Write-Up For Bitumen Cooler

Diunggah oleh

Debatosh RoyDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Write-Up For Bitumen Cooler

Diunggah oleh

Debatosh RoyHak Cipta:

Format Tersedia

WRITE-UP FOR BITUMEN COOLER

A. Type of heat exchanger

The bitumen cooler is designed as a forced draft air cooler heat exchanger. Hot bitumen enters the tube bundle from the top and is cooled by ambient air flowing up from the bottom of the tube bundle. Cold bitumen leaves from the bottom of the air cooler. Direction of air flow is from bottom to top and the hot air is left to the atmosphere. Rectangular header boxes on either sides of the tube bundle are provided to take care of the bitumen flow across the various tube passes. Removable plugs are provided to ensure that individual tubes are accessible for cleaning purpose. The tubes are provided with aluminium fins to increase the heat transfer effectiveness. Tube support arrangements are made to avoid sagging of tubes. A forced draft fan below the tube bundle pushes ambient air through the bundle to remove heat from the hot bitumen. The fan is driven by a toothed belt drive connected to an electric motor. A plenum chamber is provided to ensure proper distribution of air across the face of the tube bundle. The tube bundle, plenum chamber, fan and motor assembly are all mounted on a steel structure to ensure that the fan has enough ground clearance for proper air flow. Fan and motor are sized based on the air quantity required for effective heat transfer and the air pressure drop through the bundle. Design of these air cooled heat exchangers is done as per ASME Sec. VIII Div. 1 and API 661 standards. The rectangular headers are designed as per Appendix 13 of ASME Sec. VIII Div.1. Refer to the figures on following pages for a clear understanding of the arrangement.

B.

Special provisions in bitumen cooler Due to the very high viscosity of bitumen, tube inserts are considered. These tube inserts increase the turbulence while bitumen flows inside the tubes. This increased turbulence leads to an increase in the heat transfer rates and thus reduces the size and cost of the installation. On the flip side, the increased turbulence leads to an increase in the pressure drop due to bitumen flow inside the tubes with tube inserts. In the absence of tube inserts, the unit size becomes very big and also the bitumen flow velocities are very less, further reducing the heat transfer effectiveness.

C.

Details of the design proposed for bitumen cooler The proposed tube bundle configuration of bitumen cooler is as given below. Tube size Number of tubes Type of fin Fin height Fin density Number of tube rows Tube layout Number of passes : : : : : : : : 25 mm OD x 2.5 mm thick x 3000 mm long 300 Embedded (G-fin), Aluminium fins 12.5 mm 433 fins per meter 6 Staggered 2

Page 1 of 3

D.

Other enhancements that can be considered for better control The following additional features may be considered (based on actual process control requirements) to have better control on the air cooler performance. 1. Provision of louvers above the tube bundle to control performance to a limited extent. 2. Provision of steam coil below the tube bundle to facilitate smooth start-up when bitumen inside the tube bundle is at ambient temperature. This will ensure easy flowability of bitumen under these conditions. 3. Slope all tubes towards the outlet direction to ensure complete drainability of bitumen from the cooler. 4. Provision of VFD to drive the fan motor. This will give fine control on the air flow rate and the heat transfer performance of the unit.

E.

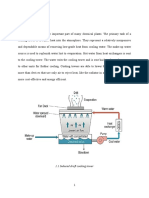

Typical tube bundle assembly

Finned tubes

Side frames

Rectangular header box

Page 2 of 3

F.

Typical air cooled heat exchanger assembly with two fans

Tube bundle assembly

Plenum

Fan ring Support structure

Typically, to conserve space at grade level, air coolers are installed on top of pipe racks.

Page 3 of 3

Anda mungkin juga menyukai

- Air Heaters: Requirement, Types ConstructionDokumen20 halamanAir Heaters: Requirement, Types ConstructionArvind ShuklaBelum ada peringkat

- Air Cooled Heat Exchangers - GEA BrochureDokumen16 halamanAir Cooled Heat Exchangers - GEA BrochurenorthstarleoBelum ada peringkat

- Catalogo HispaniaDokumen58 halamanCatalogo Hispaniapiscobar67% (6)

- Macropaver MountingDokumen4 halamanMacropaver MountingDebatosh RoyBelum ada peringkat

- Heating Coil Sizing For Fuel Oil TankDokumen2 halamanHeating Coil Sizing For Fuel Oil TankPouria Sabbagh100% (1)

- Mini Splits Lennox e Inverters Nuevo Modelo PDFDokumen4 halamanMini Splits Lennox e Inverters Nuevo Modelo PDFingridBelum ada peringkat

- Air-Cooled Heat Exchangers: LectureDokumen39 halamanAir-Cooled Heat Exchangers: LectureBaraa Shurbaji No 111Belum ada peringkat

- BoilerDokumen48 halamanBoilerSubramanian Ravishankar100% (1)

- Air Cooled Condensors: General DescriptionDokumen7 halamanAir Cooled Condensors: General DescriptionRajeev MaheshwariBelum ada peringkat

- Air Cooler PresentationDokumen9 halamanAir Cooler Presentationarcduke100% (3)

- Air-Cooled Heat Exchangers Fin-Fan: by M.M.SorourDokumen64 halamanAir-Cooled Heat Exchangers Fin-Fan: by M.M.SorourNader GaafarBelum ada peringkat

- Gas Turbine - Traning Report Bhel - 14 PageDokumen14 halamanGas Turbine - Traning Report Bhel - 14 PageVivek PatelBelum ada peringkat

- ACHE Fin Fan TechDokumen15 halamanACHE Fin Fan TechAnonymous 8Mc8boONBelum ada peringkat

- Section 4 Air Handling Units - Double Skin ScopeDokumen4 halamanSection 4 Air Handling Units - Double Skin ScopematzoyekBelum ada peringkat

- Piston Cooling SystemDokumen31 halamanPiston Cooling SystemAfiq ZikriBelum ada peringkat

- Cooling Tower REPORTDokumen25 halamanCooling Tower REPORTSaroj KumarBelum ada peringkat

- Heat Transfer Problems in Gas Turbine Combustion ChambersDokumen23 halamanHeat Transfer Problems in Gas Turbine Combustion ChambersLarry Smith50% (4)

- Energy Conservation in Cooling TowersDokumen13 halamanEnergy Conservation in Cooling TowersMohamad ChaudhariBelum ada peringkat

- Cooling Tower and Gearbox OverhaulDokumen17 halamanCooling Tower and Gearbox OverhaulIrfan UllahBelum ada peringkat

- Term Paper: Ele102 Topic:: Cooling Methods of TransformersDokumen7 halamanTerm Paper: Ele102 Topic:: Cooling Methods of Transformersshailesh singhBelum ada peringkat

- FinFan Technical InfoDokumen15 halamanFinFan Technical InfoRoozbeh PBelum ada peringkat

- 5 - Condensor, GSC and Ejector in Thermal Power PlantDokumen36 halaman5 - Condensor, GSC and Ejector in Thermal Power PlantEshwar Pawar100% (1)

- 1 212 Air PreheaterDokumen5 halaman1 212 Air Preheaterhanafy_arnandaBelum ada peringkat

- Current Trends in Cooling of BladesDokumen8 halamanCurrent Trends in Cooling of BladesPRAVEENBelum ada peringkat

- Study, Analysis and Design of Automobile Radiator PDFDokumen10 halamanStudy, Analysis and Design of Automobile Radiator PDFRamón G. PachecoBelum ada peringkat

- GE Frame 9E Turbine Stator and Rotor ConstructionDokumen14 halamanGE Frame 9E Turbine Stator and Rotor ConstructionMohammad Ibnul Hossain100% (1)

- Construction of Jet EngineDokumen28 halamanConstruction of Jet Engineapi-249277319100% (1)

- Air Preheaters Superheaters EconomizersDokumen26 halamanAir Preheaters Superheaters Economizerskowsar0221Belum ada peringkat

- Air Coolers LiteratureDokumen11 halamanAir Coolers Literatureyinkaakins200133% (3)

- Heat Transfer Problems in Gas Turbine Combustion ChambersDokumen23 halamanHeat Transfer Problems in Gas Turbine Combustion ChambersVijaya Kanth50% (4)

- CFBC General Write UpDokumen9 halamanCFBC General Write Uptelugukhan13Belum ada peringkat

- Airhandling UnitsDokumen62 halamanAirhandling UnitsMiroslav Aleksic100% (1)

- Cooling Tower ComponentsDokumen4 halamanCooling Tower ComponentsMohamed Mohsen100% (2)

- Three-Plate MoldDokumen24 halamanThree-Plate MoldRizky AntikawatiBelum ada peringkat

- Chapter 3Dokumen10 halamanChapter 3aiknathBelum ada peringkat

- Cooling Tower ComponentsDokumen4 halamanCooling Tower ComponentsArunBelum ada peringkat

- Cooling Tower Components PDFDokumen4 halamanCooling Tower Components PDFck19654840Belum ada peringkat

- Air Fin Cooler CatalougeDokumen14 halamanAir Fin Cooler Catalougesammar_10Belum ada peringkat

- General Information On Air-Cooled Heat ExchangersDokumen5 halamanGeneral Information On Air-Cooled Heat ExchangersSrinivas BobbyBelum ada peringkat

- Aph 15Dokumen0 halamanAph 15Parameswararao BillaBelum ada peringkat

- 500 MW Boiler FeaturesDokumen8 halaman500 MW Boiler FeaturesKeyur PatelBelum ada peringkat

- Synthetic Yarn Humidification PlantDokumen12 halamanSynthetic Yarn Humidification Plantardhendu1Belum ada peringkat

- Technical Specification of DuctDokumen3 halamanTechnical Specification of DuctmishtinilBelum ada peringkat

- Cooling Towers: Cold Water BasinDokumen13 halamanCooling Towers: Cold Water BasinmichsantosBelum ada peringkat

- Design of Air IDokumen5 halamanDesign of Air IInvedeBelum ada peringkat

- AFBC Boiler O&MDokumen134 halamanAFBC Boiler O&MVijay Raj87% (15)

- ZCP Mu13947 PDFDokumen36 halamanZCP Mu13947 PDFsugirinBelum ada peringkat

- Assignement 2 AEDokumen14 halamanAssignement 2 AEd purnachandraBelum ada peringkat

- Vacuum SystemDokumen49 halamanVacuum Systemssmith2007100% (3)

- Chapter 5) Engine Cooling and Lubrication System Necessity of Engine CoolingDokumen14 halamanChapter 5) Engine Cooling and Lubrication System Necessity of Engine CoolingRajBelum ada peringkat

- Boiler Tubular Air Pre-Heater - TaphDokumen18 halamanBoiler Tubular Air Pre-Heater - TaphsbmmlaBelum ada peringkat

- Presentation On Desert CoolerDokumen17 halamanPresentation On Desert CoolerAnonymous BJ9omOBelum ada peringkat

- Presentation On Desert CoolerDokumen17 halamanPresentation On Desert Coolersantaclaus99100% (1)

- Boiler Components: Super HeaterDokumen2 halamanBoiler Components: Super Heaterponnivalavans_994423Belum ada peringkat

- By: Meet Shah & Arpit ThumarDokumen27 halamanBy: Meet Shah & Arpit ThumarArpit ThumarBelum ada peringkat

- Air Cooled Heat Exchnger FormatedDokumen43 halamanAir Cooled Heat Exchnger FormatedMustafa Anwar50% (2)

- 500mwboilermahagenco 140115124304 Phpapp02Dokumen38 halaman500mwboilermahagenco 140115124304 Phpapp02Lakshmi NarayanBelum ada peringkat

- Air Cooling SystemDokumen5 halamanAir Cooling Systemtesfu tekleabBelum ada peringkat

- Air Preheater Air Preheater Steam Air Heater Shell and TubeDokumen4 halamanAir Preheater Air Preheater Steam Air Heater Shell and TubeJayant Deshmukh100% (1)

- Scientific American Supplement, No. 623, December 10, 1887Dari EverandScientific American Supplement, No. 623, December 10, 1887Belum ada peringkat

- Warm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationDari EverandWarm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationBelum ada peringkat

- Img 10Dokumen1 halamanImg 10Debatosh RoyBelum ada peringkat

- R S Sisodia PDFDokumen42 halamanR S Sisodia PDFDebatosh RoyBelum ada peringkat

- 2 Step Micro-Fiber - Presentation-Aug. 2013Dokumen24 halaman2 Step Micro-Fiber - Presentation-Aug. 2013Debatosh RoyBelum ada peringkat

- Debatosh RoyDokumen26 halamanDebatosh RoyDebatosh RoyBelum ada peringkat

- Cold Mix Patent HINCOLDokumen2 halamanCold Mix Patent HINCOLDebatosh RoyBelum ada peringkat

- Micro-Surfacing PresentationDokumen30 halamanMicro-Surfacing PresentationDebatosh Roy67% (3)

- Ethylene PipesDokumen8 halamanEthylene Pipesingbarragan87Belum ada peringkat

- MRSPTU M.tech. Mechanical Engg. (Sem 1-4) Syllabus Updated On 19.3.2017Dokumen15 halamanMRSPTU M.tech. Mechanical Engg. (Sem 1-4) Syllabus Updated On 19.3.2017Robin NanchahalBelum ada peringkat

- Heat High Velocity FlowsDokumen116 halamanHeat High Velocity FlowsP KBelum ada peringkat

- Insulation Presentation - LucasDokumen8 halamanInsulation Presentation - Lucasapi-502219083Belum ada peringkat

- Belimo CRK24-B1 - 1 - 1 - enDokumen12 halamanBelimo CRK24-B1 - 1 - 1 - enpitanje1991Belum ada peringkat

- Refrigerator and Air-Conditioner Condensers: Condenser CondenserDokumen2 halamanRefrigerator and Air-Conditioner Condensers: Condenser CondenserKifayat UllahBelum ada peringkat

- Mini Temp Plus Brochure.cDokumen16 halamanMini Temp Plus Brochure.cJesus David Muñoz RoblesBelum ada peringkat

- R744 and R290Dokumen7 halamanR744 and R290SURAJ NAGBelum ada peringkat

- Temperature and Heat: Dr. Anis Nazihah Binti Mat DaudDokumen16 halamanTemperature and Heat: Dr. Anis Nazihah Binti Mat DaudNik AshrafBelum ada peringkat

- Trane ComercialDokumen152 halamanTrane ComercialMartin Bourgon100% (2)

- 4990 - Habibullah Associates For HVAC Works at Dolmen Mall, KarachiDokumen7 halaman4990 - Habibullah Associates For HVAC Works at Dolmen Mall, KarachiZain KhanBelum ada peringkat

- Crespo Et Al. - 2023 - Thermal Performance Assessment and Control OptimizDokumen16 halamanCrespo Et Al. - 2023 - Thermal Performance Assessment and Control OptimizencrocateBelum ada peringkat

- Loeffler BoilerDokumen22 halamanLoeffler BoilerDr. BIBIN CHIDAMBARANATHAN0% (1)

- Design of A Low Cost Loop Heat PipeDokumen12 halamanDesign of A Low Cost Loop Heat PipeSuraj Kuber AbdanBelum ada peringkat

- Manual Compact Pressure Solar Water Heater PDFDokumen11 halamanManual Compact Pressure Solar Water Heater PDFklp_kedarpBelum ada peringkat

- 3 Ntu MethodDokumen72 halaman3 Ntu MethodPradyumna DhamangaonkarBelum ada peringkat

- Testing Commisioning Report Calorifier: ProjectDokumen1 halamanTesting Commisioning Report Calorifier: Projectagun gunawanBelum ada peringkat

- Prextherm RSW 2010 GB - 1Dokumen8 halamanPrextherm RSW 2010 GB - 1kasztakatikaBelum ada peringkat

- 01.heat Pump - Hoval PDFDokumen13 halaman01.heat Pump - Hoval PDFPhạmVănTiếnBelum ada peringkat

- Chapter 11 Heat TransferDokumen21 halamanChapter 11 Heat TransferaimanrslnBelum ada peringkat

- Aircycle 5.1 - Heat Recovery UnitDokumen2 halamanAircycle 5.1 - Heat Recovery UnitValentin MalihinBelum ada peringkat

- Ch4 - Refrigeration SystemsDokumen47 halamanCh4 - Refrigeration SystemsShiau FenBelum ada peringkat

- A Review of Solar Chimney Power Generation Technology: February 2013Dokumen18 halamanA Review of Solar Chimney Power Generation Technology: February 2013manuelBelum ada peringkat

- TDokumen2 halamanTmariaBelum ada peringkat

- Internal Flow: Heat TransferDokumen22 halamanInternal Flow: Heat TransferSana Nasser100% (1)

- Arc 315-18 Lecture Part 1Dokumen3 halamanArc 315-18 Lecture Part 1Melaine A. FranciscoBelum ada peringkat

- Fire SafetyDokumen23 halamanFire SafetyNalin100% (3)

- Samsung-Rt 31-2007 PDFDokumen24 halamanSamsung-Rt 31-2007 PDFviveck.guptaBelum ada peringkat