1448 40

Diunggah oleh

Ajit SamalDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

1448 40

Diunggah oleh

Ajit SamalHak Cipta:

Format Tersedia

Is:i448[e:40]-1987 ( Redlhd

1993 )

Indian Standard

METHODS OF TEST FOR PETROLEUM AND ITS PRODUCTS

[P:

WATER

403

BY DISTILLATION

( .Third Revision )

Second Reprint

DECEMBER 19%

Designation 95-81,

UDC

Adapted

6656/7 : 543 : 812 : 66048

with permission from the joint publication ASTM API 2560 and IP Designation 74182

1. SCOPE 1.1 This

products, materials method covers the determination of tars and products derived from tars. specific considered water in petroleum range of

1.1.1 The

products listed in 7.1.1 represent the in developing the details of this method.

2. SUMMARY

OF METHOD

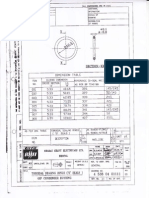

material is heated under reflux with a water-immiscible solvent which co-distils with the water in the sample. Condensed solvent and water are continuously separated in a trap, the water settling in the graduated section of the trap and the solvent returning to the still. 3. APPARATUS 3.1 The apparatus comprises of a glass or metal still, a heater, a refiux condenser, and a graduted glass trap. The still, trap and condenser may be connected by any suitable method for producing a leak-proof joint. Preferred connections are ground joints for glass 2nd O-rings for metal to glass. Typical assemblies are illustrated in Fig. 1 to 3. @

2.1 The

BUREAU

MANAK

OF

BHAVAN,

Copyright 1987 INDIAN STANDARDS

ZAFAR MARC

9 BAHADUR SHAH NEW DELHI 110002

Gr2

October 1987

IS:1448[P:40]-1987

FICL 1 TYPICAL ASSEMBLY WITH GLASS STILL ( DEAN AND STARK APPARATUS ) 2

IS :1448 [P:40]-

1987

I-

101015

1 -I

50

E

819 ID2

JOINT

I 95?lfi

-70

--

1\ t

B 3L JOINT\

90

LO

L

3

All dimensions in millimetres.

FIG. 2

5 ml RECIEVER SHOWING ALTERNATWE CONNECTIONS

TO DISTILLATION VESSEL

IS:l449[Pt

49 ] - 1997

l-h

-

FIG. 3

DPICAL ASSEMBLY WITH METAL 4

1s; 1448[P:49]-1987 3.1.1 Still - A glass or metal vessel with a short neck and suitable Vessels joint for accommodating the reflux tube of the trap. of 500, 1000 and 2 000 ml nominal capacities have been found satisfactory. 3.1.2 Heater - Any suitable gas burner or electric heater may be A gas ring burner with ports on the insidr used with the glass still. circumference shall be used with the metal still, and shall be of such dimensions that it may be moved up and down the vessel when testing materials which are liable to foam or to solidify in the still. 3.2 Dimensions and description of typical glassware for use in this A method are given in relevant Indian Standards on glass apparatus. straight water-cooled condenser with a length of 400 mm is recommended. The stills and traps should be chosen to cover the range of materials and water content expected ( see Note ). NOTE-Instead of standardizing on a particular apparatus with respect to dimensions and style, a given apparatus will be deemed as satisfactory when accurate results are obtained by the standard addition technique obtained in 6. 4. SOLVENT-CARRIER LIQWID

4.1 Any suitable hydrocarbon boiling in the range of 100 to 200C may be used. With residual fuel oils and bitumens, aromatic solvents For the are desirable in order to avoid separation of asphaltenes. determination of water in certain lubricating greases, close boiling range petroleum distillate ( see 4.3 ) has been found to be necessary. 4.2 The following solvents have been found suitable: a) Commercial toluene b) Commercial c) Petroleum 200C.

xylene -

industrial industrial fractions

grade, grade, and in the boiling range of 100 to Iso-octane

which are the liquid. *

distillate

4.3 Petroleum spirit in the boiling 95 percent purity or better.

range

of 100 to 120C.

CAUTION - Toluene and xylene are toxic, volatile hydrocarbons absorbed by inhaling the vapour or through the skin by contact with Use adequate ventilation and avoid skin contact.

5. SAMPLE 5.1 The portion of the sample used for the test shall be thoroughly representative of the total sample. If the material is liquid, thoroughly 5

IS:1448[

P:

40]- 1987

mix the sample as received, warming if necessary, to ensure uniformity. Crush the solid materials that are sufficiently brittle, mix t Irorot!ghly, and take a representative sample for analysis. When there 1s doubt as to the uniformity of the material, run a number of samples and average the data. Sampling procedure is described in the appropriate clauses of IS : 1447-1966*. 5.2 A sample size of 100 ml or 100 g is recommended. Should however the quantity of water exceed the capacity of the largest permitted trap, the quantity of sample may be decreased or the trap fitted with a stopcock used, where excess water may be withdrawn into a graduated cylinder. 6. STANDARDIZATION

6.1 A given assembly of apparatus wi!l be considered satisfactory when accurate readings are obtained from addition of known amounts of water from a calibrated burette or pipette to a clear hydrocarbon oil and tested in accordance with 7.

6.2 The readings will be judged accurate if conformity to the permissible limits given in Table 1 for the various sized graduated traps are not exceeded.

TABLE CAPAOITY OF RECEIVZR IN ml AT 20% 5 10 10 25 1 PERMISSIBLE LlMITS PERMISSIBLELIMITS FOB RZOOVZRZD WATER IN ml AT 20% 1 f01 1 *o-1 5 f 02 12 f 0.2

VOLUME or WATZB IN ml ADDED TO FLASK AT 20% 1 1 5 12

6.3 A reading outside the permissible due to vapour leaks, too rapid boiling, trap, or ingress of extraneous moisture. repeating the standardization. 7. PROCEDURE 7.1 Measure of fl percent a suitable of sample

limits suggests malfunctioning inaccuracies in calibration of Eliminate these factors before

amount of sample (see 5.2 ) to an accuracy and transfer it to the still.

*Methods of sampling of petroleum and itr products.

IS : 1448[P:

401 -1987

7.1.1 Measure ordinary liquid samples in a graduated cylinder of Rinse the material adhering to the cylinder into tllc appropriate size. still with one 50 ml and two 25 ml portions of the solvent-carriel liquid; the latter being one selected from those described in 4 ant1 corresponding to the type suggested in Table 2 for the specific material Drain the cylinder thoroughly after the sample tr:lnsfcr under test. and each rinsing.

TABLE 2 SOLVENT CARRIER TO BE USED SAMPLE MATERIALS FOR VARIOUS

TYPE OF SOLVENTCARRIER LIQUID Aromatic Petroleum Volatile distillate

MATENIALS Asphalt, tar, coal tar, water gas tar, road tar, cutback bitumen, liquid asphalt and tar acid Road oil, fuel sulphonates Lubricating oil, lubricating oil and petroleum

spirits

grease

7.1.2Weigh

add

solid or viscous materials directly 100 ml of the selected solvent-carrier liquid.

into

the

still

and

7.1.3 In case of low water content material when samples larger than 100 g or 100 ml may be used, a solvent-carrier volume in excess of 100 ml may be necessary. 7.1.4 Glass beads to reduce bumping. or other boiling aids may be added, if necessary,

7.2 Assemble the components of the apparatus as illustrated in Fig. 1 to 3 choosing the trap in accordance with the expected water content of the sample and making all connections, vapour and liquid If a metal still with removable cover is used, insert a gasket of tight. heavy paper, moistened with solvent, between the still body and cover. The condenser tube and trap shall be chemically clean to ensure free drainage of water into the bottom of the trap. Insert a loose cotton plug in the top of the condenser to prevent condensation of atmospheric moisture inside it. Circulate cold water through the .jacket of the condenser. 7.3 Apply heat to the still, adjusting the rate of boiling so that condensed distillate discharges from the condenser at the rate of 2 to 5 drops per second. If the metal still is used, start heating with the ring burner about 76 mm above the bottom of the still and gradually lower the burner as the distillation proceeds. Continue distillation until no

7

IS : 1448[ P : 491 - 1987

water is visible in any part of the apparatus except m the trap and the If there volume of water in the trap remains constant for 5 minutes. is a persistent ring of water in the condenser tube, carefully increase the rate of distillation or cut off the condenser water for a few minutes. 7.4 When the evolution of water is complete, allow the trap and Dislodge any drops of water contents to cool to room temperature. adhering to the sides of the trap with a glass rod or other suitable Read the volume of the means and transfer them to the water layer. water in the trap to the nearest scale division. 8. CALCULATION 8.1 Calculate the water in the sample, as mass or volume percent according to the basis on which the sample was taken, as follows: Water, 8.1.1 water. percent volume of water in trap _-~= ~ mass ( or volume ) of sample material, if present, x 100 as

Volatile

water-soluble

may be measured

9. REPORT 9.1 Report the result as the water content to the nearest 01 percent, if 100 ml or 100 g of sample has been used for results 10 percent and above. Report to the nearest 005 percent for results below 10 percent.

10. PRECXSION

10.1 Results of duplicate following amounts: Water Collected 0 to 10 ml 11 to 25 ml tests shall not differ by more than the

Repeatability 01 ml 0 1 ml or 2 percent of the mean, whichever is greater

Reproducibility 02 ml 02 ml or 10 percent the mean, whichever greater of is

8 Reprography Unit. BIS, New Delhi, India

Anda mungkin juga menyukai

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- He's Got The Whole World in His Hands: African-American Spiritual 120 120Dokumen1 halamanHe's Got The Whole World in His Hands: African-American Spiritual 120 120kcpsBelum ada peringkat

- Aits Open Test Jee Paper 1Dokumen19 halamanAits Open Test Jee Paper 1Viny GBelum ada peringkat

- Lal Kitab Hindi OriginalDokumen521 halamanLal Kitab Hindi Originaljagdish bhatt (જગદીશ ભટ્ટ)100% (2)

- IS 3400 rubber testing standard parts 1-22Dokumen1 halamanIS 3400 rubber testing standard parts 1-22Ajit SamalBelum ada peringkat

- Fabric Textile Testing SRFDokumen6 halamanFabric Textile Testing SRFAjit SamalBelum ada peringkat

- Iso 7619-1Dokumen19 halamanIso 7619-1Luis AlfredoBelum ada peringkat

- Waldner Fume Cupboard Default ValuesDokumen16 halamanWaldner Fume Cupboard Default ValuestuzlucayirBelum ada peringkat

- NP-ISO - 3302 - 1 - Rubber Tolerances For Products PDFDokumen13 halamanNP-ISO - 3302 - 1 - Rubber Tolerances For Products PDFluis martinezBelum ada peringkat

- Tear Strengh Various Shape DetailsDokumen18 halamanTear Strengh Various Shape DetailsAjit SamalBelum ada peringkat

- Rubber Bloomong PDFDokumen13 halamanRubber Bloomong PDFAjit SamalBelum ada peringkat

- Hydrogenated Nitrile Butadiene Rubber (HNBR) : Properties and ApplicationsDokumen4 halamanHydrogenated Nitrile Butadiene Rubber (HNBR) : Properties and ApplicationsAjit SamalBelum ada peringkat

- Iso 48 - Is .3400.2.2003 PartDokumen18 halamanIso 48 - Is .3400.2.2003 PartAjit SamalBelum ada peringkat

- Zeon Productguide 20150608 PDFDokumen16 halamanZeon Productguide 20150608 PDFAjit SamalBelum ada peringkat

- Solvent-Extractable Material in Black Pigments1Dokumen2 halamanSolvent-Extractable Material in Black Pigments1Ajit SamalBelum ada peringkat

- Rubber BloomongDokumen13 halamanRubber BloomongAjit SamalBelum ada peringkat

- E2540526 Viton PDFDokumen2 halamanE2540526 Viton PDFAjit SamalBelum ada peringkat

- E7543074 DRG 45380401111 PDFDokumen1 halamanE7543074 DRG 45380401111 PDFAjit SamalBelum ada peringkat

- 1zba115006 2Dokumen2 halaman1zba115006 2Ajit SamalBelum ada peringkat

- 1zyn115006 1 PDFDokumen4 halaman1zyn115006 1 PDFAjit SamalBelum ada peringkat

- FMEA Nu CorkDokumen19 halamanFMEA Nu CorkAjit SamalBelum ada peringkat

- Nu-Cork Products (P) LTD.: Grade: NC RS 1Dokumen2 halamanNu-Cork Products (P) LTD.: Grade: NC RS 1Ajit SamalBelum ada peringkat

- AA59807 Rev 04 PDFDokumen5 halamanAA59807 Rev 04 PDFAjit SamalBelum ada peringkat

- 07 Chapter 1Dokumen39 halaman07 Chapter 1Ajit SamalBelum ada peringkat

- Title Identify Main Points, Opinions, and Specific Details From Spoken Texts in Spanish Level 3 Credits 6Dokumen3 halamanTitle Identify Main Points, Opinions, and Specific Details From Spoken Texts in Spanish Level 3 Credits 6Ajit SamalBelum ada peringkat

- Acid Test in OilDokumen4 halamanAcid Test in OilAjit SamalBelum ada peringkat

- Mantoux WallchartDokumen1 halamanMantoux WallchartJoe AndersonBelum ada peringkat

- Diverter Valve Wam BrochureDokumen4 halamanDiverter Valve Wam BrochureEzequiel Guillermo Trejo NavasBelum ada peringkat

- Chemical CarcinogenesisDokumen24 halamanChemical CarcinogenesisKavitha S DineshBelum ada peringkat

- Journal 9 PDFDokumen45 halamanJournal 9 PDFRuzengulalebih ZEta's-ListikBelum ada peringkat

- 2019 Cre Ii L24-26Dokumen32 halaman2019 Cre Ii L24-26Aman PrasadBelum ada peringkat

- Copy of Pharmacognosy-and-Plant-ChemistryDokumen25 halamanCopy of Pharmacognosy-and-Plant-ChemistryDecemae FuentesBelum ada peringkat

- MSDS Mindray M-30 LyseDokumen2 halamanMSDS Mindray M-30 LyseSandra HubayaBelum ada peringkat

- DeLonghi Instruction Manual ECP3220 - 3420 - 3630Dokumen7 halamanDeLonghi Instruction Manual ECP3220 - 3420 - 3630ureehwsenqBelum ada peringkat

- GSAP - Shell HelixDokumen16 halamanGSAP - Shell HelixJoseph Rubyanto SudrajadBelum ada peringkat

- ADAGEDokumen32 halamanADAGEDSGBelum ada peringkat

- Antimony Deposit Types & Origins: The Composite Gold-Antimony Vein Deposit at Kharma (Bolivia)Dokumen2 halamanAntimony Deposit Types & Origins: The Composite Gold-Antimony Vein Deposit at Kharma (Bolivia)Milton ObandoBelum ada peringkat

- Bermad Strainer Model BC-70F-P: Buildings & ConstructionDokumen2 halamanBermad Strainer Model BC-70F-P: Buildings & ConstructionGuillermo GuzmánBelum ada peringkat

- Manufacture of The Ceramic Tiles and Sanitary: Produced By: Framed byDokumen21 halamanManufacture of The Ceramic Tiles and Sanitary: Produced By: Framed byAmina CHAHBOUNIBelum ada peringkat

- Evacuated Tube SystemDokumen2 halamanEvacuated Tube SystemAaron James RuedasBelum ada peringkat

- Soils of Karnataka-361Dokumen10 halamanSoils of Karnataka-361naturewisdom100% (3)

- Bomba Dosificadora Iwaki PDFDokumen29 halamanBomba Dosificadora Iwaki PDFMaykolth BarrantesBelum ada peringkat

- Guida Step-By-Step SR Nexco Gingiva SolutionDokumen38 halamanGuida Step-By-Step SR Nexco Gingiva SolutionCostin SilviuBelum ada peringkat

- Fisa Tehnica ROBODURDokumen1 halamanFisa Tehnica ROBODURdneprmt1Belum ada peringkat

- Shelf Life Vs Expiry Date of A Chemical StandardDokumen3 halamanShelf Life Vs Expiry Date of A Chemical Standardsl1828Belum ada peringkat

- Melin Catalog 2005Dokumen122 halamanMelin Catalog 2005Sujata KulkarniBelum ada peringkat

- Coating Procedure - Shuqaiq Desalination PJT - Rev.2Dokumen19 halamanCoating Procedure - Shuqaiq Desalination PJT - Rev.2ABAID ULLAHBelum ada peringkat

- Organizaational ChangeDokumen94 halamanOrganizaational ChangeAravind Kumar KotamsettyBelum ada peringkat

- Balauro Worksheet Protein SynthesisDokumen4 halamanBalauro Worksheet Protein SynthesisHami BalauroBelum ada peringkat

- SHS Physical Science Q1 SLM - 3Dokumen25 halamanSHS Physical Science Q1 SLM - 3Adalee ColleenBelum ada peringkat

- Solid, Liquid, Gas Explanation TextDokumen2 halamanSolid, Liquid, Gas Explanation Textnettexts100% (1)

- Precipitation-Hardening Bolting (UNS N07718) For High Temperature ServiceDokumen4 halamanPrecipitation-Hardening Bolting (UNS N07718) For High Temperature ServiceJose Anisio SilvaBelum ada peringkat

- Lecture 2 - Cellulose Structure PDFDokumen55 halamanLecture 2 - Cellulose Structure PDFpipers10Belum ada peringkat

- Product UserManual Pulsarlube V EnglishDokumen2 halamanProduct UserManual Pulsarlube V EnglishTiago LimaBelum ada peringkat