SM New Final Manual1

Diunggah oleh

K Nallathambi K NallathambiHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

SM New Final Manual1

Diunggah oleh

K Nallathambi K NallathambiHak Cipta:

Format Tersedia

ANNA UNIVERSITY - COIMBATORE

THE KAVERY ENGINEERING COLLEGE

M.KALIPATTI, METTUR (TK), SALEM (DT) 636453

DEPARTMENT OF MECHANICAL ENGINEERING

STRENGTH OF MATERIALS LABORATORY MANUAL

IV SEMESTER MECHANICAL ENGINEERING (R-2008 SYLLABUS)

Name of the student: ______________________________________________ Register Number : ______________________________________________

Strength of Materials Lab

Prepared By Sasikumar.M & Sudhagar.M Department of Mechanical Engineering

The Kavery Engineering college

Department of Mechanical

Strength of Materials Lab

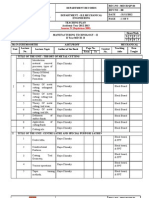

INDEX

The Kavery Engineering college

Department of Mechanical

Strength of Materials Lab

Ex. No 1 2 3 4 5 6 7 8 9 10 11 12

Date

Name of the experiment

TENSION TEST ON A MILD STEEL ROD DOUBLE SHEAR TEST ON MILD STEEL DOUBLE SHEAR TEST ON ALUMINUM IMPACT STRENGTH TEST (CHARPYS TEST) IMPACT STRENGTH TEST ( IZOD TEST) BRINELL HARDNESS TEST ROCKWELL HARDNESS TEST DEFLECTION TEST ON SIMPLY SUPPORTED BEAM (MILD STEEL) COMPRESSION TEST ON HELICAL SPRING TORSION TEST ON MILD STEEL ROD EFFECT OF HARDENING IN IMPACT RESISTANCE OF STEEL STUDY OF MICROSCOPIC EXAMINATION OF HARDENED TEMPERED SAMPLE STUDY OF MICROSCOPIC EXAMINATION OF UNHARDENED SAMPLES AND

Page No 5 11 15 19 23 27 31 35 39 43 45 51

Marks Obtai ned

Staff signat ure

Remar ks

13

53

The Kavery Engineering college

Department of Mechanical

Strength of Materials Lab

SYLLABUS

STRENGTH OF MATERIALS LAB

(Common to Mechanical & Production)

LIST OF EXPERIMENTS

1. Tension test on a mild steel rod 2. Double shear test on Mild steel and Aluminum rods 3. Torsion test on mild steel rod 4. Impact test on metal specimen 5. Hardness test on metals - Brinnell and Rockwell Hardness Number 6. Deflection test on beams 7. Compression test on helical springs 8. Strain Measurement using Rosette strain gauge 9. Effect of hardening- Improvement in hardness and impact resistance of steels. 10. Tempering- Improvement Mechanical properties Comparison (i) Unhardened specimen (ii) Quenched Specimen and (iii) Quenched and tempered specimen. 11. Microscopic Examination of Hardened samples and (ii) Hardened and tempered samples. LIST OF EQUIPMENT (For a batch of 30 students) 1. Universal Tensile Testing machine with double 1 2. shear attachment 40 Ton Capacity 3. Torsion Testing Machine (60 NM Capacity) 1 4. Impact Testing Machine (300 J Capacity) 1 5. Brinell Hardness Testing Machine 1 6. Rockwell Hardness Testing Machine 1 7. Spring Testing Machine for tensile and compressive loads (2500 N) 1 8. Metallurgical Microscopes 3 9. Muffle Furnace (800 C) Quantity: one each.

The Kavery Engineering college

Total Number of Periods: P=45

Department of Mechanical

Strength of Materials Lab

Exp. No: 1 Date :

TENSION TEST ON A MILD STEEL ROD

AIM: To conduct tension test on the given specimen and determine the following Yield Stress Nominal stress Actual breaking Stress Ultimate stress Percentage of elongation Percentage reduction in cross sectional area / E APPARATUS REQUIRED: Universal Testing Machine (UTM) Mild steel specimen Ruler Divider Vernier caliper THEORY: The tensile test is most applied one, of all mechanical tests. In this test ends of test piece are fixed into grips connected to a straining device and to a load measuring device. If the applied load is small enough, the deformation of any solid body is entirely elastic. An elastically deformed solid will return to its original from as soon as load is removed. However, if the load is too large, the material can be deformed permanently. The initial part of the tension curve which is recoverable immediately after unloading is termed. As elastic and the rest of the curve which represents the manner in which solid undergoes plastic deformation is termed plastic. The stress below which the deformations essentially entirely elastic is known as the yield strength of material. In some material the onset of plastic deformation is denoted by a sudden drop in load indicating both an upper and a lower yield point. However, some materials do not exhibit a sharp yield point. During plastic deformation, at larger extensions strain hardening cannot compensate for the decrease in section and thus the load passes through a maximum and then begins to decrease. This stage the ultimate strength which is defined as the ratio of the load on the specimen to original cross-sectional area, reaches a maximum value. Further loading will eventually cause neck formation and rupture.

The Kavery Engineering college

Department of Mechanical

Strength of Materials Lab

OBSERVATION: 1. Given material of specimen = _____ 2. Initial diameter of specimen d1 = ____ 3. Initial gauge length of specimen L1 = ______ 4. cross-section area of specimen A1 = _____ 5. Final length after specimen breaking L2 =______ 6. Diameter of specimen at breaking place (Neck Dia.) d2 = ______ 7. Cross section area at breaking place (Neck area) A2 = ______ 8. Load of yield point = ______ 9. Ultimate load of specimen =______ 10. Breaking load of specimen = ______

TABULATION: LOAD ( KN) EXTENSION STRESS (mm) (N/mm2)

SL.NO

STRAIN

The Kavery Engineering college

Department of Mechanical

Strength of Materials Lab

FORMULAE USED: Yield Load 1) Yield Stress = Cross Sectional Area Ultimate Load 2) Ultimate Stress = Cross Sectional Area Breaking Load 3) Nominal Breaking Stress = Cross Sectional Area of Specimen Breaking Load 4) Actual Breaking Stress = Neck Area Change in length 5) Percentage of Elongation = Original gauge Length Change in area 6) Percentage reduction in Area of cross section = Original area x 100 % x 100 % N/mm2 N/mm2 N/mm2 N/mm2

The Kavery Engineering college

Department of Mechanical

Strength of Materials Lab

TENSILE TESTING MACHINE

GRAPH:

Where, P Proportional Limit E Elastic limit YU Upper Yield Point YL Lower Yield Point

The Kavery Engineering college

Department of Mechanical

Strength of Materials Lab

S Ultimate Tensile strength B Fracture point

The Kavery Engineering college

Department of Mechanical

10

Strength of Materials Lab

PROCEDURE: 1. Measure the original length and diameter of the specimen. The length may either be length of gauge section which is marked in the specimen with a preset punch. 2. Insert the specimen into grips of the test machine and attach strain measuring device to it. 3. Begin the load application and record load versus elongation data. 4. Take readings more frequently and record as yield point is approached. 5. Measure elongation values with the help of dividers and a ruler. 6. Continue the test till fracture occurs. 7. By joining the two broken halves of the specimen together the final length and diameter of specimen.

RESULT: Different parameters of the given specimen are. 1. Yield stress 2. Ultimate stress 3. Nominal breaking stress 4. Actual breaking stress 5. Percentage of elongation 6. Percentage reduction in Cross sectional area = __________ % = __________N/mm2 = __________ N/mm2 = __________N/mm2 = __________N/mm2 = __________ %

The Kavery Engineering college

Department of Mechanical

11

Strength of Materials Lab

The Kavery Engineering college

Department of Mechanical

12

Strength of Materials Lab

Exp. No: 2 Date : AIM:

DOUBLE SHEAR TEST ON MILD STEEL ROD

To determine shear stress by conducting shear test on the specimen under double shear.

APPARATUS REQUIRED: Universal Testing Machine Double Shear assembly box Vernier caliper Test specimen THEORY: A type of force which causes or tends to cause two contiguous parts of the body to slide relative to each other in a direction parallel to their plane of contact is called the shear force. The stress required to produce fracture in the plane of cross-section, acted on by the shear force is called shear strength. Place the shear test attachment on the lower table, this attachment consists of cutter. The specimen is inserted in shear test attachment & lift the lower table so that the zero is adjusted, then apply the load such that the specimen breaks in two or three pieces. If the specimen breaks in two pieces then it will be in single shear & if it breaks in three pieces then it will be in double shear. FORMULAE USED:

Ultimate Shear Stress ( ) =

W 2A

N/mm2

Where, W A - Ultimate Shear strength (N/mm2) - Ultimate load in (N) - area of the specimen in mm2

Department of Mechanical

The Kavery Engineering college

13

Strength of Materials Lab

OBSERVATION:

Given material of specimen = Mild steel Diameter of specimen rod Maximum Shear Load = -----= ------

TABULATION: Diameter of Specimen the specimen d (mm) Cross Sectional area A(mm2) Maximum Shear Load W (kN) Ultimate Shear stress ( N/mm2)

Mild steel Rod

The Kavery Engineering college

Department of Mechanical

14

Strength of Materials Lab

PROCEDURE: 1. The diameter of rod is measured using vernier caliper. 2. The specimen is inserted in position in double shear assembly box and is gripped between the compression plates of universal testing machine. 3. The universal testing machine is switched on. 4. A suitable load is selected. 5. Left side valve is kept in a closed position and right side loading valve is gradually opened and the load is applied on the specimen till it shear. 6. The maximum load taken by the specimen at that time is noted. 7. Then the machine is stopped and the ultimate shear strength of the specimen is noted.

RESULT: The ultimate Double shear stress of the Mild steel specimen is_____________ N/mm2.

The Kavery Engineering college

Department of Mechanical

15

Strength of Materials Lab

The Kavery Engineering college

Department of Mechanical

16

Strength of Materials Lab

Exp. No: 3 Date : AIM:

DOUBLE SHEAR TEST ON ALUMINIUM ROD

To determine shear stress by conducting shear test on the specimen under double shear.

APPARATUS REQUIRED: Universal Testing Machine Double Shear assembly box Vernier caliper Test specimen THEORY: A type of force which causes or tends to cause two contiguous parts of the body to slide relative to each other in a direction parallel to their plane of contact is called the shear force. The stress required to produce fracture in the plane of cross-section, acted on by the shear force is called shear strength. Place the shear test attachment on the lower table, this attachment consists of cutter. The specimen is inserted in shear test attachment & lift the lower table so that the zero is adjusted, then apply the load such that the specimen breaks in two or three pieces. If the specimen breaks in two pieces then it will be in single shear & if it breaks in three pieces then it will be in double shear. FORMULAE USED:

Ultimate Shear Stress ( ) =

W 2A

N/mm2

Where, W A - Ultimate Shear strength (N/mm2) - Ultimate load in (N) - area of the specimen in mm2

Department of Mechanical

The Kavery Engineering college

17

Strength of Materials Lab

OBSERVATION:

Given material of specimen = Aluminum rod Diameter of specimen rod Maximum Shear Load = -----= ------

TABULATION: Diameter of Specimen the specimen d (mm) Cross Sectional area A(mm2) Maximum Shear Load W (kN) Ultimate Shear stress ( N/mm2)

Aluminum rod

The Kavery Engineering college

Department of Mechanical

18

Strength of Materials Lab

PROCEDURE: 1. The diameter of rod is measured using vernier caliper. 2. The specimen is inserted in position in double shear assembly box and is gripped between the compression plates of universal testing machine. 3. The universal testing machine is switched on. 4. A suitable load is selected. 5. Left side valve is kept in a closed position and right side loading valve is gradually opened and the load is applied on the specimen till it shears. 6. The maximum load taken by the specimen at that time is noted. 7. Then the machine is stopped and the ultimate shear strength of the specimen is noted.

RESULT: The ultimate Double shear stress of the Aluminum specimen is_____________ N/mm2.

The Kavery Engineering college

Department of Mechanical

19

Strength of Materials Lab

The Kavery Engineering college

Department of Mechanical

20

Strength of Materials Lab

Exp. No: 4 Date AIM: :

IMPACT STRENGTH TEST (CHARPYS TEST)

To determine the impact strength of material of the given specimen by charpys impact test. APPARATUS REQUIRED: Impact testing machine Charpys test specimen Vernier caliper.

THEORY: In manufacturing locomotive wheels, coins, connecting rods etc. the components are subjected to impact (shock) loads. These loads are applied suddenly. The stresses induced in these components are many times more than the stress produced by gradual loading. Therefore, impact tests are performed to asses shock absorbing capacity of

materials subjected to suddenly applied loads. These capabilities are expressed as (i) Rupture energy (ii) Modulus of rupture and (iii) Notch impact strength. Two types of notch impact tests are commonly Charpy test Izod test In charpys test, the specimen is placed as 'cantilever beam'. The specimens have Vshaped notch of 45. U- Shaped notch is also common. The notch is located on tension side of specimen during impact loading. Depth of notch is generally taken as t.5 to t/3 where t is thickness of the specimen.

The Kavery Engineering college

Department of Mechanical

21

Strength of Materials Lab

TEST SPECIMEN:

OBSERVATION: Breath of specimen (b) Depth of specimen (d) Length of specimen (l) Depth of notch TABULATION: Dimensions of Specimen Depth of Breath Depth Length Notch b d l d mm mm mm mm Impact Energy Observed k J (d1) = ________ mm = ________ mm = ________ mm = ________ mm

Specimen

Impact Strength I=k/A J / m2

MODEL CALCULATION: Area of cross- section of specimen (A) = b X (d-d1) Impact energy observed Impact strength (K) = _______ (I) = K/A J/m2 mm2 J

The Kavery Engineering college

Department of Mechanical

22

Strength of Materials Lab

FORMULAE USED: Notch Impact Strength I =K/A Where, I = Notch impact strength in J/m2 K = Impact energy absorbed by specimen in Joules A = Area of the cross section of specimen below notch before test in m2 J/m2

PROCEDURE: 1) The hammer is raised and locked. 2) The pointer is set at maximum position of graduated energy of dial. 3) The safety load bar is placed horizontally arms of projecting bars. 4) The trigger is released and pendulum is allowed to swing. This actuates the pointer to move in the dial. 5) See that no person is on within range to swing of pendulum. 6) The specimen is placed in such a way that notch is opposite to the direction of the pendulum for contact centering of specimen. The end stop is provided. 7) The latches are released and pendulum is allowed to strike on specimen (or) bending the specimen is noted in the dial. 8) Then the impact energy required for the rupture of the specimen is directly measured on indicator.

RESULT: The Charpy impact strength is calculated as, The impact strength of the given specimen (I) = J/m2

The Kavery Engineering college

Department of Mechanical

23

Strength of Materials Lab

The Kavery Engineering college

Department of Mechanical

24

Strength of Materials Lab

Exp. No: 5 Date AIM: :

IMPACT STRENGTH TEST (IZOD TEST)

To determine the impact strength of the given specimen by Izod impact test.

APPARATUS REQUIRED: Impact testing machine Izod specimen Vernier caliper. THEORY: In manufacturing locomotive wheels, coins, connecting rods etc. the components are subjected to impact (shock) loads. These loads are applied suddenly. The stresses induced in these components are many times more than the stress produced by gradual loading. Therefore, impact tests are performed to asses shock absorbing capacity of materials subjected to suddenly applied loads. These capabilities are expressed as (i) Rupture energy (ii) Modulus of rupture and (iii) Notch impact strength. Two types of notch impact tests are commonly Charpy test Izod test In Izod test, the specimen is placed as cantilever beam. The specimens have V-shaped notch of 45. U- Shaped notch is also common. The notch is located on tension side of specimen during impact loading. Depth of notch is generally taken as t.5 to t/3 wheret is thickness of the specimen.

The Kavery Engineering college

Department of Mechanical

25

Strength of Materials Lab

TEST SPECIMEN:

OBSERVATION: Breath of specimen (b) Depth of specimen (d) Length of specimen (l) Depth of notch = ________ mm = ________ mm = ________ mm

(d1) = ________ mm

TABULATION: Dimensions of Specimen Depth of Breath Depth Length Notch b d l d mm mm mm mm Impact Energy Observed k J

Specimen

Impact Strength I=k/A J / m2

MODEL CALCULATION: Area of cross- section of specimen (A) Impact energy observed Impact strength (K) (I) = b X (d-d1) = _______ = K/A mm2 J J/m2

The Kavery Engineering college

Department of Mechanical

26

Strength of Materials Lab

FORMULAE USED: Notch Impact Strength I =K/A Where, I = Notch impact strength in J/m2 K = Impact energy absorbed by specimen in Joules A = Area of the cross section of specimen below notch before test in m2 PROCEDURE: 1. The hammer is raised and locked. 2. The pointer is set at max. position of graduated energy of dial. 3. The safety load bar is placed horizontally arms of projecting bars. 4. The trigger is released and pendulum is allowed to swing. This actuates the pointer to move in the dial. 5. See that no person is on within range to swing of pendulum. 6. The specimen is placed vertically ie cantilever position in such a way that notch is opposite to the direction of the pendulum for contact centering of specimen. The end stop is provided. 7. The latches are released and pendulum is allowed to strike on specimen (or) bending the specimen is noted in the dial. 8. Then the impact energy required for the rupture of the specimen is directly measured on indicator. J/m2

RESULT: The Izod impact strength is calculated as, The impact strength of the given specimen (I) =

The Kavery Engineering college

J/m2

Department of Mechanical

27

Strength of Materials Lab

Brinell hardness Testing Machine

LOADING TABLE: Loading in Kg Ball diame ter D in mm 1 2 Exp. No: 6

The Kavery Engineering college

(P) Ferrous (Steel & Iron) (30D2) 3000 750 Non Ferrous Brass (10D2) 1000 250 Aluminum (5D2) 500 -

S.No

10 5

BRINELL HARDNESS TEST

Department of Mechanical

28

Strength of Materials Lab

Date

AIM: To determine the brinell hardness number of the given specimen. APPARATUS REQUIRED: Brinell Hardness Testing Machine Brinell Microscope Ball Indenter (5,10 mm) Test specimens

THEORY: Hardness represents the resistance of material surface to abrasion, scratching and cutting, hardness after gives clear identification of strength. In all hardness testes, a define force is mechanically applied on the test piece for about 15 seconds. The indenter, which transmits the load to the test piece, varies in size and shape for different tastes. Common indenters are made of hardened steel or diamond. In Brinell hardness testing, steel balls are used as indenter. Diameter of the indenter and the applied force depend upon the thickness of the test specimen, because for accurate results, depth of indentation should be less than 1/8th of the thickness of the test pieces. According to the thickness of the test piece increase, the diameter of the indenter and force are changed.

The Kavery Engineering college

Department of Mechanical

29

Strength of Materials Lab

TABULATION: Load (Kgf) P Diameter of Impression d1

(mm)

S. No

Name of the Material

d2

(mm)

Mean dia of Impressio n (mm) d

Area A mm2

Brinell Hardnes s Number (BHN)

MODEL CALCULATION: Name of the Specimen Applied Load (P) Ball diameter (D) Diameter of the impression d1 Diameter of the impression d2 Surface Area of Impression (A)

=

= = = = = D 2 [D Kg mm mm mm. (D2 d2 ) ] mm2

Brinell Hardness Number (P/A) PROCEDURE:

= _____________ Kg/mm2 Or BHN

1. The type of ball indenter of specified diameter is selected and fixed in machine head.

The Kavery Engineering college

Department of Mechanical

30

Strength of Materials Lab

2. The surface of specimen is to be cleaned from dust, oil etc. before placing it on the test platform. 3. The platform with specimen is raised until gap between indenter and specimen is minimum. Now the machine is switched on. 4. The load-applying lever is released to original position. 5. A minor load is applied manually while the specimen is made contact with the indenter. 6. The platform is lowered and the machine is switched off. 7. Then with the help of brinell microscope the diameter of impression is measured and tabulated. 8. Then with the help of brinell microscope the dia of impression is measured in two directions at right angle to each other and average dia to be taken and tabulated. 9. The above procedure is repeated for different specimen with minimum three readings in each specimen.

RESULT: The Brinell hardness number of 1. ____________with _______ Ball diameter = __________ BHN 2. ____________with _______ Ball diameter = __________ BHN 3. ____________with _______ Ball diameter = __________ BHN

Rockwell hardness Testing Machine

The Kavery Engineering college

Department of Mechanical

31

Strength of Materials Lab

LOAD TABLE:

Material Relatively soft Material Purely hard Material Hard Material

Penetrates Diamond cone(1200 ) 1/16 Ball point Diamond Cone (800)

Load (Kgf) 60 100 150

Scale A B C

Exp. No: 7 Date :

ROCKWELL HARDNESS TEST

The Kavery Engineering college

Department of Mechanical

32

Strength of Materials Lab

AIM: To determine the Rockwell hardness Number of given specimen. APPARATUS REQUIRED: 1. Rockwell hardness testing machine 2. Penetrates 3. Test specimen. THEORY: Hardness represents the resistance of material surface to abrasion, scratching and cutting, hardness after gives clear indication of strength. In all hardness tests, a define force is mechanically applied on the piece, varies in size and shape for different tests. Common indenters are made of hardened steel or diamond. Rockwell hardness tester presents direct reading of hardness number on a dial provided with the m/c. Principally this testing is similar to Brinell hardness testing. It differs only in diameter and material of the indenter and the applied force. Although there are many scales having different combinations of load and size of indenter but commonly 'C' scale is used and hardness is presented as HRC. Here the indenter has a diamond cone at the tip and applied force is of 150 kgf. Soft materials are often tested in 'B' scale with a 1.6mm diameter steel indenter at 60kgf.

The Kavery Engineering college

Department of Mechanical

33

Strength of Materials Lab

TABULATION:

S.No

Name of the Material

Load (Kgf)

Load (N)

Penetrates

Scale

Dial Reading

Rockwell Hardness Number

1.

2.

3.

4.

PROCEDURE: 1. Insert ball of dia. 'D' in ball holder of the m/c. 2. Make the specimen surface clean by removing dust, dirt, oil and grease etc. 3. Make contact between the specimen surface and the ball by rotating the jack adjusting wheel.

The Kavery Engineering college

Department of Mechanical

34

Strength of Materials Lab

4. Push the required button for loading. 5. Pull the load release lever wait for minimum 15 second. The load will automatically apply gradually. 6. Remove the specimen from support table and locate the indentation so made. 7. Repeat the entire operation, 3-times.

RESULT: The Rockwell hardness number of 1. 2. 3. 4. ____________with _______penetrate ____________with _______penetrate ____________with _______penetrate ____________with _______penetrate = __________ RHN = __________ RHN = __________ RHN = __________ RHN

The Kavery Engineering college

Department of Mechanical

35

Strength of Materials Lab

Exp. No: 8 Date AIM: :

DEFLECTION TEST ON SIMPLY SUPPORTED BEAM (MILD STEEL)

To find the values of Youngs modulus of the material of a simply supported beam (mild steel) by conducting deflection test.

The Kavery Engineering college

Department of Mechanical

36

Strength of Materials Lab

APPARATUS REQUIRED: 1) Deflection of beam apparatus 2) Weight 3) Beam ( steel) 4) Deflect meter 5) Knife edge support 6) Loading hanger 7) Vernier caliper THEORY: If a beam is simply supported at the ends and carries a point load at its centre, the beam bends concave upwards. The distance between the original position of the beam and its position after bending is different at different points along the length of the beam, being maximum at the centre in this case. The difference is known is deflection. FORMULA USED: W a x (L2 a2 x2) Youngs Modulus Where, bd3 I W L x a b d = = = = = = = = Moment of inertia in mm Load applied in N Effective span of the beam in mm Mean deflection of the beam in mm Distance between the deflect meter and one knife edge in mm Distance between the load hanger and another knife edge in mm Breath of specimen in mm Thickness of the specimen in mm = = = = =

Department of Mechanical

4

E= 6 IL

N/mm2

= 12

OBSERVATIONS: Effective span of the beam L Breath of specimen in b Thickness of the specimen ind Least count deflection of the beam Distance between the deflect meter and one knife edge x

The Kavery Engineering college

37

Strength of Materials Lab

Distance between the load hanger and another knife edge in a

TABULATION: Load applied S.No ( W) Kg 1 2 3 4 5 6 7 8 Load applied ( W) N Loading Unloading Deflect meter Reading Mean Deflection () mm Youngs Modulus (E) N/mm2

PROCEDURE: 1. Place the beam on the knife edges on the blocks so as to project equally beyond each knife edge. See that the load is applied at the centre of the beam. 2. Note the initial reading of vernier scale 3. Add a weight of 50 N (say) and again note the reading of the vernier scale.

The Kavery Engineering college

Department of Mechanical

38

Strength of Materials Lab

4. Go on taking reading adding 50 N (say) each time till you have readings.

minimum six

5. Find the deflection in each case by subtracting the initial reading of vernier scale. Plot the graph between load and deflection. On the graph choose any two convenient points and between these points find the corresponding values of W and . Putting these values in the above relation, we can find the E.

GRAPH: X-Axis Y-Axis Deflection (mm) Load (N)

RESULT: The Youngs modulus of given mild steel material is Theoretical (E) Graphical (E) = =

The Kavery Engineering college

Department of Mechanical

39

Strength of Materials Lab

COMPRESSION TEST ON HELICAL SPRING

MODEL GRAPH OBSERVATION: Diameter of the rod (d) Diameter of the spring (D) Inner diameter of spring (D1) Height of the spring (h) Number of turns (n) = = = = = d + D1 Mean radius of spring ( R) = 2 mm mm mm mm mm

The Kavery Engineering college

Department of Mechanical

40

Strength of Materials Lab

Exp. No : 9 Date AIM: :

COMPRESSION TEST ON HELICAL SPRING

To study the load deflection behavior of the helical spring and to determine the Stiffness of spring and Modulus of rigidity. APPARATUS REQUIRED: Spring testing machine A spring Micrometer Vernier caliper Scale FORMULA USED: 1. Stiffness of spring S

(Slope of W- curve)

W/

N/mm

2. Modulus of rigidity (C) W R n d -

64 WR3n d

4

N/mm2

applied Load (N) Mean radius of the spring (mm) No. of turns Deflection of the spring ( mm ) diameter of the spring Wire (mm)

The Kavery Engineering college

Department of Mechanical

41

Strength of Materials Lab

TABULATION: Applie d Load (Kg) Applied Load (N) Compression due to the load Mean Loading Unloading (mm) (mm) (mm) Modulus of rigidity C (N/mm2) Stiffness S (N/mm)

Sl. No

Mean

PROCEDURE: 1. Measure the diameter (d) of the spring bar forming the coil at 3 locations and take the average value as the diameter of the bar.

The Kavery Engineering college

Department of Mechanical

42

Strength of Materials Lab

2. Determine the mean radius(r) of the spring, record the number of turns (n). Determine the pitch (p) of the spring and measure the free height of spring (h). 3. The compression spring is placed centrally on the bottom plate and the upper plate is lowered such that it just touches the upper plate . 4. The pointer on the dial is set to zero. The Load is gradually applied. 5. Note the deflections for both loading as well as Unloading. Calculate the average of the loads for the various deflections. 6. Unlock the testing machine and fix the spring in position. Make zero adjustment in the dial by adjusting the weight on the spring. 7. Apply the load slowly note the deflections for both loading and unloading by 20N steps. At least 6 readings have to be noted.

RESULT: 1. Stiffness of spring (S) i) From calculation ii) From graph 2. Modulus of rigidity (C) i) From calculation ii) From graph = ________ N/mm2 = ________ N/mm2 = ________ N/mm = ________ N/mm

The Kavery Engineering college

Department of Mechanical

43

Strength of Materials Lab

Exp. No : 10 Date :

TORSION TEST ON MILD STEEL

AIM: To conduct torsion test on mild steel specimens to find the following Modulus of rigidity Maximum Shear stress

The Kavery Engineering college

Department of Mechanical

44

Strength of Materials Lab

APPARATUS REQUIRED: A torsion testing machine. Twist meter for measuring angles of twist A steel rule and Vernier Caliper or micrometer. THEORY: A torsion test is quite instrumental in determining the value of modulus of rigidity of a metallic specimen. The value of modulus of rigidity can be found out thought observations made during the experiment by using the torsion equation FORMULA USED: Torsion test of square rod 4.8 Tmax Maximum Shear stress = b3 5.5 T L Modulus of rigidity T C L b = = = = = = C = b4 Torque applied (Nmm) Modulus of rigidity (N/mm2) Angle of twist (radians) Gauge length (mm) Shear stress (N/mm2) width of the square rod (mm)

OBSERVATION:

Width of the square rod (b) Gauge length (L)

= =

mm mm

The Kavery Engineering college

Department of Mechanical

45

Strength of Materials Lab

TABULATION: Angle of S.No Twist (deg)

Tropotometer reading Kgf(cm)

Torque Nmm

Modulus of rigidity (C) N/mm2

1 2 3 4 5 6 7 8 9

PROCEDURE:

1. Select the driving dogs to suit the size of the specimen and clamp it in the machine by adjusting the length of the specimen by means of a sliding spindle. 2. Measure the diameter at about three places and take the average value. 3. Choose the appropriate range by capacity change lever 4. Set the maximum load pointer to zero.

The Kavery Engineering college

Department of Mechanical

46

Strength of Materials Lab

5. Set the protector to zero for convenience and clamp it by means of knurled screw. 6. Carry out straining by rotating the hand wheel in either direction. 7. Load the machine in suitable increments. 8. Then load out to failure as to cause equal increments of strain reading. 9. Plot a torque- twist (T- ) graph. 10. Read off co-ordinates of a convenient point from the straight line portion of the torque twist (T- ) graph and calculate the value of C by using relation

RESULT:

Maximum shear stress =__________N/mm2

Modulus of rigidity C (From Calculation) =__________ N/mm2 Modulus of rigidity C (From Graph) =__________ N/mm2

The Kavery Engineering college

Department of Mechanical

47

Strength of Materials Lab

Exp. No: 11 Date :

EFFECT OF HARDENING IN IMPACT RESISTANCE OF STEEL

AIM: To determine the effect of hardening in impact resistance resistance of steel before and after hardening.

The Kavery Engineering college

Department of Mechanical

48

Strength of Materials Lab

APPARATUS REQUIRED: Impact testing machine Furnace Vernier caliper Scale

PROCEDURE:

1. The hammer is raised and locked. 2. The pointer is set at maximum position of graduated energy of dial. 3. The safety load bar is placed horizontally arms of projecting bars. 4. The trigger is released and pendulum is allowed is to swing this actuates the pointer to more in the dial. 5. The specimen is placed in such a way that notch is opposite to the direction of the pendulum for contact centering of specimen the end stop is provided. 6. The latches are released and pendulum is allowed to strike on specimen or bending the specimen is noted in the dial. 7. Then the input energy required for the rapture of the specimen is directly measured on indicator. 8. Now another specimen is taken and kept into a furnace at 8500C to 9500C. 9. The specimen is the same piece is cooled suddenly in quenching media. 10. Now the variation in the input strength before and after hardening is studied.

OBSERVATION: Breadth of specimen (b):__________________ Depth of Specimen (d):___________________ Length of Specimen (L):___________________ Depth of notch (d1):______________________

The Kavery Engineering college

Department of Mechanical

49

Strength of Materials Lab

TABULATION: Dimension of specimen Depth Depth of Breadth b Length L d notch d1 (mm) (mm) (mm) (mm) Are of cross section A (mm2) Impact energy observed K (J) Impact strength I=K/A (J/m2)

Specimen

Before hardening After hardening

MODEL CALCULATION: Area of the cross section of specimen (A) = b (d -d1) mm2 Impact strength (I) = K/A J/m2

The Kavery Engineering college

Department of Mechanical

50

Strength of Materials Lab

RESULT: The charpy impact strength is calculated as, 1. The impact strength of the given specimen (Before hardening) = ________ J/m2 2. The impact strength of the given specimen (After hardening) = __________J/m2

The Kavery Engineering college

Department of Mechanical

51

Strength of Materials Lab

Exp. No : 12 Date :

STUDY OF MICROSCOPIC EXAMINATION OF HARDENED AND TEMPERED SAMPLES

AIM: To determine the microscopic examination of hardened and tempered samples (steel)

The Kavery Engineering college

Department of Mechanical

52

Strength of Materials Lab

APPARATUS REQUIRED: Specimen Metallurgical microscope COMPOSITION:

C=0.6% Si=0.4% Mn=0.1% P=0.05% S=0.05%

Heat treatment: yes Mechanical treatment:: NIL

OBSERVATION: The structure contains tempered martensite. The given structure is identified as quenched and tempered steel.

The Kavery Engineering college

Department of Mechanical

53

Strength of Materials Lab

Exp. No : 13 Date :

STUDY OF MICROSCOPIC EXAMINATION OF UNHARDENED SAMPLES

AIM: To determine the microscopic examination of unhardened samples (medium carbon steel)

The Kavery Engineering college

Department of Mechanical

54

Strength of Materials Lab

APPARATUS REQUIRED: Specimen Metallurgical microscope COMPOSITION:

C=0.6% Si=0.6% Mn=0.8% P=0.004% S=0.004%

Heat treatment: NIL Mechanical treatment: NIL

OBSERVATION: The structure contains pearlite and ferrite. The given structure is identified as medium carbon steel.

The Kavery Engineering college

Department of Mechanical

55

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- B.E. Mech PDFDokumen113 halamanB.E. Mech PDFarulmuruguBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Surface Modification by Electro-Discharge Coating and Its CharacterisationDokumen9 halamanSurface Modification by Electro-Discharge Coating and Its CharacterisationK Nallathambi K NallathambiBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Me6404 - Thermal EngineeringDokumen195 halamanMe6404 - Thermal EngineeringSasidharan MadhavikrishnankuttyBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Attendance Shortage LetterDokumen1 halamanAttendance Shortage LetterK Nallathambi K NallathambiBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- ME8493-Thermal Engineering-I PDFDokumen19 halamanME8493-Thermal Engineering-I PDFK Nallathambi K NallathambiBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Machine Drawing Through CadDokumen91 halamanMachine Drawing Through CadmjdaleneziBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- ME8493-Thermal Engineering-I PDFDokumen19 halamanME8493-Thermal Engineering-I PDFK Nallathambi K NallathambiBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- (1991) Analysis of Non-Ideal Step Down Matrix Converter Based On Circuit DQ Transformation PDFDokumen5 halaman(1991) Analysis of Non-Ideal Step Down Matrix Converter Based On Circuit DQ Transformation PDFK Nallathambi K NallathambiBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- BC MMMMMMDokumen2 halamanBC MMMMMMK Nallathambi K NallathambiBelum ada peringkat

- Mechanical Property CharacterizationDokumen4 halamanMechanical Property CharacterizationK Nallathambi K NallathambiBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Diagram and Datas of Cooling Tower PDFDokumen52 halamanDiagram and Datas of Cooling Tower PDFK Nallathambi K NallathambiBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- CNC 1-7Dokumen1 halamanCNC 1-7K Nallathambi K NallathambiBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- CNC 1-7Dokumen1 halamanCNC 1-7K Nallathambi K NallathambiBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Turret LatheDokumen12 halamanTurret LatheK Nallathambi K NallathambiBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Mt-II Lesson PlanDokumen5 halamanMt-II Lesson PlanK Nallathambi K NallathambiBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Sample Question PaperDokumen15 halamanSample Question PaperK Nallathambi K NallathambiBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Lathes For Mt2 LabsDokumen13 halamanLathes For Mt2 LabsK Nallathambi K NallathambiBelum ada peringkat

- Question Bank With Solutions: Rajath PublishersDokumen55 halamanQuestion Bank With Solutions: Rajath Publishersafzal646100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Lathe: Common Types of Lathes: Engine LatheDokumen9 halamanLathe: Common Types of Lathes: Engine LatheRavi_Kiran_5665Belum ada peringkat

- MT2 Draft Manual44Dokumen69 halamanMT2 Draft Manual44K Nallathambi K NallathambiBelum ada peringkat

- ViewPlannerInstallationAndUserGuide 20110127Dokumen70 halamanViewPlannerInstallationAndUserGuide 20110127K Nallathambi K NallathambiBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Final Heat Power Lab Manual14Dokumen70 halamanFinal Heat Power Lab Manual14K Nallathambi K NallathambiBelum ada peringkat

- CADD Manual EditingDokumen35 halamanCADD Manual EditingK Nallathambi K NallathambiBelum ada peringkat

- MOMLAB - EXP5 (Open Ended) - GROUP1 - SEC04BDokumen11 halamanMOMLAB - EXP5 (Open Ended) - GROUP1 - SEC04BSolehen100% (1)

- TUGAS-04 Chap 11-13 PDFDokumen8 halamanTUGAS-04 Chap 11-13 PDFAdita EvalinaBelum ada peringkat

- Engineering MaterialsDokumen16 halamanEngineering MaterialsYosef Ganang Jati NugrohoBelum ada peringkat

- 8620 Case Hardening SteelDokumen3 halaman8620 Case Hardening Steelkumarsathish2009Belum ada peringkat

- Control of Gas Nitriding ProcessDokumen9 halamanControl of Gas Nitriding ProcessKevin ThomasBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- PipingDokumen54 halamanPipingakhilsyam21Belum ada peringkat

- Development of Electroless NiP-PTFE-SiC Composite CoatingDokumen5 halamanDevelopment of Electroless NiP-PTFE-SiC Composite CoatingJosé Emilio Román de AndaBelum ada peringkat

- Heat Treating SteelDokumen4 halamanHeat Treating Steelbforbes82Belum ada peringkat

- Ansi Agma 6114 A06Dokumen78 halamanAnsi Agma 6114 A06Marno Prinsloo100% (1)

- Steel Mill Industrial TrainingDokumen34 halamanSteel Mill Industrial TrainingBenBelum ada peringkat

- Microstructures of The Commercial 7075 AI Alloy in The T651 and T7 TempersDokumen2 halamanMicrostructures of The Commercial 7075 AI Alloy in The T651 and T7 TempersPutra Temas ToyebBelum ada peringkat

- TS For NML Supply of ValvesDokumen19 halamanTS For NML Supply of ValvesKalai SelvanBelum ada peringkat

- 2019 - DatasheetsQuard500 UK LRDokumen2 halaman2019 - DatasheetsQuard500 UK LRGabriel CamargoBelum ada peringkat

- Engineering Materials-Istanbul .Technical UniversityDokumen40 halamanEngineering Materials-Istanbul .Technical UniversitybuggrraaBelum ada peringkat

- Steel Forgings, Carbon and Alloy, For Pinions, Gears and Shafts For Reduction GearsDokumen5 halamanSteel Forgings, Carbon and Alloy, For Pinions, Gears and Shafts For Reduction GearsDanZel DanBelum ada peringkat

- Jfap 0501 P 041 WDokumen14 halamanJfap 0501 P 041 WJulio C. Sierra PalominoBelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Factor PerlitizanteDokumen4 halamanFactor Perlitizantejose.figueroa@foseco.comBelum ada peringkat

- Presentation of Procast Casting SimulationDokumen127 halamanPresentation of Procast Casting Simulationrahul989100% (3)

- Dies and Die SelectionDokumen10 halamanDies and Die SelectionAlexandru IonescuBelum ada peringkat

- NI 0133 (English)Dokumen112 halamanNI 0133 (English)Cebrac ItatibaBelum ada peringkat

- Welding Quiz 1Dokumen2 halamanWelding Quiz 1Thanga PandiBelum ada peringkat

- Katalog Weldotherm 10 2013 GB EmailDokumen40 halamanKatalog Weldotherm 10 2013 GB Emailimran jamilBelum ada peringkat

- A1028-03 (2015) Standard Specification For Stainless Steel Bars For Compressor and Turbine AirfoilsDokumen4 halamanA1028-03 (2015) Standard Specification For Stainless Steel Bars For Compressor and Turbine Airfoilstjt4779Belum ada peringkat

- Manual Hoist ProductsDokumen40 halamanManual Hoist Productskavin bhagavathyBelum ada peringkat

- Investigation Influence of Post Weld Heat - Between P91 and P11 PDFDokumen9 halamanInvestigation Influence of Post Weld Heat - Between P91 and P11 PDFAnonymous 1i8lWtZxBelum ada peringkat

- Heat TreatmentDokumen14 halamanHeat TreatmentAkhilesh KumarBelum ada peringkat

- Dissimilar WeldDokumen24 halamanDissimilar WeldBenjapon bt7Belum ada peringkat

- WS410Dokumen7 halamanWS410Martin OusephBelum ada peringkat

- Technical Notes FOR Butt Welded, Socket Welded and Screwed Pipe FittingsDokumen10 halamanTechnical Notes FOR Butt Welded, Socket Welded and Screwed Pipe FittingsMunishBelum ada peringkat