CR (Physics) ProtocolDRAFT8 0

Diunggah oleh

emsmonteiroDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

CR (Physics) ProtocolDRAFT8 0

Diunggah oleh

emsmonteiroHak Cipta:

Format Tersedia

Protocol for the QA of Computed Radiography Systems

Commissioning and Annual QA Tests

This document describes a series of tests to assess CR plate and reader performance.

The tests are intended to detect artefacts and monitor image quality and sensitivity.

The tests are split into the following categories,

- commissioning tests

- annual QA tests.

All the tests described should be performed on all available reader systems.

KCARE have data from performing tests on all manufacturers CR systems and are

available for advice and information.

1 Commissioning Tests

List of equipment

Tape measure

Adhesive tape

1.0 mm Copper filtration (>10 x 10 cm)

1.5 mm Copper filtration (>10 x 10 cm)- for Agfa only

0.5 mm Copper and 1mm Aluminium filtration (>10 x 10 cm) for Kodak only

TO20 threshold contrast test object

Resolution test object (e.g. Huttner 18)

M1 geometry test object or lead ruler

Contact mesh

Ionisation chamber

Small lead or Copper block (~5 x 5 cm)

Steel ruler

In all tests described the unique plate identification code should be recorded.

These tests should be performed using an x-ray unit that has recently passed QC tests.

In particular, the accuracy of the kVp selected for detector dose indicator consistency

and calibration should be tested.

It may be possible to undertake some of these tests on a review workstation depending

on the processing tools available (which will be dependent on the manufacturer).

However certain tests require the use of the higher quality reporting workstation.

KCARE CR QA Protocol Draft 8.0 Release Date 01/06/2005 1

1.1 Dark Noise

Purpose: To assess the level of noise inherent in the system

a) Erase an image plate and without making an exposure read it using the

following parameters

b) Examine the images visually for uniformity and record the detector

dose indicator value for Agfa (SAL at centre of plate) and Kodak (Exposure

Index).

c) Record a mean pixel value using region of interest analysis (for

systems not offering ROI analysis see appendix for details of how to measure

a mean pixel value).

d) If possible either archive or print the image for future reference.

Tolerance: For Agfa and Fuji systems a uniform artefact free image should be

expected. Kodak systems add a collector profile to the image to compensate for non

uniform collection efficiency across the place. This results in series of bands

appearing across the image. Agfa systems should have an SAL < 100. For Fuji the

pixel value should be <280. For Kodak the EI value should be <80 for GP plates and

<380 for GP plates. For Konica a pixel value >3975 should be expected.

1.2 Dosimetry

Purpose: To measure receptor doses required for later tests 1.3,1.5, 1.6, 1.7 and 1.11

a) Position an ion chamber at ~1.2 m from the focus (see figure 1) and at

least 30 cm above the table (record the actual distances). Collimate to the ion

chamber.

KCARE CR QA Protocol Draft 8.0 Release Date 01/06/2005 2

Agfa: S=800,

examination type - System Diagnosis

processing Flat Field

Fuji: Readout mode Fixed

S = 10000

L = 1

Kodak:Mode pattern

Konica: Readout mode Fix

b) Expose the chamber at 70kVp with 1.0mm of copper in filtration at the

tube head. The mAs should, by trial and error, be set such that the inverse

square law corrected dose to the table level is approximately 10Gy

c) Record the measured dose and repeat twice.

d) Under the same beam conditions determine the mAs required to deliver

a receptor entrance air kerma of 1Gy, 4Gy 12Gy and 50Gy

e) If a Fuji system is being tested determine the mAs to deliver a receptor

entrance air kerma of 10Gy at 80kVp with no filtration in the beam.

If a Kodak system is being tested determine the mAs to deliver a receptor

entrance air kerma of 10Gy at 80kVp with 1mm Al and 0.5mm Cu filtration

at the tube head.

1.3 Linearity and System transfer properties

Purpose: To establish the relationship between receptor dose and pixel value so that

this relationship can be corrected for in tests 1.4 and 1.7. Also to establish that the

indicated exposure (calculated from the detector dose indicator) responds linearly to

increases in dose.

KCARE CR QA Protocol Draft 8.0 Release Date 01/06/2005 3

focus

added filter

chamber

CR plate

> 150 cm

Figure 1: Set-up for exposure index calibration

> 30cm

a) Place a 24 x 30 cm cassette on the table at ~1.50m (as described for test 1.2).

Set the field to just cover the cassette. Mark the corners of the cassette on the

table with transpore, so that the cassette can be easily repositioned.

b) Expose a plate at 70kVp with 1.0mm copper at the tube head to deliver a dose

of order 1Gy as measured in test 1.2.

c) After a minimal fixed time delay (e.g.1 to 5 mins), read the plate as described

below.

d) Record the detector dose indicator value.

e) Record a pixel value from the centre of the image.

For Agfa systems the SAL values obtained from ROI analysis

on the review workstation should be used.

For Fuji, Konica and Kodak systems the images should be

transferred to reporting workstations to use ROI analysis tools

if available.

f) Repeat for doses of order 4Gy, 12Gy and 50Gy.

g) Plot a graph of pixel value versus receptor dose using a graph plotting package

(e.g. Microsoft excel). Obtain the equation of the trend-line for this graph (i.e.

the pixel value as a function of receptor dose). This equation is the system

transfer properties (STP) equation and is used for making corrections in tests

1.4 and 1.7. An equation of the form

KCARE CR QA Protocol Draft 8.0 Release Date 01/06/2005 4

Agfa: S=200, system diagnosis/flat field processing

Kodak: Pattern mode body part.

Fuji: semi-auto, L=1 or 2

Konica: QC S-value, E and F processing turned off

Agfa: SAL (draw an region of interest covering at least 10000 pixels at

the centre of the image

Kodak: Exposure index (EI)

Fuji: Linearity mode (S=200)

Konica: Fix mode

dose =f(pixel value)

where f is some arbitrary function is required.

Tolerance: For all images the ratio, k, of indicated exposure to exposure should not

differ by greater than t 10% from the mean k value. The trend-line plotted in excel

should have an R

2

fit value >0.95. There is no tolerance for the STP equation.

However the pixel value to dose relationship should be a simple relationship (e.g. log,

linear or square root). For systems evaluated by KCARE the following has been

found.

Manufacturer STP Relationship

Agfa Square root *

Fuji Logarithmic

Kodak Logarithmic

Konica Logarithmic

* For the Agfa system there is a square root relationship between SAL values and

dose. The relationship between raw data pixel values and dose however was

logarithmic for systems evaluated by KCARE

1.4 Erasure cycle efficiency

Purpose: To test that minimal residual signal (ghosting) remains on a plate after

readout and erasure.

a) Position a plate on the table at ~1.5 m. Set a 10 cm x 10 cm field and

position a piece of attenuating material (e.g. Copper or lead) at the centre of

the CR plate. Expose at 80kVp, 25mAs with no filtration.

b) Read the plate (the readout parameters are not important).

c) Re-expose the plate with a 9 cm x 9 cm field centred on the same point

on the plate with no attenuating material in place, using 80kVp, 0.5mAs and

no filtration.

d) Read the plate using the following parameters.

KCARE CR QA Protocol Draft 8.0 Release Date 01/06/2005 5

e) Set a very narrow window and adjust the level. Visually inspect the

image for any remnant of the previous image (look for both the attenuating

material and the position of the collimators). If a remnant is visible, use region

of interest analysis to quantify the difference in pixel value between the

ghosted and unghosted areas.

For Agfa systems the SAL values obtained from ROI analysis

on the review workstation should be used.

For Fuji, Konica and Kodak systems the images should be

transferred to reporting workstations to use ROI analysis tools if

available.

The ROI values should be used to calculate indicated receptor doses using the

STP equation established in test 1.3.

Tolerance: If no evidence of ghosting is found from visual inspection of the images

then the test is passed and there is no need to perform ROI analysis. There should be

<1% (remedial) difference between the STP corrected pixel values in the ghosted

region and the surrounding areas. A suspension level of <5% is set.

1.5 Detector dose indicator calibration

Purpose: To assess the accuracy of the plate exposure values calculated using

exposure indicators.

a) Position a 24 30 plate on the table as described for test 1.3

b) Expose the plate to a known dose of ~10 Gy using the kVp and filtration

listed below (use mAs found in test 1.2).

KCARE CR QA Protocol Draft 8.0 Release Date 01/06/2005 6

Agfa: S=200,

examination type - System Diagnosis

processing Flat Field

Kodak:Mode Pattern

Fuji: Readout mode Semi Auto

L = 1 or 2

Konica: Semi fix

g=1

CR system Filtration Tube Voltage

(kVp)

Agfa 1.5mm Cu 75

Kodak 0.5mm Cu

+1mm Al

80

Konica info not known info not known

Fuji none 80

c) Read the plate out as described below

d) Record the detector dose indicator, and calculate the indicated exposure using

the equations given below.

e)

Repeat twice and take a mean value of the indicated exposures.

Tolerance: The indicated exposure should agree with the measured exposure within

20%.

1.6 Detector dose indicator consistency

KCARE CR QA Protocol Draft 8.0 Release Date 01/06/2005 7

Agfa: no delay between exposure and readout, S=200, system

diagnosis/flat field processing and linear sensitomitry.

Kodak: A 15 minute delay between exposure and readout, readout on

Pattern mode body part.

Fuji: A 10 minute delay between exposure and readout, readout using

semi-auto, L=1 or 2

Konica: Details of the Konica calibration protocol are not available

c

For Agfa systems the indicated exposure, E

Agfa

, in Gy, for a 200 speed readout is

given by

E

Agfa

= 5.90 10

6

SAL

2

(1)

For Kodak systems the indicated exposure, E

Kodak

, in Gy, is given by

n

kodak

E 10 7 . 8

,

where

,

_

1000

2000 EI

n

(2)

For Fuji systems the indicated exposure, E

fuji

, in Gy, is given by

S

E

fuji

1740

(3)

For Konica systems the equation linking to dose and S value is not available

Purpose: To assess the variation of sensitivity between plates, and set a baseline for

monitoring system sensitivity for future QA testing

a) Place a 24 x 30 cm CR cassette on the couch and set up as described

for test 1.2/1.3 (see figure 1) and with 1.0mm Cu filtration.

b) Expose the plate at 70kVp to give a known dose of ~10 Gy. The dose

to the plate calculated from inverse square law corrected ion chamber

measurements should be recorded (see test 1.2)

c) Read the plate as described for test 1.5.

d) Record the detector dose indicator, and calculate the indicated

exposure using equations 1-3. Repeat twice for the same plate.

e) Calculate the indicated exposure using equations given in test 1.5

f) Repeat this test for all plates for acceptance testing(making only one

exposure to each plate). It is helpful at this point to identify a plate that has a

detector dose indicator in the middle of the range for future QA.

Tolerance: The variation in the calculated indicated exposures should not differ by

greater than 20% between plates. The measurements repeated on the same plate

should be used to lay down a baseline for future QA tests. Al images should be

inspected for gross artefacts

1.7 Uniformity

Purpose: To assess the uniformity of the recorded signal from a uniformly exposed

plate. A non-uniform response could affect clinical image quality.

a) Expose a plate as described for test 1.6 but with half the mAs.

b) Rotate the plate through 180

o

about the vertical axis and re-expose

using the same parameters (this should largely cancel out the non uniformities

due to the anode heal affect).

c) Read the plate as described for test 1.3.

d) Visually inspect all images obtained in test 1.3, 1.5 and 1.6 for

uniformity and artefacts. Likely artefacts include dust on the plate or readout

optics, and scratches on plates.

e) The uniformity of the image obtained in 1.7b should be assessed using

region of interest analysis (ROI ) if available, to measure the mean pixel

values in positions a-e, as indicated in figure 2 below (i.e.at the centre of the

image, and at the centre of each of the four quadrants of the image). The size

of ROI should be of order 10000 pixels.

KCARE CR QA Protocol Draft 8.0 Release Date 01/06/2005 8

c

For Agfa systems the SAL values obtained from ROI analysis on the

review workstation should be used.

For Fuji, Konica and Kodak systems the images should be transferred

to reporting workstations to use ROI analysis tools if available.

f) The five values obtained from ROI analysis should be used to calculate

five indicated receptor dose values using the STP equation obtained in test 1.3

Tolerance: The images should not have obvious artefacts. The ratio of the standard

deviation of the 5 STP corrected ROI values to their mean (the coefficient of

variation) should be less than 10%.

1.8 Scaling errors

Purpose: To assess the accuracy of software distance indicators and check for

distortion.

a) Position the M1 test object directly on the centre of a CR cassette at >

150 FDD.

b) Expose at 50-60 kVp with no filtration and 10mAs.

N.B. A lead ruler could be used in place of the M1 test object. If so 2 exposures

should be made with the ruler placed in first the scan direction then the subscan

direction.

c) Read out plate using processing as for test 1.3.

d) Using the distance measuring software tools measure the dimensions (x

and y) of five central squares in both fast and slow scan directions. Calculate

the aspect ratio x/y. For Agfa systems the review workstation software can be

used. For Fuji, Kodak and Konica systems the images should be transferred to

the reporting workstation to use distance measuring software tools if available.

If images are reported from film then they should be printed at full size.

Distances can then be measured with a ruler.

KCARE CR QA Protocol Draft 8.0 Release Date 01/06/2005 9

Fig 2: Positions of the ROIs for uniformity tests

c

a

d

b

e

e) Reposition the test object over the edge of the plate as indicated in

figure 3 and repeat steps b and c

f) Along the edge of the plate measure the horizontal (x1) and vertical

(y1) sizes of two squares as indicated in figure 4. Calculate the aspect ratio

x1/y1.

g) If possible download the image as a DICOM file. Open the image

using a DICOM viewer such as Santeviewer. Hold the curser over a corner of

a square in the grid. Record the position within the image (i.e. the x and y

coordinates). Move the curser to the corner of the square of the grid 10cm

from the first corner in the x direction. Record the coordinates again. Calculate

the pixel pitch, p(mm)=100/n, where n =number of pixels covering 10cm of

the grid. Repeat for the y direction. This test is only necessary on

commissioning. Compare the pixel pitch to that stated by the manufacturer.

The difference should be no greater than the estimated measurement error.

Tolerance: The measured distances x and y should agree within 3% of the actual

distances at the centre of the plate and 5% at the edge. All calculated aspect ratios

should be within 1.00 t 0.03 at the centre of the plate, or 1.00 t 0.05 at the edge.

KCARE CR QA Protocol Draft 8.0 Release Date 01/06/2005 10

x1

y1

Figure 4

scan direction

sub-scan

direction

Figure 3

1.9 Blurring

Purpose: To test for any localised distortion or blurring of the image.

a) With the contact mesh in placed on the cassette at >150cm FDD,

expose at 50-60 kVp, fine focus, with no filtration and 10mAs.Read the plate

as described for test 1.3.

b) Visually inspect the image for distortions. If distortion occurs clean the

plate and repeat.

c) Repeat for at least two other plates.

d) Repeat with a fine mesh if available.

Tolerance: No blurring should be present. If blurring is present on all plates this

suggests the reader is at fault, whilst imperfections in individual plates may also lead

to blurring. If blurring remains on a region of a plate after cleaning it should not be

used clinically.

1.10 Limiting Spatial Resolution

Purpose: To test the high contrast limit of the systems ability to resolve details.

a) Place a general purpose cassette on the couch with the Huttner test

object positioned at its centre aligned at 45

o

to its edges.

NB A Huttner test object with line spacings up to 8 lp.mm

-1

may be required.

b) Set 50-60 kVp, fine focus, and expose the cassette using 10mAs.

c) Readout the plate using the following parameters

d) Adjust the window level and magnification to optimise the resolution.

Score the number of resolvable groups of lines from the screen. Look up the

corresponding resolution. The image should be scored at a magnification of

KCARE CR QA Protocol Draft 8.0 Release Date 01/06/2005 11

Agfa: S=100,

examination type - System Diagnosis

processing Flat Field

Fuji: Readout mode fix with L=2 and S=200

Kodak:Mode Pattern with raw data and no edge enhancement

Konica: QC S-value, E and F processing off

order x 5. If this facility is not available on the review workstation then images

should be transferred to the reporting workstation for scoring.

e) Repeat the measurement twice with the resolution test object placed at

a slight angle to the first the lateral or then the longitudinal axis.

f) Repeat this process for all available image pixel pitches (nb different

plate sizes will often default to being scanned at different pixel pitches).

g) If possible either archive or print the image for future reference.

Tolerance: These measurements should be used to set a baseline for future QA tests.

Print or save the images for future reference, if possible. Comparable images are

available for most systems through KCARE.

N.B. The limiting resolution should be expected to approach the Nyquist limit. At 45

o

the Nyquist frequency is defined by 2/2p where p is the pixel pitch. The measured

limiting resolution may be limited by display when scoring from a review

workstation, particularly if no zoom or limited zoom facilities are available.

1.11 Threshold Contrast Detail Detectability

Purpose: To monitor image quality by assessing the visibility of low contrast details.

a) With the tube, plate, and 1.0mm copper filtration in the same positions

as for the sensitivity tests, place the TO20 (or equivalent) test object on the

plate. Collimate down to the size of the test object.

b) Set 70 kVp and an mAs to deliver ~4 Gy. Read the plate using the following

parameters.

b) Ascertain whether clinical images are most commonly viewed soft or

hard copy. If they view hardcopy, adjust the window to optimise the visibility

of the details, ensuring that background noise is perceptible, and print the

image out on the largest film size. View the image on a masked light box, and

score each detail size using fixed distance viewing (<1m). If images are

viewed softcopy, score them on a reporting workstation optimising window

and level settings for each detail size.

KCARE CR QA Protocol Draft 8.0 Release Date 01/06/2005 12

Agfa: S=200,

examination type - System Diagnosis

processing Flat Field

Fuji: Readout mode semi-auto with test/sensitivity GA=1

Kodak:Mode Pattern with raw data and no edge enhancement

Konica: QC S-value, E and F processing off

c) Calculate an image quality factor, IQF,

( )

( )

5 . 0

1

1

1

]

1

D

D

A H

A H

n

IQF

ref

n

i

i

ref

T

i T

(4)

where

H

T

(A) = threshold contrast detail index values calculated from the image,

H

T

ref

(A) = threshold contrast detail index values calculated from a reference

image of a system known to be in good adjustment

D = the dose to the image plate

D

ref

= the dose to the image plate for the reference image

n = the number of details in the test object.

d) Repeat this test for two other imaging plates and also for a single plate

at exposures of ~1Gy and ~12Gy.

e) If possible either archive or print the images for future reference.

Tolerance: The results of this test are used to set a baseline for future QA tests.

Results could be compared to those from other similar systems if available.

1.12 Laser beam function

Purpose: To assess laser beam scanline integrity and jitter

a) Place a steel ruler slightly angled to the subscan direction on a large

cassette.

b) Expose at ~70 kVp, 150cm FSD and an mAs to deliver an incident

exposure of ~50Gy. Read the plate as described for test 1.3

c) Using the software magnify the image x10. This will usually require

the image to be viewed from a reporting monitor. Select a narrow window

width such that the image appears largely polarised to black or white. This

should allow the edge to be easily differentiated from the background. Laser

beam jitter can be evaluated by examining the edge of the ruler on the image.

Tolerance: The edge should be continuous across the full length of the image. Stair

step characteristics should be uniform across the length of the image. Regions of over

or undershoot of the scan lines indicate a timer or laser beam modulation problem.

1.13 Moir Patterns

Purpose: To test for the presence of Moir pattern artefacts caused by grids.

KCARE CR QA Protocol Draft 8.0 Release Date 01/06/2005 13

a) Place a CR cassette in the bucky such that the scan lines are vertical to

the gridlines. The cassette should be 1.5m from the focus, and the collimation

should cover the whole plate.

b) Expose at 70 kVp using the AEC with 1.0 mm of copper in the beam,

and the grid in place.

c) Read the plate as described for test 1.3.

d) Visually inspect the image for Moir line pattern artefacts.

e) Repeat with the CR cassette positioned in the bucky such that the scan

lines are horizontal to the gridlines.

f) Repeat for all buckies and grids that may be used with the CR system,

including any grids used in mobile radiography.

Tolerance: No Moir patterns should be visible. If Moir patterns are visible with a

particular grid, it should not be used with the CR plates. The cause of Moire patterns

may be the failure of the motion of moving grids or insufficient grid density.

KCARE CR QA Protocol Draft 8.0 Release Date 01/06/2005 14

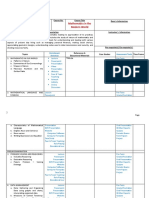

2 Annual QA tests

The following routine QA tests should be performed approximately annually

1.2 Dosimetry (only for 4Gy and 10Gy with 70kVp and 1.0mmCu)

1.4 Erasure cycle efficiency

1.6 Detector dose indicator consistency/sensitivity (for 1 plate of each size)

1.7 Uniformity

1.8 Scaling errors

1.9 Blurring

1.10 Limiting resolution (45

o

only)

1.11 TCDD (only 4Gy).

The tests should be performed as described in the previous section. Table 1 below

summarises the relevant remedial levels where these are different to those described

for commissioning.

Test Remedial Level

detector dose indicator consistency

(sensitivity)

baseline t 20% exposure equivalent

limiting resolution

baseline t 20%

TCDD (Quality Index)

baseline t 30%

It should be noted that TCDD and limiting resolution are subjective measures. Some

effort should therefore be made to train scorers to score to similar thresholds.

KCARE CR QA Protocol Draft 8.0 Release Date 01/06/2005 15

Appendix A Measuring a mean pixel value using a Fuji CR system

Reduce the window width to 1, so that the image has only pixels appear as either one

of just two levels, black or white. Adjust the level until approximately half the pixels

are black and half are white. This level value is the mean pixel value of the image.

KCARE CR QA Protocol Draft 8.0 Release Date 01/06/2005 16

References

[1] Draft Report of Task Group #10, American Association of Physicists in Medicine,

Acceptance Testing and Quality Control of Photostimulable Storage Phosphor

Imaging Systems, August 1998

[2] British Institute of Radiology, Assurance of the quality in the diagnostic imaging

department, 2001, ISBN 0-905749-48-0

[3] IPEM draft CR QC protocol

[4] Samei E, Seibert JA, Willis CE, Flynn MJ, Mah E, Junck KL, Performance

evaluation of computed radiography systems, 2001, Med.Phys. Vol28 (3) p361-371.

KCARE CR QA Protocol Draft 8.0 Release Date 01/06/2005 17

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Mds Ti-Alloy Ta15 0720 enDokumen3 halamanMds Ti-Alloy Ta15 0720 enshahin_723Belum ada peringkat

- The Network+ Cram Sheet: Networking ConceptsDokumen4 halamanThe Network+ Cram Sheet: Networking ConceptsISTAKHAR UDDIN AHAMED100% (1)

- 1.bitwise OperatorsDokumen2 halaman1.bitwise OperatorsPaul kollamBelum ada peringkat

- Maths4u SylDokumen87 halamanMaths4u SylDJBelum ada peringkat

- Bohmian Mechanics Versus Madelung Quantum HydrodynamicsDokumen8 halamanBohmian Mechanics Versus Madelung Quantum HydrodynamicsregectBelum ada peringkat

- Conectar A BD en SeleniumDokumen4 halamanConectar A BD en SeleniumCristhian Andrés GonzálezBelum ada peringkat

- Electricity Markets PDFDokumen2 halamanElectricity Markets PDFAhmed KhairiBelum ada peringkat

- Ratio Worksheet AKDokumen12 halamanRatio Worksheet AKChika AuliaBelum ada peringkat

- As 400Dokumen70 halamanAs 400Radhakrishnan KandhasamyBelum ada peringkat

- Mathematics in The Modern World: Course No. Course Title Dean's InformationDokumen5 halamanMathematics in The Modern World: Course No. Course Title Dean's InformationJayson SantelicesBelum ada peringkat

- Medium Voltage Swgr9Dokumen3 halamanMedium Voltage Swgr9kjfensBelum ada peringkat

- Opposite Corners CourseworkDokumen8 halamanOpposite Corners Courseworkpqltufajd100% (2)

- Supercritical CO2: Properties and Technological Applications - A ReviewDokumen38 halamanSupercritical CO2: Properties and Technological Applications - A ReviewXuân ĐứcBelum ada peringkat

- (DT-0581) 21010-BAE-70000-IN-RL-0002 - Revb2Dokumen8 halaman(DT-0581) 21010-BAE-70000-IN-RL-0002 - Revb2karthikesan6Belum ada peringkat

- Smith Meter Microloadnet Operator Reference Manual-A Voir PDFDokumen96 halamanSmith Meter Microloadnet Operator Reference Manual-A Voir PDFmehrezBelum ada peringkat

- OS Prelude-1Dokumen16 halamanOS Prelude-1YayatiBelum ada peringkat

- Grade9 Physics PDFDokumen2 halamanGrade9 Physics PDFRajBelum ada peringkat

- Metric Ton Is 1000 KGDokumen5 halamanMetric Ton Is 1000 KGmcpayodBelum ada peringkat

- Calibar Plate3Dokumen10 halamanCalibar Plate3Gerald FernandezBelum ada peringkat

- 1st Mid-Term Test (Add Maths f4)Dokumen5 halaman1st Mid-Term Test (Add Maths f4)Jarnice Ling Yee ChingBelum ada peringkat

- Rockschool Popular Music Theory Syllabus 2015 18Dokumen33 halamanRockschool Popular Music Theory Syllabus 2015 18Archit AnandBelum ada peringkat

- White Paper: Professor Dr. Thorsten Hens Msc. Ba Anna MeierDokumen29 halamanWhite Paper: Professor Dr. Thorsten Hens Msc. Ba Anna MeierDark11Belum ada peringkat

- HCL McQs SET-3Dokumen8 halamanHCL McQs SET-3ThorBelum ada peringkat

- Oracle Process Manufacturing Master SetupsDokumen42 halamanOracle Process Manufacturing Master SetupsMadhuri Uppala100% (2)

- S3 3 TrigonometryDokumen81 halamanS3 3 TrigonometryEugene ChoongBelum ada peringkat

- Image Processing Math Prob1Dokumen13 halamanImage Processing Math Prob1MunmunBelum ada peringkat

- Workspace Satisfaction - The Privacy-Communication Trade-Off in Open-Plan OfficesDokumen9 halamanWorkspace Satisfaction - The Privacy-Communication Trade-Off in Open-Plan OfficesAyşe Nur TürkerBelum ada peringkat

- Assignment and Exam Content: Always Delete Your Cloud Resources To Avoid $$ ChargesDokumen11 halamanAssignment and Exam Content: Always Delete Your Cloud Resources To Avoid $$ ChargesMouhamadou NdiayeBelum ada peringkat

- Zalzalah Cesar Thesis 2016Dokumen72 halamanZalzalah Cesar Thesis 2016feezy11Belum ada peringkat

- Quadratic Equation - MATH IS FUNDokumen8 halamanQuadratic Equation - MATH IS FUNChanchan LebumfacilBelum ada peringkat