Timber silo design

Diunggah oleh

Johnnie JohnDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Timber silo design

Diunggah oleh

Johnnie JohnHak Cipta:

Format Tersedia

Seminary 1

RURAL CONSTRUCTION

Design the structural members of a timber silo which stocks cereals. The

silo has a circular shape in horizontal section and it is loaded by an

uniformly distributed load is P. The volume of the silo is V

s

and the silo

diameter is noted with D

s

. The roof beam and the silo columns are made

from oak for students with even (trad. par) number and fir for students with

odd (trad. impar) n = odd

There are given the followings:

1. personal number, n

2. the silo volume, V

s

=20+0,1n [m

3

]

3. the silo diameter, D

s

=2+0,05n [m]

4. the permanent load, P=1,5+0,05n [kN/m

2

]

5. the variable load, S=2+0.01n [kN/m

2

]

6. allowable deflection, f

adm

=L/250

7. slenderness ratio, =120

The design permanent load, P

c

, at the roof level is given by dead load and

S

c

is snow load. The silo is situated in a covered zone so the wind load is

neglected.

We consider the roof beam having a rectangular cross section and the silo

column with a round cross section.

The characteristic strengths and the properties stiffness are given in tables

The design procedures will be solved using limit states design method

(LSDM).

The problems which must be solved contain the followings:

I. design of the roof beam

II. design of the central and marginal columns

III. drawing plans:

a. front view of the silo,

b. two cross section of the silo at the different levels (top and

the middle sides)

1

I. Design of the roof beam

Step 1 Determination of the load q and impose h/b=1,5 (b=10-15) cm

360

s

D

P q [kN/m]

Step 2 Drawing of the bending moment diagram and the shear forces

Mmax maximum value of bending moment

Tmax maximum value of shear force

Step 3 Checking of the strength condition

Pag. 76, LSDM timber structures, Pag 10 NP 005 - 2003

(M)max < Mr = Rdi =

i

n Ti i

i Ti n

c

i

W m R

k m W R

mod,

[Nmm]

(T)max < Lr = Rdf =

S

bI m R

k m

S

bI

R

f

Tf f

i Tf

c

f

//

//

mod, //

[Nmm]

softwood hardwood

Rdi design bending resistance [Nmm] [Nmm]

Rdf design shear resistance [N] [N]

Mr resisting moment

Lr resisting shear force

R

c

i design bending strength

Ri characteristic bending strength 16,8 [N/mm

2

] 28,0 [N/mm

2

]

Rf// characteristic shear strength 2,7 [N/mm

2

] 5,7 [N/mm

2

]

mTi The coefficient due to the use of

preservative substances

tab 4.1 NP 005

tab Timber str

Coef. de tratare 1,0 (no treated wood)

0,9 (lemn ignifugat)

kmod,I Modification factor taking into account the effect on the

strength parameters of the duration of the actions and the

moisture content

= muimdi

mui Working condition coefficient or

modification factor,

pag. 52, Timber

tab. 2.5 NP 005

Coef ai conditiilor de lucru

functie de clasa de

exploatare a materialului

lemnos

1,00

clasa I de

exploatare

1,00

clasa I de

exploatare

2

L=D

s

/2

R

B

R

A

q

b

h

L

af

q

mdi Working condition coefficient or

modification factor,

tab. 2.10 Timber

tab 2.6 NP 005

Coef. ai cond. de lucru

fctie de durata de actiune

a incarcarilor

0,55

perm load

0,60

0,65

variable load

0,70

kmod,f factors for shear parallel to the

grain

Aceeasi coef = mufmdf

mdf

perm load

variable load

0,55 0,60

0,65 0,70

muf clasa I de exploatare 1,00 1,00

i the partial safety factor for the

material property for bending

1,10 1,10

f// the partial safety factor for the

material property for shear

1,25 1,25

EL Modulus of elasticity 10000 [N/mm

2

] 11500 [N/mm

2

]

density 410 [Kg/cm

3

] 610 [Kg/cm

3

]

Step 4 Checking of the deflection under loading

See page 88 from Timber structures

4 3 2 1 max, max

f f f f f f

final

+ +

fadm

f1 Deflection of the beam due to the

permanent loads

Sageata datorata incarc. permanente

f2 Deflection of the beam due to the

variable loads

Sageata datorata incarc. temporare

f3 Deflection of the joints

deformation

Tab 3.3 - NP 005

Sageata din curgerea lenta a

imbinarilor

- nu este cazul

f4 Precamber of the beam in the

unloaded state

Contrasageata initiala a grinzii

incarcate

- pt l< 6,00 m nu avem contrasageata

kdef Deformation factors, =0,00 1,00

Table 3.2 NP 005

Functie de clasa de exploatare si de

durata incarcarilor.

Beam deflection f1 and f2 are evaluated with equation

) 1 (

, def init i i

k f f +

) 1 (

1 def p

k f f +

kdef = 0.50

) 1 (

2 def t

k f f +

kdef = 0.25

I second moment of inertia [mm

4

]

33

qH

Wn nominal value of section modulus [mm

3

]

Wn = Ixx/y = bh/6

S - first moment of area [mm

3

]

S = b h/2 h/4 = bh

2

/8

II. Column design: central and marginal

II.1. Central column subjected to axial compression forces

The effective value must be compared with permissible strengths given by the cods and

standards following limit states design method LSDM

Step 1. Determination of the load N

N = 8VA

Step 2. Checking of the strength condition

] [

mod,

//

N m A

R

k m A R R C N

Tc c

c

c

c Tc c

c

dc r c

c

75 ,

100

8 , 0 1

2

,

_

when

75 ,

3100

2

>

when

II.2. Marginal column

The marginal column is subjected to axial compression force and bending moment.

Step 1. Determination of the load N

N = VB

Step 2 Drawing of the bending moment diagram and the axial forces

Mmax maximum value of bending moment

Nmax maximum value of axial compression force

4

L=D

s

/2

V

B

V

A

q

H

V

B

l

f

=l/2

for wood

l

f

=0,65l

d

=

qH

Section A-A Section B-B

se scrie ecuatia de conditie in metoda fortelor

0

1 1 11

+

p

X

11

1

1

p

X

6 3 2

3

0

11

H H H H

dy

EI

m m

H

...... .. ..........

0

1

H

p

p

dy

EI

M m

X, N, q pozitionate pe stalp dau diagrame de forta axiala, taietoare si moment

incovoietor.

Step 3. Checking of the strength condition

1 t

r

f

ef

r

c

M

M

C

N

where

] [

mod,

mm N m W

R

k m W R R M

Ti n

i

i

i Ti n

c

i di r

] [

mod,

//

N m A

R

k m A R R C

Tc c

c

c

c Tc c

c

dc r

c

The maximum value of the final bending moment

f

ef

M

is given by eq.

] [

1

1

max ,

Nmm

C

N

M M

E

c

ef

f

ef

1

1

1

1

]

1

5

2

l

l

f

for wood

lf=0,80l

H

V

B

q=gHL

L = 2R/8

H*1

m

X=1 X

qH

M

p

q=gH

L

q

X

N

M

Mmax

Section A-A Section B-B

And

2

, 05 , 0

2

f

TE E u E

l

I

m m E C

softwood hardwood

Rdc=Cr design compression resistance [Nmm] [Nmm]

Rc characteristic compression

strength, the value are given in

NP005, tab 2.3

12 [N/mm

2

] 15,8 [N/mm

2

]

Ri characteristic bending strength 16,8 [N/mm

2

] 28,0 [N/mm

2

]

CE Axial compression force applied

on moment direction

Efort axial de

compresiune pe directia

de aplicare a momentului

[N]

c the partial safety factor for the

material property for

compression

1,25 1,25

i the partial safety factor for the

material property for bending

1,10 1,10

kmod,I Modification factor taking into account the effect on the

strength parameters of the duration of the actions and the

moisture content

= muimdi

mui Working condition coefficient or

modification factor,

T. S. pag. 52, NP005 tab. 2.5

Coef ai cond de lucru fct

de clasa de exploatare a

materialului lemnos

1,00

clasa I de

exploatare

1,00

clasa I de

exploatare

mdi Working condition coefficient or

modification factor,

T.S. tab. 2.10, NP005 tab 2.6

Coef. ai cond. de lucru

fctie de durata de actiune

a incarcarilor

0,55

perm load

0,60

0,65

variable load

0,70

Buckling coefficient

muE, Working condition factor

NP005 tab 2.5

and tab 4.1

Coef. ai cond. de lucru

fctie de solicitare si de

clasele de exploatare

1,00 Clasa I de exploatare

mTE 1,00 lemn netratat

E0,05 =0,67 E//

E// Characteristic elasticity modulus

parallel to grain direction

Mmax,ef Maximum effective bending

moment, Mmax

I Second moment area

lf Effective length

6

D

s

H

s

A

A

Section A-A Section B-B

B

B

D

s

H

s

7

Anda mungkin juga menyukai

- Silo Design ProjectDokumen7 halamanSilo Design ProjectDragosPatrascuBelum ada peringkat

- Crackwidth (Gergely & Lutz)Dokumen61 halamanCrackwidth (Gergely & Lutz)Medianna Novita100% (1)

- Selecting the Right Plastic for Engineering ApplicationsDokumen30 halamanSelecting the Right Plastic for Engineering ApplicationsFatimah Binti Abd RahmanBelum ada peringkat

- Timber DesignDokumen26 halamanTimber DesignRichmon Pangilinan100% (6)

- Practical Design To Eurocode 2: Strain CompatibilityDokumen30 halamanPractical Design To Eurocode 2: Strain CompatibilityschneekhanBelum ada peringkat

- RC2009 University of HongKong Reinforced Concrete DesignDokumen29 halamanRC2009 University of HongKong Reinforced Concrete DesignApril IngramBelum ada peringkat

- Servicability LimitsDokumen51 halamanServicability LimitsjadlouisBelum ada peringkat

- F3 Floor JoistsDokumen6 halamanF3 Floor JoistsJimmyBelum ada peringkat

- Timber Column Design To Bs5268-2:2002: Project Job RefDokumen2 halamanTimber Column Design To Bs5268-2:2002: Project Job RefZayyan RomjonBelum ada peringkat

- NOTES SeviceabilityDokumen81 halamanNOTES Seviceabilitydileep 443Belum ada peringkat

- Cold Formed BendingDokumen8 halamanCold Formed BendinggeorgeispasoiuBelum ada peringkat

- Column Design EC2Dokumen41 halamanColumn Design EC2Azrai AzizBelum ada peringkat

- Difference Beetween Is 800-2007 & Is 800-1984Dokumen96 halamanDifference Beetween Is 800-2007 & Is 800-1984ayazmadBelum ada peringkat

- 03 1 Weynand Moment Resistant JointsDokumen71 halaman03 1 Weynand Moment Resistant Jointsdeepak_dce_meBelum ada peringkat

- Indrumator Metal - EGDokumen37 halamanIndrumator Metal - EGhooky1100% (1)

- Prestress Concrete (24-30)Dokumen33 halamanPrestress Concrete (24-30)Prantik Adhar SamantaBelum ada peringkat

- Philosophy of Limit State Design and Classification of SectionsDokumen96 halamanPhilosophy of Limit State Design and Classification of Sectionsybm987100% (1)

- Hanger DesignDokumen4 halamanHanger Designkamaraj2k3Belum ada peringkat

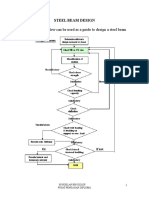

- Steel Beam DesignDokumen27 halamanSteel Beam DesignSyazwi Akram Ab RazakBelum ada peringkat

- Dos II - Lecture NotesDokumen71 halamanDos II - Lecture NotesSajee SweetBelum ada peringkat

- Sahyd c23 EngDokumen7 halamanSahyd c23 EngDragos NackaBelum ada peringkat

- Solved Example On Design of Slender Columns According To EC2Dokumen7 halamanSolved Example On Design of Slender Columns According To EC2Mouhamad Wehbe100% (1)

- ME307-11 Tutorial 9Dokumen9 halamanME307-11 Tutorial 9Mohammed A IsaBelum ada peringkat

- Advanced Design of Steel Structure Composite Beam DesignDokumen6 halamanAdvanced Design of Steel Structure Composite Beam DesignNaim YaqeenBelum ada peringkat

- 6-Prof. Zahid Ahmad Siddiqi Lec-6-Flexural Analysis and Design of BeamsDokumen17 halaman6-Prof. Zahid Ahmad Siddiqi Lec-6-Flexural Analysis and Design of BeamsMuhammadAboubakarFarooqBelum ada peringkat

- Plate Girder DesignDokumen8 halamanPlate Girder Designkalpanaadhi100% (1)

- Unit 3 Limit State of ServiceabilityDokumen55 halamanUnit 3 Limit State of ServiceabilityManoj SharmaBelum ada peringkat

- Example On Design of Timber Structure Part2Dokumen21 halamanExample On Design of Timber Structure Part2Nur Syazana88% (8)

- CE2306 - Design of RC ElementsDokumen22 halamanCE2306 - Design of RC ElementsViswanathan NatesanBelum ada peringkat

- Properties of Materials - Part A - 1Dokumen115 halamanProperties of Materials - Part A - 1Prasad MadhavanBelum ada peringkat

- Design of Machine Elements Assignment 2 Roll 07Dokumen6 halamanDesign of Machine Elements Assignment 2 Roll 07Sharthak GhoshBelum ada peringkat

- STEEL BEAM DESIGN GUIDEDokumen27 halamanSTEEL BEAM DESIGN GUIDEnasyahrahBelum ada peringkat

- Mechanical Design For Sieve Plate ColumnDokumen14 halamanMechanical Design For Sieve Plate ColumnIan Zuhair II100% (1)

- Structural design of timber beams in BS 5268Dokumen15 halamanStructural design of timber beams in BS 5268ablarence100% (1)

- Structural Steel Design UGNA3032Dokumen74 halamanStructural Steel Design UGNA3032木辛耳总Belum ada peringkat

- Design of MonorailDokumen9 halamanDesign of MonorailAnonymous Q8XIGqHyCBelum ada peringkat

- Example Beam Simply Supported With Lateral RestraintDokumen11 halamanExample Beam Simply Supported With Lateral RestraintjplezpBelum ada peringkat

- Ex 7b, One Way SlabDokumen3 halamanEx 7b, One Way SlabMohafisto SofistoBelum ada peringkat

- Timber Design Tip QC 1s1415 p1Dokumen24 halamanTimber Design Tip QC 1s1415 p1Manuelito ZapataBelum ada peringkat

- Built Up Steel ColumnDokumen26 halamanBuilt Up Steel ColumnKyle Foreman100% (1)

- Sky Light - 1Dokumen32 halamanSky Light - 1Nazar Bazaraa100% (1)

- Wall.l2 Solution Design ExampleDokumen4 halamanWall.l2 Solution Design Examplezms msswiBelum ada peringkat

- CIE3150 2017 Case Study Beam V 03-2Dokumen19 halamanCIE3150 2017 Case Study Beam V 03-2FerdiVKBelum ada peringkat

- Glulam Floor Beam Design Data AnalysisDokumen9 halamanGlulam Floor Beam Design Data AnalysisJake WilliamsBelum ada peringkat

- BS8110 SpreadsheetDokumen30 halamanBS8110 SpreadsheetPcEng100% (2)

- Lecture 3 Columns - Oct 12 - EndDokumen70 halamanLecture 3 Columns - Oct 12 - EndLiam WilliamsBelum ada peringkat

- Jutpani SS20Dokumen23 halamanJutpani SS20Suman NakarmiBelum ada peringkat

- RC Deflection & CrackingDokumen27 halamanRC Deflection & CrackingGerald Maginga50% (2)

- Mechanics of Composite Materials - Coursework-2022-23-ResitDokumen8 halamanMechanics of Composite Materials - Coursework-2022-23-ResitAdham SamanoudyBelum ada peringkat

- Determination of Moment Capacity Mp for Rectangular Reinforced Concrete ColumnsDokumen20 halamanDetermination of Moment Capacity Mp for Rectangular Reinforced Concrete ColumnsRatul RanjanBelum ada peringkat

- Flexural Member DesignDokumen21 halamanFlexural Member Designbaraka100% (1)

- CE6306 StrengthOfMaterialsPart BDokumen37 halamanCE6306 StrengthOfMaterialsPart Bavinash100% (1)

- Design of Corriguteed Sheet PDFDokumen41 halamanDesign of Corriguteed Sheet PDFflorinelvvBelum ada peringkat

- Pretensioned Beam Example: CE 437/537, Spring 2011 1 / 15Dokumen15 halamanPretensioned Beam Example: CE 437/537, Spring 2011 1 / 15Haris AlamBelum ada peringkat

- The Flow Chart Below Can Be Used As A Guide To Design A Steel Beam MemberDokumen27 halamanThe Flow Chart Below Can Be Used As A Guide To Design A Steel Beam MemberIrfan SyafriBelum ada peringkat

- A5 SolutionDokumen7 halamanA5 Solutionskata999Belum ada peringkat

- Mechanical Science for Technicians: Volume 1Dari EverandMechanical Science for Technicians: Volume 1Penilaian: 5 dari 5 bintang5/5 (1)

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresDari EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresPenilaian: 4 dari 5 bintang4/5 (1)

- Daily Dawn Newspaper Vocabulary with Urdu MeaningsDokumen4 halamanDaily Dawn Newspaper Vocabulary with Urdu MeaningsBahawal Khan JamaliBelum ada peringkat

- The Importance of Understanding A CommunityDokumen23 halamanThe Importance of Understanding A Communityra sBelum ada peringkat

- VnDoc - Tải tài liệu, văn bản pháp luật, biểu mẫu miễn phíDokumen7 halamanVnDoc - Tải tài liệu, văn bản pháp luật, biểu mẫu miễn phíStranger NonameBelum ada peringkat

- FlowTradersSOP PDFDokumen1 halamanFlowTradersSOP PDFAvinash IyerBelum ada peringkat

- 1 Crisp Projects: Erode Salem Madurai Trichy Kochi Bengaluru CoimbatoreDokumen20 halaman1 Crisp Projects: Erode Salem Madurai Trichy Kochi Bengaluru CoimbatoreKathir VelBelum ada peringkat

- Manual de Diagnostico D3E PDFDokumen72 halamanManual de Diagnostico D3E PDFJosé Luis Contreras Calderón100% (3)

- Ese 570 Mos Inverters Static Characteristics: Kenneth R. Laker, University of Pennsylvania, Updated 13feb12 1Dokumen44 halamanEse 570 Mos Inverters Static Characteristics: Kenneth R. Laker, University of Pennsylvania, Updated 13feb12 1het shahBelum ada peringkat

- Handout 4: Course Notes Were Prepared by Dr. R.M.A.P. Rajatheva and Revised by Dr. Poompat SaengudomlertDokumen7 halamanHandout 4: Course Notes Were Prepared by Dr. R.M.A.P. Rajatheva and Revised by Dr. Poompat SaengudomlertBryan YaranonBelum ada peringkat

- PAPTAC-FW Quality ExcursionsDokumen5 halamanPAPTAC-FW Quality ExcursionsGarth110Belum ada peringkat

- Presentation of Mind and AwarenessDokumen6 halamanPresentation of Mind and AwarenessLia PribadiBelum ada peringkat

- #C C C$ C%C& C' C (CDokumen4 halaman#C C C$ C%C& C' C (CThong Chee WheiBelum ada peringkat

- Elements of TQM: Dr. Sanjay MahalingamDokumen7 halamanElements of TQM: Dr. Sanjay Mahalingamuday saiBelum ada peringkat

- Asphalt Laboratory Manual RevDokumen13 halamanAsphalt Laboratory Manual RevKurian C ChackoBelum ada peringkat

- Simulation and Performance of Double Gate Finfet Devices: B.Sethupathy, P.Aruna PriyaDokumen3 halamanSimulation and Performance of Double Gate Finfet Devices: B.Sethupathy, P.Aruna PriyaKrisumraj PurkaitBelum ada peringkat

- Corporate Presentation Codex International Fev 2022Dokumen9 halamanCorporate Presentation Codex International Fev 2022Stephane SeguierBelum ada peringkat

- Secondary SourcesDokumen4 halamanSecondary SourcesKevin NgoBelum ada peringkat

- London Business School Interview Guide Clear Admit 2015Dokumen38 halamanLondon Business School Interview Guide Clear Admit 2015Nakul RathiBelum ada peringkat

- VUCG Guia de Instalacion y Comisionamiento en Ingles 1ZSC000562-AAY en Rev 1 - LowDokumen56 halamanVUCG Guia de Instalacion y Comisionamiento en Ingles 1ZSC000562-AAY en Rev 1 - Lowarmandoa71565Belum ada peringkat

- Coal Gasification, Liquid Fuel Conversion (CTL), and CogenerationDokumen66 halamanCoal Gasification, Liquid Fuel Conversion (CTL), and CogenerationVăn Đại - BKHNBelum ada peringkat

- BMED148 Assessment 1Dokumen5 halamanBMED148 Assessment 1ROMEL ALJUN TARROBALBelum ada peringkat

- Preview-9780429675119 A38620781Dokumen53 halamanPreview-9780429675119 A38620781Milton Alexandre ZiehlsdorffBelum ada peringkat

- Speedface-V5L (Ti) : Face & Palm Verification and Thermal Imaging Temperature Detection TerminalDokumen2 halamanSpeedface-V5L (Ti) : Face & Palm Verification and Thermal Imaging Temperature Detection TerminalardiBelum ada peringkat

- Spe 143287 MS PDokumen11 halamanSpe 143287 MS PbvkvijaiBelum ada peringkat

- POOJA TRADING CO. Price List for FRP Manhole CoversDokumen1 halamanPOOJA TRADING CO. Price List for FRP Manhole Coversmitesh20281Belum ada peringkat

- Hydraulic System Trainer AS-10Dokumen13 halamanHydraulic System Trainer AS-10Tanlets Gery100% (1)

- A. Soriano Corporation 2009 Annual Stockholders Meeting Notice and AgendaDokumen47 halamanA. Soriano Corporation 2009 Annual Stockholders Meeting Notice and AgendaGabriel uyBelum ada peringkat

- Standard 2Dokumen10 halamanStandard 2Bridget GumboBelum ada peringkat

- Format Question Bank RevisedDokumen21 halamanFormat Question Bank RevisedkhananuBelum ada peringkat

- Catalogs - SchlumbergerDokumen2 halamanCatalogs - SchlumbergerchengcaiwangBelum ada peringkat

- Real Time Braille To Speech Using PythonDokumen10 halamanReal Time Braille To Speech Using PythonKali LinuxBelum ada peringkat