 7.953 kN

R B_min = 7.953 kN

240

90 100

Timber section details Breadth of timber sections; Depth of timber sections; Number of timber sections in member; Overall breadth of timber member; b = 45 mm d = 240 mm N=2 b b = N b = 90 mm

Project

Job no.

TCI

Calcs for

Start page no./Revision

3

Calcs by Calcs date Checked by Checked date Approved by Approved date

Y Timber species; Moisture condition; Timber strength grade - Table H2.1; Member details Load duration - cl.2.4.1; Length of bearing; Section properties Cross sectional area of member; Section modulus; Second moment of area; Radius of gyration;

18/04/2012 Mixed softw ood species (excl.Pinus species) Seasoned F8

Long-term L b = 100 mm A = N b d = 21600 mm 2 Z x = N b d 2 / 6 = 864000 mm 3 Z y = d (N b) 2 / 6 = 324000 mm 3 Ix = N b d 3 / 12 = 103680000 mm 4 Iy = d (N b)3 / 12 = 14580000 mm 4 r x = (Ix / A) = 69.3 mm r y = (I y / A) = 26.0 mm

Modification factors Duration of load factor for strength - Table 2.3; Moisture condition factor - cl.2.4.2.3; Temperature factor - cl.2.4.3; Length and position of bearing factor - Table 2.6; Strength sharing factor - Table 2.7; Temporary design action ratio; Material constant - exp.E2(1); Distance between discrete lateral restraints; Major axis slenderness coefficient - cl.3.2.3.2(b); Major axis bending stability factor - exp.3.2(10); Minor axis slenderness coefficient - cl.3.2.3.2 (c); Minor axis bending stability factor - cl.3.2.4; Bearing strength - cl.3.2.6 Capacity factor - Table 2.1; Bearing area for loading perpendicular to grain; p = 0.9 A p = N b L b = 9000 mm 2 N p = p k 1 k 4 k 6 k 7 f'p A p = 44.064 kN PASS - Design capacity in bearing perpendicular to the grain exceeds design bearing load Bending strength - cl.3.2.1 Capacity factor - Table 2.1; Design capacity in bending - cl.3.2(2); b = 0.9 M = b k 1 k 4 k 6 k 9 k 12bx f'b Z x = 15.602 kNm PASS - Design capacity in bending exceeds design bending moment Flexural shear strength - cl.3.2.5 Capacity factor - Table 2.1; Shear plane area; Design shear capacity - exp.3.2(14); s = 0.9 A s = N b d 2 / 3 = 14400 mm 2 V = s k 1 k 4 k 6 f's A s = 22.810 kN PASS - Design shear capacity exceeds design shear force Deflection - AS/NZS 1170.0 Deflection limit - Table C1; Deflection due to permanent load; lim = min(14 mm, 0.004 L s1 ) = 12.000 mm G = 3.180 mm k 1 = 0.80 k 4 = 1.00 k 6 = 1.00 k 7 = 1.00 k 9 = 1.14 r = 0.25 b = 14.71 (E / f'b) -0.480 r -0.061 = 0.89 L ay = 1200 mm; S 1 = 0.00 k 12bx = 1.00 S 2 = 0.00 k 12by = 1.00 L ay / d < 64 [N b / ( b d)]2

Design capacity in bearing perpendicular to grain - exp.3.2(16)

Project

Job no.

TCI

Calcs for

Start page no./Revision

4

Calcs by Calcs date Checked by Checked date Approved by Approved date

Y Deflection due to imposed load; Load factor - Table 4.1; Creep factor (Long-term); Total deflection;

18/04/2012 Q = 1.769 mm = 0.7 j2 = 1.850 tot = j2 [ G + Q ] = 8.173 mm PASS - Total deflection is less than the deflection limit

Project

Job no.

TCI

Calcs for

Start page no./Revision

1

Calcs by Calcs date Checked by Checked date Approved by Approved date

18/04/2012

STRUCTURAL LVL BEAM ANALYSIS & DESIGN TO AS1720.1-2010

TEDDS calculation version 1.5.01

mm A

4250 1

3750 2

Unfactored Loads 6.000 Permanent Live

Self weight included

0.0 mm A 4250 1 B 3750 2 C

Load Envelope - Com bination 1 12.889

0.0 mm A 4250 1 B 3750 2 C

Load Envelope - Com bination 2 12.889

0.0 mm A 4250 1 B 3750 2 C

Load Envelope - Com bination 3 12.889

0.0 mm A 4250 1 B 3750 2 C

Project

Job no.

TCI

Calcs for

Start page no./Revision

2

Calcs by Calcs date Checked by Checked date Approved by Approved date

18/04/2012

Load Com bination 1 (show n in proportion)

Live

Permanent

mm A

4250 1

3750 2

Load Com bination 2 (show n in proportion)

Live

Permanent

mm A

4250 1

3750 2

Load Com bination 3 (show n in proportion)

Live

Permanent

mm A

4250 1

3750 2

kNm -26.080

Bending Mom ent Envelope -26.1

0.0

20.742 mm A

20.7 4250 1 B

16.0 3750 2 C

kN 31.122

Shear Force Envelope 31.1 23.1

0.0 -20.3 -33.526 mm A 4250 1 -33.5 B 3750 2 C

Applied loading Beam loads Permanent self weight of beam 1 Permanent full UDL 3.000 kN/m Live full UDL 6.000 kN/m

Project

Job no.

TCI

Calcs for

Start page no./Revision

3

Calcs by Calcs date Checked by Checked date Approved by Approved date

Y Load combinations Load combination 1

18/04/2012

Support A Span 1 Support B Span 2 Support C

Permanent 1.20 Live 1.50 Permanent 1.20 Live 1.50 Permanent 1.20 Live 1.50 Permanent 1.00 Live 0.00 Permanent 1.00 Live 0.00 Permanent 1.00 Live 0.00 Permanent 1.00 Live 0.00 Permanent 1.20 Live 1.50 Permanent 1.20 Live 1.50 Permanent 1.20 Live 1.50 Permanent 1.20 Live 1.50 Permanent 1.20 Live 1.50 Permanent 1.20 Live 1.50 Permanent 1.20 Live 1.50 Permanent 1.20 Live 1.50

Load combination 2

Support A Span 1 Support B Span 2 Support C

Load combination 3

Support A Span 1 Support B Span 2 Support C

Analysis results Maximum moment; Design moment; Maximum shear; Design shear; Total load on member; Reactions at support A; Unfactored permanent load reaction at support A; Unfactored live load reaction at support A; Reactions at support B; Unfactored permanent load reaction at support B; Unfactored live load reaction at support B; Reactions at support C; Unfactored permanent load reaction at support C; M max = 20.742 kNm;

M min = -26.080 kNm M = max(abs(M max ),abs(M min )) = 26.080 kNm V max = 31.122 kN; V min = -33.526 kN V = max(abs(V max ),abs(V min )) = 33.526 kN W tot = 103.113 kN R A_max = 23.123 kN; R A_Permanent = 5.344 kN R A_Live = 9.893 kN R B_max = 64.648 kN; R B_Permanent = 16.256 kN R B_Live = 30.094 kN R C_max = 20.298 kN; R C_Permanent = 4.328 kN R C_min = 1.242 kN R A_min = 3.473 kN

R B_min = 38.336 kN

Project

Job no.

TCI

Calcs for

Start page no./Revision

4

Calcs by Calcs date Checked by Checked date Approved by Approved date

Y Unfactored live load reaction at support C;

18/04/2012 R C_Live = 8.012 kN

300

126 100

Structural LVL section details Breadth of LVL section; Depth of LVL section; Number of LVL sections in member; Overall breadth of LVL member; Structural LVL properties Bending; Tension parallel to grain; Shear in member; Compression parallel to grain; f'b = 48 MPa f't = 33 MPa f's = 5.3 MPa f'c = 45 MPa f'p = 12 MPa b = 63 mm d = 300 mm N=2 b b = N b = 126 mm

Bearing perpendicular to grain; Short duration average modulus of elasticity parallel to the grain

E = 13200 MPa Short duration average modulus of rigidity for members G = 660 MPa Design density; Member details Load duration - cl.2.4.1; Length of bearing; Section properties Cross sectional area of member; Section modulus; Second moment of area; Radius of gyration; A = N b d = 37800 mm 2 Z x = N b d 2 / 6 = 1890000 mm 3 Z y = d (N b) 2 / 6 = 793800 mm 3 Ix = N b d 3 / 12 = 283500000 mm 4 Iy = d (N b)3 / 12 = 50009400 mm 4 r x = (Ix / A) = 86.6 mm r y = (I y / A) = 36.4 mm Modification factors Duration of load factor for strength - Table 2.3; Moisture content factor for bending - Table 8.1; k 1 = 0.80 k 4b = 1.00 Long-term L b = 100 mm = 650 kg/m 3

Moisture content factor for compression - Table 8.1; k 4c = 1.00 Moisture content factor for tension - Table 8.1; k 4t = 1.00 Moisture content factor for shear - Table 8.1; k 4s = 1.00 Moisture content factor for modulus of elasticity - Table 8.1 j6 = 1.00 Temperature factor - cl.2.4.3; k 6 = 1.00

Project

Job no.

TCI

Calcs for

Start page no./Revision

5

Calcs by Calcs date Checked by Checked date Approved by Approved date

Y Length and position of bearing factor - Table 2.6; Strength sharing factor - cl.8.4.6; Size factor for bending - cl.8.3.1; Size factor for tension parallel - cl.8.3.1; Temporary design action ratio; Material constant - exp.E2(1); Distance between discrete lateral restraints; Major axis slenderness coefficient - cl.3.2.3.2(b); Major axis bending stability factor - exp.3.2(10); Minor axis slenderness coefficient - cl.3.2.3.2 (c); Minor axis bending stability factor - cl.3.2.4; Bearing strength - cl.3.2.6 Capacity factor - Table 2.1; Bearing area for loading perpendicular to grain;

18/04/2012 k 7 = 1.13 k 9 = 1.00 k 11b = min((300 mm / d) 0.167 , 1) = 1.00 k 11t = min((150 mm / d)0.167 , 1) = 0.89 r = 0.25 b = 14.71 (E / f'b) -0.480 r -0.061 = 1.08 L ay = 1200 mm; S 1 = 0.00 k 12bx = 1.00 S 2 = 0.00 k 12by = 1.00 p = 0.95 A p = N b L b = 12600 mm 2 N p = p k 1 k 4c k 6 k 7 f'p A p = 129.276 kN L ay / d < 64 [N b / ( b d)]2

Design capacity in bearing perpendicular to grain - exp.3.2(16) PASS - Design capacity in bearing perpendicular to the grain exceeds design bearing load Bending strength - cl.3.2.1 Capacity factor - Table 2.1; Design capacity in bending - cl.3.2(2); b = 0.95 M = b k 1 k 4b k 6 k 9 k 11b k 12bx f'b Z x = 68.947 kNm PASS - Design capacity in bending exceeds design bending moment Flexural shear strength - cl.3.2.5 Capacity factor - Table 2.1; Shear plane area; Design shear capacity - exp.3.2(14); s = 0.95 A s = N b d 2 / 3 = 25200 mm 2 V = s k 1 k 4s k 6 f's A s = 101.506 kN PASS - Design shear capacity exceeds design shear force Deflection - AS/NZS 1170.0 Deflection limit - Table C1; Deflection due to permanent load; Deflection due to imposed load; Load factor - Table 4.1; Creep factor (Long-term); Total deflection; lim = min(14 mm, 0.004 L s1 ) = 14.000 mm G = 2.271 mm Q = 4.205 mm = 0.7 j2 = 1.850 tot = j2 [ G + Q ] = 9.646 mm PASS - Total deflection is less than the deflection limit

Project

Job no.

TCI

Calcs for

Start page no./Revision

1

Calcs by Calcs date Checked by Checked date Approved by Approved date

18/04/2012

GLULAM MEMBER DESIGN TO AS1720.1-2010

TEDDS calculation version 1.5.01

Analysis results Design moment in major axis; Design axial compression; M x = 75.900 kNm N c = 113.500 kN

540 135

Glulam section details Breadth of glulam section; Depth of glulam section; Number of glulam sections in member; Overall breadth of glulam member; Glulam strength grade - Table 7.1; Strength group - Table 2.3(A); Member details Load duration - cl.2.4.1; Overall length of member; Effective length factor - Table 3.2; Distance between lateral restraints in major axis; Distance between lateral restraints in minor axis; Section properties Cross sectional area of member; Section modulus; Second moment of area; Radius of gyration; A = N b d = 72900 mm 2 Z x = N b d 2 / 6 = 6561000 mm 3 Z y = d (N b) 2 / 6 = 1640250 mm 3 Ix = N b d 3 / 12 = 1771470000 mm 4 Iy = d (N b)3 / 12 = 110716875 mm 4 r x = (Ix / A) = 155.9 mm r y = (I y / A) = 39.0 mm Modification factors Duration of load factor for strength - Table 2.3; Moisture condition factor - cl.2.4.2.3; Temperature factor - cl.2.4.3; Length and position of bearing factor - cl.2.4.4; Strength sharing factor - cl.7.4.3; Temporary design action ratio; Material constant - exp.E2(1); Distance between discrete lateral restraints; Major axis slenderness coefficient - cl.3.2.3.2(b); k 1 = 0.94 k 4 = 1.00 k 6 = 1.00 k 7 = 1.00 k 9 = 1.00 r = 0.25 b = 14.71 (E / f'b) -0.480 r -0.061 = 0.88 L ay = 1620 mm; S 1 = 0.00 L ay / d < 64 [N b / ( b d)]2 Medium-term L x = 8100 mm g 13 = 1 L ax = 8100 mm L ay = 1620 mm b = 135 mm d = 540 mm N=1 b b = N b = 135 mm GL8 SD4

Project

Job no.

TCI

Calcs for

Start page no./Revision

2

Calcs by Calcs date Checked by Checked date Approved by Approved date

Y Major axis bending stability factor - exp.3.2(10); Minor axis slenderness coefficient - cl.3.2.3.2 (c); Minor axis bending stability factor - cl.3.2.4; Material constant - exp.E2(3); Major axis slenderness coefficient - exp.3.3(5); Major axis comp.stability factor - exp.3.3(11b); Minor axis slenderness coefficient - exp.3.3(8); Minor axis comp.stability factor - exp.3.3(11b); Bending strength - cl.3.2.1 Capacity factor - Table 2.1; Design capacity in major axis bending - cl.3.2(2);

18/04/2012 k 12bx = 1.00 S 2 = 0.00 k 12by = 1.00 c = 11.39 (E / f'c) -0.408 r -0.074 = 1.18 S 3 = L ax / d = 15.00 k 12cx = 1.5 - 0.05 c S 3 = 0.62 S 4 = L ay / (N b) = 12.00 k 12cy = 1.5 - 0.05 c S 4 = 0.79 b = 0.85 M x = b k 1 k 4 k 6 k 9 k 12bx f'b Z x = 99.603 kNm PASS - Design capacity in bending exceeds design bending moment

Compressive strength - cl.3.3.1 Capacity factor - Table 2.1; Cross-sectional area of member; c = 0.85 A c = N b d = 72900 mm 2 N cx = c k 1 k 4 k 6 k 12cx f'c A c = 860.127 kN Minor axis design capacity in compression - exp.3.3(2) N cy = c k 1 k 4 k 6 k 12cy f'c A c = 1107.481 kN PASS - Design capacity in compression exceeds design compression Combined bending and compression - cl.3.5.1 Combined bending and compression check - exp.3.5(1) and exp.3.5(2) [M x / M x ]2 + [N c / N cy] = 0.683; < 1 [M x / M x ] + [N c / N cx ] = 0.894; < 1 PASS - Beam design meets combined bending and compression criteria

Major axis design capacity in compression - exp.3.3(2)

Project

Job no.

TCI

Calcs for

Start page no./Revision

1

Calcs by Calcs date Checked by Checked date Approved by Approved date

18/04/2012

TIMBER MEMBER DESIGNTIMBER MEMBER DESIGN TO AS1720.1-2010

TEDDS calculation version 1.5.01

Analysis results Design moment in major axis; Design axial compression; M x = 2.800 kNm N c = 8.100 kN

194

60

Timber section details Breadth of timber sections; Depth of timber sections; Number of timber sections in member; Overall breadth of timber member; Timber species; Moisture condition; Timber strength grade - Table H2.1; Member details Load duration - cl.2.4.1; Overall length of member; Effective length factor - Table 3.2; Distance between lateral restraints in major axis; Distance between lateral restraints in minor axis; Section properties Cross sectional area of member; Section modulus; Second moment of area; Radius of gyration; A = N b d = 11640 mm 2 Z x = N b d 2 / 6 = 376360 mm 3 Z y = d (N b) 2 / 6 = 116400 mm 3 Ix = N b d 3 / 12 = 36506920 mm 4 Iy = d (N b)3 / 12 = 3492000 mm 4 r x = (Ix / A) = 56.0 mm r y = (I y / A) = 17.3 mm Modification factors Duration of load factor for strength - Table 2.3; Moisture condition factor - cl.2.4.2.3; Temperature factor - cl.2.4.3; Length and position of bearing factor - cl.2.4.4; Strength sharing factor - Table 2.7; Temporary design action ratio; Material constant - exp.E2(1); Distance between discrete lateral restraints; Major axis slenderness coefficient - exp.3.2(4); k 1 = 0.80 k 4 = 1.00 k 6 = 1.00 k 7 = 1.00 k 9 = 1.00 r = 0.25 b = 14.71 (E / f'b) -0.480 r -0.061 = 0.94 L ay = 1400 mm; S 1 = 1.25 d / (N b) (L ay / d)

0.5

b = 60 mm d = 194 mm N=1 b b = N b = 60 mm Mixed softw ood species (excl.Pinus species) Seasoned F8

Long-term L x = 4200 mm g 13 = 1 L ax = 4200 mm L ay = 1400 mm

L ay / d > 64 [N b / ( b d)]2 = 10.86

Project

Job no.

TCI

Calcs for

Start page no./Revision

2

Calcs by Calcs date Checked by Checked date Approved by Approved date

Y Major axis bending stability factor - exp.3.2(11); Minor axis slenderness coefficient - cl.3.2.3.2 (c); Minor axis bending stability factor - cl.3.2.4; Material constant - exp.E2(3); Major axis slenderness coefficient - exp.3.3(5); Major axis comp.stability factor - exp.3.3(11c); Minor axis slenderness coefficient - exp.3.3(8); Minor axis comp.stability factor - exp.3.3(11c); Bending strength - cl.3.2.1 Capacity factor - Table 2.1; Design capacity in major axis bending - cl.3.2(2);

18/04/2012 k 12bx = 1.5 - 0.05 b S 1 = 0.99 S 2 = 0.00 k 12by = 1.00 c = 11.39 (E / f'c) -0.408 r -0.074 = 1.04 S 3 = L ax / d = 21.65 k 12cx = 200 / ( c S 3) 2 = 0.40 S 4 = L ay / (N b) = 23.33 k 12cy = 200 / ( c S 4) 2 = 0.34 b = 0.8 M x = b k 1 k 4 k 6 k 9 k 12bx f'b Z x = 5.946 kNm PASS - Design capacity in bending exceeds design bending moment

Compressive strength - cl.3.3.1 Capacity factor - Table 2.1; Cross-sectional area of member; c = 0.8 A c = N b d = 11640 mm 2 N cx = c k 1 k 4 k 6 k 12cx f'c A c = 58.896 kN Minor axis design capacity in compression - exp.3.3(2) N cy = c k 1 k 4 k 6 k 12cy f'c A c = 50.702 kN PASS - Design capacity in compression exceeds design compression Combined bending and compression - cl.3.5.1 Combined bending and compression check - exp.3.5(1) and exp.3.5(2) [M x / M x ]2 + [N c / N cy] = 0.381; < 1 [M x / M x ] + [N c / N cx ] = 0.608; < 1 PASS - Beam design meets combined bending and compression criteria

Major axis design capacity in compression - exp.3.3(2)

Project

Job no.

TCI

Calcs for

Start page no./Revision

1

Calcs by Calcs date Checked by Checked date Approved by Approved date

18/04/2012

TIMBER MEMBER DESIGNSTRUCTURAL LVL MEMBER DESIGN TO AS1720.1-2010

TEDDS calculation version 1.5.01

Analysis results Design moment in major axis; Design axial compression; M x = 3.700 kNm N c = 70.200 kN

150

150

Structural LVL section details Breadth of LVL section; Depth of LVL section; Number of LVL sections in member; Overall breadth of LVL member; Structural LVL properties Bending; Tension parallel to grain; Shear in member; f'b = 48 MPa f't = 33 MPa f's = 5.3 MPa b = 150 mm d = 150 mm N=1 b b = N b = 150 mm

Compression parallel to grain; f'c = 45 MPa Bearing perpendicular to grain; f'p = 12 MPa Short duration average modulus of elasticity parallel to the grain E = 13200 MPa Short duration average modulus of rigidity for members G = 660 MPa Design density; Member details Load duration - cl.2.4.1; Overall length of member; Effective length factor - Table 3.2; Distance between lateral restraints in major axis; Distance between lateral restraints in minor axis; Section properties Cross sectional area of member; Section modulus; Second moment of area; Radius of gyration; A = N b d = 22500 mm 2 Z x = N b d 2 / 6 = 562500 mm 3 Z y = d (N b) 2 / 6 = 562500 mm 3 Ix = N b d 3 / 12 = 42187500 mm 4 Iy = d (N b)3 / 12 = 42187500 mm 4 r x = (Ix / A) = 43.3 mm r y = (I y / A) = 43.3 mm Medium-term L x = 4250 mm g 13 = 1 L ax = 4250 mm L ay = 4250 mm = 650 kg/m 3

Project

Job no.

TCI

Calcs for

Start page no./Revision

2

Calcs by Calcs date Checked by Checked date Approved by Approved date

Y Modification factors Duration of load factor for strength - Table 2.3; Moisture content factor for bending - Table 8.1; Moisture content factor for tension - Table 8.1;

18/04/2012

k 1 = 0.94 k 4b = 1.00

Moisture content factor for compression - Table 8.1; k 4c = 1.00 k 4t = 1.00 Moisture content factor for shear - Table 8.1; k 4s = 1.00 Moisture content factor for modulus of elasticity - Table 8.1 j6 = 1.00 Temperature factor - cl.2.4.3; Length and position of bearing factor - cl.2.4.4; Strength sharing factor - cl.8.4.6; Size factor for bending - cl.8.3.1; Size factor for tension parallel - cl.8.3.1; Temporary design action ratio; Material constant - exp.E2(1); Distance between discrete lateral restraints; Major axis slenderness coefficient - cl.3.2.3.2(b); Major axis bending stability factor - exp.3.2(10); Minor axis slenderness coefficient - cl.3.2.3.2 (c); Minor axis bending stability factor - cl.3.2.4; Material constant - exp.E2(3); Major axis slenderness coefficient - exp.3.3(5); Major axis comp.stability factor - exp.3.3(11c); Minor axis slenderness coefficient - exp.3.3(8); Minor axis comp.stability factor - exp.3.3(11c); Bending strength - cl.3.2.1 Capacity factor - Table 2.1; Design capacity in major axis bending - cl.3.2(2); b = 0.9 M x = b k 1 k 4b k 6 k 9 k 11b k 12bx f'b Z x = 22.842 kNm PASS - Design capacity in bending exceeds design bending moment Compressive strength - cl.3.3.1 Capacity factor - Table 2.1; Cross-sectional area of member; c = 0.9 A c = N b d = 22500 mm 2 N cx = c k 1 k 4c k 6 k 12cx f'c A c = 138.170 kN Minor axis design capacity in compression - exp.3.3(2) N cy = c k 1 k 4c k 6 k 12cy f'c A c = 138.170 kN PASS - Design capacity in compression exceeds design compression Combined bending and compression - cl.3.5.1 Combined bending and compression check - exp.3.5(1) and exp.3.5(2) [M x / M x ]2 + [N c / N cy] = 0.534; < 1 [M x / M x ] + [N c / N cx ] = 0.670; < 1 PASS - Beam design meets combined bending and compression criteria k 6 = 1.00 k 7 = 1.00 k 9 = 1.00 k 11b = min((300 mm / d) 0.167 , 1) = 1.00 k 11t = min((150 mm / d)0.167 , 1) = 1.00 r = 0.25 b = 14.71 (E / f'b) -0.480 r -0.061 = 1.08 L ay = 4250 mm; S 1 = 0.00 k 12bx = 1.00 S 2 = 0.00 k 12by = 1.00 c = 11.39 (E / f'c) -0.408 r -0.074 = 1.24 S 3 = L ax / d = 28.33 k 12cx = 200 / ( c S 3) 2 = 0.16 S 4 = L ay / (N b) = 28.33 k 12cy = 200 / ( c S 4) 2 = 0.16 L ay / d < 64 [N b / ( b d)]2

Major axis design capacity in compression - exp.3.3(2)

Anda mungkin juga menyukai

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionDari EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionBelum ada peringkat

- Aw-01-07 ColumnDokumen14 halamanAw-01-07 ColumnalexanderBelum ada peringkat

- Multi Deck 146Dokumen36 halamanMulti Deck 146bondar1100% (1)

- CVE30002 HS1 2019 Design ProjectDokumen8 halamanCVE30002 HS1 2019 Design ProjectOliver Sharpe0% (1)

- Epoxy Connection TimberDokumen6 halamanEpoxy Connection TimberJeffery RoweBelum ada peringkat

- General Design of Rectangular Tanks: The Walls Are Designed Both For Direct Tension and Bending MomentDokumen17 halamanGeneral Design of Rectangular Tanks: The Walls Are Designed Both For Direct Tension and Bending MomentAlvin AsinguaBelum ada peringkat

- t02 Austroads LoadingsDokumen11 halamant02 Austroads Loadingskushar_geoBelum ada peringkat

- Column Design GuideDokumen8 halamanColumn Design GuideegozenovieBelum ada peringkat

- CIVL5277 Lecture 8 - Design of Tension and Compression MembersDokumen48 halamanCIVL5277 Lecture 8 - Design of Tension and Compression Membersjihe0020Belum ada peringkat

- Comflor Composite Floor Deck Brochure UKDokumen68 halamanComflor Composite Floor Deck Brochure UKSuciu Bogdan AlexandruBelum ada peringkat

- BIA - Steel Lintel DesignDokumen7 halamanBIA - Steel Lintel Designgpax42Belum ada peringkat

- Glass ThicknessDokumen2 halamanGlass ThicknessShanil BussooaBelum ada peringkat

- Introduction Nash HB RLRSFDokumen8 halamanIntroduction Nash HB RLRSFDenise2512Belum ada peringkat

- Factors Affecting Strength of Epoxy Repaired TimberDokumen15 halamanFactors Affecting Strength of Epoxy Repaired TimberJosé PeBelum ada peringkat

- Slab On GradeDokumen57 halamanSlab On GradeGurnam Singh SodhiBelum ada peringkat

- LongitudinalShearReinforcementDesign C10 bk800 PDFDokumen7 halamanLongitudinalShearReinforcementDesign C10 bk800 PDFBehairy AhmedBelum ada peringkat

- Rectangular Spread Footing DesignDokumen42 halamanRectangular Spread Footing DesignJedidiah MelakuBelum ada peringkat

- Design of Concrete & Masonry Structures: Dr. Ye Lu Lecture #7-2 (Week 7)Dokumen20 halamanDesign of Concrete & Masonry Structures: Dr. Ye Lu Lecture #7-2 (Week 7)tien2506onlineBelum ada peringkat

- New Zealand Standart For ShootcreteDokumen11 halamanNew Zealand Standart For ShootcreteAbdul Wahid AlkindyBelum ada peringkat

- Direct Strength Design of Cold-Formed C-Sections FDokumen15 halamanDirect Strength Design of Cold-Formed C-Sections FHassan Ali SadiqBelum ada peringkat

- Crack Width Calculation for BS 8110 BeamDokumen1 halamanCrack Width Calculation for BS 8110 Beamjacs127Belum ada peringkat

- ESKOM Medupi Power Station Crawl Beam Calculation SheetDokumen22 halamanESKOM Medupi Power Station Crawl Beam Calculation SheetMbalekelwa MpembeBelum ada peringkat

- Mitek 12kN Pile FixingDokumen2 halamanMitek 12kN Pile FixingTuroyBelum ada peringkat

- Con 1303Dokumen8 halamanCon 1303chef100% (1)

- Beam Truss AnalogyDokumen4 halamanBeam Truss AnalogyspamBelum ada peringkat

- Flooring Design GuideDokumen81 halamanFlooring Design GuideArmin KovacevicBelum ada peringkat

- Structural Steelwork Design 2012-2013 Calculation SheetDokumen3 halamanStructural Steelwork Design 2012-2013 Calculation SheetIbnuyusoff77Belum ada peringkat

- Seismic Design Guide For Masonry Buildings: Donald Anderson Svetlana BrzevDokumen113 halamanSeismic Design Guide For Masonry Buildings: Donald Anderson Svetlana BrzevVladimir Sánchez CalderónBelum ada peringkat

- Spreadsheets To BS 8110Dokumen11 halamanSpreadsheets To BS 8110NitinShepurBelum ada peringkat

- Constructing Coastal Buildings on Pile FoundationsDokumen61 halamanConstructing Coastal Buildings on Pile FoundationsAr Amit MehtaBelum ada peringkat

- Title Page and ContentsDokumen11 halamanTitle Page and ContentsAshlin AarthiBelum ada peringkat

- RC Beam Design CCAA - Revised 1.2 JWWDokumen12 halamanRC Beam Design CCAA - Revised 1.2 JWWFerdie TolosaBelum ada peringkat

- Guide For Compliant Construction of Timber Windows and Doors in Bushfi Re-Prone AreasDokumen16 halamanGuide For Compliant Construction of Timber Windows and Doors in Bushfi Re-Prone AreasCarlos D. GuiradosBelum ada peringkat

- Structural Engineering VUDokumen6 halamanStructural Engineering VUshan kumarBelum ada peringkat

- Gang-Nail Connectors - How They Work Gang-Nail Truss SystemDokumen5 halamanGang-Nail Connectors - How They Work Gang-Nail Truss SystemAnonymous acaD5VBelum ada peringkat

- Daniel Tian Li: Plain Concrete Footing Design Based On ACI 318-05Dokumen2 halamanDaniel Tian Li: Plain Concrete Footing Design Based On ACI 318-05Wintun73Belum ada peringkat

- Mathcad - 09-Wind LoadsDokumen3 halamanMathcad - 09-Wind LoadsLCARDILES6337100% (1)

- AD 261 - Elastic Modulus of AnglesDokumen1 halamanAD 261 - Elastic Modulus of Anglessymon ellimacBelum ada peringkat

- Civil Design Help - Foundation For Rotating Equipment PDFDokumen31 halamanCivil Design Help - Foundation For Rotating Equipment PDFoluomo1Belum ada peringkat

- Bitexco Financial Tower rises as symbol of Vietnam's global emergenceDokumen9 halamanBitexco Financial Tower rises as symbol of Vietnam's global emergenceyamibarisonziBelum ada peringkat

- DDA 3164 BEAM Shear Deflection and CrackDokumen20 halamanDDA 3164 BEAM Shear Deflection and CrackZayyan RomjonBelum ada peringkat

- Example Flat Slab Design - CarDokumen31 halamanExample Flat Slab Design - CarRayGaintBelum ada peringkat

- Truss DeflectionDokumen2 halamanTruss DeflectionAb_AlizadehBelum ada peringkat

- Ener CalcDokumen1 halamanEner Calcseljak_veseljakBelum ada peringkat

- Notes On Design of Steel Parking Structures IncludDokumen42 halamanNotes On Design of Steel Parking Structures IncludSudhakar KrishnamurthyBelum ada peringkat

- RCFootingDesignWebDokumen3 halamanRCFootingDesignWebjudeBelum ada peringkat

- Assignment 1 GRAD 2019Dokumen4 halamanAssignment 1 GRAD 2019RamonErnestoICBelum ada peringkat

- Isolated Footing Design (ACI-318)Dokumen7 halamanIsolated Footing Design (ACI-318)Abu Yaseen AzizBelum ada peringkat

- Building Girt CalcDokumen2 halamanBuilding Girt Calcwudongxiao3953Belum ada peringkat

- Structural Design and Analysis Proposed Three Storey Commercial ResidenceDokumen79 halamanStructural Design and Analysis Proposed Three Storey Commercial ResidenceGEREMY SANTIAGOBelum ada peringkat

- Shear Lug DesignDokumen19 halamanShear Lug DesignariyaBelum ada peringkat

- Shear Lug Verification Example 2Dokumen1 halamanShear Lug Verification Example 2Nasrul AdliBelum ada peringkat

- Anchor Design HILTIDokumen14 halamanAnchor Design HILTIRohit GadekarBelum ada peringkat

- Shearwall Basics Using SDPWS DesignDokumen132 halamanShearwall Basics Using SDPWS DesignDixon Antonio MaradiagaBelum ada peringkat

- Constructions: Load Bearing Constructions Using Wood-Concrete-Composite Technique With Glued-In - Shear ConnectorsDokumen35 halamanConstructions: Load Bearing Constructions Using Wood-Concrete-Composite Technique With Glued-In - Shear ConnectorsPATRICIO SARAVIABelum ada peringkat

- Footing DesignDokumen35 halamanFooting DesignAngel MouriBelum ada peringkat

- Software Verification: AISC-360-10 Example 001Dokumen9 halamanSoftware Verification: AISC-360-10 Example 001Davico HernandezBelum ada peringkat

- Digsilent Powerfactory: Technical Reference DocumentationDokumen19 halamanDigsilent Powerfactory: Technical Reference DocumentationAlexBelum ada peringkat

- BE 8256 - Basic Mechanical Engineering / U – II / Compiled by R.Arul KamalakumarDokumen24 halamanBE 8256 - Basic Mechanical Engineering / U – II / Compiled by R.Arul KamalakumararulrakkBelum ada peringkat

- Finite Element MethodDokumen32 halamanFinite Element MethodParvind LolldharryBelum ada peringkat

- Study Material: Free Master Class SeriesDokumen13 halamanStudy Material: Free Master Class SeriesRizwan Salim100% (1)

- Design Pipe Systems Pumps Gea Hilge Manual 272424Dokumen60 halamanDesign Pipe Systems Pumps Gea Hilge Manual 272424Geferson GonçalvesBelum ada peringkat

- Application of Differential EquationsDokumen2 halamanApplication of Differential EquationsATHARVA KOTKARBelum ada peringkat

- Physics of The Impossible: A Scientific Exploration Into The World of Phasers, Force Fields, Teleportation, and Time Travel by Michio KakuDokumen2 halamanPhysics of The Impossible: A Scientific Exploration Into The World of Phasers, Force Fields, Teleportation, and Time Travel by Michio KakuHomeroom TabBelum ada peringkat

- Manual of Basic Air Flow BenchDokumen24 halamanManual of Basic Air Flow BenchPung Kang Qin100% (1)

- Physical property tablesDokumen27 halamanPhysical property tablesIan Oscar Gomez HuamaniBelum ada peringkat

- Heat Balance GCLDokumen6 halamanHeat Balance GCLIrshad HussainBelum ada peringkat

- Exer 8 DV-3LDokumen5 halamanExer 8 DV-3LdeusleanBelum ada peringkat

- M.Sc. Applied Physics (Photonics)Dokumen25 halamanM.Sc. Applied Physics (Photonics)KARMA FOWLBelum ada peringkat

- Principles of TurbomachineryDokumen276 halamanPrinciples of TurbomachineryNavneet PAndeBelum ada peringkat

- FIITJEE ALL INDIA TEST SERIES PART TEST – I PHYSICS ANSWERS, HINTS & SOLUTIONSDokumen18 halamanFIITJEE ALL INDIA TEST SERIES PART TEST – I PHYSICS ANSWERS, HINTS & SOLUTIONSShiromani BujdilBelum ada peringkat

- CHEE2940 Mid-Semester Quiz 2012 - SolutionsDokumen10 halamanCHEE2940 Mid-Semester Quiz 2012 - Solutionspetecooper7159Belum ada peringkat

- Quantum Entanglement LectureDokumen4 halamanQuantum Entanglement LectureBasman BasmanBelum ada peringkat

- UeeDokumen4 halamanUeeAditya ShrivastavBelum ada peringkat

- FC Sem 3 NATURE AND DEVELOPMENT OF SCIENCEDokumen11 halamanFC Sem 3 NATURE AND DEVELOPMENT OF SCIENCEPravin RnsBelum ada peringkat

- Scanning Electron Microscope (SEM)Dokumen51 halamanScanning Electron Microscope (SEM)Maaz ZafarBelum ada peringkat

- Electrodynamometer Type InstrumentDokumen9 halamanElectrodynamometer Type Instrumentanon_463330020Belum ada peringkat

- LC OscillationDokumen20 halamanLC Oscillationaditya66605Belum ada peringkat

- Introduction To Simple StressDokumen13 halamanIntroduction To Simple StressRie LiBelum ada peringkat

- Calculus Based Physics Q#1 PrelimDokumen6 halamanCalculus Based Physics Q#1 PrelimAlan Dela CruzBelum ada peringkat

- CFD Abl2Dokumen38 halamanCFD Abl2Rahul ShuklaBelum ada peringkat

- Magnetisum @kvpy - AspirantsDokumen4 halamanMagnetisum @kvpy - AspirantssagarBelum ada peringkat

- NET December 2016 Physics Exam QuestionsDokumen21 halamanNET December 2016 Physics Exam QuestionsRamesh IswaraBelum ada peringkat

- Chapter 2Dokumen62 halamanChapter 2kere evaBelum ada peringkat

- Experiment #5 Pulse Response of Simple RC & RL CircuitsDokumen11 halamanExperiment #5 Pulse Response of Simple RC & RL CircuitsAhmed HamoudaBelum ada peringkat

- Numerical Modeling of Physical Process of Far Field Underwater ExplosionsDokumen11 halamanNumerical Modeling of Physical Process of Far Field Underwater ExplosionsKristjan TabriBelum ada peringkat

- H.L. Stormer and D.C. Tsui - The Fractional Quantum Hall EffectDokumen2 halamanH.L. Stormer and D.C. Tsui - The Fractional Quantum Hall EffectGreamxxBelum ada peringkat