Captulo 6 Referencias Bibliograficas/capitulo 6

Diunggah oleh

aluminaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Captulo 6 Referencias Bibliograficas/capitulo 6

Diunggah oleh

aluminaHak Cipta:

Format Tersedia

Lmites de la PM convencional (loose sintering) en la obtencin de Ti poroso para aplicaciones biomdicas

CAPITULO VI

REFERENCIAS BIBLIOGRFICAS

Crowninshield. R. D.. et al. Clinical Orthopaedics and Related Research. 2006. Vol. 443. pgs. 266-272. www.datamonitor.com. Brunski. J.B. Biomaterials Science: An Introduction to Materials in Medicine. [ed.] P.D. Ratner. et. al. Segunda edicin. California : Elsevier Academic Press. 2004. pg. 137. Ritchie. R. O. ASM. St. Paul. Minnesota: s.n.. 2004. www.biomet.es. www.lafitt-sa.com. Wehmller. M. y otros. CAD/CAM - prefabricated titanium implants for large skull defects-clinical experience with 166 patients from 1994 to 2000. International Congress series. 2004. Vol. 1268. pgs. 667-672. Collins. E. W. The Physical Metallurgy of Titanium Alloys. Ohio: ASM. Metals Park. 1984. Currey. J. Handbook of Biomaterials Properties. [ed.] J. H. Black y Garth. London: Springer - Velag. pg. 629.

2 3

4 5 6 7

10 Bonfield. W.. et al.. Biomaterials. 1981. Vol. 2(3). pgs. 185-186. 11 Ryan. G.. et al.. 2006. Vol. 27(13). pgs. 2651-2670. 12 Banhart. J.Progress in Materials Science. 2001. Vol. 46 (6). pgs. 559-632. 13 Krner. C. Singer. R.F. Advanced Engineering Materials. 2000.Vol. 24 (4). pgs. 159-165. 14 Chino. Y.. Dunand. D. C. Acta Materialia. 2008. Vol. 56 (1). pgs. 105-113. 15 Ryan. G. E.. et al. Biomaterials. 2008. Vol. 29(27). pgs. 3625-3635. 1 CAPITULO VI

Lmites de la PM convencional (loose sintering) en la obtencin de Ti poroso para aplicaciones biomdicas 16 Thieme. M.. et al.. Journal of Materials Science: Materials in Medicine. 2001. Vol. 12 (3). pgs. 225-231. 17 Vamsi Krishna. B. y al.. et. Acta Biomaterialia. Vol. 4 (3). 2008. pgs. 697-706. 18 Deckard. C. y Beaman. J. J.. American Society of Mechanical Engineers. Production Engineering Division (PED). 1988.Vol. 33. pgs. 191-197. 19 Traini. T. y al.. et. Dental Materials. Vol. 24(11). 2008. pgs. 1525-1533. 20 Xiang. L.. y otros.. Matrials Letters. 2009. Vol. 63. pgs. 403-405. 21 Parthasarathy. J.. y otros.. Journal of the Mechanical Behavior of Biomedica Materials. 2010. Vol. 3(3). pgs. 249-259. 22 Asaoka. K.. et al.. Journal of Biomedical Materials Research. Vol. 19 (6). 1985. pgs. 699-173. 23 Cirincione. R.. et al. Processing and Properties of Lightweight Cellular Metals and Structures. 2002. pg. 189. 24 Dunand. D. C. Advanced Engineering Materials. Vol. 6 (6). 2004. pgs. 369376. 25 Schuh. C.. et.al. Acta Materialia. Vol. 48(8). 2000. pgs. 1639-1653. 26 Taylor. N.. Acta Metallurgica Et Materialia. Vol. 41(3). 1993. pgs. 955-965. 27 Spoerke. E. D.. et al.. Journal of Biomedical Materials Research - Part A. Vol. 84(2). 2008. pgs. 402-412. 28 Davis. N. G.. et al.. Journal of Materials Research. Vol. 16(5). 2001. pgs. 1508-1519. 29 Kearns. M. W.. et al.. Metals and Materials. Vol. 3(2). 1987. pgs. 85-88. 30 Ricceri. R.. Matteazzi. P. International Journal of Powder Metallurgy. Vol. 39(3). 2003. pgs. 53-61. 31 Andersen. O.. et al.. Advanced Engineering Materials. Vol. 2(4). 2000. pgs. 192-195. 32 Tuchinskiy. L.. Loutfy. R. Materials and Processes for Medical Devices ASM. 2003.. pg. 1. 33 Wen. C. E.. et al.. Scripta Materialia. Vol. 45(10). 2001. pgs. 1147-1153. 2 CAPITULO VI

Lmites de la PM convencional (loose sintering) en la obtencin de Ti poroso para aplicaciones biomdicas 34 Wen. C. E.. et al.. Journal of Materials Science: Materials in Medicine. Vol. 13(4). 2002. pgs. 397-401. 35 Wen. C.E.. et al.. Journal of Materials Research. Vol. 17(10). 2002. pgs. 26332639. 36 Niu. W.. et al.. Materials Science and Engineering. Vol. 506(1-2). 2009. pgs. 148-151. 37 Bansiddhi. A. y Dunand. D. C. s.l.: Acta Biomaterialia. Vol. 6(4). 2008. pgs. 1996-2007. 38 Khl. M.. y otros. Advanced Engineering Materials. Vol. 11(12). 2009. pgs. 959-968. 39 Okazaki. K.. Reviews in Particulate Materials. 1994.Vol. 2. pgs. 215-269. 40 Okasaki. K.. et al.. Journal of Biomedical Materials Research. Vol. 25(12). 1991. pgs. 14717-1430. 41 Lee. W. H.. Hyun. C. Y.. Journal of Biomedical Processing Technology. Vol. 18925(1-3). 2007. pgs. 219-223. 42 Miyao. R. 6. J. Dent. Mater.. 2001.Vol. 20. pgs. 344-355. 43 Montealegre-Melendez. I.. Neubauer. E.. Danninger. H. Powder Metallurgy. Vol. 52(4). 2009. pgs. 322-328. 44 http://es.wikipedia.org/wiki/Material_biocompatible

45 Daniel ngel Bellido Aguilar. Los biomateriales. ALEPH ZERO 46. Octubre Diciembre, 2007. 46 Update on bone cell biology. Arnett, T. 1990, Eur. J. Orthod, Vol. 12, pgs. 8190. 47 Cellular biology of bone-resorbing cells. Athanasou, N. 1996, J bone joint Surg Am, Vol. 78, pgs. 1096-1112. 48 Bone remodeling. Hill, P. 1998, Br J Orthod, Vol. 25, pgs. 101-107. 49 Hill Buckwalter, J., y otros. Bone biology I & II. s.l. : Instr Course Lect 45, 1996. 50 Pavn Palacio, J.J. Biomecnica del cuerpo humano: comportamiento mecnico del hueso. 3 CAPITULO VI

Lmites de la PM convencional (loose sintering) en la obtencin de Ti poroso para aplicaciones biomdicas 51 Mehelich, C.S., Van Kiuken, L. y Woelfel, M.M. Metals Handbook: Surface Engineering. Ohio : ASM, 1995. pgs. 138-149. Vol. 5 52 Ratner, B.D. Biomaterials Science: An Introduccion to Materials in Medicine. [ed.] D. Ratner, y otros. 1 edicin. California : Academic Press, 2004. pg. 864. 53 Gotfredsen, K., y otros. 2, 1995, Journal of Biomedical Materials Research, Vol. 29, pgs. 1223-1231. 54 Bowers, K.T., y otros., The international journal of oral & maxillogacial implants, Vol. 7(3), 1992, pgs. 302-310. 55 Henrich, V. E. y Cox, P.A. The Surface Science of Metal Oxides. New York : Cambrigge University Press., 1994. pg. 478. 56 Brunski, J. B., Clinical Materials, Vol. 10(3), 1992, pgs. 153-201. 57 Bobyn, J. D., y otros. 1992, Clinical Orthopaedics an related research, Vol. 274, pgs. 79-96. 58 Hench, L. L. y Anderson, . An Introduction to Bioceramics. [ed.] L.L. Hench y J. Wilson. London : World Scientific Pub. Co., 1993. pg. 386. 59 Cameron, H. U. Bone implant Interface. [ed.] R. Hunley. St. Luis : Mosby, 1994. pg. 390. 60 Cheal, E.J., Spector, M. y Hayes, W. C. 3, 1992, Journal of Orthopaedic Research, Vol. 10, pgs. 405-422. 61 Dujovne, A. R., y otros., Journal of Arthroplasty, Vol. 8(1), 1993, pgs. 7-22. 62 Huiskes, R., Weinans, H. y Vanrietbergen, B. 1992, Clinical Orthopaedics and Related Research, Vol. 274, pgs. 124-134. 63 Summer, D.R. y Galante, J. O. 1992, Clinical Orthopaedics and Related Research, Vol. 274, pgs. 202-212. 64 Spoerke, E. D., y otros., Acta Biomaterialia, Vol. 1(5), 2005, pgs. 523-533. 65 Albrektsson, T., y otros., ActanOrthopaedica Scandinavica, Vol. 52(2), 1981, pgs. 155-170. 66 Cook, S.D., y otros., Clinical Orthopaedics and Related Research, Vol. 232,1988, pgs. 225-243. 67 Brunette, D. M., y otros. Titanium in Medicine. s.l. : Spinger, 2001. pg. 1019. 4 CAPITULO VI

Lmites de la PM convencional (loose sintering) en la obtencin de Ti poroso para aplicaciones biomdicas 68 Degroot, K., y otros. : s.n., Journal of Biomedical Materials research, Vol. 21(12), 1987, pgs. 1375-1381. 69 Filiaggi, M. J., Coombs, N. A. y Pilliar, R.M. 10, 1991, Journal of Biomediacal Materials Research, Vol. 25, pgs. 1211-1229. 70 Bonfield, W., y otros., Biomaterials, Vol. 2(3), 1981, pgs. 185-186. 71 Chang, F.K., Perez, J.L. y Davidson, J.A. Journal o Biomedical Materials Research, Vol. 24(7), 2002, pgs. 873-899. 72 Stamboulis, A.G., Boccaccini, A.R. y Hench, L.L., Advanced Engineering Materials, Vol. 4(3), 2002, pgs. 105-109. 73 Wang, M., Biomaterials, Vol. 24(13), 2003, pgs. 2133-2151. 74 Wang, M., Hench, L.L. y Bonfield, W., Journal of Biomedical Materials Research, Vol. 42(4), 1998, pgs. 577-586. 75 Christel, P., y otros. A2, , Journal of Biomedical Materials Research - Applied Biomaterials, Vol. 21,1987, pgs. 191-218. 76 Long, M. y Rack, H.J., Biomaterials, Vol. 19(18), 1998, pgs. 1621-1639. 77 Qazi, J.I., Marquardt, B. y Rack, H.J., Journal of Materials, Vol. 56, pgs. 4951. 78 Fabrication of Ti/Polymer biocomposites for load-bearing implant applications. Wang, J.F., Liu, X.Y. y Luan, B. 1-3, 2008, Journal of Materials Procesing Technology, Vol. 197(11), 2004, pgs. 428-433. 79 Gibson, L. y Ashby, M. Cellular Solids: Structure and Properties. Cambridge: Cambridge University Press, 1997. 80 Oh, I.H., Nomura, N. y Hanada, S., Materials Transactions, Vol. 43(3), 2002, pgs. 443-446. 81 Oh, I.H., y otros., Scripta Materialia, Vol. 49(12), 2003, pgs. 1197-1202. 82 Cirincione, R. y et al., Processing and Properties of Lightweight Cellular Metals and Structures, 2002, pg. 189. 83 Dunand, D. C., Advanced Engineering Materials, Vol. 6(6), 2004, pgs. 369376. 84 Schuh, C. y et.al., Acta Materialia, Vol. 48(8), 2000, pgs. 1639-1653. 5 CAPITULO VI

Lmites de la PM convencional (loose sintering) en la obtencin de Ti poroso para aplicaciones biomdicas 85 Taylor, N. y et al., Acta Metallurgica Et Materialia, Vol. 41(3), 1993, pgs. 955965. 86 Jo, Y.J., y otros., Journal of Materials Processing Technology, Vol. 194(1-3), 2007, pgs. 121-125. 87 Ji, S.C., Materials Science and Engineering a-Structural Materials Properties Microstructure and Processing, Vol. 366(1), 2004, pgs. 195-201. 88 German, Randall. Particle Packing Characteristics. s.l. : Metal Powder Industries Federation Publishers, 1989. 89 Upadhyaya, G.S. Powder Metallurgy Technology. England : Cambridge International Science Publishing, 2002. ISBN 1 898326 40 1. 90 Ashby, Michael, Sherdiff, Hugh y Cebon, David. Materials: engineering science processing and design. First Edition. s.l. : Elsevier, 2007. ISBN-13: 978-0-7 506-8391-3. 91 Neikov, Oleg D. Introduction. [ed.] Oleg D Neikov, Stanislav S Naboychenko and Goron Dowson. Handbook of Non-ferrous metal powders: Technologies and applications. First edition. Oxford : Elsevier, 2009. 92 Explosivity of Metal Powders. Jacobson, M, Cooper, A.R and Nagy, J. 1964, Bureau of mines, Vol. Report 6516. 93 Effects of lubrication procedure on the consolidation, sintering and microstructural features of powder compacts. SIMCHI, A. 2003, Materials and Design, Vol. 24, pp. 585-594. 94 Engineered approach to high density forming using internal and external lubricants. RAWLINGS, A., LUK, S. and HANEJKO. 2001, Advances in Powder Metallurgy and Particulate Materials, Vol. 1, p. 9. 95 Combining electrostatic die wall lubrication and warm compaction to enhance green and sintered properties of P/M components. LEMIEUX, P., et al. 2002, Advances in Powder Metallurgy and Particulate Materials, Vol. 3. 96 Study on mechanical properties of warm compacted iron-base materials. LI, Y., et al. 2002, Journal of Central South University of Technology, Vol. 9, pp. 154158. 97 Effect of die wall lubrication on warm compaction powder metallurgy. LI, Y., et al. 2002b, Journal of Materials Processing Technology, Vol. 129, pp. 354-358. 98 Waldron, M.B. and Daniell, B.L. Sintering. London : Heyden & Son, 1978. p. 44. 6 CAPITULO VI

Lmites de la PM convencional (loose sintering) en la obtencin de Ti poroso para aplicaciones biomdicas 99 ASTM International. ASTM B 265-06a. Standard Specification for Titanium and Titanium Alloy strip. Sheet and Plate. 100Imwinkelried. Thomas. Mechanical properties of open-pore titanium foam. 2007. pg. 967. 101ASM International. ASM Handbook: Alloy Phase Diagrams. pgs. 205. 299. 324. 367. Vol. 3. 102Neikov. Oleg D.. Naboychenko. Stanislav S. y Dowson. Goron. [ed.]. Handbook of Non-Ferrous Metal Powders: Technologies and applications. First edition. Oxford. UK : s.n.. 2009. pg. 621. ISBN: 978-1-85617-422-0. 103ASTM B 212-89. Annual Book of ASTM Standards. 02.05. Phiadelpha. USA : Staff. 1989. 104PANREAC. [En lnea] [Citado el: 13 de Abril www.panreac.es/spanish/catalgo/fichastec/131659ES.HTM. de 2010.]

105http://www.alfa.com/es/GP100W.pgm?DSSTK=012980&rnd=387822390 106Properties of solid core and porous surface Ti6Al4V implants manufactured by powder metallurgy. Dewidar. Montasser M. 2008. Journal of Alloys and Compounds. Vol. 454. pgs. 442-446. 107Production and Characterization of High Porosity Ti-6Al-4V Foam by Space Holder Technique in Powder Metallurgy. Kotan. Gher y Bor. A. Sakir. 2007. Turkish J. Eng. Env. Sci.. Vol. 31. pgs. 149 156. 108ASTM E9-89a. Standard Test Methods of Compression Testing of Metallic Materials at Room Temperature. 2000. 109Chaves Chaves. Manuel Fernando. Manual de Laboratorio. Proyecto fin de carrera. Sevilla : s.n.. 2000. 110Hernndez Vzquez. Glenda Beatriz. Procesado y caracterizacin de titanio poroso usando la tcnica de espaciadores. Sevilla. 2010. 111Optimizacin de las propiedades mecnicas de Ti6Al4V poroso sinterizado por el mtodo de espaciadores. C. Tojal. V. Amig. III Congreso Nacional de Pulvimetalurgia Valencia. 13 y 14 de junio de 2010. 397-404. 112ASTM C373-88. Standard Test Method for Water Absortion Bulk density. Apparent Porosity. and Apparent Specific Gravity of Fired Whiteware Products. 1999.

CAPITULO VI

Lmites de la PM convencional (loose sintering) en la obtencin de Ti poroso para aplicaciones biomdicas 113Jorge Luis Bris Cabrera. Comportamiento mecnico de aceros sinterizados de alta densidad. Tesis doctoral. Barcelona. 2006: p. 40-41. 114Yadir Torres Hernndez. Comportamiento a fractura y fatiga de carburos cementados WC-Co. Tesis doctoral. Barcelona. 2002: p. 21-24. 115Metals Handbook Ninth Edition. Volume 17: Nondestructive Evaluation and Quality Control. 1989: p.235 116Collins. E. W.. The physical Metallurgy of Titanium Alloys. 1984. Ohio: ASM. Metals Park. 117H.W. Mllner. A. Fritsch. C. Hohlhauser. R. Reihsner. C. Hellmich. D. Godlinski. A. Rota. R. Slesinski and J. Eberhardsteiner. Acoustical and Poromechanical Characterisation of Titanium Scaffolds for Biomedical Applications. 2007: p. 159. 118Thomas Imwinkelried. Mechanical properties of open-pore titanium foam. 2007: p. 966 Fig.2. 119Recio Lpez. Jos Manuel. Obtencin y caracterizacin de titanio poroso para implantes dentales. Sevilla. 2010. 120Torres Y.. et al. 2010. Anales de Mecnica de la Fractura. Vol. I. pgs. 63-68. 121Gibson. L.J. and Ashby. M.F.. Cellular Solids: Structure and Properties. second edition. Cambridge University Press. 1997. 122Pabst. W. and Gregorov. E.. J. Mater. Sci.. 39: p. 3501. 2004. 123Ke Zhu. Chengfeng Li. Zhengnag Zhu. C. S. Liu: Measurement of the dynamic Youngs Modulus of porous titanium and Ti6Al4V. J Mater Sci (2007) 42:73487353. 124B. Vamsi Krishna et al. Acta Biomaterialia. Vol. 3. 2007. pgs. 997-1006 125Eudier, M. 1962. The mechanical properties of sintered low-alloy steels. Powder Metallurgy 5 (1962) 278-290 126Fleck, N. y Smith, R. 1981a. Effect of density on tensile strength, fracture toughness and fatigue crack propagation behaviour of sintered steel. Powder Metallurgy, 3 (1981) 121-125. 127Hyun, S. Murakami, K. y Nakajima, H. 2001. Anisotropic mechanical properties pf porous copper fabricated by unidirectional solidification. Materials Science Engineering A299 (2001) 241-248.

CAPITULO VI

Lmites de la PM convencional (loose sintering) en la obtencin de Ti poroso para aplicaciones biomdicas 128Haynes, R. 1871. Effect of porosity content on the tensile strength of porous materials. Powder Metallurgy, 14 (1971) 64-70. 129Weiss, B., Stickler, R., y Sychra, H. 1990. The influenceof porosity on static and dynamic properties of P/M iron. Metal Powder Report, 45 (1990)187-192. 130Kubicki, B. 1995 Stress concentration at pores in sintered materials. Powder Metallurgy, 38 (1995) 295-298. 131Dieter, G. 1988. Mechanical metallurgy. McGraw Hill. London, England.

CAPITULO VI

Anda mungkin juga menyukai

- CamiDokumen1 halamanCamialuminaBelum ada peringkat

- Evaluacion Final Matematicas ADokumen5 halamanEvaluacion Final Matematicas AaluminaBelum ada peringkat

- Teresa Ceramica MetalDokumen252 halamanTeresa Ceramica MetalaluminaBelum ada peringkat

- Marcos DiazDokumen157 halamanMarcos DiazaluminaBelum ada peringkat

- Boam 7698 07072016144004029Dokumen46 halamanBoam 7698 07072016144004029aluminaBelum ada peringkat

- Evaluacion Final Matematicas BDokumen6 halamanEvaluacion Final Matematicas BaluminaBelum ada peringkat

- So Luci OnesDokumen3 halamanSo Luci OnesaluminaBelum ada peringkat

- Evaluacion Final Matematicas ADokumen5 halamanEvaluacion Final Matematicas AaluminaBelum ada peringkat

- Boam7701 1620Dokumen36 halamanBoam7701 1620aluminaBelum ada peringkat

- Uso del titanio biomaterial prótesis e implantes médicosDokumen1 halamanUso del titanio biomaterial prótesis e implantes médicosDiego Canedo100% (3)

- Revision Az As Biomaterial EsDokumen81 halamanRevision Az As Biomaterial EsaluminaBelum ada peringkat

- El concreto: material durable y popularDokumen8 halamanEl concreto: material durable y popularJamil BironBelum ada peringkat

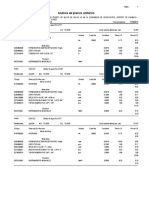

- Presupuesto SerenazgoDokumen23 halamanPresupuesto SerenazgoRobert Puchulan ReyesBelum ada peringkat

- 650 Estructuras de AceroDokumen53 halaman650 Estructuras de AceroCesar CortesBelum ada peringkat

- Materiales cerámicos: características y clasificaciónDokumen15 halamanMateriales cerámicos: características y clasificaciónEstefania Chab DiazBelum ada peringkat

- 04 MetradosDokumen18 halaman04 MetradosAxl VasquezBelum ada peringkat

- Catalogo Conectores Simpson Strong-TieDokumen36 halamanCatalogo Conectores Simpson Strong-TierodlbBelum ada peringkat

- Yeso y CalDokumen5 halamanYeso y CalAlexis Paredes BendezúBelum ada peringkat

- Metrados Caseta VálvulasDokumen9 halamanMetrados Caseta VálvulasFrank Chavez CaluaBelum ada peringkat

- Informacion - Constructivo EscalerasDokumen37 halamanInformacion - Constructivo EscalerasEdy PLBelum ada peringkat

- Informe Tecnologia 6Dokumen8 halamanInforme Tecnologia 6Jhampier Huaman RodriguezBelum ada peringkat

- Tuberia Multicapa PEX AL PEXDokumen2 halamanTuberia Multicapa PEX AL PEXCarlos Mendoza100% (1)

- Laminas MedidasDokumen4 halamanLaminas MedidasRmao CIBelum ada peringkat

- Policloruro de ViniloDokumen15 halamanPolicloruro de ViniloEstefany BonifazBelum ada peringkat

- CaperDokumen16 halamanCaperLucia Pereira da SilveiraBelum ada peringkat

- Eett Ecovilla Molinero 24-07-11 REV.2Dokumen20 halamanEett Ecovilla Molinero 24-07-11 REV.2Carolina Nicole Sepúlveda VásquezBelum ada peringkat

- FREYSSINERDokumen36 halamanFREYSSINERGeorge White100% (1)

- 06 - ANEXO - Industria Del ConcretoDokumen20 halaman06 - ANEXO - Industria Del ConcretoAbraham PortillaBelum ada peringkat

- Ipn QuimicaDokumen29 halamanIpn QuimicaDavid Lavín CarballoBelum ada peringkat

- Material EsDokumen10 halamanMaterial EsJuan VíctorBelum ada peringkat

- Concreto MasivoDokumen32 halamanConcreto MasivoLuis Alejandro Fierro Perez100% (1)

- Inventario de HerramientasDokumen19 halamanInventario de HerramientasOscar CalsinBelum ada peringkat

- Ejercicio 1 ForjadosDokumen22 halamanEjercicio 1 ForjadosCatalina100% (1)

- CompósitosDokumen14 halamanCompósitosKarla VillanuevaBelum ada peringkat

- Acondicionamiento térmico vivienda tipoDokumen13 halamanAcondicionamiento térmico vivienda tipoSimon Reyes Reyes100% (2)

- Proceso de Soldadura de OxicombustibleDokumen8 halamanProceso de Soldadura de OxicombustibleJacob CamarenaBelum ada peringkat

- Calificacion de La Ficha de Evaluacion SocioeconomicaemyDokumen15 halamanCalificacion de La Ficha de Evaluacion SocioeconomicaemyYsabel Advincula RebattaBelum ada peringkat

- Desmontaje AsbestoDokumen5 halamanDesmontaje AsbestoWilmer P MendozaBelum ada peringkat

- Apu SanDokumen25 halamanApu SanYordan DelgadoBelum ada peringkat

- MaxiLift 12Pg SpanishDokumen12 halamanMaxiLift 12Pg SpanishGustavo Adolfo Herrera MurgasBelum ada peringkat

- Catalogo Construlita 2011Dokumen116 halamanCatalogo Construlita 2011Juan Carlos Soria SanchezBelum ada peringkat