University Question Part A-Two Marks

Diunggah oleh

Mohamad ShafiqDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

University Question Part A-Two Marks

Diunggah oleh

Mohamad ShafiqHak Cipta:

Format Tersedia

UNIVERSITY QUESTION PART A- TWO MARKS 1. Define strain rate hardening. 2. What are the deformation modes? 3.

Define Transient creep time. 4. What are the difference between ductile fracture and brittle fracture? 5. How Micro Void Coalescence occurs? 6. Define Monk-mann Grant Formula? 7. Define Pilling Bed worth Ratio? 8. What is meant by Fluxing mechanism? 9. What are the properties of Super alloys? 10. Define Intermetallics? 11. Define Homologous temperature. 12. Write a relation between creep strain and time for various stages of creep 13. Define time hardening and strain hardening for step loading for the design of primary creep. 14. What are the strengthening mechanisms? 15. What are the necessary conditions favorable for fracture? 16. Define Rupture? 17. What are types of Nickel Base alloys? 18. What are the strengthening methods used for alloys? 19. Name few examples for super alloys applicable for high temperatures. 20. What is Acidic fluxing and Basic fluxing in Hot corrosion? 21. Define strain rate sensitivity. 22. What are the problems associated with materials used at high elevated temperature? 23. Define Rupture life of creep. 24. Distinguish between Creep ductile fracture and brittle fracture? 25. What is meant by Equicohesive temperature (ECT)? PART B 16 MARKS 1. What are the structural changes involved during creep? Explain in detail. Briefly explain the three stages of creep with a creep curve. 2. Analyze the interaction of corrosion and mechanical properties at high temperatures. 3. Analyze time hardening and strain hardening mathematically and pictorially and prove that for gradual loading strain hardening reduces to time hardening. 4. what are the methods used for strengthening materials? Explain about Strain hardening process with example.

5. Derive an expression for cleavage I fracture based on Orowan and Griffith theory and comment how the various terms in these equations are responsible for strengthening and toughening the materials.

6. Discuss the fracture maps for any F.C.C alloy in detail with necessary sketches. 7. (i) Write a short note on methods to combat hot corrosion. (ii) Pilling bed worth ratio. 8. Compare parameters in controlling aqueous and dry corrosion. Discuss the kinetic laws of high temperature corrosion with special effect of doping on corrosion kinetics. 9. Write technical note on the evolution of super alloys? 10. Discuss (i) TCP Phase (ii) Embrittlement. 11. Write the consecutive equations for plastic and creep deformation from high stress and low stress and high temperatures and comment on the mechanism of deformation for each equation. 12. Explain about the various mechanisms of creep with necessary sketches. 13. Define Rupture and derive the expressions for Rupture life of creep. 14. What is the significance of transient creep time? Explain about Design of transient creep formation? 15. (i) Write short notes on Transgranular creep fracture and Intergranular creep Fracture. (ii) Draw the fracture maps for a B.C.C or a ceramic and mark all regimes of Fracture. 16. Explain the theory of Ductile to Brittle transition with neat diagram. 17. (i) Write a short note on Defect structure of Oxidation process (ii) Analyze the various stages of hot corrosion with respect to exposure time by various chemical equations and degradation mechanisms. 18. (i) Explain the Kinetic Laws of Oxidation with a neat graph. (ii) What are the various types of high temperature corrosion explain in detail. 19. Explain the strengthening mechanisms of cobalt based super alloys. 20. Write short notes on Intermetallics and high temperature ceramics. 21. Define creep. What are the various factors affecting creep? Explain in detail. 22. Discuss the mechanism of creep deformation briefly with necessary sketches. 23. (i) How will you obtain creep resistance through strain hardening? (ii) Explain stress rupture test at elevated temperature.

24. Derive expressions for Creep ductile and Creep brittle fractures. Also comment on the instantaneous fractures in both cases. 25. Draw the fracture maps for nickel, nickel base super alloy and thoria dispersed nickel and explain the shrink or disappearance of some regimes. 26. Derive an expression for cleavage II fracture and ductile brittle transition based on Micro Void Formation by plastic deformation and comment on the various metallurgical parameters affecting ductile-brittle transition. 27. Analyze the hot corrosion mechanisms involved in basic fluxing acidic fluxing. 28. Describe the different metal gas reactions and their remedies. 29. Explain precipitation hardening by gamma prime. 30. Analyze how the processing parameters can influence the mechanical properties of Super alloys at high temperatures.

Anda mungkin juga menyukai

- 16marks HTM PDFDokumen5 halaman16marks HTM PDFJ.R.Vinod KumaarBelum ada peringkat

- Mechanical Behaviour of Materials Questions PART 1Dokumen3 halamanMechanical Behaviour of Materials Questions PART 1Sachi Dhanandam100% (2)

- Metallurgy Question Bank - Questions OnlyDokumen6 halamanMetallurgy Question Bank - Questions OnlyMANYAM. HARI KRISHNA MECHANICAL ENGINEERINGBelum ada peringkat

- CH 6604 Materials Science and Technology Part A Questions Unit IDokumen3 halamanCH 6604 Materials Science and Technology Part A Questions Unit Ichitra123Belum ada peringkat

- PMSM ALL IMP 3rd Sem Mechatronics GTU QUESTIONSDokumen4 halamanPMSM ALL IMP 3rd Sem Mechatronics GTU QUESTIONSSwastik PanchalBelum ada peringkat

- Me6403 Engineering Materials and Metallurgy: Unit 1.alloys and Phase Diagram Part ADokumen6 halamanMe6403 Engineering Materials and Metallurgy: Unit 1.alloys and Phase Diagram Part Ajamunaa83Belum ada peringkat

- Important Questions Material ScienceDokumen3 halamanImportant Questions Material Sciencetheamg7272Belum ada peringkat

- Unit 1: Two MarksDokumen5 halamanUnit 1: Two MarksAravind PhoenixBelum ada peringkat

- Material Science Important Questions For AMIE Section-ADokumen8 halamanMaterial Science Important Questions For AMIE Section-AThota Sai Swaroop67% (3)

- Unit-I - Alloys and Phase Diagrams Part-A (2 Marks) : Question BankDokumen10 halamanUnit-I - Alloys and Phase Diagrams Part-A (2 Marks) : Question BankDr.A.Maniram KumarBelum ada peringkat

- Mechanical Behaviour and Testing of MaterialsDokumen5 halamanMechanical Behaviour and Testing of MaterialsSachi DhanandamBelum ada peringkat

- Assignment Questions Set - 3 (Module 3)Dokumen1 halamanAssignment Questions Set - 3 (Module 3)nkar037Belum ada peringkat

- ME1253-Engineering Materials and MetallurgyDokumen0 halamanME1253-Engineering Materials and MetallurgybalajimeieBelum ada peringkat

- Materials Science Important QuestionDokumen1 halamanMaterials Science Important Questionmani kandanBelum ada peringkat

- Engineering Material AssignmentDokumen3 halamanEngineering Material AssignmentSharjeel Faisal100% (1)

- S3 Question Bank: Department of Mechanical EngineeeringDokumen27 halamanS3 Question Bank: Department of Mechanical EngineeeringVishesh RainaBelum ada peringkat

- MF9211 Jan 2012Dokumen3 halamanMF9211 Jan 2012pravi2010Belum ada peringkat

- Engineering Metallurgy Part.A Unit - IDokumen4 halamanEngineering Metallurgy Part.A Unit - Ijamunaa83Belum ada peringkat

- AE 6604 Aircraft Materials and Processes-Question Bank Unit I Part - BDokumen3 halamanAE 6604 Aircraft Materials and Processes-Question Bank Unit I Part - BRahul100% (1)

- Material Science and Metallurgy Question BankDokumen3 halamanMaterial Science and Metallurgy Question BankVinay KorekarBelum ada peringkat

- Principles of Material Selection Question BankDokumen7 halamanPrinciples of Material Selection Question BankGurpreet SinghBelum ada peringkat

- Engineering Materials and MetallurgyDokumen11 halamanEngineering Materials and Metallurgyabdulhere4uBelum ada peringkat

- 123 DwqdweDokumen2 halaman123 Dwqdwepravi2010Belum ada peringkat

- ST010 503-Material ScienceDokumen2 halamanST010 503-Material SciencepramodBelum ada peringkat

- QdweDokumen9 halamanQdwepravi2010Belum ada peringkat

- Question Bank Subject: Material Science & Metallurgy (3131904) Semester: B.E. (ME) Sem. - 3Dokumen4 halamanQuestion Bank Subject: Material Science & Metallurgy (3131904) Semester: B.E. (ME) Sem. - 3Jay SathwaraBelum ada peringkat

- Material Science Question BankDokumen3 halamanMaterial Science Question BankSirish Chand PutlaBelum ada peringkat

- Irjet V3i2175Dokumen1 halamanIrjet V3i2175AbhayBelum ada peringkat

- ME6403-Engineering Materials and MetallurgyDokumen12 halamanME6403-Engineering Materials and Metallurgysanthanam102Belum ada peringkat

- Material Science: Most Frequently Asked Questions in Amie ExamsDokumen13 halamanMaterial Science: Most Frequently Asked Questions in Amie ExamsTushar LanjekarBelum ada peringkat

- MFP QB PDFDokumen6 halamanMFP QB PDFCharan KumarBelum ada peringkat

- MII Manufacturing TechnologyDokumen5 halamanMII Manufacturing TechnologyRameez FaroukBelum ada peringkat

- CH 6604 Materials Science and Technology Part B Questions Unit IDokumen3 halamanCH 6604 Materials Science and Technology Part B Questions Unit Ichitra123Belum ada peringkat

- Material Science Question BankDokumen4 halamanMaterial Science Question BankpramodBelum ada peringkat

- Ec QuestionsDokumen6 halamanEc QuestionsrajeshBelum ada peringkat

- Mod 1 MBCET PDFDokumen112 halamanMod 1 MBCET PDFAkshay Kumar E HBelum ada peringkat

- Ph8251 Ms Rejinpaul Iq Am19Dokumen1 halamanPh8251 Ms Rejinpaul Iq Am19JairusBelum ada peringkat

- CH 08Dokumen5 halamanCH 08Ben FreidenbergBelum ada peringkat

- ECL 1704 Assignment 1Dokumen2 halamanECL 1704 Assignment 1Nishant MishraBelum ada peringkat

- Unit 1: 13 Marks Questions: Anna University QuestionsDokumen4 halamanUnit 1: 13 Marks Questions: Anna University Questions10BShalini.B IgmmBelum ada peringkat

- Ph8251 - Material ScienceDokumen6 halamanPh8251 - Material ScienceAbc AcademyBelum ada peringkat

- ME2253 - Engineering Materials and Metallurgy QBDokumen3 halamanME2253 - Engineering Materials and Metallurgy QBVasantha KumarBelum ada peringkat

- Pharmaceutical Engineering (2230002) : Ch.1 IntroductionDokumen3 halamanPharmaceutical Engineering (2230002) : Ch.1 IntroductionkbnarkhedeBelum ada peringkat

- 4 Me MQ EMMDokumen2 halaman4 Me MQ EMMBIBIN CHIDAMBARANATHANBelum ada peringkat

- ME-8491 EM QB For UT1Dokumen2 halamanME-8491 EM QB For UT1ajaymBelum ada peringkat

- Ac Imp QuestionsDokumen4 halamanAc Imp QuestionsBhargav ChanduBelum ada peringkat

- Materials Science - Examination QuestionsDokumen2 halamanMaterials Science - Examination QuestionsNoura Nour ElshamsBelum ada peringkat

- Part A: PM6501 - Mass Transfer - IDokumen5 halamanPart A: PM6501 - Mass Transfer - ISampathkumar MtechBelum ada peringkat

- Question Papers - Heat TreatmentDokumen9 halamanQuestion Papers - Heat TreatmentSrilakshmi Shunmugaraj100% (3)

- Department of Chemistry: Question Bank Unit 1 Electrochemistry Part ADokumen4 halamanDepartment of Chemistry: Question Bank Unit 1 Electrochemistry Part AJahith HussainBelum ada peringkat

- Engineering Chemistry-II - May-June 2009 Question Paper Studyhaunters PDFDokumen3 halamanEngineering Chemistry-II - May-June 2009 Question Paper Studyhaunters PDFSriram JBelum ada peringkat

- Chemistry Question BankDokumen5 halamanChemistry Question Banksoftsen10Belum ada peringkat

- Cy6181 Ec1 Rejinpaul Iq Jan 2018Dokumen1 halamanCy6181 Ec1 Rejinpaul Iq Jan 2018arunBelum ada peringkat

- List of QuestionsDokumen2 halamanList of Questionstripathi522003Belum ada peringkat

- Heat Transfer EngineeringDokumen1 halamanHeat Transfer EngineeringGebeyaw DemekeBelum ada peringkat

- Ultra-High Temperature Ceramics: Materials for Extreme Environment ApplicationsDari EverandUltra-High Temperature Ceramics: Materials for Extreme Environment ApplicationsWilliam G. FahrenholtzBelum ada peringkat

- Engineering Materials 2: An Introduction to Microstructures, Processing and DesignDari EverandEngineering Materials 2: An Introduction to Microstructures, Processing and DesignBelum ada peringkat

- Metallurgy and Mechanics of Welding: Processes and Industrial ApplicationsDari EverandMetallurgy and Mechanics of Welding: Processes and Industrial ApplicationsRegis BlondeauBelum ada peringkat

- Damage Mechanics in Metal Forming: Advanced Modeling and Numerical SimulationDari EverandDamage Mechanics in Metal Forming: Advanced Modeling and Numerical SimulationBelum ada peringkat

- Foundations of the Non-Linear Mechanics of Continua: International Series of Monographs in Interdisciplinary and Advanced Topics in Science and Engineering, Vol. 1Dari EverandFoundations of the Non-Linear Mechanics of Continua: International Series of Monographs in Interdisciplinary and Advanced Topics in Science and Engineering, Vol. 1Penilaian: 5 dari 5 bintang5/5 (1)

- April 2016Dokumen68 halamanApril 2016Treatment Plant Operator MagazineBelum ada peringkat

- Building 16 PrintDokumen112 halamanBuilding 16 PrintNALEEMBelum ada peringkat

- Ilovepdf Merged MergedDokumen209 halamanIlovepdf Merged MergedDeepak AgrawalBelum ada peringkat

- Quality Risk ManagementDokumen29 halamanQuality Risk ManagementmmmmmBelum ada peringkat

- GFF (T) ... MenglischNANNI (DMG-39 25.11.05) PDFDokumen38 halamanGFF (T) ... MenglischNANNI (DMG-39 25.11.05) PDFjuricic2100% (2)

- 2015 Audi q5 sq5 71153 PDFDokumen302 halaman2015 Audi q5 sq5 71153 PDFPraveen100% (1)

- Is 15707 2006Dokumen23 halamanIs 15707 2006anupam789Belum ada peringkat

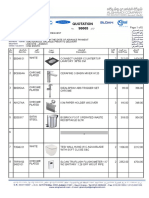

- Quotation 98665Dokumen5 halamanQuotation 98665Reda IsmailBelum ada peringkat

- RT120 ManualDokumen161 halamanRT120 ManualPawełBelum ada peringkat

- Apple A9Dokumen10 halamanApple A9Savithri NandadasaBelum ada peringkat

- Sd-1-Parts-Book Manual Propietario SpreaderDokumen30 halamanSd-1-Parts-Book Manual Propietario Spreadergabriel sanchezBelum ada peringkat

- Mandat 040310062548 21Dokumen379 halamanMandat 040310062548 21Sujeet BiradarBelum ada peringkat

- Renovation Modernization and Uprating of Hydro Power StationsDokumen5 halamanRenovation Modernization and Uprating of Hydro Power StationsAbhijeet SinghBelum ada peringkat

- Cable Ties DatasheetDokumen7 halamanCable Ties DatasheetGovind ChaudhariBelum ada peringkat

- Fire Protection Design For Healthcare FacilitiesDokumen34 halamanFire Protection Design For Healthcare Facilitiesapi_fabianBelum ada peringkat

- MCS-011 Solved Assignment 2015-16 IpDokumen12 halamanMCS-011 Solved Assignment 2015-16 IpJigar NanduBelum ada peringkat

- CHE 322 - Gaseous Fuel ProblemsDokumen26 halamanCHE 322 - Gaseous Fuel ProblemsDanice LunaBelum ada peringkat

- Quidway 20S5300 20series 20ethernet 20switches 20hardware 20Dokumen98 halamanQuidway 20S5300 20series 20ethernet 20switches 20hardware 20Hamza_yakan967Belum ada peringkat

- ANSYS Mechanical Basic Structural NonlinearitiesDokumen41 halamanANSYS Mechanical Basic Structural NonlinearitiesalexBelum ada peringkat

- GL 314Dokumen2 halamanGL 314Vinayak SinghBelum ada peringkat

- Technical Data For Elevator Buckets - Bucket ElevatorDokumen1 halamanTechnical Data For Elevator Buckets - Bucket ElevatorFitra VertikalBelum ada peringkat

- Interfacing Seven Segment Display With LPC1769Dokumen18 halamanInterfacing Seven Segment Display With LPC1769Gurudatta Palankar0% (1)

- SA Flight Instructors Training ProceduresDokumen371 halamanSA Flight Instructors Training ProceduresGuilioBelum ada peringkat

- Brochure sp761lfDokumen10 halamanBrochure sp761lfkathy fernandezBelum ada peringkat

- 1SDA066479R1 Rhe xt1 xt3 F P Stand ReturnedDokumen3 halaman1SDA066479R1 Rhe xt1 xt3 F P Stand ReturnedAndrés Muñoz PeraltaBelum ada peringkat

- Project Based Lab Report ON Voting Information System: K L UniversityDokumen13 halamanProject Based Lab Report ON Voting Information System: K L UniversitySai Gargeya100% (1)

- Crisfield - Vol1 - NonLinear Finite Element Analysis of Solids and Structures EssentialsDokumen360 halamanCrisfield - Vol1 - NonLinear Finite Element Analysis of Solids and Structures EssentialsAnonymous eCD5ZRBelum ada peringkat

- Computer Laboratory Maintenance Plan and ScheduleDokumen5 halamanComputer Laboratory Maintenance Plan and ScheduleJm Valiente100% (3)

- 200 Questions AnswersDokumen150 halaman200 Questions AnswersvempadareddyBelum ada peringkat

- The Effects of Crankshaft Offset On The Engine FrictionDokumen15 halamanThe Effects of Crankshaft Offset On The Engine Frictionqingcaohe100% (1)