Order-Processing Tasks Information Flow From The Order To Delivery

Diunggah oleh

Joey ScofieldDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Order-Processing Tasks Information Flow From The Order To Delivery

Diunggah oleh

Joey ScofieldHak Cipta:

Format Tersedia

DHL Logbook - in cooperation with Technical University Darmstadt

Order-processing tasks Information flow from the order to delivery

An order forms the basis for the information flow in a logistics system. It has three principal functions - it creates a flow of information that precedes the goods, accompanies them and follows them. The tasks of order processing are divided into six phases: order transmission, preparation, routing, picking, shipment and invoicing

Order processing tasks

The order and its impact

The transmission of the customers order triggers the logistics processes within the company. On the information-flow level, order processing addresses the handling and monitoring of an order - from the time it is placed by the customer to the delivery of the shipment documents and invoice to the customer. The time required for order processing makes up a substantial amount of the total delivery time .

Order transmission

Order transmission can be done by mail, fax, telephone, e-mail or electronic data exchange (web-)EDI . To avoid uneven capacity use of a logistics system, the appropriate means of transmission should be selected in each case [1].

Preparation

Preparation adjusts the order to meet internal company requirements and integrates the order into the logistics systems planning. This includes obtaining missing information, and checking pricing conditions, delivery conditions and customer creditworthiness as well as the availability of the material in the warehouse [1].

Routing

Order preparation is usually followed by order routing, a process that includes order confirmation and the generation of internal job orders - manually, mechanically or electronically. For example, a delivery notification containing all related shipping documents is prepared and tells the storage point to process the shipment. As the integration of electronic data processing expands, the routing process is becoming increasingly automated, reducing paperwork associated with the information flow [1].

1/3

DHL Logbook - in cooperation with Technical University Darmstadt

Picking

Based on prepared and processed orders, goods are picked in the warehouse. Picking is organized according to factors such as order size, urgency and orders that have to be delivered simultaneously. In this phase, order processing provides information to the warehouse and inventories that can be used for tasks such as management of storage and retrieval equipment or for inventory book keeping [1].

Shipment

Picking is followed by preparation of shipping documents. When options are available, this phase includes selecting the optimal means of transport and route for delivery. This information is closely linked to transportation because both loading and movement of goods are initiated in this phase [1].

Invoicing

Invoicing of orders may be done at various points - either as post-invoicing after shipping has been arranged or as pre-invoicing before or while compilation and shipping are being done. The strength of post-invoicing is that an order can smoothly proceed to the warehouse. The strength of pre-invoicing is that as much paperwork as possible can be completed in one phase [1].

Functions of order processing

Order processing serves to plan, manage and monitor the flow of goods. This requires an information flow that precedes, accompanies and follows the flow of goods.

Advance information flow

Once the customer has placed his order, the manufacturer or retailer sends the customer an order confirmation specifying the scheduled delivery time. All parties involved in the flow of goods also receive prompt notification about the scheduled delivery. As a result, these parties have the time they need to plan and schedule, two necessary conditions for optimally executing the flow of goods in terms of costs and services [1].

Accompanying information flow

The information flow that accompanies the flow of goods is designed to provide all parties with operational information needed on site to carry out transport, handling and storage activities. This information includes proper handling of hazardous goods. In addition, tracking of the flow of goods through the logistics network is to be supported. An RFID tag, for example, can be used in the information flow accompanying the flow of goods. A special sensor monitors and documents the temperature of the shipment throughout the transport. The measured data are available at each monitoring point, a feature that enables the shipper, recipient and controller to continually check the condition of the products. This is especially important for pharmaceutical products like vaccines whose effectiveness can

2/3

DHL Logbook - in cooperation with Technical University Darmstadt

be harmed by temperature fluctuations outside the recommended range [1].

Follow-up information flow

The information flow that follows the flow of goods consists of information that is available only after the flow of goods has been completed. A case in point is an invoice that the recipient receives a few days after a delivery. However, information can also flow in the opposite direction of the flow of goods. This involves a status report on the execution of the order - including information that is reported to the dispatching point about matters such as the time when the flow of goods passed critical stations in the transport chain . These stations can include borders in international shipments. This information is also part of the follow-up information flow [1].

Recommended reading

Strategic Logistics Management | Stock / Lambert 2001 Information Logistics in Supply Chain Networks. Concept, Empirical Analysis, and Design | Fricke 2007

References

[1] Logistiksysteme | Pfohl 2004

Related articles

Communication technologies in logistics

URL

http://www.dhldiscoverlogistics.com/cms/en/course/tasks_functions/order_processing/tasks.j sp

3/3

Anda mungkin juga menyukai

- Colibri - DEMSU P01 PDFDokumen15 halamanColibri - DEMSU P01 PDFRahul Solanki100% (4)

- Warehouse Management System OverviewDokumen12 halamanWarehouse Management System OverviewKoustubha Khare100% (2)

- Summary Logistics Principles and Practice Visser Van GoorDokumen38 halamanSummary Logistics Principles and Practice Visser Van GoorParbatty Arjune100% (1)

- Key Logistics ActivitiesDokumen2 halamanKey Logistics ActivitiesVikash Ranjan33% (3)

- All About DHL Logistics - Live ProjectDokumen39 halamanAll About DHL Logistics - Live ProjectMihir Thakkar85% (26)

- Logistics NotesDokumen8 halamanLogistics NotesJerry Wong100% (2)

- Warehouse OperationsDokumen4 halamanWarehouse OperationsSafijo AlphonsBelum ada peringkat

- Pie in The Sky 3Dokumen5 halamanPie in The Sky 3arsi_yaarBelum ada peringkat

- PepsicoDokumen2 halamanPepsicoAnh QuocBelum ada peringkat

- Logistics Management Assignment 1Dokumen2 halamanLogistics Management Assignment 1Amar Chotai50% (2)

- Inbound LogisticsDokumen4 halamanInbound LogisticsNoopur Gandhi100% (2)

- Logistics ActivitiesDokumen4 halamanLogistics ActivitiesadnanBelum ada peringkat

- 10 Tips For Reducing Supply Chain Logistics CostsDokumen13 halaman10 Tips For Reducing Supply Chain Logistics CostsRahul IndiaBelum ada peringkat

- Gs1 Broch Stand HealthcareDokumen8 halamanGs1 Broch Stand HealthcaresigiryaBelum ada peringkat

- Determination of External Demands: Goods IssueDokumen2 halamanDetermination of External Demands: Goods IssueLovely Angell FermanBelum ada peringkat

- Business LogisticsDokumen22 halamanBusiness LogisticsClarine KuoBelum ada peringkat

- Various Flow in Supply Chain-: EducbaDokumen6 halamanVarious Flow in Supply Chain-: EducbaRitik SinghBelum ada peringkat

- TL 057Dokumen6 halamanTL 057Dennis BriteBelum ada peringkat

- Material Management: External ProcurementDokumen1 halamanMaterial Management: External ProcurementBandila KalyanBelum ada peringkat

- Inbound Delivery SapDokumen1 halamanInbound Delivery SapKumar AjitBelum ada peringkat

- Unit 1logistics ManagementDokumen13 halamanUnit 1logistics ManagementSidhu boiiBelum ada peringkat

- Sap Gts Customs End To End ProcessDokumen2 halamanSap Gts Customs End To End Processsubbbu0% (1)

- Supply ChainDokumen9 halamanSupply ChainUynn LêBelum ada peringkat

- Logistic Management: Unit 3Dokumen23 halamanLogistic Management: Unit 3Akhil CrastaBelum ada peringkat

- UNIT 1 LogisticsDokumen10 halamanUNIT 1 Logisticsanon_124527471Belum ada peringkat

- Logistical Process: Lakshya JindalDokumen13 halamanLogistical Process: Lakshya JindalRitika ChughBelum ada peringkat

- LSCM - NotesDokumen20 halamanLSCM - NotesJoju JohnyBelum ada peringkat

- Application of E-Commerce in Cold Chain LogisticsDokumen4 halamanApplication of E-Commerce in Cold Chain LogisticsAdhip Pal ChaudhuriBelum ada peringkat

- MOPIN NEW PDF 2 PDFDokumen66 halamanMOPIN NEW PDF 2 PDFDivya AvBelum ada peringkat

- Logestic 1Dokumen30 halamanLogestic 1wahid mohdBelum ada peringkat

- Inbound LogisticsDokumen2 halamanInbound LogisticsMohit TalrejaBelum ada peringkat

- Supply Chain ManagementDokumen5 halamanSupply Chain ManagementRitik Singh100% (1)

- Logistic Functional InfoDokumen4 halamanLogistic Functional Infov10dulkarBelum ada peringkat

- Definition of LogisticsDokumen31 halamanDefinition of LogisticsArun Narayanan100% (1)

- TransDokumen45 halamanTransMikaella MorenoBelum ada peringkat

- Physical Distribution and Logistics Management Physical Distribution ManagementDokumen4 halamanPhysical Distribution and Logistics Management Physical Distribution ManagementMukesh MenonBelum ada peringkat

- Assignment LogisticsDokumen9 halamanAssignment LogisticsArham Orb100% (1)

- SCM Unit-2Dokumen22 halamanSCM Unit-2Aashish Singh IIBelum ada peringkat

- Chapter-2 Role of Logistics in Supply ChainDokumen29 halamanChapter-2 Role of Logistics in Supply ChainnidamahBelum ada peringkat

- 2 - Introduction To Transaction ProcessingDokumen91 halaman2 - Introduction To Transaction ProcessingShandy MojicaBelum ada peringkat

- Logistics AnswersDokumen23 halamanLogistics AnswersSagar NankaniBelum ada peringkat

- Logistics Management Unit IIDokumen50 halamanLogistics Management Unit IInarenmadhavBelum ada peringkat

- Unit 3 I.logisticsDokumen14 halamanUnit 3 I.logisticsBeverly Diane P. De Luna-AngioBelum ada peringkat

- Maharashtra State Board of Technical Education: CertificateDokumen21 halamanMaharashtra State Board of Technical Education: CertificateRehan PathanBelum ada peringkat

- Integrated LogisticsDokumen9 halamanIntegrated Logisticsyuktim100% (2)

- Order Processing and Supply Chain ManagementDokumen16 halamanOrder Processing and Supply Chain ManagementNikita GargBelum ada peringkat

- TerminologiesDokumen12 halamanTerminologiesPrince Yeboah MarfoBelum ada peringkat

- International LogisticsDokumen6 halamanInternational LogisticsCarlo AlancadoBelum ada peringkat

- Deliver in Supply Chain Management: Group 3Dokumen27 halamanDeliver in Supply Chain Management: Group 3Mark Louie Santos RabaBelum ada peringkat

- Objectives of Logistics Management: Rapid ResponseDokumen14 halamanObjectives of Logistics Management: Rapid ResponserajisumaBelum ada peringkat

- Logistics ManagementDokumen7 halamanLogistics ManagementAdnan AhmedBelum ada peringkat

- Online Supply Chain PracticesDokumen2 halamanOnline Supply Chain PracticesKëërtäñ SubramaniamBelum ada peringkat

- Introduction To LogisticsDokumen38 halamanIntroduction To LogisticsVivekanand SinghBelum ada peringkat

- LOGISTICSDokumen5 halamanLOGISTICSPeachy CamBelum ada peringkat

- Procedure and Documentation in Supply Chain Management: Business strategy books, #1Dari EverandProcedure and Documentation in Supply Chain Management: Business strategy books, #1Belum ada peringkat

- W Hy Logistics ? History of Logistics:: Type of Logistics: How To Improve Your Logistics Network FlowDokumen10 halamanW Hy Logistics ? History of Logistics:: Type of Logistics: How To Improve Your Logistics Network FlowAnas BouchikhiBelum ada peringkat

- Logistics ManagementDokumen52 halamanLogistics ManagementDeva Ardha Nareswara67% (9)

- Supply Chain and Logistics in Marketing - CDokumen20 halamanSupply Chain and Logistics in Marketing - CvibuBelum ada peringkat

- Certified in Supply Chain ManagementDari EverandCertified in Supply Chain ManagementPenilaian: 5 dari 5 bintang5/5 (1)

- Logistics in Manufacturing, Supply Chain, and DistributionDari EverandLogistics in Manufacturing, Supply Chain, and DistributionBelum ada peringkat

- Week 1 - Xi YeDokumen4 halamanWeek 1 - Xi YeJoey ScofieldBelum ada peringkat

- Model 7&11Dokumen1 halamanModel 7&11Joey ScofieldBelum ada peringkat

- LowcostersDokumen2 halamanLowcostersJoey ScofieldBelum ada peringkat

- Behavioural Competences Self Evaluation: Time ManagementDokumen13 halamanBehavioural Competences Self Evaluation: Time ManagementJoey ScofieldBelum ada peringkat

- Sigma Valve 2-WayDokumen2 halamanSigma Valve 2-WayRahimBelum ada peringkat

- Relationship Between Principal Leadership Skills and Teachers' Organizational Citizenship BehaviourDokumen16 halamanRelationship Between Principal Leadership Skills and Teachers' Organizational Citizenship BehaviourToe ToeBelum ada peringkat

- Singapore Electricity MarketDokumen25 halamanSingapore Electricity MarketTonia GlennBelum ada peringkat

- Grace Strux Beton PDFDokumen33 halamanGrace Strux Beton PDFmpilgirBelum ada peringkat

- PRELEC 1 Updates in Managerial Accounting Notes PDFDokumen6 halamanPRELEC 1 Updates in Managerial Accounting Notes PDFRaichele FranciscoBelum ada peringkat

- Elb v2 ApiDokumen180 halamanElb v2 ApikhalandharBelum ada peringkat

- Fcode 54 en El SytucDokumen2 halamanFcode 54 en El SytucAga MenonBelum ada peringkat

- Expected MCQs CompressedDokumen31 halamanExpected MCQs CompressedAdithya kesavBelum ada peringkat

- For Email Daily Thermetrics TSTC Product BrochureDokumen5 halamanFor Email Daily Thermetrics TSTC Product BrochureIlkuBelum ada peringkat

- I.V. FluidDokumen4 halamanI.V. FluidOdunlamiBelum ada peringkat

- Relay Interface ModulesDokumen2 halamanRelay Interface Modulesmahdi aghamohamadiBelum ada peringkat

- Perhitungan Manual Metode Correlated Naïve Bayes Classifier: December 2020Dokumen6 halamanPerhitungan Manual Metode Correlated Naïve Bayes Classifier: December 2020andreas evanBelum ada peringkat

- Rideable Segway Clone - Low Cost and Easy Build: Digital MPU6050 Accelerometer/gyro IMU BoardDokumen45 halamanRideable Segway Clone - Low Cost and Easy Build: Digital MPU6050 Accelerometer/gyro IMU BoardpaolaBelum ada peringkat

- Mathematics 2 First Quarter - Module 5 "Recognizing Money and Counting The Value of Money"Dokumen6 halamanMathematics 2 First Quarter - Module 5 "Recognizing Money and Counting The Value of Money"Kenneth NuñezBelum ada peringkat

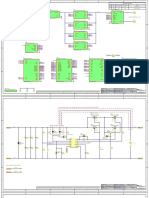

- Scheme Bidirectional DC-DC ConverterDokumen16 halamanScheme Bidirectional DC-DC ConverterNguyễn Quang KhoaBelum ada peringkat

- Bench VortexDokumen3 halamanBench VortexRio FebriantoBelum ada peringkat

- Chapter 123 RevisedDokumen23 halamanChapter 123 RevisedCristy Ann BallanBelum ada peringkat

- Reading TPO 49 Used June 17 To 20 10am To 12pm Small Group Tutoring1Dokumen27 halamanReading TPO 49 Used June 17 To 20 10am To 12pm Small Group Tutoring1shehla khanBelum ada peringkat

- Electric Arc Furnace STEEL MAKINGDokumen28 halamanElectric Arc Furnace STEEL MAKINGAMMASI A SHARAN100% (3)

- Solved - in Capital Budgeting, Should The Following Be Ignored, ...Dokumen3 halamanSolved - in Capital Budgeting, Should The Following Be Ignored, ...rifa hanaBelum ada peringkat

- Hoja Tecnica Item 2 DRC-9-04X12-D-H-D UV BK LSZH - F904804Q6B PDFDokumen2 halamanHoja Tecnica Item 2 DRC-9-04X12-D-H-D UV BK LSZH - F904804Q6B PDFMarco Antonio Gutierrez PulchaBelum ada peringkat

- Double Inlet Airfoil Fans - AtzafDokumen52 halamanDouble Inlet Airfoil Fans - AtzafDaniel AlonsoBelum ada peringkat

- Catalogue of The Herbert Allen Collection of English PorcelainDokumen298 halamanCatalogue of The Herbert Allen Collection of English PorcelainPuiu Vasile ChiojdoiuBelum ada peringkat

- Salva v. MakalintalDokumen2 halamanSalva v. MakalintalGain DeeBelum ada peringkat

- SVPWM PDFDokumen5 halamanSVPWM PDFmauricetappaBelum ada peringkat

- Chap 06 Ans Part 2Dokumen18 halamanChap 06 Ans Part 2Janelle Joyce MuhiBelum ada peringkat

- Drug Study TemplateDokumen2 halamanDrug Study TemplateKistlerzane CABALLEROBelum ada peringkat

- Applications of MathematicsDokumen35 halamanApplications of MathematicsRamdas Sonawane100% (1)