A Comparative Evaluation of Various Additives

Diunggah oleh

agus_ip3808Deskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

A Comparative Evaluation of Various Additives

Diunggah oleh

agus_ip3808Hak Cipta:

Format Tersedia

Amer Ali Al-Rawas,1 Ramzi Taha,2 John D.

Nelson,3 Thamer Beit Al-Shab,4 and Hilal Al-Siyabi4

A Comparative Evaluation of Various Additives Used in the Stabilization of Expansive Soils

REFERENCE: Al-Rawas, A. A., Taha, R., Nelson, J. D., AlShab, T. B., and Al-Siyabi, H., A Comparative Evaluation of Various Additives Used in the Stabilization of Expansive Soils, Geotechnical Testing Journal, GTJODJ, Vol. 25, No. 2, June 2002, pp. 199209. ABSTRACT: This paper investigates the effectiveness of using cement by-pass dust, copper slag, granulated blast furnace slag, and slag-cement in reducing the swelling potential and plasticity of expansive soils. The soil used in this study was brought from Al-Khod (a town located in Northern Oman) where structural damage was observed. The first stage of the experimental program dealt with the determination of the chemical, mineralogical, and geotechnical characteristics of the untreated soil. The soil was then mixed with the stabilizers at 3, 6, and 9% of the dry weight of the soil. The treated samples were subjected to liquid limit, plastic limit, swell percent, and swell pressure tests. Furthermore, the cation exchange capacity, exchangeable cations (Na , Ca , Mg , and K ), and pH of the treated samples were also measured. The study showed that copper slag caused a significant increase in the swelling potential of the treated samples. Other stabilizers reduced the swelling potential and plasticity at varying degrees. The study further indicated that cation exchange capacity and the amount of sodium and calcium cations are good indicators of the effectiveness of chemical stabilizers used in soil stabilization. KEYWORDS: soil stabilization, expansive, swelling, stabilizer

bilization, soil replacement with compaction control, prewetting, moisture control, surcharge loading, and use of geosynthetics. In Oman, soil replacement, moisture and compaction control, and structural design methods have been used with success in various projects to overcome the problems associated with expansive soils. The use of chemical stabilizers seems to be very limited and there is lack of information on the stabilization of expansive soils from Oman. Therefore, a research program was undertaken with the objective of exploring potential chemical stabilizers that are locally produced and economically available, such as lime, cement, sarooj (artificial pozzolans), cement by-pass dust (CBPD), slag-cement, and slogs. The expansive clay used in the study was obtained from Al-Khod (a town situated approximately 40 km west of Muscat in Northern Oman). As a result of this program, a paper was published on the stabilization of Omani expansive soil using lime, cement, sand, and salt (Basra et al. 1998). The paper evaluates the effectiveness of utilizing cement by-pass dust, copper slag, granulated blast furnace slag (GBFS), and slag-cement, as soil stabilizing agents. Previous Work on Chemical Stabilization Chemical additives, such as lime, cement, fly ash, and other chemical compounds, have been used in soil stabilization for many years at various degrees of success. The effectiveness of these additives depends on the soil conditions, stabilizer properties, and type of construction (i.e., houses, roads, etc.). The selection of a particular additive depends on costs, benefits, availability, and practicality of its application. The following paragraphs give background information on the common additives that are used in soil stabilization. Lime Stabilization Lime stabilization is covered extensively in the literature (Rogers and Glendinning 2000; Quaint et al. 2000; Little et al. 1987; Mitchell 1986; NLA 1985; Armani and Moonfish 1972; Stocker 1972; Thompson 1969). Lime will primarily react with medium, moderately fine, and fine-grained soils to produce decreased elasticity, increased workability, reduced swell, and increased strength. Such improved soil properties are the result of three basic chemical reactions (Fang 1991): 1. Cation exchange and flocculation-agglomeration; 2. Cementation (pozzolanic reaction); and 3. Carbonation. The cation exchange process involves an agglomeration of the fine clay particles into coarse particles. The cementation process

Introduction Expansive soils are a worldwide problem that poses several challenges for civil engineers. They are considered a potential natural hazard, which can cause extensive damage to structures if not adequately treated. Such soils swell when given an access to water and shrink when they dry out. The swelling and shrinkage phenomenon depends on several factors, including type and amount of clay minerals and cations, moisture content, dry density, soil structure, and loading conditions. There are several methods that have been used to minimize or eliminate the effect of expansive soils before and after construction of structures. These methods include chemical sta1 Associate Professor, Department of Civil Engineering, Sultan Qaboos University, P.O. Box 33, Al-Khod 123, Sultanate of Oman. E-mail: ameraar@squ. edu.om. 2 Associate Professor, Department of Civil Engineering, Sultan Qaboos University, P.O. Box 33, Al-Khod 123, Sultanate of Oman. 3 Professor, Civil Engineering Department, Colorado State University, Fort Collins, CO 80523. 4 Undergraduate Students, Department of Civil Engineering, Sultan Qaboos University, P.O. Box 33, Al-Khod 123, Sultanate of Oman.

Copyright 2002 byInt'l (all rights reserved); Thu Mar 22 13:13:52 EDTBox C700, West Conshohocken, PA 19428-2959. Copyright by ASTM ASTM International, 100 Barr Harbor Drive, PO 2012 Downloaded/printed by www.astm.org Curtin University of Technology pursuant to License Agreement. No further reproductions authorized.

199

200

GEOTECHNICAL TESTING JOURNAL

develops from the reaction between calcium present in lime and silica and alumina in the soil, forming calcium-silicate and calciumaluminate or calcium-aluminate-silicates. The cementitious compounds produced are characterized by their high strength and low-volume change. Previous researchers reported that small lime additions (from 28%) significantly decrease the liquid limit, plasticity index, maximum dry density, and swell, and increase plastic limit, the optimum water content, and strength of expansive soils (Croft 1967; Abduljauwad 1995; Basma et al. 1998). It was reported by Sivapullaiah et al. (1997) that lime added in excess of the amount required for cation exchange could only produce cementitious compounds, which bind the flocculated particles and develop extra strength. Cement Stabilization Cement stabilization develops from the cementitious links between the calcium silicate and aluminate hydration products and the soil particles. Cement addition to clay soils reduces the liquid limit, plasticity index, and swelling potential, and increases the shrinkage limit and shear strength (Nelson and Miller 1992). Previous work carried on by Basma et al. (1998) showed that the addition of cement in small percentages (39% of the dry weight of the soil) resulted in a decrease in the swelling characteristics. Cement By-Pass Dust (CBPD) Stabilization Cement by-pass dust (CBPD) is a fine powder material produced as a by-product of the manufacturing of Portland cement, which is also referred to in the literature as cement kiln dust. It is generated during the calcining process in the kiln. The composition of CBPD is quite variable from source to source, due to raw materials and process variations. It is primarily made up of variable amounts of fine calcined and uncalcined feed materials, fine cement clinker, fuel combustion by-products, and condensed alkali compounds. Morgan and Halff (1984) reported that cement kiln dust is a costeffective and efficient solidifying agent compared to lime, cement, fly ash, and sulphur. It was reported that cement kiln dust results in significant reduction in the plasticity index and swell percent, and an increase in the compressive strength of soil (McCoy 1971; Zaman et al. 1992). Zaman et al. (1992) showed that the addition of 25% cement kiln dust of the dry weight of a highly expansive soil resulted in reducing the swell percent from 9.1% to 0%, and increasing the unconfined compressive strength from 103 kPa to 290 kPa in a 56-day curing period. Slag Stabilization Slag materials are produced as by-products, and they can be grouped, based on their composition, into two categories: iron and steel slags, and nonferrous slags. Blast furnace slag is derived from producing iron in a blast furnace. The slag consists mainly of silicates and alumino-silicates of lime. Blast furnace slag can be produced in three forms: air-cooled, granulated, and expanded forms. Air-cooled slag is commonly used in concrete, asphalt, and road bases, and as fill material. Granulated slag is used as slag-cement. Expanded slag is used as an aggregate. Steel slags consist mainly of calcium, iron, unslaked lime, and magnesium. Steel slag usually contains sufficient amounts (on the order of 3050%) of lime, which can be mixed with fly ash to provide lime for pozzolanic reactions (Chu and Kao 1993). A useful review of the composition, types, and uses of various types of slags was presented by Collins and Ciesielski (1994).

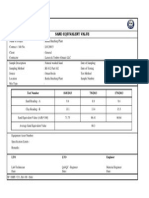

Chemical Compounds Other chemical compounds, such as sodium silicate, calcium hydroxide, sodium chloride, calcium chloride, and potassium nitrate, have been utilized in stabilizing soils. However, there is no supporting evidence that any of them has economically worthwhile benefits (Gromko 1974). Furthermore, Nelson and Miller (1992) reported that there is insufficient evidence that salts other than sodium chloride and calcium chloride have adequate soil stabilization capabilities to be economically justifiable. Objectives The main objectives of this study were: 1. To determine the chemical, mineralogical, and geotechnical properties of Al-Khod expansive clay, and 2. To investigate the influence of mixing different percentages of cement by-pass dust, copper slag, slag-cement, and granulated blast furnace slag (GBFS) on the swelling potential, plasticity, and chemical properties of the treated soil. Experimental Program Chemical Stabilizers Used In this study, cement by-pass dust (a by-product), copper slag (a by-product), slag-cement, and granulated blast furnace slag were utilized. Cement by-pass dust, slag-cement, and granulated blast furnace slag were supplied by Oman Cement Company. Slagcement is composed of Portland cement clinker, granulated blast furnace slag (about 70%), and gypsum. Granulated blast furnace slag is imported by Oman Cement Company from Italy for the production of slag-cement. Copper slag was produced as a waste product during the extraction of copper in Sohar (Northern Oman). A full chemical analysis was carried out on all stabilizers used in this study. The chemical compositions of the stabilizers used are given in Table 1. The chemical analyses include pH, cation exchange capacity (CEC), exchangeable cations, and chemical compounds. The chemical composition tests were performed in accordance with Omanian Standard 25 (1979) (equivalent to ASTM C 114-99, Test Methods for Chemical Analysis of Hydraulic Cement). The exchangeable cations were extracted with ammonium acetate, with subsequent determination of the cations by the standard methods (Chapman 1965). The Na and K were measured by the flame photometry method, and Ca and Mg were measured by atomic absorption spectrophotometry. The CEC was measured by the sodium acetate method. It is known generally that swelling potential of a soil is influenced greatly by its chemical composition. The higher the CEC and Na , the higher the swelling of the soil and vice-versa. On the other hand, the higher the Ca , the lower the swelling potential of the soil. Sodium-montmorillonite is significantly more swelling than calcium-montmorillonite. Table 1 shows that CBPD has the highest values of CEC (140 meq/100g) and Ca (92%), while copper slag has the highest percentage of Na (38%), and the lowest percentage of Ca (4%). Based on chemical results alone, it is expected that copper slag will increase the swelling potential of the soil, while other stabilizers will reduce the swelling potential of the soil with varying degrees. Site Selection, Sampling, and Properties of Tested Soil The site selected for obtaining samples is located at Al-Khod (between Sultan Qaboos University and Married Quarter Village of the Ministry of Defense). The site selection was based on the structural

Copyright by ASTM Int'l (all rights reserved); Thu Mar 22 13:13:52 EDT 2012 Downloaded/printed by Curtin University of Technology pursuant to License Agreement. No further reproductions authorized.

AL-RAWAS ET AL. ON EXPANSIVE SOILS

201

TABLE 1Chemical composition of the stabilizers used. Chemical Stabilizers Characteristics PH CECa, meq/100g Cations, % Sodium (Na) Calcium (Ca) Magnesium (Mg) Potassium (K) Compounds, % SiO2 Al2O3 Fe2O3 CaO MgO SO3 K2O Na2O TiO2 Mn2O3 Cl LOI

a

Cement By-Pass Dust (CBPD) 140.00 0.10 92.00 4.90 0.30 15.84 3.57 2.76 63.76 1.93 1.65 2.99 0.33 0.48 0.07 1.09 5.38

Copper Slag 9.10 76.20 38.00 4.00 2.00 2.00 35.70 1.43 47.35 9.40 4.37 0.28 0.22 0.15 0.98 0.04 0.06 -2.91

Slag-Cement 10.30 55.00 15.00 27.00 3.00 2.00 31.50 8.50 1.90 47.60 5.10 2.90 0.33 0.22 0.39 0.33 0.03 1.30

Granulated Blast Furnace Slag (GBFS) 8.80 67.00 10.00 22.00 1.00 1.00 33.97 14.51 1.43 41.24 7.56 2.22 0.33 0.20 0.54 0.31 0.01 1.71

CEC

cation exchange capacity.

damage evidenced in houses located at the Married Quarter Village. The site contains expansive materials of Oligocene age that possess high swelling potential (Al-Rawas and Qamaruddin 1998). A test pit (1.4 m 1.4 m 1.2 m) was excavated to obtain disturbed samples. The expansive soil was encountered at a depth of about 1.2 m, overlaid by a layer of sand and gravel. A field density test was carried out in the pit using the Sand Cone Method. The disturbed expansive soil was excavated, placed in plastic bags, and transported to Sultan Qaboos University for preparation and testing. The physical, mineralogical, and chemical characteristics of the untreated soil are shown in Table 2. All geotechnical tests were performed in accordance with British Standard 1377 (1990). Based on Casagrande plasticity chart, the soil was classified as inorganic silt of high plasticity (MH). The soil showed a high plasticity index (20.5%) and an activity of 1.03. Generally, the higher the plasticity index and activity of a soil, the higher the swelling potential. According to the classification systems developed by Dakshanamurthy and Raman (1973) and Van der Merwe (1975), the soil was classified as having high and medium swelling potential, respectively. X-ray diffraction analysis carried by Al-Rawas et al. (1998) showed the presence of montmorillonite (43%), palygorskite (23%), illite (23%), and kaolinite (16%). The results showed that montmorillonite, which is known as the most active clay mineral, was the major clay mineral. The CEC, Na , and Ca values of the soil are 70% (meq/100g), 41%, and 6%, respectively. The physical, mineralogical, and chemical results indicate that the soil possesses a high swelling potential. Initial Testing Conditions The swelling potential of expansive soils depends primarily on the initial testing conditions of the samples (Al-Rawas 1999). Therefore, in order to compare the effectiveness of different stabilizing agents, it was essential to test the samples at identical placement conditions. In this study, the natural water content and dry

TABLE 2Physical, mineralogical, and chemical results of the untreated soil. Characteristics Color Depth, m Natural water content, % Field dry unit weight, kN/m3 Specific gravity Passing No. 200 Sieve, % Clay content (less than 2 m), % Liquid limit, % Plastic limit, % Plasticity index, % Clay activity Unified Soil Classification System (USCS) Compaction properties Optimum water content (%) Maximum dry unit weight (kN/m3) Clay minerals, % Montmorillonite Palygorskite Illite Kaolinite Cations, % Sodium (Na) Calcium (Ca) Magnesium (Mg) Potassium (K) Cation exchange capacity (meq/100g) PH Values and Descriptions Yellowish 1.20 8.90 17.00 2.80 60.00 20.00 50.00 29.50 20.50 1.03 MH 21.00 17.50 43.00 23.00 23.00 16.00 41.00 6.00 1.00 1.00 70.00 9.20

unit weight were used to prepare the test samples (Table 2). Since swelling potential of a soil also depends on the surcharge pressure applied to the sample, an initial surcharge pressure of 25 kPa was selected for the testing program. This pressure was estimated based on the depth of 12 m from which the soil was obtained.

Copyright by ASTM Int'l (all rights reserved); Thu Mar 22 13:13:52 EDT 2012 Downloaded/printed by Curtin University of Technology pursuant to License Agreement. No further reproductions authorized.

202

GEOTECHNICAL TESTING JOURNAL

Sample Preparation for Swelling Potential Tests To prepare remolded samples, the soil was first cut into small pieces and air-dried for 24 h, and then it was pulverized repeatedly using a plastic hammer. Because of its cohesive nature, the soil was then fully soaked for another 24 h. After soaking, the soil disintegrated into its individual components, and additional lumps were broken by hand. The soil was then placed in an oven at 105C for 24 h to ensure complete dryness. The dry soil was further pulverized to minus 10 sieve size. At this stage, the soil was ready for remolding. For performing swelling potential tests, an amount of dry soil required for the desired dry unit weight was weighed and mixed with stabilizers at 3, 6, and 9% by dry weight of the soil. The water needed for a specific water content was also weighed. The soiladditive mixture was mixed thoroughly with water until a wet homogenous mixture was achieved. The wet soil-additive was then placed into the mold and compacted to fit exactly the cutting ring. All remolded specimens were left in a desiccator for 24 h before testing. This process allowed the water to be distributed uniformly within the sample without any loss of moisture. Measurement of Swelling Potential Many researchers have used the term swelling potential; however, a clear definition of the term has not been established. Generally, swelling potential has been used to describe the ability of a soil to swell, in terms of volume change or the pressure required to prevent swelling. Therefore, it has two components: the swell percent that is defined as the percentage increase in height in relation to the original height, and the swell pressure that is designated as the pressure required to prevent swelling. Swell PercentThe swell percent of each test specimen was measured using the Loaded-Swell Method (Al-Rawas 1993). The apparatus used was the standard one-dimensional oedometer. The specimen in its ring was placed between two porous stones, with load plate resting on the upper porous stone. The consolidation cell was assembled in the consolidation frame. The specimen was then

loaded to a seating pressure of 25 kPa. The pressure was maintained until full settlement was achieved. The specimen was then flooded with water and allowed to swell under the seating load. Deformation readings were taken at 0, 0.5, 1.0, 2.0, 4.0, 8.0, 15.0, 30.0, 60.0, 120, and 1440 min, and then every 4 h on subsequent days until no further changes in readings were observed and full swell was attained. The increase in vertical height of a sample, expressed as a percentage, due to the increase in moisture content was designated as the Swell Percent Swell Percent h ho

where h is the change in height and ho is the initial height. Swell PressureThe swell pressure of each test specimen was measured using the Constant Volume Method (Al-Rawas 1993). The specimen placement in the consolidation cell and the seating pressure (25 kPa) were the same as in the swell percent test. The specimen was then given free access to water, while the volume was kept constant by continuous addition of loads at each vertical expansion of the tested specimen. Loads were applied using sand added to a plastic bag hanging from the loading arm. The addition of loads was continued until deformation ceased. At this stage, the swell pressure was calculated as the load required to prevent swelling divided by the area of the specimen. Results and Discussion Chemical Properties A summary of the chemical results of the untreated and treated soil samples is given in Table 3. The variations in cation exchange capacity, sodium and calcium cations, and pH values with addition of stabilizers are shown in Figs. 1 to 4, respectively. Figure 1 shows that CEC decreases with an increase in stabilizer content, except for samples treated with copper slag, which showed an opposite trend. Samples treated with slag-cement and granulated blast furnace slag (GBFS) showed a reduction in CEC from 70 to about 57 meq/100g (Table 3). This reduction is attributed to the cation ex-

TABLE 3Chemical results of the treated samples. Cations, % Chemical Stabilizer, % Untreated soil Cement by-pass dust 3 6 9 Copper slag 3 6 9 Slag-cement 3 6 9 Granulated blast furnace slag 3 6 9

a

Sodium 41.0 15.0 14.9 12.5 19.0 26.0 28.0 15.0 10.0 5.0 11.0 7.0 5.0

Calcium 6.0 67.2 37.9 27.7 11.0 4.0 4.0 22.0 27.0 29.0 25.0 28.0 32.0

Magnesium 1.0 6.3 6.9 7.6 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0

Potassium 1.0 13.6 16.1 17.4 1.0 1.0 3.0 3.0 2.0 2.0 3.0 2.0 1.0

CECa, meq/100 g 70.0 55.0 40.0 34.0 70.0 72.0 75.0 58.4 57.3 57.0 59.3 59.0 58.9

pH 9.2 10.9 11.0 11.1 9.0 9.0 9.0 9.2 9.3 9.4 8.9 9.0 9.0

CEC

cation exchange capacity.

Copyright by ASTM Int'l (all rights reserved); Thu Mar 22 13:13:52 EDT 2012 Downloaded/printed by Curtin University of Technology pursuant to License Agreement. No further reproductions authorized.

AL-RAWAS ET AL. ON EXPANSIVE SOILS

203

FIG. 1Cation exchange capacity versus stabilizer content.

FIG. 2Variations in Na with addition of stabilizers.

change capacity, which caused the replacement of Na by Ca provided by the additives. Cement by-pass dust (CBPD) treated samples showed a significant reduction in CEC (34%) with the addition of 9% CBPD (Fig. 1). It is believed that this reduction is due (92%) and lime (63.76%), and low to the high contents of Ca percentage of Na (0.1%). On the other hand, copper slag caused a slight increase of 5 meq/100g in CEC with the addition of 9% stabilizer. Copper slag contains a high percentage of Na (38%), and

low percentages of Ca (4%) and CaO (9.4%), which are responsible for the increase in CEC. Figure 2 shows the variations in Na contents with the additions of stabilizers. All treated samples showed a general reduction in Na with an increase in stabilizer content. Samples treated with slag-cement and granulated blast furnace slag (?) exhibited a significant reduction in Na . Both slag-cement and GBFS resulted in a reduction in Na content from 41% to 5%, which occurred with

Copyright by ASTM Int'l (all rights reserved); Thu Mar 22 13:13:52 EDT 2012 Downloaded/printed by Curtin University of Technology pursuant to License Agreement. No further reproductions authorized.

204

GEOTECHNICAL TESTING JOURNAL

FIG. 3Variations in Ca

with addition of stabilizers.

FIG. 4Variations in pH with addition of stabilizers.

the addition of 9% stabilizer. Samples treated with copper slag, on the other hand, showed an initial decrease in Na with the addition of 3%, followed by an increase with additions of 6 and 9%. However, the maximum Na concentration value at 9% addition was only 28%. The untreated soil had a high percentage of Na (41%), which was reduced upon addition of all stabilizers. It is surprising to note that the lowest value of Na was obtained with 9% addition of slagcement and GBFS and not by CBPD, which had the highest per(92%). It is believed that this is due to a combicentage of Ca

nation of both cation exchange and cementation processes, which resulted in the formation of new compounds with low exchangeable Na concentration. This explanation is supported by the fact that slag-cement and GBFS had higher concentrations of SiO2 and Al2O3 than CBPD (Table 1). Copper slag caused a reduction in Na from 41% to 28% at 9% stabilizer addition, in spite of its low contents of Ca (4%) and CaO (9.4%), which are responsible for the replacement of Na in the soil. has occurred with the addition of A general increase in Ca has increased CBPD, slag-cement, and GBFS (Fig. 3). The Ca

Copyright by ASTM Int'l (all rights reserved); Thu Mar 22 13:13:52 EDT 2012 Downloaded/printed by Curtin University of Technology pursuant to License Agreement. No further reproductions authorized.

AL-RAWAS ET AL. ON EXPANSIVE SOILS

205

TABLE 4Physical results of the treated samples. Soil Properties Chemical Stabilizers, % Untreated soil Cement by-pass dust 3 6 9 Copper slag 3 6 9 Slag-cement 3 6 9 Granulated blast furnace slag 3 6 9

a

Liquid Limit, % 50.0 65.2 60.4 56.3 48.0 50.0 52.0 54.0 50.0 49.0 50.0 49.0 46.0

Plastic Limit, % 29.5 37.6 40.7 38.9 28.0 29.0 22.5 24.0 26.0 27.0 20.5 22.5 24.0

Plasticity Index, % 20.5 27.6 19.7 17.4 20.0 21.0 29.5 30.0 24.0 22.0 29.5 26.5 22.0

Swell Percent 9.39 5.10 6.90 4.10 10.20 10.60 11.90 6.00 5.00 5.00 7.40 7.60 8.00

Swell Pressure, kPa 249 259 261 202 353 354 356 311 262 200 162 189 190

USCSa MH MH MH MH ML MH CH CH CH CL CH CL CL

USCS

unified soil classification system.

from 6% to 2628%, with the addition of 9% stabilizer. It is interesting to note that a sharp increase in Ca at 3% CBPD addition has occurred. This was followed by a gradual decrease with the addition of 6 and 9% stabilizer. It appears that, with the addition of 3% CBPD, an initial cation exchange process took place raising the in the soil; however, additional increments of CBPD conCa tributed to the formation of new cementitious compounds with relatively lower concentrations of Ca . Similar behavior was observed for samples treated with copper slag, which showed a slight increase in Ca at 3% addition and a reduction to 4% Ca at additions of 6 and 9%. Figure 4 shows the variation in pH with stabilizer content. Copper slag and GBFS treated soil exhibited a slight decrease in pH from 9.2 to 9.0, while CBPD treated soil showed a considerable increase in pH with the addition of CBPD. This behavior is expected due to the high percentage of lime (CaO) present in CBPD (63.76%). A slight increase in pH was observed for slag-cement treated samples, which is probably due to lime content. Atterberg Limits The liquid limit (LL), plastic limit (PL), and plasticity index (PI) of the untreated and treated samples are shown in Table 4 and Figs. 57. The samples treated with GBFS showed a slight reduction in liquid limit. Slag-cement caused a slight increase in liquid limit of 4% with the addition of 3% stabilizer. Cement by-pass dust caused a significant LL increase to 65.2% with the addition of 3% stabilizer, and then gradually decreased to liquid limit of 60.4% and 56.3% with the additions of 6 and 9% stabilizer, respectively. A different trend was observed in samples treated with copper slag where there was an initial slight reduction from 50% to 48% with addition of 3% stabilizer, followed by a gradual increase to 52% with the addition of 9% stabilizer. The plasticity index for samples treated with CBPD, slag-cement, and GBFS slag showed a similar behavior of an initial increase in plasticity index with the addition of 3% stabilizer, followed by a gradual decrease in plasticity index at 6 and 9% additions. It appears that the addition of 3% stabilizer had caused cation exchange only,

and with further additions (6 and 9%) new cementitious products were formed having lower values of liquid limit and plasticity index, and higher values of plastic limit (Table 4). Copper slag treated samples, on the other hand, showed a gradual increase in PI with a maximum value of 29.5% with stabilizer addition. The change in liquid limit and plasticity index values of the treated samples has altered the untreated soil classification (MH), as shown in Table 4 and Fig. 7. The soil designation for some of the treated samples remained the same, while for others, it was changed to CH (high plasticity clay) and CL (low plasticity clay). Swelling Potential The results depicted in Fig. 8 indicate that copper slag caused the maximum increase in swell pressure by about 100 kPa with all stabilizer additions. Samples treated with 3% CBPD, slag-cement, and GBFS exhibited different swell pressure values of 259, 311, and 162 kPa, respectively, while with 9% stabilizer addition, the swell pressure for these samples was reduced to about 200 kPa. Figure 9 shows the effect of the stabilizers used on the swell percent of the treated samples. All stabilizers reduced the swell percent with varying degrees, except copper slag, which caused a slight increase in swell percent. The variations of swell percent with time for all treated samples are shown in Fig. 10. Figures 8 and 9 showed that copper slag caused an increase in both swell percent and swell pressure of the treated soil, which is content (4%), and high values of Na attributed to its low Ca (38%) and CEC (76.2 meq/100g). Therefore, it appears that Na and CEC have promoted the activity or tendency of the treated soil, thereby increasing its swell percent, swell pressure, plasticity index, and CEC (Tables 3 and 4). The maximum swell percent and swell pressure were attained with the addition of 3% copper slag, which remained relatively the same with further additions (6 and 9%). The results showed the effect of the Ca and Na and CEC of the stabilizers on the swell percent and swell pressure of the soil. Therefore, prior knowledge of the chemical composition to determine Na , Ca , and CEC of the stabilizers will help to predict the effectiveness of soil additives.

Copyright by ASTM Int'l (all rights reserved); Thu Mar 22 13:13:52 EDT 2012 Downloaded/printed by Curtin University of Technology pursuant to License Agreement. No further reproductions authorized.

206

GEOTECHNICAL TESTING JOURNAL

FIG. 5Effect of stabilizer addition on liquid limit.

FIG. 6Effect of stabilizer addition on plasticity index.

Conclusions The main conclusions drawn from this study are as follows: 1. The cement by-pass dust (CBPD), slag-cement, and granulated blast furnace slag (GBFS) treated samples showed a reduction in cation exchange capacity (CEC) with an increase in the stabilizer content. This is attributed to the replacement provided by the additives. On the other of Na by Ca hand, copper slag treated samples exhibited an increase in CEC, which could be due to the high amount of Na present in copper slag.

2. All treated samples exhibited a significant reduction in Na , except for the copper slag treated samples, where the reduction was insignificant. An opposite trend was observed for Ca , except for copper slag treated samples, which showed a slight reduction. The CBPD treated samples showed a sharp increase in Ca at the addition of 3%, followed by a gradual decrease with further additions. It appears that the addition of 3% CBPD is sufficient for cation exchange giving rise to Ca , and further additions of the stabilizer result in the formation of new cementitious compounds. The CBPD caused a significant increase in the pH value, which is due to the high percentage of lime present in CBPD.

Copyright by ASTM Int'l (all rights reserved); Thu Mar 22 13:13:52 EDT 2012 Downloaded/printed by Curtin University of Technology pursuant to License Agreement. No further reproductions authorized.

AL-RAWAS ET AL. ON EXPANSIVE SOILS

207

3. The liquid limit and plasticity index of the treated samples showed similar behavior of an initial increase at the addition of 3% stabilizer, followed by a gradual decrease, while an opposite trend was observed for copper slag treated samples. This is due to the cation exchange process that took place at the addition of 3% stabilizers. 4. The copper slag treated samples showed consistent increase in swell pressure and swell percent. However, the other

treated samples exhibited a reduction in swell percent with varying degrees. The CBPD, slag-cement, and GBFS treated samples showed different behavior for the swell pressure, but at 9% addition they all have similar reduction. The swell percent and swell pressure reduction ranges were 1.395.29% and 087 kPa, respectively. 5. The study showed the effect of sodium and calcium cations, and cation exchange capacity of the stabilizers on the liquid

FIG. 7Liquid limit versus plasticity index for treated samples.

FIG. 8Effect of stabilizer addition on swell pressure.

Copyright by ASTM Int'l (all rights reserved); Thu Mar 22 13:13:52 EDT 2012 Downloaded/printed by Curtin University of Technology pursuant to License Agreement. No further reproductions authorized.

208

GEOTECHNICAL TESTING JOURNAL

FIG. 9Effect of stabilizer addition on swell percent.

FIG. 10Variation of swell % with time.

Copyright by ASTM Int'l (all rights reserved); Thu Mar 22 13:13:52 EDT 2012 Downloaded/printed by Curtin University of Technology pursuant to License Agreement. No further reproductions authorized.

AL-RAWAS ET AL. ON EXPANSIVE SOILS

209

limit, plasticity index, swell percent, and swell pressure of the treated soil. Therefore, these parameters can be taken as good indicators of the effectiveness of soil stabilizers. Acknowledgments The authors are very grateful to Oman Cement Company for providing CBPD, slag-cement, and GBFS, and for carrying out the chemical analyses on these stabilizers. Many thanks are due to the technical staff of the Departments of Civil Engineering, and Soils and Water (College of Agriculture) at Sultan Qaboos University for carrying out chemical tests. References Abduljauwad, S. N., 1995, Improvement of Plasticity and Swelling Potential of Calcareous Expansive Clays, Geotechnical Engineering Journal, Southeast Asian Geotechnical Society, SEAGS, Vol. 26, No. 1, pp. 316. Al-Rawas, A. A., 1993, The Characteristics of Expansive Soils and Rocks in Northern Oman, Ph.D. Thesis, University of Strathclyde, Glasgow, Scotland, UK. Al-Rawas, A. A., 1999, The Factors Controlling the Expansive Nature of the Soils and Rocks of Northern Oman, Engineering Geology, Vol. 53, pp. 327350. Al-Rawas, A. A., Sutherland, H., Hago, A. W., Basma, A. A. and Al-Shihi, B., 1998, Quantitative Analysis of Clay Minerals Using X-ray Diffraction Technique - Part I, Journal of Science and Technology, Sultan Qaboos University, Sultanate of Oman, Volume 3, pp. 3139. Al-Rawas, A. A. and Qamaruddin, M., 1998, Construction Problems of Engineering Structures Founded on Expansive Soils and Rocks in Northern Oman, Building and Environment Journal, Vol. 33, Nos. 23, pp. 159171. ASTM C 114, Test Methods for Chemical Analysis of Hydraulic Cement, 1999. Arman, A. and Munfakh, G. A., 1972, Lime Stabilization of Organic Soils, Highway Research Record, No. 381, Washington, D.C., pp. 3745. Basma, A. A., Al-Rawas, A. A., Al-Saadi, S. N., and Al-Zadjali, T. F., 1998, Stabilization of Expansive Clays in Oman, Environmental and Engineering Geoscience, Vol. IV, No. 4, pp. 503510. British Standard, 1990, British Standard 1377, Methods of Test for Soils for Civil Engineering Purposes, British Standards Institution, London. Chapman, H. D., 1965, Cation Exchange Capacity, in Methods of Soil Analysis, American Society of Agronomy, C. A. Black et al., Eds., Madison, WI, pp. 891901. Chu, S. C. and Kao, H. S., 1993, A Study of Engineering Properties of a Clay Modified by Fly Ash and Slag, Proceedings, Fly Ash for Soil Improvement, American Society of Civil Engineers, Geotechnical Special Publication, No. 36, pp. 8999. Collins, R. J. and Ciesielski, S. K., 1994, Production and Use of Industrial Wastes, Synthesis of Highway Practice 199Recycling and Use of Waste Materials and By-Products in Highway Construction, Transportation Research Board, National Research Council, Washington, D.C., Chapter 3. Croft, J. B., 1967, The Influence of Soil Mineralogical Composition on Cement Stabilization, Geotechnique, London, UK, Vol. 17, pp. 119135.

Dakshanamurthy, V. and Raman, V., 1973, A Simple Method of Identifying an Expansive Soil, Soils and Foundations Journal, Japanese Society on Soil Mechanics and Foundation Engineering, Vol. 13, No. 1, pp. 79104. Fang, H. Y., 1991, Foundation Engineering Handbook, 2nd ed., Van Nostrand Reinhold Publishing Company. Gromko, G. J., 1974, Review of Expansive Soils, Journal of the Geotechnical Engineering Division, American Society for Civil Engineers, ASCE 100, GT6, pp. 667687. Little, D. N., Thompson, M. R., Terrell, R. L., Epps, J. A., and Barenberg, E. J., 1987, Soil Stabilization for Roadways and Airfields, Final Report, Submitted to the Air Force Engineering and Services Center, Tyndall Air Force Base, FL. McCoy, W. J., 1971, Use of Waste Kiln Dust for Soil Consolidation, Lehigh Portland Cement Company, Allentown, PA. Mitchell, J. K., 1986, Practical Problems from Surprising Soil Behavior, Journal of the Geotechnical Engineering Division, American Society of Civil Engineers, ASCE, Vol. 112, No. 3, pp. 259289. Morgan, S. and Halff, A. H., 1984, Oil Sludge Solidification Using Cement Kiln Dust, Journal of Environmental Engineering, American Society for Civil Engineers, ASCE, Vol. 10, No. 5. Nelson, J. D. and Miller, J. D., 1992, Expansive Soils: Problems and Practice in Foundation and Pavement Engineering, John Wiley Publication. Lime Stabilization Construction Manual, Bulletin 326, National Lime Association, Arlington, VA, 1985. Omanian Standard 25, Methods of Testing CementChemical Tests, Ministry of Commerce and Industry, Directorate General for Specifications and Measurements, Sultanate of Oman, 1979. Qubain, B. S., Seksinsky, E. J., and Li, J., 2000, Incorporating Subgrade Lime Stabilization into Pavement Design, Transportation Research Record, No. 1721, Transportation Research Board, National Research Council, Washington, D.C., pp. 38. Rogers, C. D. and Glendinning, S., 2000, Lime Requirement for Stabilization, Transportation Research Record, No. 1721, Transportation Research Board, National Research Council, Washington, D.C., pp. 918. Sivapullaiah, P. V., Sridharan, A., Prashanth, J. P., and Raju, K. V. B., Role of Fabric and Bonding in the Lime Stabilization of Soils, Proceedings of the 4th International Conference on Civil Engineering, Sharif University of Technology, Tehran, Iran, Vol. 2, 46 May 1997, pp. 345352. Stocker, P. T., 1972, Diffusion and Diffuse Cementation in Lime and Cement Stabilized Clayey Soils, Special Report 8, Australian Road Research Board, Victoria, Australia. Thompson, M. R., 1969, Engineering Properties of Lime-Soil Mixtures, Journal of Materials, American Society for Testing and Materials, Vol. 4, No. 4, pp. 968969. Van der Merwe, D. H., 1975, Contribution to Specialty Session B, Current Theory and Practice for Building on Expansive Clays, Proceedings of the 6th Regional Conference for Africa on Soil Mechanics and Foundation Engineering, Durban, Vol. 2, pp. 166167. Zaman, M., Laguros, J. G., and Sayah, A., Soil Stabilization Using Cement Kiln Dust, Proceedings of the 7th International Conference on Expansive Soils, Dallas, TX, Vol. 1, 35 August 1992, pp. 347351.

Copyright by ASTM Int'l (all rights reserved); Thu Mar 22 13:13:52 EDT 2012 Downloaded/printed by Curtin University of Technology pursuant to License Agreement. No further reproductions authorized.

Anda mungkin juga menyukai

- Expansive Soils PaperDokumen7 halamanExpansive Soils PaperM Ramzan QadirBelum ada peringkat

- Soil testing methods guideDokumen2 halamanSoil testing methods guideDr Wong Kim YuenBelum ada peringkat

- Soil Stabilization by Using: Fly AshDokumen12 halamanSoil Stabilization by Using: Fly AshRavi HirulkarBelum ada peringkat

- Feasibility of Using 100% Recycled Asphalt Pavement Mixtures ForDokumen81 halamanFeasibility of Using 100% Recycled Asphalt Pavement Mixtures ForMalek Abou HarbBelum ada peringkat

- Slurry W Alls: Design, Construction, and Quality Contro/: Ichard - SoDokumen4 halamanSlurry W Alls: Design, Construction, and Quality Contro/: Ichard - SoAyman SobhyBelum ada peringkat

- Using Pindan Sand-Clay in Pavement Structural LayersDokumen15 halamanUsing Pindan Sand-Clay in Pavement Structural Layersganguly147147Belum ada peringkat

- Aashto T307Dokumen27 halamanAashto T307Viviana CruzBelum ada peringkat

- Swelling PressureDokumen26 halamanSwelling Pressureteomalancu100% (1)

- Design of Hot Mix Asphalt Using Bailey Method of GradationDokumen8 halamanDesign of Hot Mix Asphalt Using Bailey Method of GradationInternational Journal of Research in Engineering and TechnologyBelum ada peringkat

- C 1005 - 00 QzewmduDokumen3 halamanC 1005 - 00 QzewmduGarcia ManuelBelum ada peringkat

- Triaxial Testing of Granular Soil (Colliat-Dangus, 1988)Dokumen21 halamanTriaxial Testing of Granular Soil (Colliat-Dangus, 1988)Abraham FIgueroa ARevaloBelum ada peringkat

- 2013 Asem13 Geotubes FemDokumen11 halaman2013 Asem13 Geotubes FemJose Leo MissionBelum ada peringkat

- Soil Stabilization Using Lime: Presented By: Harshit Agarwal Rahul Sharma Ashish ChakroborthyDokumen19 halamanSoil Stabilization Using Lime: Presented By: Harshit Agarwal Rahul Sharma Ashish ChakroborthyRahulSharmaBelum ada peringkat

- Assessment of Liquefaction Susceptibility of Fine Grained Soils Bray - SancioDokumen187 halamanAssessment of Liquefaction Susceptibility of Fine Grained Soils Bray - SancioFernando ChiribogaBelum ada peringkat

- Final-Soil Reinforcement Material - A Review On Its Application-BaruDokumen6 halamanFinal-Soil Reinforcement Material - A Review On Its Application-BaruMuhammad Farhan GulBelum ada peringkat

- Stabilization of Soil in Road Construction Using Lime and Fly AshDokumen9 halamanStabilization of Soil in Road Construction Using Lime and Fly AshIJRASETPublicationsBelum ada peringkat

- Rilem Ii.4Dokumen4 halamanRilem Ii.4manil_5Belum ada peringkat

- Asadzadeh - Direct Shear Testing On A Rockfill MaterialDokumen18 halamanAsadzadeh - Direct Shear Testing On A Rockfill MaterialDavid CastañoBelum ada peringkat

- 3 Bray Liquefaction Peru NOV2014Dokumen48 halaman3 Bray Liquefaction Peru NOV2014marinex_84Belum ada peringkat

- No Fines ConcreteDokumen5 halamanNo Fines ConcretedannyBelum ada peringkat

- Shear Strength of SoilDokumen43 halamanShear Strength of SoilChristian Jude LegaspiBelum ada peringkat

- Compaction & Its Consequances PDFDokumen12 halamanCompaction & Its Consequances PDFHamidullah Asady WardakBelum ada peringkat

- Friction Angles for Sand, Gravel and Rockfill DataDokumen13 halamanFriction Angles for Sand, Gravel and Rockfill Dataasder02Belum ada peringkat

- Astm D4829Dokumen4 halamanAstm D4829Felipe Ignacio Córdoba rebolledoBelum ada peringkat

- Day, R. W. (1995) - Engineering Properties of Diatomaceous Fill. Journal of Geotechnical EngineeringDokumen3 halamanDay, R. W. (1995) - Engineering Properties of Diatomaceous Fill. Journal of Geotechnical EngineeringDaniel Felipe Rodriguez RamirezBelum ada peringkat

- Lecture 2-1Dokumen55 halamanLecture 2-1Aftab hussainBelum ada peringkat

- Micro Pile Liquefaction MitigationDokumen6 halamanMicro Pile Liquefaction MitigationViswanathan NaraBelum ada peringkat

- Job-2 Relative DensityDokumen5 halamanJob-2 Relative DensityUmair JuttBelum ada peringkat

- Stabilization of Expansive SoilDokumen4 halamanStabilization of Expansive SoilSamara LujanBelum ada peringkat

- Shrinkage of Clays Unsat 06Dokumen12 halamanShrinkage of Clays Unsat 06jcazBelum ada peringkat

- Us-Sa ReportDokumen154 halamanUs-Sa Reportapi-319627739100% (1)

- Challenges Associated With Expansive Soils and Remedial MeasuresDokumen13 halamanChallenges Associated With Expansive Soils and Remedial MeasuresSaurav BhattacharjeeBelum ada peringkat

- Modelling Study On The Geotextile, Geogrid and Steel Strip Reinforced SlopesDokumen15 halamanModelling Study On The Geotextile, Geogrid and Steel Strip Reinforced SlopesAnupEkboteBelum ada peringkat

- Compressive Strength of Bituminous Mixtures: Standard Test Method ForDokumen5 halamanCompressive Strength of Bituminous Mixtures: Standard Test Method Foraastha mehtaBelum ada peringkat

- Using Density To Determine The Sugar Content in Commercial BeveragesDokumen12 halamanUsing Density To Determine The Sugar Content in Commercial BeveragesMax DornelesBelum ada peringkat

- Delayed Ettringite Formation in ConcreteDokumen1 halamanDelayed Ettringite Formation in ConcretemakhsmyBelum ada peringkat

- Method B12 - The Determination of The Effect of Soluble Deleterious Material in Fine Aggregate For Concrete.Dokumen5 halamanMethod B12 - The Determination of The Effect of Soluble Deleterious Material in Fine Aggregate For Concrete.GUO LEIBelum ada peringkat

- Astm D-5239 PDFDokumen3 halamanAstm D-5239 PDFgtorrentes1Belum ada peringkat

- Faroukhi - Monogram On Thermal CoductivityDokumen151 halamanFaroukhi - Monogram On Thermal CoductivitynitingkulkarniBelum ada peringkat

- Asphalt Pavements A PracticalDokumen2 halamanAsphalt Pavements A PracticalMahmoudRadi0% (1)

- Chapter 1 (Sandy Lean Clay)Dokumen17 halamanChapter 1 (Sandy Lean Clay)John Raymund TanugaBelum ada peringkat

- Ground ImprovementDokumen17 halamanGround Improvementpatelahmad77Belum ada peringkat

- Lime Stabilization of Expansive SoilDokumen14 halamanLime Stabilization of Expansive Soilعبدالرحمن العليميBelum ada peringkat

- Definition of PavementDokumen7 halamanDefinition of PavementSujon AhmmedBelum ada peringkat

- PreviewpdfDokumen51 halamanPreviewpdfIrfan WiranataBelum ada peringkat

- Matos Road Proposal Offers Thin, Strong and Cost-Effective PavementDokumen29 halamanMatos Road Proposal Offers Thin, Strong and Cost-Effective PavementTarik Faisal Faisal HabibBelum ada peringkat

- Characterising Engineering Properties of Undisturbed Sedimentary Rock MassesDokumen9 halamanCharacterising Engineering Properties of Undisturbed Sedimentary Rock Massesecossich123100% (1)

- D3551-08 Standard Practice For Laboratory Preparation of Soil-Lime Mixtures Using Mechanical MixerDokumen2 halamanD3551-08 Standard Practice For Laboratory Preparation of Soil-Lime Mixtures Using Mechanical MixerFaten Abou ShakraBelum ada peringkat

- Physical Properties of Sands and Gravels for FiltrationDokumen12 halamanPhysical Properties of Sands and Gravels for FiltrationFernando Alvarado BlohmBelum ada peringkat

- BS ConsolidationDokumen25 halamanBS ConsolidationKamukwema johnBelum ada peringkat

- Determination of Degree of Saturation of Soil Samples by B Value MeasurementDokumen5 halamanDetermination of Degree of Saturation of Soil Samples by B Value Measurementcamillelele100% (1)

- ASTM Code For CU Triaxial Test PDFDokumen13 halamanASTM Code For CU Triaxial Test PDFAhmedHossainBelum ada peringkat

- As 1289.6.2.1-2001 Methods of Testing Soils For Engineering Purposes Soil Strength and Consolidation TestsDokumen2 halamanAs 1289.6.2.1-2001 Methods of Testing Soils For Engineering Purposes Soil Strength and Consolidation TestsSAI Global - APACBelum ada peringkat

- General Report S5 Rigid Inclusions and Stone Columns: June 2012Dokumen39 halamanGeneral Report S5 Rigid Inclusions and Stone Columns: June 2012Vetriselvan Arumugam100% (1)

- D 2974 - 00 PDFDokumen4 halamanD 2974 - 00 PDFashrafBelum ada peringkat

- Roberson 2012 PDFDokumen22 halamanRoberson 2012 PDFAdy NugrahaBelum ada peringkat

- Review of Peat Strength, Peat Characterisation and Constitutive Modelling of Peat With Reference To LandslidesDokumen24 halamanReview of Peat Strength, Peat Characterisation and Constitutive Modelling of Peat With Reference To LandslidesAnbasBelum ada peringkat

- C 11 - R0 Sand Equivalent Value - Barka Batching PlantDokumen1 halamanC 11 - R0 Sand Equivalent Value - Barka Batching PlantUtpal Mondal100% (1)

- Top Job Interview Questions and AnswersDokumen4 halamanTop Job Interview Questions and Answersagus_ip3808Belum ada peringkat

- Engineering Road Note 9 - May 2012 - Uploaded To Main Roads Web SiteDokumen52 halamanEngineering Road Note 9 - May 2012 - Uploaded To Main Roads Web SiteRahma SariBelum ada peringkat

- Engineering Road Note 9 - May 2012 - Uploaded To Main Roads Web SiteDokumen52 halamanEngineering Road Note 9 - May 2012 - Uploaded To Main Roads Web SiteRahma SariBelum ada peringkat

- Cement Stabilisation PracticeDokumen10 halamanCement Stabilisation PracticeAnonymous Re62LKaACBelum ada peringkat

- TP 06Dokumen10 halamanTP 06agus_ip3808Belum ada peringkat

- Subgrade Construction: Pav2-1 Pav2-2Dokumen6 halamanSubgrade Construction: Pav2-1 Pav2-2agus_ip3808Belum ada peringkat

- Effect of Alternating StressDokumen11 halamanEffect of Alternating Stressagus_ip3808Belum ada peringkat

- Identify Sedimentary RocksDokumen45 halamanIdentify Sedimentary RocksRomel PozoBelum ada peringkat

- Lab Test ResultDokumen4 halamanLab Test ResultPrabha KaranBelum ada peringkat

- Science at The Environment Agency - Essay - United State Literature - Professor Mike DepledgeDokumen343 halamanScience at The Environment Agency - Essay - United State Literature - Professor Mike Depledgeadnan-hBelum ada peringkat

- Flotationof Iron Ores AReview 3Dokumen31 halamanFlotationof Iron Ores AReview 3ephremBelum ada peringkat

- Viscose Fabric Quality ListDokumen1 halamanViscose Fabric Quality ListParth GolakiyaBelum ada peringkat

- Hydraulic Breakers - Mining ApplicationsDokumen29 halamanHydraulic Breakers - Mining ApplicationsFirman CahyadiBelum ada peringkat

- Fundamentals of Soil ScienceDokumen92 halamanFundamentals of Soil ScienceVikas Tiwari100% (1)

- 1990 Prof. J.B. Burland On The Compressibility and Shear Strength of Natural Clays Vol. 40 No. 3 PP 329-378Dokumen50 halaman1990 Prof. J.B. Burland On The Compressibility and Shear Strength of Natural Clays Vol. 40 No. 3 PP 329-378Mikis Palates0% (1)

- CIVL 314-2013 (Week 7) Structural Design of Retaining Walls-StudentDokumen55 halamanCIVL 314-2013 (Week 7) Structural Design of Retaining Walls-StudentAsfin HaqueBelum ada peringkat

- Highway Compaction Research: Methods, Equipment and PracticesDokumen92 halamanHighway Compaction Research: Methods, Equipment and PracticesyawhgihBelum ada peringkat

- Specularite-Alunite Mineralization atDokumen12 halamanSpecularite-Alunite Mineralization atabaBelum ada peringkat

- Isotope Systematics and Fluid InclusionDokumen17 halamanIsotope Systematics and Fluid InclusionJULIO CONDEZOBelum ada peringkat

- 8237Dokumen6 halaman8237FARY MARIYAMBelum ada peringkat

- Soil Component and Its PropertiesDokumen21 halamanSoil Component and Its PropertiesThe Musician DharanBelum ada peringkat

- An Experimental Study On Stabilization of Expansive Soil by Copper SlagDokumen14 halamanAn Experimental Study On Stabilization of Expansive Soil by Copper SlagIJRASETPublicationsBelum ada peringkat

- Annual Qualified Persons Report for Konongo Gold Project, GhanaDokumen150 halamanAnnual Qualified Persons Report for Konongo Gold Project, GhanaJimmy TorresBelum ada peringkat

- Lesson IV - Stresses in SoilDokumen6 halamanLesson IV - Stresses in SoilLight HouseBelum ada peringkat

- NS1s Unit 5 7.2 ReviewerDokumen13 halamanNS1s Unit 5 7.2 ReviewerRia Franchesca MALALAYBelum ada peringkat

- Soil Classification GuideDokumen21 halamanSoil Classification GuideSalih MohayaddinBelum ada peringkat

- Water Retention of Soil LabDokumen3 halamanWater Retention of Soil LabKafara Ellis100% (1)

- Stratigraphy and geologic history of Central AmericaDokumen51 halamanStratigraphy and geologic history of Central AmericaSohini ChatterjeeBelum ada peringkat

- Hydrologic and Hydraulic Design ConceptDokumen53 halamanHydrologic and Hydraulic Design ConceptlimenihBelum ada peringkat

- Preliminary Boring Log: Clays, Lowly Plastic, Very MoistDokumen1 halamanPreliminary Boring Log: Clays, Lowly Plastic, Very MoistVicky MunienBelum ada peringkat

- Liquefaction Triggering Criterion Using Shake Table Test: Dr. S. R. Pathak, M.P.Kshirsagar, M. S. JoshiDokumen11 halamanLiquefaction Triggering Criterion Using Shake Table Test: Dr. S. R. Pathak, M.P.Kshirsagar, M. S. JoshiCristobal MadridBelum ada peringkat

- Engineering Geology Lab Manual: St. Martin'S Engineering CollegeDokumen82 halamanEngineering Geology Lab Manual: St. Martin'S Engineering CollegeJai JadavBelum ada peringkat

- Presentation Raymond AuerbachDokumen16 halamanPresentation Raymond AuerbachQuynh H NguyenBelum ada peringkat

- Aashto m288 Recommended Products ChartDokumen1 halamanAashto m288 Recommended Products ChartГригорий ЛевашовBelum ada peringkat

- Yarn BrochureDokumen21 halamanYarn Brochuresivasankari11Belum ada peringkat

- Site Planning Assignment On Soil and Its Types: Characteristics Formation Properties TypesDokumen12 halamanSite Planning Assignment On Soil and Its Types: Characteristics Formation Properties TypesShee JaBelum ada peringkat

- Soil PollutionDokumen6 halamanSoil PollutionBipinBelum ada peringkat