Rs Service Instructions

Diunggah oleh

Central HydraulicsDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Rs Service Instructions

Diunggah oleh

Central HydraulicsHak Cipta:

Format Tersedia

PI222002

Rev. 2.06

whitedriveproducts

SERVICE INSTRUCTIONS FOR THE RS [200 & 201] SERIES MOTORS

For Use With Seal Kits: 200222001 & 200222002 dimensions: mm [in]

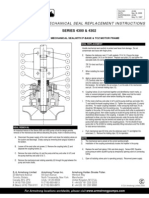

IMPORTANT NOTE: The RS(200/201) Series Motors depend on the correct orientation of parts as well as correct internal timing for proper motor operation. Before disassembling the motor, it is highly recommended that paint or a marker be used to make a V shaped set of lines from the endcover to the housing. This will aid in reassembling the motor components properly. It is also important that the steps involving internal parts timing be followed carefully to insure proper motor operation. A) Remove all shaft related components from shaft (21) (i.e. keys, wire rings, nuts). To aid in reassembly of the motor, make a V shaped set of lines from the endcover (16) to the housing using either paint or a marker. With shaft facing down, secure motor in vise by clamping on to housing (19). B) Loosen and remove four bolts (18) holding motor assembly together. Remove endcover (16). Remove body seal (8) and discard seal. Remove rotor assembly (14) and wear plate (13). Remove body seals (8) from rotor assembly (14) and housing (19) and discard seals. Remove drive link pin (15) and drive link (12) from motor and lay aside. C) Gently tap shaft (21) upward through housing (19) and remove through rear of housing. Turn shaft over and remove cooling plug (20). Remove housing (19) from vise and turn over. Pry dust seal (1) from housing. Push the seal carrier (9), thrust washer (10) and thrust bearing (11) down and remove through rear of housing. (NOTE: When removing items 9-11, care should be taken so that housing bore is not scratched or nicked.) If a new seal carrier and thrust washer is included in kit, old items may be discarded. If not, carefully pry shaft seal (7), Teon backup seal (6) and metal backup shim (5) from seal carrier (9) and discard items 5-7. Lay seal carrier (9) aside. Remove wire ring (2), metal backup shim (3) and high pressure seal (4) from inner bore groove of housing with a small screwdriver and discard items. At this point, all parts should be cleaned in an oil-based solvent and dried using compressed air (For safety, observe all OSHA safety guidelines). All new seals should be lightly coated in clean oil prior to installation. D) Place shaft (21) on a clean at surface with output end facing up. Place thrust bearing (11) then thrust washer (10) on shaft. Install shaft seal (7) down onto shaft (21) making sure that lip on seal faces down (See Figure 1 for correct seal orientation). Install the Teon backup seal (6) onto the shaft (21) with the at side up and the seal lip facing the shaft seal (7). Place the metal backup shim (5) onto the shaft and against the Teon backup seal (6). Place the seal carrier (9) onto the shaft (large end down) and carefully press the seal carrier (9) down onto the seal assembly using an arbor press and sleeve to compress the seals into the carrier. E) Install high pressure seal (4) into groove in housing. Install metal backup shim (3) against high pressure seal (4) in groove in housing bore by squeezing the shim (3) between thumb and forenger to bow shim (bow in the shim should be in the shape of a hill and not a valley for easier installation). While maintaining bow in shim, start the shim into the groove and use a small screwdriver to push the shim into groove. Install wire ring (2) into the groove making sure that the ends are butted. RS (200/201) SHAFT/DRIVE LINK TIMING PROCEDURES NOTE: To return the RS Series Motors to proper operation, the rotation code of the motor must be known. The rotation code of the motor is 200(standard) 201(reverse timed)- the rst 3 digits of the model code. If the rotational code is not known, motors that are to have the shafts turning clockwise (as viewed from the shaft end) should be timed using the 200 series and motors that are to have the shafts turning counterclockwise (as viewed from shaft end) should be timed using the 201 series. F) Turn shaft (21) over so that output end of shaft faces down. Install cooling plug (20) down into shaft (21) making sure large O.D. end of cooling plug (20) faces up. Lower drive link (12) into shaft making sure that timing mark end of drive link faces up and that the timing mark on the end of the drive link (12) is aligned with one of the through holes in the shaft (21). When splines contact each other, slowly rotate drive link (12) counterclockwise for a 200 series, or clockwise for a 201 series motor until drive link splines engage with those on shaft (21). G) Turn housing (19) over so that pilot of housing faces down and secure housing (19) in vise. Without disturbing seal carrier assembly (9) or drive link (12), carefully lower shaft assembly into housing. To seat seal carrier (9) against wire ring (2), gently tap drive link (12) down until end of shaft (21) is nearly ush with rear surface of housing. H) Place a body seal (8) in the groove in the rear surface of the housing (19). Using alignment marks as a guide, place wear plate (13) on housing making sure that notch in wear plate (13) is aligned with port side of housing (20) (See Figure 2). I) Place a body seal (8) in the groove in the face of the rotor assembly (14). Lower rotor (14) onto drive link (12) making sure that timing mark on drive link is aligned with a peak on the rotor (14) (See Figure 3). Once splines are engaged, rotate rotor (14) so that notch on rotor is aligned with notch on wear plate (13) and ports on housing (19) (See Figure 2). Insert drive link pin (15) into end of drive link (12) making sure that concave end faces up.

White Drive Products, Inc.

P.O. Box 1127

Hopkinsville, KY 42241

Phone: 270.885.1110

Fax: 270.886.8462

1(800)264-9571

Central Hydraulics, Inc. Stocking Distributor for White Hydraulic motors

www.CenHyd.com

J)

Place remaining body seal (8) in groove in endcover (16). Using alignment marks as a guide, place endcover (16) onto motor making sure that end of drive link pin (15) is in hole in center of endcover. Insert four assembly bolts (18) into bolt holes and pretorque to 13,6 Nm [10 ft. lb.]. Using a crisscross pattern, torque bolts to 67,8 Nm [50 ft. lb.].

K) Remove motor from vise and place on work surface with shaft (21) facing up. Making sure that lip on dust seal (1) faces up, place dust seal (1) over shaft (21). Using a sleeve and hammer, carefully drive dust seal (1) into place.

dust seal metal backup shim seal carrier backup seal notch in stator notch in rotor

timing mark

peak on rotor

housing ports

wire ring high pressure seal metal bakup shim

shaft seal

FIGURE 1

FIGURE 2

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. * * * * * * * * * * *

FIGURE 3

Dust Seal Split Wire Ring Metal Backup Shim High Pressure Seal Metal Backup Shim Backup Seal Shaft Seal Body Seal (3) Seal Carrier Thrust Washer Thrust Bearing Drive Llink Wear Plate Rotor Assembly Drive Link Pin Endcover I.D. Tag Assembly Assembly Bolts (4) Housing Cooling Plug Shaft Shaft Key

18 17

8 12 20 15 14 13 16

Contained in Seal Kit 200222001 Contained in Seal Kit 200222002

21 22 10 6 9 3 1 11 7 5 4 2

White Drive Products, Inc. P.O. Box 1127 Hopkinsville, KY 42241 Phone: 270.885.1110 Fax: 270.886.8462

19

1(800)264-9571

Central Hydraulics, Inc. Stocking Distributor for White Hydraulic motors

www.CenHyd.com

Anda mungkin juga menyukai

- Volvo d12 Workshop Manual Less Specifications AbbyDokumen709 halamanVolvo d12 Workshop Manual Less Specifications Abbykoaa8597% (60)

- T 176Dokumen9 halamanT 176ashkansoheylBelum ada peringkat

- Assembly ProcedureDokumen115 halamanAssembly ProcedureAlex Castillo100% (1)

- Toyota 5e Fhe 1 PDFDokumen13 halamanToyota 5e Fhe 1 PDFJuan Carlos Díaz Cardozo100% (2)

- Bobcat S300 Parts ManualDokumen400 halamanBobcat S300 Parts ManualDobos01100% (1)

- Marine Transmission Service Manual: DMT 25AL 280HLDokumen38 halamanMarine Transmission Service Manual: DMT 25AL 280HLFabian AstudilloBelum ada peringkat

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDari EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceBelum ada peringkat

- 07-124 Motor CharlynDokumen12 halaman07-124 Motor CharlynMiguel Angel Santos Pintado100% (2)

- Transmission Koleos mk1Dokumen165 halamanTransmission Koleos mk1E Ovidiu100% (1)

- Caterpillar Cat 329DL Excavator (Prefix TZL) Service Repair Manual (TZL00001 and Up) PDFDokumen21 halamanCaterpillar Cat 329DL Excavator (Prefix TZL) Service Repair Manual (TZL00001 and Up) PDFfkdmma100% (1)

- 3230F350 PARTS CatalogDokumen5 halaman3230F350 PARTS CatalogLIONN TESTE2021Belum ada peringkat

- C Molo TM003 eDokumen8 halamanC Molo TM003 ejcclaBelum ada peringkat

- DR 600 Service PartsDokumen8 halamanDR 600 Service PartsCentral HydraulicsBelum ada peringkat

- Injector Installation 107 EngineDokumen5 halamanInjector Installation 107 EnginevalterripBelum ada peringkat

- TTNFC EN 00 - CircuitDokumen18 halamanTTNFC EN 00 - CircuitRoseller SumonodBelum ada peringkat

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDari EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementBelum ada peringkat

- Ce Service PartsDokumen6 halamanCe Service PartsCentral HydraulicsBelum ada peringkat

- Common Wire Splices and JointsDokumen19 halamanCommon Wire Splices and JointsJames Adrian Abalde Sabo100% (6)

- VOLVO EC210 NLC EC210NLC EXCAVATOR Service Repair Manual PDFDokumen16 halamanVOLVO EC210 NLC EC210NLC EXCAVATOR Service Repair Manual PDFfjjsjekdmme67% (3)

- d9 800 Service PartsDokumen2 halamand9 800 Service PartsCentral HydraulicsBelum ada peringkat

- WD Cross ReferenceDokumen12 halamanWD Cross ReferenceCentral HydraulicsBelum ada peringkat

- DT Service PartsDokumen2 halamanDT Service PartsCentral HydraulicsBelum ada peringkat

- Anson E Typs Gate Valve With Fail Safe Closed ActuatorDokumen12 halamanAnson E Typs Gate Valve With Fail Safe Closed ActuatorWeniton Oliveira0% (1)

- 966c Torque Convertidor Desarmado y ArmadoDokumen7 halaman966c Torque Convertidor Desarmado y ArmadoJohn Ceballos100% (1)

- Eaton: Model 74318 and 74348 Piston Motors Fixed Displacement, Valve Plate DesignDokumen9 halamanEaton: Model 74318 and 74348 Piston Motors Fixed Displacement, Valve Plate Designluisbravo1264Belum ada peringkat

- DT Service PartsDokumen4 halamanDT Service PartsCentral HydraulicsBelum ada peringkat

- Despiece Ewdx11l3egDokumen8 halamanDespiece Ewdx11l3egHEDIXON CARDOZOBelum ada peringkat

- Barrilete e Cabeçote - SondeqDokumen7 halamanBarrilete e Cabeçote - SondeqCompras Servdrill100% (1)

- Dynexpv2029 2994 - 3239partslistDokumen2 halamanDynexpv2029 2994 - 3239partslistjulianmata67% (3)

- DR Service InstructionsDokumen4 halamanDR Service InstructionsCentral HydraulicsBelum ada peringkat

- Flow Doc 2 PDFDokumen18 halamanFlow Doc 2 PDFJozefBelum ada peringkat

- WD Service InstructionsDokumen2 halamanWD Service InstructionsCentral HydraulicsBelum ada peringkat

- cirrusSR22 32-20Dokumen22 halamancirrusSR22 32-20Dario ForestiereBelum ada peringkat

- Sherwood 29000 - Tech GuideDokumen8 halamanSherwood 29000 - Tech GuidePaško KelavaBelum ada peringkat

- Procedimento Desmonte Bequilha 39400030 Cessna 182 Skylane Procedimentos de ManutencaoDokumen7 halamanProcedimento Desmonte Bequilha 39400030 Cessna 182 Skylane Procedimentos de ManutencaoadrianvieroBelum ada peringkat

- Roatary Actuators - Micromatic Repair Manual - SS-0.2A & SS-0.5ADokumen7 halamanRoatary Actuators - Micromatic Repair Manual - SS-0.2A & SS-0.5AtungBelum ada peringkat

- Rotation Joint 1.5 - Forum N156RJ30N-REV0Dokumen6 halamanRotation Joint 1.5 - Forum N156RJ30N-REV0Владислав ВиршинитBelum ada peringkat

- Flow Doc.1 PDFDokumen12 halamanFlow Doc.1 PDFJozefBelum ada peringkat

- Baarra 725Dokumen4 halamanBaarra 725ericBelum ada peringkat

- 6.0L Turbo Rebuild Instructions PDFDokumen5 halaman6.0L Turbo Rebuild Instructions PDFW MoralesBelum ada peringkat

- Mechanical Seal Replacement InstructionsDokumen1 halamanMechanical Seal Replacement InstructionsGiorgio FerBelum ada peringkat

- Fork Strip ExtractDokumen24 halamanFork Strip Extract张连杉Belum ada peringkat

- 950F CaterpillarDokumen15 halaman950F CaterpillarMartinez Mauricio Martinez GomezBelum ada peringkat

- Desarmado Bomba 416Dokumen16 halamanDesarmado Bomba 416Anword TelefonosBelum ada peringkat

- Armado de OrbitrolDokumen10 halamanArmado de OrbitrolANTONIO CRUZBelum ada peringkat

- Group 7 RCV Lever: 1. Removal and InstallDokumen15 halamanGroup 7 RCV Lever: 1. Removal and InstallRafał DworakBelum ada peringkat

- Crankshaft - InstallDokumen7 halamanCrankshaft - InstallLeonardo PerezBelum ada peringkat

- Caterpillar Cat 245B EXCAVATOR (Prefix 1SJ) Service Repair Manual (1SJ00001-00712)Dokumen24 halamanCaterpillar Cat 245B EXCAVATOR (Prefix 1SJ) Service Repair Manual (1SJ00001-00712)rpoy9396615Belum ada peringkat

- 43.88UK Mechanical Seal Replacement Instructions TCDokumen4 halaman43.88UK Mechanical Seal Replacement Instructions TCMohammed Mostafa El HaddadBelum ada peringkat

- Instructions For The Use of Fixture Group - Parts ReusabilityDokumen7 halamanInstructions For The Use of Fixture Group - Parts ReusabilityRASOUL KHADIBIBelum ada peringkat

- Crankshaft - Install PDFDokumen7 halamanCrankshaft - Install PDFsonjisahuriBelum ada peringkat

- Travel Motor AssembleDokumen10 halamanTravel Motor AssembleMaimun maimunBelum ada peringkat

- Swing Rack - InstallDokumen7 halamanSwing Rack - InstallGilney FreitasBelum ada peringkat

- Https 127.0.0.1 Sisweb Sisweb Techdoc Techdoc Print PageDokumen9 halamanHttps 127.0.0.1 Sisweb Sisweb Techdoc Techdoc Print Pagep.motortechBelum ada peringkat

- XL Series Actuators 1: Installation, Operating and Maintenance InstructionsDokumen8 halamanXL Series Actuators 1: Installation, Operating and Maintenance InstructionsFranco M. CaverzanBelum ada peringkat

- Group 10 Rear AxleDokumen42 halamanGroup 10 Rear AxleTaha RdmanBelum ada peringkat

- Orbitrol Repairing1Dokumen30 halamanOrbitrol Repairing1Islam ShoukryBelum ada peringkat

- 43 88 - Mechanical - Seal - Replacement - Instructions - TCDokumen4 halaman43 88 - Mechanical - Seal - Replacement - Instructions - TCAlan MercesBelum ada peringkat

- Armado de Rueda DelanteraDokumen10 halamanArmado de Rueda DelanteraWilson Castillo AlvarezBelum ada peringkat

- Cylinder Blok c4Dokumen7 halamanCylinder Blok c4lilikBelum ada peringkat

- Makita BJR182 18VDokumen11 halamanMakita BJR182 18VJose Sanchez100% (2)

- Convertidor de Torque D5BDokumen13 halamanConvertidor de Torque D5BDeyner PerezBelum ada peringkat

- ManualDokumen4 halamanManualMano Negra100% (1)

- Install Piston and ConrodDokumen8 halamanInstall Piston and ConrodLUIZ GUSTAVOBelum ada peringkat

- Bevel and Transfer Gears - AssembleDokumen14 halamanBevel and Transfer Gears - AssembleIginio Malaver VargasBelum ada peringkat

- Repair Procedure HS14 - S7.4x2.5 - 26-10-7632Dokumen9 halamanRepair Procedure HS14 - S7.4x2.5 - 26-10-7632Cesar Camones100% (1)

- TA30 A894 Parte C PDFDokumen148 halamanTA30 A894 Parte C PDFoctavio hernandezBelum ada peringkat

- Group 5 Swing Device: 1. Removal and Install of MotorDokumen25 halamanGroup 5 Swing Device: 1. Removal and Install of MotorHậu MinhBelum ada peringkat

- Differential & Bevel GearDokumen7 halamanDifferential & Bevel GearNadhifatulBelum ada peringkat

- Orbit RolDokumen12 halamanOrbit RolFabio MartinsBelum ada peringkat

- Dif and Carrier 966cDokumen18 halamanDif and Carrier 966cHector VallesBelum ada peringkat

- Circle Drive - Assemble-I08509292Dokumen13 halamanCircle Drive - Assemble-I08509292Taller HeavytechBelum ada peringkat

- Crankshaft - Install: Desmontagem e MontagemDokumen11 halamanCrankshaft - Install: Desmontagem e MontagemTatiano BrolloBelum ada peringkat

- Caterpillar Cat 160h Motor Grader Prefix 9jm Service Repair Manual 9jm00001 and UpDokumen23 halamanCaterpillar Cat 160h Motor Grader Prefix 9jm Service Repair Manual 9jm00001 and UpWalter RodriguezBelum ada peringkat

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeDari EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeBelum ada peringkat

- White Drive Products: Central Hydraulics, Inc. Stocking Distributor For White Hydraulic Motors 1 (800) 264-9571Dokumen8 halamanWhite Drive Products: Central Hydraulics, Inc. Stocking Distributor For White Hydraulic Motors 1 (800) 264-9571Central HydraulicsBelum ada peringkat

- WP Cross ReferenceDokumen12 halamanWP Cross ReferenceCentral HydraulicsBelum ada peringkat

- White Drive Products: Central Hydraulics, Inc. Stocking Distributor For White Hydraulic Motors 1 (800) 264-9571Dokumen20 halamanWhite Drive Products: Central Hydraulics, Inc. Stocking Distributor For White Hydraulic Motors 1 (800) 264-9571Central HydraulicsBelum ada peringkat

- Central Hydraulics Has Flexmaster Gaskets & Assemblies in Stock - Expedited Shipping Available WorldwideDokumen21 halamanCentral Hydraulics Has Flexmaster Gaskets & Assemblies in Stock - Expedited Shipping Available WorldwideCentral HydraulicsBelum ada peringkat

- White Drive Products: Central Hydraulics, Inc. Stocking Distributor For White Hydraulic Motors 1 (800) 264-9571Dokumen16 halamanWhite Drive Products: Central Hydraulics, Inc. Stocking Distributor For White Hydraulic Motors 1 (800) 264-9571Central HydraulicsBelum ada peringkat

- HB Service PartsDokumen2 halamanHB Service PartsCentral HydraulicsBelum ada peringkat

- Re CatalogDokumen28 halamanRe CatalogCentral HydraulicsBelum ada peringkat

- Ce Service PartsDokumen3 halamanCe Service PartsCentral HydraulicsBelum ada peringkat

- Rs Service PartsDokumen2 halamanRs Service PartsCentral HydraulicsBelum ada peringkat

- HB Service PartsDokumen2 halamanHB Service PartsCentral HydraulicsBelum ada peringkat

- FD CatalogDokumen20 halamanFD CatalogCentral HydraulicsBelum ada peringkat

- SB CatalogDokumen20 halamanSB CatalogCentral HydraulicsBelum ada peringkat

- Ce CatalogDokumen20 halamanCe CatalogCentral HydraulicsBelum ada peringkat

- PHENOM 100 - 2 - 212434 BKDokumen1 halamanPHENOM 100 - 2 - 212434 BKFranco DeottoBelum ada peringkat

- Spare-And Replacement Parts For PumpsDokumen37 halamanSpare-And Replacement Parts For PumpsEng MBBelum ada peringkat

- EasyNote TJ Series DisassemblyDokumen70 halamanEasyNote TJ Series DisassemblyBlack OnionBelum ada peringkat

- Oppo F5 - 4Gb - Gold: Apa Yang Ada Di Dalam KotakDokumen1 halamanOppo F5 - 4Gb - Gold: Apa Yang Ada Di Dalam KotakTry Lestari Kusuma PutriBelum ada peringkat

- DBCM 09 Maret 2021 Awal Shift IDokumen4 halamanDBCM 09 Maret 2021 Awal Shift IHenny Komala Sari SibaraniBelum ada peringkat

- Piutang CustomerDokumen1.031 halamanPiutang Customeranon_75262887Belum ada peringkat

- Edtfmt392031 Fxzq-AvmDokumen52 halamanEdtfmt392031 Fxzq-AvmEduardo RodriguezBelum ada peringkat

- Manual Roddryer TK8Dokumen7 halamanManual Roddryer TK8Júlio SierraBelum ada peringkat

- EIG P Installation RulesDokumen13 halamanEIG P Installation RulesBlanaru BogdanBelum ada peringkat

- Control Bop Ideal-NovDokumen25 halamanControl Bop Ideal-NovpabloBelum ada peringkat

- 01 - 05 - Bac A Huile 01 - 05 - OIL SUMPDokumen2 halaman01 - 05 - Bac A Huile 01 - 05 - OIL SUMPsxturboBelum ada peringkat

- MF 30.2 PLUS: REACH IN Blast Chiller and Shock Freezer Standard Construction FeaturesDokumen3 halamanMF 30.2 PLUS: REACH IN Blast Chiller and Shock Freezer Standard Construction FeaturesOmer ElsamaniBelum ada peringkat

- Furniture Multiple Choice Activity Picture Description Exercises Picture Dictionaries - 78199Dokumen1 halamanFurniture Multiple Choice Activity Picture Description Exercises Picture Dictionaries - 78199Ariunjargal RagchaabazarBelum ada peringkat

- Karcher KM 90 60 R Rider Sweeper Parts ListDokumen61 halamanKarcher KM 90 60 R Rider Sweeper Parts ListDavid VaquerizoBelum ada peringkat

- Shaper and Types of Shaper MachinesDokumen6 halamanShaper and Types of Shaper MachinesGeraldBelum ada peringkat

- EE002Dokumen1 halamanEE002johnkarl.bentingBelum ada peringkat

- Calape, Daanbantayan Cebu 2 Periodical Test in TLE-Grade XDokumen2 halamanCalape, Daanbantayan Cebu 2 Periodical Test in TLE-Grade XResneth Mondejar100% (6)

- Wiring Color Codes - Color Codes - Electronics TextbookDokumen2 halamanWiring Color Codes - Color Codes - Electronics TextbookKelly chatingBelum ada peringkat

- Denon AVR-3802 User GuideDokumen74 halamanDenon AVR-3802 User GuidedelanossBelum ada peringkat

- LaverdaDokumen78 halamanLaverdaArmorBelum ada peringkat