User Interface 2946 1044 00

Diunggah oleh

gak66Deskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

User Interface 2946 1044 00

Diunggah oleh

gak66Hak Cipta:

Format Tersedia

Atlas Copco Airpower n.

v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 1/27

User interface

1. User Interface.............................................................................................................. 3 1.1 Brief Description ........................................................................................................ 3 1.2 Main Screen 3 1.3 Getting Started 5 1.4 Unit Information 6 1.5 Measurements 10 1.5.1 Readings 10 1.5.2 Pressure Graph 10 1.6 Commands and selections 10 1.6.1 Integrate/Isolate 10 1.6.2 ES Command buttons 11 1.6.3 Shutdown Reset button 11 1.6.4 Pressure Regulation method 12 1.7 Configuration 13 1.7.1 SPS 14 1.7.2 Automatic Functions 15 1.7.2.1 Automatic Restart After Voltage Failure (ARAVF) ............................. 17 1.7.2.2 Automatic integration after communication error ............................... 18 1.7.2.3 Automatic integration after LAN selection.......................................... 18 1.7.2.4 Automatic Pressure Shutdown recovery............................................ 18 1.7.3 Spare Capacity 18 1.7.4 Forced Sequence 19 1.7.5 Equal Wear 20 1.7.6 Group Management 21 1.7.7 Common Configuration 24 1.7.7.1 Manual set-up .................................................................................... 24

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium. PM: 2946 1044 00 24/10/2007

Atlas Copco Airpower n.v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 2/27

1.7.7.2 Periodical set-up ................................................................................ 24 1.8 Common Buttons 25 1.8.1 Language 25 1.8.2 Keyboard 25 1.8.3 Command Viewer 26 1.8.4 Lock Device 26 1.8.5 Password 26 1.8.6 Window access 26 1.8.7 Soft Restart 26 1.8.8 Version Information 26 1.8.9 Time and date 26 1.8.10 ES Type Label 27

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium.

PM:

2946 1044 00 24/10/2007

Atlas Copco Airpower n.v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 3/27

1. USER INTERFACE 1.1 BRIEF DESCRIPTION

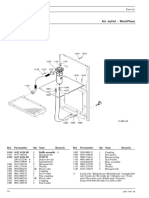

This part of the Software Instruction explains the functionalities and the use of the graphical user interface (GUI). The GUI will provide an overview of the compressor installation and the possibility to configure the ES system. Below, the main screen is shown followed by a detailed description of each function. This document should provide enough information to the end user to operate the ES system, assuming having some basic knowledge working in a windows environment. 1.2 Main Screen Below, the main screen is shown followed by a detailed description of each function. Legend: 1. Language 2. Keyboard (Not available when using 1900 0707 70 Hardware) 3. Compressor Command Viewer 4. Lock device 5. Password 6. Windows 7. Soft Restart 8. Configuration - SPS 9. Configuration - Automatic functions 10. Configuration - Spare Capacity 11. Configuration - Forced Sequence 12. Configuration - Equal Wear 13. Configuration - Group Management 14. Compressor Mode / ES Commands 15. Compressor Node 16. Compressor Communication Status 17. Compressor Information 18. Compressor Control Request 19. Version information 20. ES Control Mode/Request 21. Pressure regulation mode 22. Analogue Input reading 23. Pressure graph 24. Time and Date 25. Label ES Type

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium.

PM:

2946 1044 00 24/10/2007

Atlas Copco Airpower n.v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 4/27

Note: Some functions require a password with a certain access level (1-4). The access level of each function can be defined by the commissioning engineer only and can be done by means of the ES commissioner. (See Software Instruction Part 2: Site Configuration)

10 11

09

12

08 01

13

14

15 02 16 03 17 04 18 05 20 06 07 19

21 22

23 24 25

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium.

PM:

2946 1044 00 24/10/2007

Atlas Copco Airpower n.v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 5/27

1.3 Getting Started In order to set the ES 130 in ES-control and integrate compressors, some conditions need to be fulfilled and some actions are required. The steps to start the ES taking over the control of the compressors are: 1. Configure SPS 2. Select a pressure Regulation Mode 3. Prepare the compressors to be integrated a. For MKIII Turn Key in Position 2 b. For MKIV Place in LAN c. For ZH-PLC Place Key in position 1 + Press F10 4. Set the Request to Integrate on the ES 5. Set the ES in ES control"

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium.

PM:

2946 1044 00 24/10/2007

Atlas Copco Airpower n.v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 6/27

1.4 Unit Information

01

02

03 04 05

1. Unit Controller Mode/Compressor messages: This field (1) is used to show compressor messages and the compressor controller mode. If the compressor is isolated the information will be displayed in following priority: 1. Shutdown 2. Controller mode (Local/LAN/Remote)

If the compressor is integrated the information will be displayed in following priority: 1. 2. 3. 4. 5. Shutdown Not ready to start Warning Compressor commands Controller mode (Local/LAN/Remote)

The Compressor controller mode can only be changed on the compressor itself

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium.

PM:

2946 1044 00 24/10/2007

Atlas Copco Airpower n.v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 7/27

and can be in: Local LAN Remote Compressor is not ready to be integrated Compressor is ready to be integrated Compressor controller is controlled by a third party system

Click on button (3) to monitor the commands towards a compressor. This is only possible for an integrated compressor and for users with the highest (5) access level.

2. Unit ID: A blinking number indicates Isolated whilst a steady number indicates Integrated and under ES control. The number will not blink for units that cannot be integrated such as dryers, filters and Z or ZD etc.

A screen with unit data information pops-up by clicking on the number itself.

3. Communication Status: Communication OK

? !

Communication Error Not Responding (The compressor didnt respond within a reasonable time to an ES command)

4. Unit Type/name: Unit type and unit name are to be defined during the commissioning process.

5. Unit Status: Some statuses are type dependent. More detailed information can be found in the Software instruction Regulation.

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium.

PM:

2946 1044 00 24/10/2007

Atlas Copco Airpower n.v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 8/27

Compressors Load/NoLoad VSD ZH

----------------------------------------------------------------------------------------NR Start: R Start: UL: Not Ready To Start Ready To Start Unload x x x x x x x x x

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium.

PM:

2946 1044 00 24/10/2007

Atlas Copco Airpower n.v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 9/27

Dryers

MD FD CD BD XD Zero Purge XD Split Flow X3D ----------------------------------------------------------------------------------------------------Started Stopped Starting Stopping Purge Saving Shifting Towers A > B Shifting Towers B > A Pressure Relief Tower A Pressure Relief Tower B x x x x x x x x x x x x x x x x x x x x x x x x x x x x x

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium.

PM:

2946 1044 00 24/10/2007

Atlas Copco Airpower n.v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 10/27

1.5 Measurements 1.5.1 Readings On the main screen, 6 readings can be displayed. These can be either analogue input readings (e.g. air net pressure) or virtual reading (e.g. calculated flow and power). (See Software Instruction Site Configuration)

A sensor error is indicated by a yellow background.

1.5.2 Pressure Graph The pressure graph displays the analogue value of the actual airnet pressure. The graph is scaled automatically between the Load and Unload pressure level, if the actual pressure is in band and not more then 20% out band. If the pressure is out band for more then 20%, the automatic scaling is done between the high and low pressure shutdown level.

SPS configuration can be accessed by clicking on the complete pressure graph area. 1.6 Commands and selections 1.6.1 Integrate/Isolate Set the compressor to Request to integrate as shown The compressor will be integrated only if it is set in LAN mode (see unit information) and ES is set to ES Control (see ES Commands)

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium.

PM:

2946 1044 00 24/10/2007

Atlas Copco Airpower n.v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 11/27

Set the compressor to Request to Isolate status. The compressor will be isolated always.

1.6.2 ES Command buttons

For security reason, all ES button will only react when they are continuously pressed for 3 seconds. The active mode is displayed with a blue frame.

Local Control: Click the Local Control button to stop ES regulation. All integrated compressors will isolate one by one, respecting the Time between two isolations setting. ES Control: Click the ES Control button to start the ES regulation. All (In LAN mode and with the request to integrate) compressors will be integrated at once. Central Stop: Central stop will stop all integrated compressors. Three steps are required to go to central stop: 1. Enable the Central stop button 2. Press for 3 seconds the Central Stop button 3. Confirm that you want to stop all the compressors

1.6.3 Shutdown Reset button An ES can go into shutdown (only in ES control) when: Pressure sensor deviation to too high Both pressure sensors indicate sensor error Pressure exceed the pressure high/low shutdown level

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium.

PM:

2946 1044 00 24/10/2007

Atlas Copco Airpower n.v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 12/27

The ES will go to Local control. Before the ES can be placed in ES control again, the Shutdown need to be acknowleged by pressing for 3 seconds the Reset button. 1.6.4 Pressure Regulation method

Click on Button (21) to change the Pressure Regulation Method

There are four regulation methods:

1. Optimized Energy Saving: The selection to load, unload and start compressors will be based on the actual flow demand and the cost of a solution. The cheapest or best solution to meet the required flow demand will be executed. 2. Forced Sequence: Pressure regulation is done in a forced and predefined sequence. When during the regulation an upload is required, the first compressor in line of the active sequence, which is not yet delivering air, will provide the required flow. As for a download the last compressor in line of the active sequence will be downloaded. 3. Equal Wear: The running hours of a compressor will be kept within a configurable range. This means that running hours are taken into account during the decision process in the pressure regulation. This means that an installation (depending on compressor mix), can operate in a less energetic condition. In case there is a large difference in compressor capacities and variety of type, it is recommended to use Group Management mode to keep the running hours within a range.

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium.

PM:

2946 1044 00 24/10/2007

Atlas Copco Airpower n.v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 13/27

4. Group Management: Compressors will be placed in groups (defined by capacity or type). Within each group one of the above regulation methods can be activated. Over the group one of the above regulation method rules, called profiles further in this document, will apply. More Information concerning the pressure regulation methods and regulation behaviors can be found in the Software Part 3 Regulation Concept Instruction. Some regulation method needs to be configured before they can be selected. (See section Configuration) Note: 1. Regardless of the selected regulation method, Optimization is done at all times if the option is enabled (See Software Instruction Tuning section Air net Options). Optimization exists out of two modules: Power Optimizer: The Power Optimizer will calculate the cost if it is possible to unload a compressor. Zone Optimizer: The Zone optimizer will calculate the cost to place running and loaded compressors in their most optimum zone. (VSD, ZH, ZB) The Optimizer will compare both result with the current situation and execute the cheapest (less energy) solution. This means optimization is done regardless the selected regulation method. 2. For some pressure regulation modes it is important that time and date are correctly set.

1.7 Configuration Below, all specific configurations are explained in detail. Some configuration flows are common for different functions (e.g. week timer). Those common configurations are explained separately.

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium.

PM:

2946 1044 00 24/10/2007

Atlas Copco Airpower n.v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 14/27

1.7.1 SPS Three SPS settings can be configured .Set/change SPS related settings is done a follows: Click button or on the pressure graph on the main window to open the SPS configuration screen. Click on the button of the SPS number to be set or changed and configure with the preferred method o Fixed Point: Enter a Set point and an offset o Fixed Band: Enter the Load and Unload pressure Define the protection setting

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium.

PM:

2946 1044 00 24/10/2007

Atlas Copco Airpower n.v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 15/27

The system will calculate the warning levels and the required pressure for the regulation. The result of the calculations can be found by clicking the advanced button. If the proposed system settings do not meet the requirements they can be individually changed.

Note: Changing the proposed setting can have consequences on the regulation and should only be done by an expert. Two Operating Modes can be selected: Manual Mode: (detailed description see common configuration) o Click on Manual Mode to select this Operating Mode o Click on Set-up Manual Mode and select the required SPS number Weektimer Mode: (detailed description see common configuration) o Click on Weektimer Mode to select this Operating Mode o Click on Set-up Weektimer Mode to configure or change the week timer (see Common configuration) 1.7.2 Automatic Functions Click the button to open the Automatic function configuration screen.

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium.

PM:

2946 1044 00 24/10/2007

Atlas Copco Airpower n.v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 16/27

Four Automatic functions can be selected where two can be configured. To enable check the option. To configure a function, click on the text button.

!!! Safety !!!: Note that some of the Automatic Functions can cause a compressor to start or load unexpectedly as the integration and ES Control request can take place automatically. Make sure to if any of the automatic Functions are set, all compressors are labeled that automatic starts can occur!

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium.

PM:

2946 1044 00 24/10/2007

Atlas Copco Airpower n.v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 17/27

1.7.2.1 Automatic Restart After Voltage Failure (ARAVF) The ARAVF function will set the ES and the compressors back in the requested state after an voltage failure or a restart of a device. The different configurations and settings are explained below. The ARAVF function is by default disabled. Delay Time: After a voltage failure, the ES will only execute the ARAVF function after the delay time is elapsed and set the ES and compressor in the correct state. Abort Time: When the period of the voltage failure takes longer then this setting the ARAVF function will not be executed. When the setting is set at zero, the function will ALWAYS be active. ES Request State: o Local Control: Regardless what the State before the Voltage failure was, the ES will always startup in Local control o Last Known State: The ES go to the state as it was before the power failure applying respecting the Delay Time and Abort Time.

ES State before voltage Failure ES State after Power failure

-----------------------------------------------------------------------------Local control Local control

Compressor Request State: o Remain Isolated: Regardless what the state was before the Voltage failure, the Compressor request will always be Isolate o Last Known State: The Compressor state will remain in the request state as it was before the power failure.

Request before voltage Failure

Request after Power Failure

------------------------------------------------------------------------------

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium.

PM:

2946 1044 00 24/10/2007

Atlas Copco Airpower n.v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 18/27

1.7.2.2 Automatic integration after communication error When a communication error occurs, an integrated compressor will isolate. When the compressor comes back on-line he will integrate again if this option is enabled. The compressor request can still be manually changed during a communication error as well.

1.7.2.3 Automatic integration after LAN selection If, on the compressor controller, the mode is switched from LAN to Local, an integrated compressor will isolate. When the compressor is placed back in LAN mode, he will integrate again if this option is enabled. The compressor request can still be manually changed when he is in Local mode. 1.7.2.4 Automatic Pressure Shutdown recovery In exceptional case it could be that the pressure will exceed the Pressure shutdown Level in ES control. The ES will switch to Local control and all compressors will be handed back to local control (direct or controlled see instruction - tuning) If this option is enabled, the ES will recover when all conditions are fulfilled, which are: Amount of retries (Retires per period) not exceeded during a time window (period length) Pressure must be In Band for certain period (Stabilization Delay) 1.7.3 Spare Capacity Click the button to open the Forced Sequence configuration screen

If a minimum of amount of (spare) flow needs to be available immediately at all time, the spare capacity option needs to be enabled (check box) and configured. Spare Capacity: The minimum amount of flow that needs to be available at all times Delay at Signal: If a shortage or an over plus of 5% on the spare capacity is detected for a continuous period equal to the delay at signal, a new Spare Capacity mix is search for.

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium.

PM:

2946 1044 00 24/10/2007

Atlas Copco Airpower n.v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 19/27

Include available upload capacity: o Enabled: The available upload flow among the loaded range compressors is seen as spare capacity. This option needs be enabled to guarantee a minimum amount of air (immediately available) to avoid undershoot (and production loss) due to a sudden increase in the flow demand o Disabled: The available upload flow among the loaded range compressors is NOT seen as spare capacity. This option needs to be disabled to guarantee a minimum amount of air (immediately available) to avoid undershoot (and production loss) due to flow loss (e.g. shutdown) by one of the loaded compressors.

1.7.4 Forced Sequence Click the button to open the Forced Sequence configuration screen.

Sequences: Add: To create an additional Sequence. The new sequence will added below the selected sequence. Modify: The selected Sequence can be modified by changing the compressor position (move up/down) in the sequence. Move up/Move Down/ Remove: The selected sequence can be moved up, down or completely removed from the configuration.

Operating Mode: A detail description to configure the Operating modes can be found in the common configuration section. Periodical Mode: A sequence shift, in ascending order, will be executed every defined period. Manual Mode: The manual selected sequence will be used. Weektimer mode: A sequence shift will be executed on a predefined time/date in a week or over a

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium.

PM:

2946 1044 00 24/10/2007

Atlas Copco Airpower n.v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 20/27

more week cycles. 1.7.5 Equal Wear Click the button to open the Equal Wear configuration screen.

Restrict to certain periods: When Equal Wear is detected, some compressors will most likely switch. It might be that the installation or the production prefers to postpone a compressor switch. Therefore equal wear control will be restricted to certain periods. (Equal Wear will only be checked during these periods) Maximum hour difference: This setting will determine within with range equal wear will be executed. Disable the option is there are no restrictions. Enabling the option implies that the restrictions needs to be configured (see above) Equal Wear hours: The regulation algorithm will take the Equal Wear hours into account in case Equal Wear regulation method is selected. Total (Equal Wear) hours = Running hours + Offset hours o Set: The Equal wear hours can be configured for each compressor individually by simply changing the offset hours. o Reset all: The Equal wear hours of all compressors will be set to zero. o Clear all: The offset hours of all compressors will be set to zero

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium.

PM:

2946 1044 00 24/10/2007

Atlas Copco Airpower n.v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 21/27

1.7.6 Group Management Click the button to open the Group Management configuration screen.

The Configuration of Group Management is done by means of a wizard. If an existing configuration needs to be changed, you have to run though the wizard completely. There are three basic steps in the configuration of Group Management for each profile (see flow chart): 1. Group Configuration 2. Group Regulation Configuration 3. Profile Configuration All Basic rules (e.g. Forced Sequence) and standard configurations (e.g. Equal Wear, week timer, ) in group management are similar as if the rules would apply for that Pressure regulation mode itself. Step 1: Group Configuration For a correct group configuration, EACH compressor needs to be placed in a group. There are two ways to do so: Automatic: Click on the Create By Capacity button. The groups will be created automatically based on a fraction of the Total Capacity of the installation and is done a follow. o Hysteresis = Fraction * Total Flow o Add a compressor to a group if his Design Flow is smaller or equal to the smallest Design Flow of a compressor (not yet allocated) increased with the calculated Hysteresis. The result of the Automatic function can still be changed if required by assigning a compressor to an other or new group in the next screen Manual: Click on the Add button in the main Group Management configuration screen to create the groups manually. Assign each compressor to the desired group.

Step 2: Group Regulation Mode For each individual group, a pressure Pressure Regulation Mode (Optimized Energy Saving, Equal Wear or Forced Sequence) needs to be selected, including the

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium.

PM:

2946 1044 00 24/10/2007

Atlas Copco Airpower n.v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 22/27

configuration of the operation Modes (e.g. periodical-, manual- or week timer mode) or extra configuration in some cases (e.g. Equal Wear Offset). The pressure regulation mode needs to be configured as described in the configuration sections (See Forced Sequence or Equal Wear), if selected. Step 3: Profile Configuration A Profile can be defined as a pressure regulation rules that apply over the groups. Profile Forced Sequence: Loading and starting compressors is done in ascending order of the group sequence. Unloading and stopping compressors is done in de ascending order of the group sequence. E.g. a compressor that belongs to a group can only be started/loaded if all compressors in the group of the previous sequence are all loaded. Profile Equal Wear: The Equal Wear hours between groups will be kept within a defined range. Equal Wear hours for each group is calculated as follows: o Average Running hours of the compressors in the group + offset Profile Capacity Management: In this profile the rules are applied as in Optimized energy Savings mode. The selection to load, unload and start compressors will be based on the actual flow demand and the cost of a solution. The cheapest or best solution to meet the required flow demand will be executed.

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium.

PM:

2946 1044 00 24/10/2007

Atlas Copco Airpower n.v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 23/27

Step 1

Step 2

Step 3

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium.

PM:

2946 1044 00 24/10/2007

Atlas Copco Airpower n.v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 24/27

1.7.7 Common Configuration During the configuration, some screens and their handlings are similar such as for: Manual set-up Periodical Set-up Week timer set-up They are used in configurations such as SPS settings, force sequence, group management etc The only different is when a selection needs to be done. That will be in case of: SPS the SPS number Force Sequence the sequence number Group management the group Number 1.7.7.1 Manual set-up When a manual selection (SPS, Sequence, group ) is required, the global flow is the same. Select the correct setting and confirm.

1.7.7.2 Periodical set-up In case of a periodical timer set up, define the change period (a change will be done every xx time). Select the configuration to start with (e.g. start with sequence number .) In case the periodical time configuration was active, the currently active configuration is high lighted.

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium.

PM:

2946 1044 00 24/10/2007

Atlas Copco Airpower n.v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 25/27

1.7.7.3 Weektimer set-up

Before a week timer can be defined, the number of cycles needs to be defined. This is the amount of weeks for 1cycle of the Weektimer. The current week will be the week where the Weektimer will start/continue after saving the configuration. The week will display the active week in case the week timer was already configured. Week timers can be added, modified or removed.

To add/modify a Weektimer, select the correct week cycle, day and time a switch needs to be activated.

1.8 Common Buttons 1.8.1 Language makes it possible to select an other language. Clicking on A default language can be selected during commissioning. (See software instruction site configuration)

1.8.2 Keyboard Click on to make the soft-keyboard appear and disappear.(Not available when using 1900 0707 70 Hardware)

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium.

PM:

2946 1044 00 24/10/2007

Atlas Copco Airpower n.v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 26/27

1.8.3 Command Viewer Clicking on enable or disabled the command view if the compressor is integrated in the compressor controller mode area (see section unit information) 1.8.4 Lock Device Click on to lock the device. If the device is currently activate with a certain password level, all access will be locked. 1.8.5 Password Click on to change a password of a certain access level. Note that only password of current active level and lower can be changes. Select the password level. Enter and confirm the new password. Clicks apply to save the changes. 1.8.6 Window access Ad the ES device is running on a windows CE platform, the windows environment can be accessed by clicking for this function. 1.8.7 Soft Restart The device can be restart by clicking be opened. 1.8.8 Version Information Click on to see the version currently running on the ES device. button. In this way the device doesnt have to button. A password level of commissioning engineer is required

1.8.9 Time and date For some regulation modes, the time and date needs to be correct. Time and date can be changed by clicking on the clock (24). Change time and date and confirm. The clock will automatically be synchronized with the clock on the server (LAN or WEB) in case of a monitoring installation. The clock may not be change manually in that case.

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium.

PM:

2946 1044 00 24/10/2007

Atlas Copco Airpower n.v

Oil -free Air division Aftermarket department

Registration code Collection: Technical Information ES130 Instr. & Doc. Page: 27/27

1.8.10 ES Type Label The ES Type label is displayed in the lower left corner. The label 130T stands for a site with at least on ZH or ZB in the mix. 130V stands for a site with at least on VSD compressor and no ZH or ZB compressors. 130 alone correspond to a site with only LNLunits.

replaces: Copyright 2007, Atlas Copco Airpower n.v., Antwerp, Belgium.

PM:

2946 1044 00 24/10/2007

Anda mungkin juga menyukai

- TI Overhaul - Transient Load Valve 2946 0797 00Dokumen14 halamanTI Overhaul - Transient Load Valve 2946 0797 00khanh khanhBelum ada peringkat

- APFF 1896 Introduction of 750W MotorDokumen7 halamanAPFF 1896 Introduction of 750W MotorjakaBelum ada peringkat

- ESM 15-22 Sparepart Recom 1984Dokumen1 halamanESM 15-22 Sparepart Recom 1984влад камрBelum ada peringkat

- Air-Dryer Atlas ASL 2007 03Dokumen22 halamanAir-Dryer Atlas ASL 2007 03Ronaz1981Belum ada peringkat

- ServicecontractproposalDokumen6 halamanServicecontractproposalNoufou DarankoumBelum ada peringkat

- 2946 1087 00 SPM-VDI Measurement GA 90-160Dokumen3 halaman2946 1087 00 SPM-VDI Measurement GA 90-160Tony Humberto GutierrezBelum ada peringkat

- ECB Priority III: Oil Carry Over From Air Filter On GA7-37VSD+Dokumen6 halamanECB Priority III: Oil Carry Over From Air Filter On GA7-37VSD+Yurdan HakimBelum ada peringkat

- Atlas Copco: Stationary Air CompressorsDokumen100 halamanAtlas Copco: Stationary Air CompressorsJavier LópezBelum ada peringkat

- GA7-15 AII-145-420 Inst 2920-1471-01Dokumen40 halamanGA7-15 AII-145-420 Inst 2920-1471-01JoeBelum ada peringkat

- SL-E Air End Service Manual Compressor ScrollDokumen35 halamanSL-E Air End Service Manual Compressor ScrollLucky Karunia Setyawan PratamaBelum ada peringkat

- SB Priority IV APP 2848 ACCIPX v3.14 Updated in CAT and Mercedes Driven Compressors PDFDokumen3 halamanSB Priority IV APP 2848 ACCIPX v3.14 Updated in CAT and Mercedes Driven Compressors PDFNoufou DarankoumBelum ada peringkat

- IRI Manual PDFDokumen79 halamanIRI Manual PDFFatah AbdoelBelum ada peringkat

- Compresor GX 5 AII 652233Dokumen38 halamanCompresor GX 5 AII 652233victor enrique lopez pedrzaBelum ada peringkat

- DL040AADokumen53 halamanDL040AAparabellum871Belum ada peringkat

- Airtelligence 2.0 Modbus Anbindung enDokumen9 halamanAirtelligence 2.0 Modbus Anbindung enPiotrBelum ada peringkat

- GHH Product Brochure enDokumen16 halamanGHH Product Brochure entomescu_sorinBelum ada peringkat

- GAVSDs - Atlas Copco - Launch New ProductDokumen23 halamanGAVSDs - Atlas Copco - Launch New ProductquocthaitnBelum ada peringkat

- Atlas Copco FX 13 15 PDFDokumen12 halamanAtlas Copco FX 13 15 PDFyeraldiscribBelum ada peringkat

- ZR 315 VSDDokumen154 halamanZR 315 VSDLIDAIRBelum ada peringkat

- DTE BrochureDokumen8 halamanDTE BrochureAnwar SaeedBelum ada peringkat

- CPA Triplex H EN 1Dokumen20 halamanCPA Triplex H EN 1Nguyễn Tấn KhiêmBelum ada peringkat

- GX2-5 Aii 641 640 (2005)Dokumen66 halamanGX2-5 Aii 641 640 (2005)Дмитрий ГагариновBelum ada peringkat

- 7 - 7005 - 10 - USE Sigma Control BasicDokumen36 halaman7 - 7005 - 10 - USE Sigma Control BasicWilliam BeadenkopfBelum ada peringkat

- Invoice CompetentDokumen1 halamanInvoice CompetentNaveen ChauhanBelum ada peringkat

- Atlas Copco Stationary Air Compressors: GA5, GA7, GA11C With Elektronikon I or Elektronikon II RegulatorDokumen78 halamanAtlas Copco Stationary Air Compressors: GA5, GA7, GA11C With Elektronikon I or Elektronikon II RegulatorKrzysiek PodsiadłoBelum ada peringkat

- Screw Compressors: Boge Air. The Air To WorkDokumen40 halamanScrew Compressors: Boge Air. The Air To WorkI'an Triple SBelum ada peringkat

- Complete air purification package Ultrapac HED/ALD/MSD 0005 to 1000Dokumen3 halamanComplete air purification package Ultrapac HED/ALD/MSD 0005 to 1000Mark CarterBelum ada peringkat

- Manual de Servicio Sx-6Dokumen107 halamanManual de Servicio Sx-6Mauricio Vargas JerezBelum ada peringkat

- NUAIR Cat MercurySirio CE-IE3!03!15 en 9041406Dokumen24 halamanNUAIR Cat MercurySirio CE-IE3!03!15 en 9041406sebastianBelum ada peringkat

- Bang Dieu Khien CurtisDokumen23 halamanBang Dieu Khien CurtisHoa Nguyen Van100% (1)

- APFF 1814 Release of New Roto-Z Oil PDFDokumen2 halamanAPFF 1814 Release of New Roto-Z Oil PDFJoelBelum ada peringkat

- Ersatzteilliste Spare Parts List Liste de Pièces de Rechange Relación de Piezas de Recambio Lista de ComponentesDokumen44 halamanErsatzteilliste Spare Parts List Liste de Pièces de Rechange Relación de Piezas de Recambio Lista de ComponentesJose Luis Cruz TiconaBelum ada peringkat

- Instruction Book Control SolutionsDokumen26 halamanInstruction Book Control SolutionsraviBelum ada peringkat

- 9845000020-01 - Installation of ER Kit On GA 90-180 (&VSD)Dokumen10 halaman9845000020-01 - Installation of ER Kit On GA 90-180 (&VSD)BRUNO MARDEGANBelum ada peringkat

- EDE99N - Parts List 13-20-502 v02 - 2010-12-19 - SN S350021Dokumen50 halamanEDE99N - Parts List 13-20-502 v02 - 2010-12-19 - SN S350021mantenimiento pierrotBelum ada peringkat

- Air Control 3 Dynamic: ManualDokumen53 halamanAir Control 3 Dynamic: ManualmadiBelum ada peringkat

- REV207 Applications Type of CompressorsDokumen86 halamanREV207 Applications Type of CompressorsDaniel Arbeláez100% (1)

- Sierra 90-300 Parts Manual 2016 80448822 - CDokumen68 halamanSierra 90-300 Parts Manual 2016 80448822 - CAgaba MohamedBelum ada peringkat

- Ficha Ig Compresoresdetornillo R37IE en 0Dokumen1 halamanFicha Ig Compresoresdetornillo R37IE en 0death666darkBelum ada peringkat

- GD Compressor ManualDokumen51 halamanGD Compressor Manualnzj564nxgfBelum ada peringkat

- Evo3-Nk: Compact UnitDokumen2 halamanEvo3-Nk: Compact Unitoussama100% (1)

- Parts list for compressor valves, elements, and drive gearsDokumen5 halamanParts list for compressor valves, elements, and drive gearsDubar ArzolaBelum ada peringkat

- 75-160kW Parts ManualDokumen81 halaman75-160kW Parts ManualANDRESBelum ada peringkat

- CE CF - English PDFDokumen8 halamanCE CF - English PDFm.b.homsy100% (1)

- Domnick Hunter Filter Housings & ElementsDokumen1 halamanDomnick Hunter Filter Housings & ElementsmuppetscrapBelum ada peringkat

- Ba Engl rs3 55 03 06Dokumen85 halamanBa Engl rs3 55 03 06Vijačni kompresori- Prodaja i servis100% (1)

- Product Range & Price Guide: Effective From January 2012Dokumen72 halamanProduct Range & Price Guide: Effective From January 2012daniel100% (1)

- For Screw Compressor Suction Control Valve HAKG65 and HAKO65Dokumen2 halamanFor Screw Compressor Suction Control Valve HAKG65 and HAKO65Csaba SándorBelum ada peringkat

- CD7-60 Year 2003Dokumen96 halamanCD7-60 Year 2003Serrefriair Garcia RefriBelum ada peringkat

- ZT275Dokumen199 halamanZT275ricardo100% (1)

- The 4 S's of Success in 40 CharactersDokumen794 halamanThe 4 S's of Success in 40 CharactersМихайло ЗахаркоBelum ada peringkat

- Instruction Manual: Hitachi Oil-Flooded Rotary Screw Air Compressor OSP-90M5AX OSP-90M5WXDokumen48 halamanInstruction Manual: Hitachi Oil-Flooded Rotary Screw Air Compressor OSP-90M5AX OSP-90M5WXRamachandra Reddy ChinthamreddyBelum ada peringkat

- Aerzen Soffiatori LobiDokumen20 halamanAerzen Soffiatori LobiBrayanBelum ada peringkat

- Specification ARX120HK EnglishDokumen5 halamanSpecification ARX120HK Englishheruono sitorusBelum ada peringkat

- Product Identification Number - IngersollrandDokumen6 halamanProduct Identification Number - Ingersollrandandy habibiBelum ada peringkat

- Atlas Copco GA 15 To GA 30 Part List 14Dokumen1 halamanAtlas Copco GA 15 To GA 30 Part List 14RICHARDBelum ada peringkat

- Tecnam P2002-JF Flight ManualDokumen262 halamanTecnam P2002-JF Flight ManualJohnBelum ada peringkat

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusDari EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusBelum ada peringkat

- Ea 767 31-002 Eicas Upgrade Ops6 PDFDokumen5 halamanEa 767 31-002 Eicas Upgrade Ops6 PDFjuanf490Belum ada peringkat

- A320 Sil 28 Centralized Fault Display System (CFDS) AnomaliesDokumen203 halamanA320 Sil 28 Centralized Fault Display System (CFDS) Anomaliestangosierra2010100% (2)

- Thermodynamic of Polymer Blends PDFDokumen34 halamanThermodynamic of Polymer Blends PDFSyam RizalBelum ada peringkat

- Evaluation PlanDokumen25 halamanEvaluation PlanJasiz Philipe OmbuguBelum ada peringkat

- CH 02Dokumen20 halamanCH 02Pauline Nguyen100% (1)

- Flowchart Common ShapesDokumen3 halamanFlowchart Common ShapeslaptoptabingBelum ada peringkat

- Model 9200-2123: 1 RS-422 Input/3 RS-422 Output ModuleDokumen2 halamanModel 9200-2123: 1 RS-422 Input/3 RS-422 Output ModuleNisar AhmedBelum ada peringkat

- 3615-Article Text-6949-1-10-20201223Dokumen13 halaman3615-Article Text-6949-1-10-20201223MinSBelum ada peringkat

- GyratoryDokumen4 halamanGyratoryFrancisco M. RamosBelum ada peringkat

- BoilerDokumen7 halamanBoilerXie ShjBelum ada peringkat

- Action Plan NEAP MaglonzoDokumen4 halamanAction Plan NEAP MaglonzoAlvin EspirituBelum ada peringkat

- Study Notes Weather MeteorologyDokumen35 halamanStudy Notes Weather MeteorologyNeeth100% (1)

- Logic A4Dokumen1.218 halamanLogic A4Alpheios Alpha100% (1)

- Competing Risks and Multistate Models With RDokumen249 halamanCompeting Risks and Multistate Models With RJuanCarlosAguilarCastro100% (1)

- Public Service InnovationDokumen112 halamanPublic Service InnovationresearchrepublicBelum ada peringkat

- Fast Arm Simulations for RehabilitationDokumen33 halamanFast Arm Simulations for RehabilitationGyrl DyamonndBelum ada peringkat

- VirginDokumen14 halamanVirginGururaj Prakash75% (4)

- Persuasive Writing G7Dokumen18 halamanPersuasive Writing G7Shorouk KaramBelum ada peringkat

- The Wheel and The BobsleighDokumen2 halamanThe Wheel and The BobsleighHarisBelum ada peringkat

- BSC Nautical Science 2015 16 PDFDokumen173 halamanBSC Nautical Science 2015 16 PDFMerchant Navy PlanetBelum ada peringkat

- MyFax User GuideDokumen47 halamanMyFax User Guidesanjaya 黄保元Belum ada peringkat

- CSIR Guest House ListDokumen4 halamanCSIR Guest House Listsoumendu.bitspBelum ada peringkat

- Designing Organisation StructureDokumen56 halamanDesigning Organisation StructureShamanth GowdaBelum ada peringkat

- PlacementDokumen3 halamanPlacementNishanth GowdaBelum ada peringkat

- SDO City of Malolos-Math5-Q4M1-Area of A Circle-Ramirez EWDokumen25 halamanSDO City of Malolos-Math5-Q4M1-Area of A Circle-Ramirez EWKris Bernadette David100% (1)

- Lesson PlanDokumen7 halamanLesson Planapi-357536453Belum ada peringkat

- Broadcasting Modernity by Yeidy M. RiveroDokumen34 halamanBroadcasting Modernity by Yeidy M. RiveroDuke University Press100% (2)

- g8m4l10 - Constant Rate Table and Graphs 3Dokumen6 halamang8m4l10 - Constant Rate Table and Graphs 3api-276774049Belum ada peringkat

- Đề 1Dokumen9 halamanĐề 1trung anBelum ada peringkat

- ACS SCPI Programming Guide V1 0Dokumen29 halamanACS SCPI Programming Guide V1 0Pedro Boanerges Paz RomeroBelum ada peringkat

- Foam ControlDokumen28 halamanFoam ControlJoselu Ordoñez Ramos100% (1)

- Applying HACCP PrinciplesDokumen88 halamanApplying HACCP Principlesbbeard90% (1)