Purchase Order

Diunggah oleh

paletir6593Deskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Purchase Order

Diunggah oleh

paletir6593Hak Cipta:

Format Tersedia

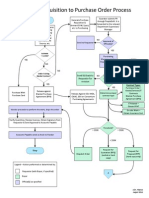

Oracle Purchase Order

There is one cycle called P2P(procure-to-pay) contain some module of Oracle Application. PO,AP,GL. Process Flow..... 1) Requisition. once it is approved. 2) Purchase Order.Once it is approved. 3) Send Po to supplier. 4) Supplier send the goods,service along with INVOICE. 5) PO matching comes in to the picture(kind of cross checking). 6) Pay to supplier (AP). 7) All transaction reflects to GL.

Step 1: Requisition When the company/person wants to purchase any item a Requisition is created Step 2: RFQ (Request For Quotation) Once Requisition is approved then the company/person will Request for Quotation (RFQ) specifying the required item, quantity.... etc and send them to the vendors who can supply the item Step 3: Quotation Once the vendor receives the RFQ then he will prepare the Quotation and send it back to the company/person

Step 4: Purchase Order (PO) After receiving different quotations from different vendors company/person will go through the quotations and approves the quotation that is best suited/reliable for the company/person. Based on the approved quotation Purchase Order is generated to the vendor. Now the vendor will supply the item. Step 5: Receipts Once the Item is shipped the vendor will raise the Receipt to the company/person. Step 6: Invoice Based on the receipt Invoice is generated. For this invoice the company/person will make Payments.

Back to Back Order Functional and Technical Flow

Business Purpose of Back to Back Order

1. Customer orders items (OM). 2. Purchase those items from the supplier (PO) and receive them into the warehouse. 3. Ship those items to the customer (OM). The B2B process automates the creation of a supply order (PO) when a sales order is booked. The supply order is hard pegged (hard-reservation) to the sales order that it is supplying so that once the PO is received, the items are not inadvertently taken by another order or demand. Where the sales order line is within the process, can be visible at all times so that customer service inquiries can be answered. This process is used for items that are not typically stocked nor manufactured. In an environment where lead times are often only a matter of 24 hours, the B2B process improves efficiency of the three steps above, by closely linking the Sales Order and the Purchase Order together.

Mandatory Item Attributes

Navigate to Item master form of Inventory responsibility

In the Order Management tab, check the Assemble to Order flag (ATO) and Customer Orderable flag. In the Purchasing tab, enable Purchasable flag, enter a value in the List Price field. In the Work in Process tab, make sure the Build in WIP flag is checked. In the General Planning tab, set the Make ohttp://oracleappsdna.com/wpadmin/post.php?post=789&action=edit&message=10r Buy flag to Buy.

Steps to Follow for back to back Order process

1. Firstly, make sure Inventory, PO, GL periods are open.

2.

Create a sales order with order type as Mixed (if Vision instance)

3.

Book the sales order, now the line status will be changed to Supply Eligible (OE_ORDER_LINES_ALL.flow_status_code = SUPPLY_ELIGIBLE). Place cursor on the line and go to Actions > Progress Order. Select Create Supply Order Eligible to progress the workflow of the line. The line status will now show PO-ReqRequested (OE_ORDER_LINES_ALL.flow_status_code = PO_REQ_REQUESTED). Now that the status got changed to PO-ReqRequested, OM has inserted a record

4.

5.

in the PO requisitions interface table to create a requisition. You can verify with the below query 6. SELECT * 7. FROM po_requisitions_interface_all 8. WHERE interface_source_line_id = 9. &order_line_id AND interface_source_code = 'CTO'; 10. Go to Purchasing > Reports > Run and run the concurrent program Requisition Import with the Import Source parameter = CTO.

Leave the other parameters as default. The concurrent program can also be run from OM > Orders, Returns > Requisition Import. Go to View > Requests and verify that the Requisition Import has completed successfully. 11. The line status of the sales order line will now show PO-ReqCreated (OE_ORDER_LINES_ALL.flow_status_code = PO_REQ_CREATED). 12. From the sales order line, go to Tools > Scheduling > Reservation Details > Supply tab. Verify that the order line is reserved against the requisition. Note down the requisition number. 13. Go to Purchasing > Requisitions > Requisition Summary. In the Find Requisitions window, enter requisition number found in the previous step and click on Find. Verify that the status is Approved. 14. Go to Purchasing > Autocreate. From Edit > Clear > Record, clear any query criteria that may be defaulted. Enter requisition number and click Find. 15. Check the checkbox to the left of the line, and click on Automatic. Enter the Supplier and Supplier site such as the following and click on Create.

16. The Purchase Order form will automatically open with the PO that got created.Click on the Approve button.

Click on the OK button in the Approval Documents window to approve the PO. Note down the PO number, and verify that the status is Approved. 17. The line status of the sales order line will now show PO-Created (OE_ORDER_LINES_ALL.flow_status_code = PO_CREATED). 18. From the sales order line, go to Tools > Scheduling > Reservation Details > Supply tab. Verify that the order line is reserved against the PO. 19. Go to Purchasing > Receiving > Receipts. Enter Purchase Order number and click on Find. In the Receipts window, check the checkbox to the left of the line and enter : Destination Type : Inventory Subinventory : FGI

Save the receipt.

20. Go to Purchasing > Receiving > Receiving Transactions Summary.Enter the Purchase Order number and click on Find. Click on the Transactions button. Verify a Receive and Delivery transaction. This means that the B2B item has been received into Inventory. 21. The line status of the sales order line will now show Awaiting Shipping (OE_ORDER_LINES_ALL.flow_status_code = AWAITING_SHIPPING).On the sales order line, Tools > Scheduling > Reservation Details will now show that the item is reserved against Inventory in Subinventory = FGI. The line can now be pick released, shipped and invoiced to the customer. This completes the flow of B2B.

Technical components of Oracle Purchasing

Oracle Purchasing allows requisitions, purchase orders, quotations, and receipts etc to be processed and integrated with modules such as General Ledger, Inventory, Order Management etc. The Oracle Purchasing design consists of various technical components like interfaces, workflows, profile options, tables etc which are summarized in this article. Main Business Components in Oracle Purchasing are Employee/Buyers

Vendor/Suppliers Requisitions Purchase Orders Receipts

Employees

You must to be setup as an employee in order to create a requisition or a PO. If Oracle HR is installed then you have to use the form defined in Oracle HRMS to define an employee. If Oracle HR is not installed then you can use a form under Setup->Personnel->Employees to setup employees. Main tables are HR_EMPLOYEES, PER_PEOPLE_F Important Note: The view HR_EMPLOYEES_CURRENT_V gives one record per active employee. PER_PEOPLE_F/PER_ALL_PEOPLE_F store multiple records per employee with specific start and end dates

Vendors

PO_VENDORS, PO_VENDOR_SITES_ALL and PO_VENDOR_CONTACTS are the main tables for this entity. Vendors are global i.e. a vendor, once defined, can be used across operating units (OU). Vendor sites are OU specific. Most of the PO tables store the VENDOR_ID and VENDOR_SITE_ID columns. VENDOR_SITE_ID is unique (not unique within a VENDOR_ID) in 11i. It used to be unique for a vendor until 11.0.PO_VENDORS PO_VENDORS stores information about your suppliers. You need one row for each supplier you define. Each row includes the supplier name as well as purchasing, receiving, payment, accounting, tax, classification, and general information. Oracle Purchasing uses this information to determine active suppliers. VENDOR_ID is the unique systemgenerated receipt header number invisible to the user. SEGMENT1 is the systemgenerated or manually assigned number you use to identify the supplier in forms and reports. Oracle Purchasing generates SEGMENT1 using the PO_UNIQUE_IDENTIFIER_CONTROL table if you choose to let Oracle Purchasing generate supplier numbers for you. This table is one of three tables that store supplier information. PO_VENDORS corresponds to the Suppliers window. PO_VENDOR_SITES_ALL PO_VENDOR_SITES_ALL stores information about your supplier sites. You need a row for each supplier site you define. Each row includes the site address, supplier reference, purchasing, payment, bank, and general information. Oracle Purchasing uses this information to store supplier address information. This table is one of three tables that store supplier information. PO_VENDOR_SITES_ALL corresponds to the Sites region of the Suppliers window.

PO_VENDOR_CONTACTS PO_VENDOR_CONTACTS stores information about contacts for a supplier site. You need one row for each supplier contact you define.

Each row includes the contact name and site. This table is one of three tables that store supplier information. PO_VENDOR_CONTACTS corresponds to the Contacts region of the Supplier Sites window

Requisition

This entity is the starting point of data flow in the PO module. Requisitions can be created by various means Enter Reqs form, Requisition Interface tables or using Self Service Purchasing. All requisitions need to be approved before being considered for future processing. An unapproved requisition has a value of Incomplete for the column AUTHORIZATION_STATUS in the table PO_REQUISITION_HEADERS. After the requisition is completed it should be submitted for Approval. Approval is a separate piece of code that is reused in both Reqs as well as PO approval. It is a combination of Workflow, PL/SQL and Pro*C code. There are 3 main tables for Reqs:

PO_REQUISITION_HEADERS: PO_REQUISITION_HEADERS_ALL stores information about requisition headers. You need one row for each requisition header you create. Each row contains the requisition number, preparer, status, and description. REQUISITION_HEADER_ID is the unique systemgenerated requisition number. REQUISITION_HEADER_ID is invisible to the user. SEGMENT1 is the number you use to identify the requisition in forms and reports. Oracle Purchasing generates SEGMENT1 using the PO_UNIQUE_IDENTIFIER_CONTROL table if you choose to let Oracle Purchasing generate requisition numbers for you. PO_REQUISITION_HEADERS_ALL corresponds to the Header region of the Requisitions window. SEGMENT1 provides unique values for each row in the table in addition to REQUISITION_HEADER_ID.

PO_REQUISITION_LINES: PO_REQUISITION_LINES stores information about requisition lines. You need one row for each requisition line you create. Each row contains the line number, item number, item category, item description, needby date, deliverto location, item quantities, units, prices, requestor, notes, and suggested supplier information for the requisition line. LINE_LOCATION_ID identifies the purchase order shipment line on which you placed the requisition. LINE_LOCATION_ID is null if you have not placed the requisition line on a purchase order. BLANKET_PO_HEADER_ID and BLANKET_PO_LINE_NUM store the suggested blanket purchase agreement or catalog quotation line information for the requisition line. PARENT_REQ_LINE_ID contains the REQUISITION_LINE_ID from the original requisition line if you exploded or multi-sourced this requisition line. This table corresponds to the Lines region of the Requisitions window. PO_REQ_DISTRIBUTIONS:

PO_REQ_DISTRIBUTIONS_ALL stores information about the accounting distributions associated with each requisition line. Each requisition line must have at least one accounting distribution. You need one row for each requisition distribution you create. Each row includes the Accounting Flexfield ID and requisition line quantity. PO_REQ_DISTRIBUTIONS_ALL is one of three tables storing your requisition information. This table corresponds to the requisition Distributions window, accessible through the Requisitions window

Purchase Order

This is the pivotal entity of Oracle Purchasing. All other entities function for or because of this entity. There are four main tables for this entity: PO_HEADERS_ALL: There are six types of documents that use PO_HEADERS_ALL: RFQs Quotations Standard purchase orders Planned purchase orders Blanket purchase orders Contracts Each row contains buyer information, supplier information, brief notes, foreign currency information, terms and conditions information, and the status of the document. Oracle Purchasing uses this information to record information that is related to a complete document. PO_HEADER_ID is the unique systemgenerated primary key and is invisible to the user. SEGMENT1 is the systemassigned number you use to identify the document in forms and reports. Oracle Purchasing generates SEGMENT1 using the PO_UNIQUE_IDENTIFIER_CONT_ALL table if you choose to let Oracle Purchasing generate document numbers for you. SEGMENT1 is not unique for the entire table. Different document types can share the same numbers. You can uniquely identify a row in PO_HEADERS_ALL using SEGMENT1 and TYPE_LOOKUP_CODE or using PO_HEADER_ID. If APPROVED_FLAG is Y, the purchase order is approved. If your document type is a blanket purchase order, contract purchase order, RFQ, or quotation, Oracle Purchasing uses START_DATE and END_DATE to store the valid date range for the document. Oracle Purchasing only uses BLANKET_TOTAL_AMOUNT for blanket PO_LINES_ALL: Is a detail of headers table. Each row includes the line number, the item number and category, unit, price, tax information, matching information, and quantity ordered for the line. Oracle Purchasing uses this information to record and update item and price information for purchase orders, quotations, and RFQs. PO_LINE_ID is the unique systemgenerated line number invisible to the user. LINE_NUM is the number of the line on the purchase order. Oracle Purchasing uses CONTRACT_NUM to reference a contract purchase order from a standard purchase order line. Oracle Purchasing uses ALLOW_PRICE_OVERRIDE_FLAG, COMMITTED_AMOUNT, QUANTITY_COMMITTED, MIN_RELEASE_AMOUNT only for blanket and planned purchase order lines. The QUANTITY field stores the total quantity of all purchase order shipment lines (found in PO_LINE_LOCATIONS_ALL). PO_LINE_LOCATIONS_ALL:

Also known as Shipments is a detail of lines. PO_LINE_LOCATIONS_ALL contains information about purchase order shipment schedules and blanket agreement price breaks. You need one row for each schedule or price break you attach to a document line. Each row includes the location, quantity, and dates for each shipment schedule. Oracle Purchasing uses this information to record delivery schedule information for purchase orders, and price break information for blanket purchase orders, quotations and RFQs. PO_RELEASE_ID applies only to blanket purchase order release shipments. PO_RELEASE_ID identifies the release on which you placed this shipment. SOURCE_SHIPMENT_ID applies only to planned purchase order release shipments. It identifies the planned purchase order shipment you chose to release from. PRICE_OVERRIDE always equals the purchase order line price for standard purchase order shipments. For blanket and planned purchase orders, PRICE_OVERRIDE depends on the values of the ALLOW_PRICE_OVERRIDE_FLAG and NOT_TO_EXCEED_PRICE in the corresponding row in PO_LINES_ALL: If ALLOW_PRICE_OVERRIDE_FLAG is N, then PRICE_OVERRIDE equals UNIT_PRICE in PO_LINES_ALL. If ALLOW_PRICE_OVERRIDE_FLAG is Y, then PRICE_OVERRIDE can take any value that is smaller than NOT_TO_EXCEED_PRICE in PO_LINES_ALL. The QUANTITY field corresponds to the total quantity ordered on all purchase order distribution lines (found in PO_DISTRIBUTIONS_ALL).

PO_DISTRIBUTIONS_ALL: PO_DISTRIBUTIONS_ALL contains accounting distribution information for a purchase order shipment line. You need one row for each distribution line you attach to a purchase order shipment. Each row includes the destination type, requestor ID, quantity ordered and deliverto location for the distribution. Oracle Purchasing uses this information to record accounting and requisition information for purchase orders and releases. PO_DISTRIBUTIONS_ALL is one of five tables storing purchase order and release information. Some columns in PO_DISTRIBUTIONS_ALL contain information only if certain conditions exist: If you autocreate this accounting distribution from a requisition, REQ_DISTRIBUTION_ID corresponds to the ID of the requisition distribution you copy on the purchase order. If you use a foreign currency on your purchase order, Oracle Purchasing stores currency conversion information in RATE and RATE_DATE. If you use encumbrance, GL_ENCUMBERED_DATE and GL_ENCUMBERED_PERIOD_NAME contain encumbrance information Oracle Purchasing uses to create journal entries in Oracle General Ledger. If you do not autocreate the purchase order from online requisitions, REQ_LINE_REFERENCE_NUM and REQ_HEADER_REFERENCE_NUM contain the requisition number and requisition line number of the corresponding paper requisition. These two columns are not foreign keys to another table. If the distribution corresponds to a blanket purchase order release, PO_RELEASE_ID identifies this release.

If SOURCE_DISTRIBUTION_ID has a value, the distribution is part of a planned purchase order release. Reqs can be converted to Purchase Orders using either the Autocreate form or Create PO workflow. If certain conditions are satisfied then multiple req lines are converted to a single PO line or a single PO shipment.

Receipt

There are two receipt source types, Supplier (PO based) and Internal Order (Internal Requisitions and Inter-org transfers) that you need to use when receiving against different source document types. You use a receipt source type of Supplier when receiving items that you ordered from an external supplier using a purchase order. When you receive items that are part of an interorganization transfer, or when receiving items that you request from your inventory using an internal requisition, the receipt type would be Internal Order. The Internal Order receipt source type populates the ORGANIZATION_ID column. There are three main tables in receiving:

RCV_SHIPMENT_HEADERS RCV_SHIPMENT_HEADERS stores common information about the source of your receipts or expected receipts. You group your receipts by the source type and the source of the receipt. Oracle Purchasing does not allow you to group receipts from different sources under one receipt header. Oracle Purchasing creates a receipt header when you are entering your receipts or when you perform inter organization transfers using Oracle Inventory. When Oracle Inventory creates a receipt header for an intransit shipment, the receipt number is not populated until you receive the shipment. RCV_SHIPMENT_LINES RCV_SHIPMENT_LINES stores information about items that have been shipped and/or received from a specific receipt source. RCV_SHIPMENT_LINES also stores information about the default destination for intransit shipments. RCV_TRANSACTIONS RCV_TRANSACTIONS stores historical information about receiving transactions that you have performed. When you enter a receiving transaction and the receiving transaction processor processes your transaction, the transaction is recorded in this table. Once a row has been inserted into this table, it will never be updated. When you correct a transaction, the net transaction quantity is maintained in RCV_SUPPLY. The original transaction quantity does not get updated. You can only delete rows from this table using the Purge feature of Oracle Purchasing.

Training Videos

http://www.youtube.com/watch?v=fmcPEhh2QlU http://www.youtube.com/watch?v=sPq28FpZEjA Oracle Sourcing PPT

http://www.slideshare.net/dharmalingamks/oracle-applications-r12-sourcing-training-1215115

PO Back 2 Back flow

Now, you can Pick Release and Ship Confirm as normal Sales Order. Following is the link for the same. http://oracleapplicationsfunctional.blogspot.com/2011/08/back-to-back-order-flow-in-oracle-r12.html

Anda mungkin juga menyukai

- Order To Cash O2C Cycle With Table Detai PDFDokumen19 halamanOrder To Cash O2C Cycle With Table Detai PDFJack DawsonBelum ada peringkat

- Procure To Pay Process Flow in Oracle FusionDokumen4 halamanProcure To Pay Process Flow in Oracle FusionDellibabu DBelum ada peringkat

- P2P and O2CDokumen74 halamanP2P and O2CRaghurami ReddyBelum ada peringkat

- Inventory and Purchase Order ReceiptsDokumen51 halamanInventory and Purchase Order ReceiptsPriya NimmagaddaBelum ada peringkat

- CTO-Sales Order FlowDokumen60 halamanCTO-Sales Order FlowAbbinav Shaw100% (4)

- ABL Sourcing Training Manual UpdatedDokumen47 halamanABL Sourcing Training Manual UpdatedRafay Farooq100% (1)

- Requisition To PO ProcessDokumen3 halamanRequisition To PO ProcessChin D EstoconingBelum ada peringkat

- Purchase Order InterfaceDokumen20 halamanPurchase Order InterfaceNaveen Shankar MauwalaBelum ada peringkat

- Oracle I Procurement TablesDokumen3 halamanOracle I Procurement TablesKrishna Victory0% (1)

- PO Requisition Update APIDokumen16 halamanPO Requisition Update APISreekanth ReddyBelum ada peringkat

- AME Setup: Assign AME Roles and ResponsibilitiesDokumen39 halamanAME Setup: Assign AME Roles and ResponsibilitiesKalyani DarbhalaBelum ada peringkat

- Procure To Pay CycleDokumen24 halamanProcure To Pay CycleSYED MUSTAFABelum ada peringkat

- Iprocurement Implementation and Administration Guide R12.2Dokumen302 halamanIprocurement Implementation and Administration Guide R12.2ValBelum ada peringkat

- Approved Supplier Lists in OracleDokumen2 halamanApproved Supplier Lists in OracleBharathiPdBelum ada peringkat

- PurchasingDokumen22 halamanPurchasingRamesh GarikapatiBelum ada peringkat

- Consignment Inventory in Oracle AppsDokumen4 halamanConsignment Inventory in Oracle AppsjunnubunnuBelum ada peringkat

- Oracle Approval Management EngineDokumen21 halamanOracle Approval Management EngineFacundo BodnerBelum ada peringkat

- Purchase Requisition in Sap The Process ManualDokumen31 halamanPurchase Requisition in Sap The Process Manualrukometlas100% (1)

- SOP Work Instruction TemplateDokumen4 halamanSOP Work Instruction Templatecost_ji051453Belum ada peringkat

- Oracle PurchasingDokumen77 halamanOracle Purchasingsourabhparande100% (1)

- Assets To Depreciation Flow ModelDokumen1 halamanAssets To Depreciation Flow ModelHitesh TutejaBelum ada peringkat

- Consign Inventory Process FlowDokumen1 halamanConsign Inventory Process FlowNaveed MohammadBelum ada peringkat

- Performence ApprisalDokumen44 halamanPerformence ApprisalRanjan Shetty100% (5)

- Purchasing Setups - Oracle R12Dokumen16 halamanPurchasing Setups - Oracle R12shankar100% (1)

- Risk InvestigationDokumen403 halamanRisk InvestigationNaguSwamyBelum ada peringkat

- Best Practices in Procure To Pay ArticleDokumen22 halamanBest Practices in Procure To Pay Articledsgandhi6006Belum ada peringkat

- How To Diagnose Purchase Order and Requisition Workflows in Deferred StatusDokumen11 halamanHow To Diagnose Purchase Order and Requisition Workflows in Deferred StatusMochamad IsaBelum ada peringkat

- Oracle Purchasing TechnicalDokumen10 halamanOracle Purchasing Technicalsridhar_vishwanathBelum ada peringkat

- Asl SourcingDokumen30 halamanAsl SourcingshankarBelum ada peringkat

- Introduction Procure To PayDokumen18 halamanIntroduction Procure To PayjaldanaBelum ada peringkat

- Vendor Vendor Site Vendor Contact Interface in r12Dokumen6 halamanVendor Vendor Site Vendor Contact Interface in r12prakash_srikanthBelum ada peringkat

- TA040 Application ArchitectureDokumen11 halamanTA040 Application ArchitectureAvijit BanerjeeBelum ada peringkat

- Answer: Is This Answer Correct ?Dokumen75 halamanAnswer: Is This Answer Correct ?harifavouriteenglishBelum ada peringkat

- Employee Performance Review TemplateDokumen1 halamanEmployee Performance Review TemplatePutu Rana JanendraBelum ada peringkat

- OPM Planning Setup TrainingDokumen17 halamanOPM Planning Setup TrainingDheeraj ThapaBelum ada peringkat

- Components and Modules in ERPDokumen26 halamanComponents and Modules in ERPChanuka Lakshan LiyanageBelum ada peringkat

- Procure To Pay Cycle (3-3-12)Dokumen11 halamanProcure To Pay Cycle (3-3-12)pranavi puttaBelum ada peringkat

- RHI P2P Test Script V4Dokumen15 halamanRHI P2P Test Script V4jhazzguaricoBelum ada peringkat

- Oracle SourcingDokumen158 halamanOracle SourcingAdams JibrinBelum ada peringkat

- Standard Procure To Pay ProcessDokumen15 halamanStandard Procure To Pay ProcessShrinivas SonawaneBelum ada peringkat

- Procure To Pay Lifecycle - MarkedDokumen15 halamanProcure To Pay Lifecycle - MarkedYogesh SalviBelum ada peringkat

- Procure To Pay CycleDokumen9 halamanProcure To Pay CycleRajashree DasBelum ada peringkat

- BR110 Security Profiles HR PayrollDokumen6 halamanBR110 Security Profiles HR PayrollAnup MishraBelum ada peringkat

- Chandra Class Corporate - BatchDokumen101 halamanChandra Class Corporate - Batchbanavaram1100% (1)

- Customer Feedback Form: Best Good Needs Improve MentDokumen2 halamanCustomer Feedback Form: Best Good Needs Improve Mentavinash_k007Belum ada peringkat

- 3 MD050 Cancelled Po OutBound Funcational SpecificationsDokumen21 halaman3 MD050 Cancelled Po OutBound Funcational SpecificationsMuraliBelum ada peringkat

- Purchasing ProceduresDokumen7 halamanPurchasing ProceduresHon Kirimi Mwobobia IIBelum ada peringkat

- Invoicing Standards Policy 1863799Dokumen7 halamanInvoicing Standards Policy 1863799amitvohraBelum ada peringkat

- Requester Change OrderDokumen30 halamanRequester Change Ordermousabm75% (4)

- Oracle Purchase Order - Functional FlowDokumen3 halamanOracle Purchase Order - Functional FlowyogoBelum ada peringkat

- Oracle Iproc. PresentationDokumen55 halamanOracle Iproc. PresentationSmart DiamondBelum ada peringkat

- Virtual Construction LTD: Purchases Order Form (POF)Dokumen31 halamanVirtual Construction LTD: Purchases Order Form (POF)Shoyeeb AhmedBelum ada peringkat

- BackTo Back OrderDokumen10 halamanBackTo Back OrderdurairajBelum ada peringkat

- What Is Drop ShipDokumen9 halamanWhat Is Drop Shipho.caroline112Belum ada peringkat

- Changes in 11i and R12 in P2P CycleDokumen15 halamanChanges in 11i and R12 in P2P CycleOraAppsAdminBelum ada peringkat

- Drop Shipment Process in Oracle AppsDokumen12 halamanDrop Shipment Process in Oracle AppsAnonymous wxcuiDWiGBelum ada peringkat

- Procure To PayDokumen43 halamanProcure To PayP RajendraBelum ada peringkat

- P2P - Oracle Procure To Pay Life Cycle Training ManualDokumen45 halamanP2P - Oracle Procure To Pay Life Cycle Training ManualCA Vara Reddy100% (1)

- Procure To Pay Cycle in Oracle Apps R12Dokumen50 halamanProcure To Pay Cycle in Oracle Apps R12Nageswara Reddy100% (6)

- 4global Capital Market 2Dokumen11 halaman4global Capital Market 2roseBelum ada peringkat

- Subject: Welcome To Hero Fincorp Family Reference Your Used Car Loan Account No. Deo0Uc00100006379290Dokumen4 halamanSubject: Welcome To Hero Fincorp Family Reference Your Used Car Loan Account No. Deo0Uc00100006379290Rimpa SenapatiBelum ada peringkat

- Ebook Essentials of Investments 12E Ise PDF Full Chapter PDFDokumen67 halamanEbook Essentials of Investments 12E Ise PDF Full Chapter PDFjanet.cochran431100% (22)

- How To Pick Stocks For 5X Returns With ChartsDokumen49 halamanHow To Pick Stocks For 5X Returns With ChartsDilip Kumar50% (2)

- Accounting Quizbowl QuestionsDokumen7 halamanAccounting Quizbowl QuestionsChabby ChabbyBelum ada peringkat

- Business Leadership Dissertation TopicsDokumen6 halamanBusiness Leadership Dissertation TopicsWhereToBuyPapersSingapore100% (1)

- Nhóm 4 - In-Class Exercise BOP - 2020Dokumen36 halamanNhóm 4 - In-Class Exercise BOP - 2020Thảo Hoàng PhươngBelum ada peringkat

- 09 Ratio AnalysisDokumen16 halaman09 Ratio AnalysisHimanshu VermaBelum ada peringkat

- HR Pepsi CoDokumen3 halamanHR Pepsi CookingBelum ada peringkat

- Graphic Design Intern (WFH) : FampayDokumen4 halamanGraphic Design Intern (WFH) : FampayS1626Belum ada peringkat

- Tan, Tiong, Tick vs. American Hypothecary Co., G.R. No. L-43682 March 31, 1938Dokumen2 halamanTan, Tiong, Tick vs. American Hypothecary Co., G.R. No. L-43682 March 31, 1938Barrymore Llegado Antonis IIBelum ada peringkat

- Use of Fonts (1.1 MB)Dokumen5 halamanUse of Fonts (1.1 MB)AIGA, the professional association for design50% (2)

- Risk Management For E-BusinessDokumen33 halamanRisk Management For E-BusinessDediNirtadinataAlQudsyBelum ada peringkat

- E3 Operating AuditingDokumen21 halamanE3 Operating AuditingPaupauBelum ada peringkat

- Assignment 2023 For BPOI - 105 (005) (DBPOFA Prog)Dokumen1 halamanAssignment 2023 For BPOI - 105 (005) (DBPOFA Prog)Pawar ComputerBelum ada peringkat

- Introduction To LocoNavDokumen29 halamanIntroduction To LocoNavShivansh AgarwalBelum ada peringkat

- Cristina Manalo Ind Dev PlanDokumen2 halamanCristina Manalo Ind Dev PlanPRinceBelum ada peringkat

- Mini Project ON "Amazon - In": Future Institute of Management & Technology Bareilly - Lucknow Road Faridpur, BareillyDokumen44 halamanMini Project ON "Amazon - In": Future Institute of Management & Technology Bareilly - Lucknow Road Faridpur, BareillyImran AnsariBelum ada peringkat

- Sharda dss10 PPT 04Dokumen38 halamanSharda dss10 PPT 04Abdulmajeed AlshehriBelum ada peringkat

- Impact of E-Commerce in The Philippines in The Time of PandemicDokumen9 halamanImpact of E-Commerce in The Philippines in The Time of PandemicAngelica Beatriz L. Benecen100% (1)

- Jennifer Wong - MKT 393 Final Draft 1Dokumen20 halamanJennifer Wong - MKT 393 Final Draft 1api-705120250Belum ada peringkat

- Mg1401 Total Quality Management 3 0 0 100Dokumen1 halamanMg1401 Total Quality Management 3 0 0 100ganku001Belum ada peringkat

- CadburyDokumen43 halamanCadburyBabasab Patil (Karrisatte)Belum ada peringkat

- Case Study of RecruitmentDokumen2 halamanCase Study of RecruitmentJuliana Chancafe IncioBelum ada peringkat

- Business EthicsDokumen29 halamanBusiness Ethicslalith kumarBelum ada peringkat

- CV Suraj Garg UpdatedDokumen3 halamanCV Suraj Garg Updatedsuraj gargBelum ada peringkat

- MB0045 Financial ManagementDokumen4 halamanMB0045 Financial ManagementAbhinav SrivastavaBelum ada peringkat

- Contractors All Risk PolicyDokumen2 halamanContractors All Risk PolicyAnonymous Q3J7APoBelum ada peringkat

- Code of EthicsDokumen37 halamanCode of EthicsDawn Rei Dangkiw100% (1)

- Proposal On The Establisment Of: MalayaDokumen23 halamanProposal On The Establisment Of: MalayaKim Loyola RonarioBelum ada peringkat

- Getting to Yes: How to Negotiate Agreement Without Giving InDari EverandGetting to Yes: How to Negotiate Agreement Without Giving InPenilaian: 4 dari 5 bintang4/5 (652)

- A Beginners Guide to QuickBooks Online 2023: A Step-by-Step Guide and Quick Reference for Small Business Owners, Churches, & Nonprofits to Track their Finances and Master QuickBooks OnlineDari EverandA Beginners Guide to QuickBooks Online 2023: A Step-by-Step Guide and Quick Reference for Small Business Owners, Churches, & Nonprofits to Track their Finances and Master QuickBooks OnlineBelum ada peringkat

- Technofeudalism: What Killed CapitalismDari EverandTechnofeudalism: What Killed CapitalismPenilaian: 5 dari 5 bintang5/5 (1)

- I Will Teach You to Be Rich: No Guilt. No Excuses. No B.S. Just a 6-Week Program That Works (Second Edition)Dari EverandI Will Teach You to Be Rich: No Guilt. No Excuses. No B.S. Just a 6-Week Program That Works (Second Edition)Penilaian: 4.5 dari 5 bintang4.5/5 (15)

- The Science of Prosperity: How to Attract Wealth, Health, and Happiness Through the Power of Your MindDari EverandThe Science of Prosperity: How to Attract Wealth, Health, and Happiness Through the Power of Your MindPenilaian: 5 dari 5 bintang5/5 (231)

- The Accounting Game: Learn the Basics of Financial Accounting - As Easy as Running a Lemonade Stand (Basics for Entrepreneurs and Small Business Owners)Dari EverandThe Accounting Game: Learn the Basics of Financial Accounting - As Easy as Running a Lemonade Stand (Basics for Entrepreneurs and Small Business Owners)Penilaian: 4 dari 5 bintang4/5 (33)

- Purchasing, Inventory, and Cash Disbursements: Common Frauds and Internal ControlsDari EverandPurchasing, Inventory, and Cash Disbursements: Common Frauds and Internal ControlsPenilaian: 5 dari 5 bintang5/5 (1)

- Project Control Methods and Best Practices: Achieving Project SuccessDari EverandProject Control Methods and Best Practices: Achieving Project SuccessBelum ada peringkat

- The ZERO Percent: Secrets of the United States, the Power of Trust, Nationality, Banking and ZERO TAXES!Dari EverandThe ZERO Percent: Secrets of the United States, the Power of Trust, Nationality, Banking and ZERO TAXES!Penilaian: 4.5 dari 5 bintang4.5/5 (14)

- How to Start a Business: Mastering Small Business, What You Need to Know to Build and Grow It, from Scratch to Launch and How to Deal With LLC Taxes and Accounting (2 in 1)Dari EverandHow to Start a Business: Mastering Small Business, What You Need to Know to Build and Grow It, from Scratch to Launch and How to Deal With LLC Taxes and Accounting (2 in 1)Penilaian: 4.5 dari 5 bintang4.5/5 (5)

- Tax-Free Wealth: How to Build Massive Wealth by Permanently Lowering Your TaxesDari EverandTax-Free Wealth: How to Build Massive Wealth by Permanently Lowering Your TaxesBelum ada peringkat

- SAP Foreign Currency Revaluation: FAS 52 and GAAP RequirementsDari EverandSAP Foreign Currency Revaluation: FAS 52 and GAAP RequirementsBelum ada peringkat

- Financial Accounting For Dummies: 2nd EditionDari EverandFinancial Accounting For Dummies: 2nd EditionPenilaian: 5 dari 5 bintang5/5 (10)

- Accounting 101: From Calculating Revenues and Profits to Determining Assets and Liabilities, an Essential Guide to Accounting BasicsDari EverandAccounting 101: From Calculating Revenues and Profits to Determining Assets and Liabilities, an Essential Guide to Accounting BasicsPenilaian: 4 dari 5 bintang4/5 (7)

- Ratio Analysis Fundamentals: How 17 Financial Ratios Can Allow You to Analyse Any Business on the PlanetDari EverandRatio Analysis Fundamentals: How 17 Financial Ratios Can Allow You to Analyse Any Business on the PlanetPenilaian: 4.5 dari 5 bintang4.5/5 (14)

- Start, Study and Pass The CPA Exam FAST - Proven 8 Step CPA Exam Study PlaybookDari EverandStart, Study and Pass The CPA Exam FAST - Proven 8 Step CPA Exam Study PlaybookPenilaian: 5 dari 5 bintang5/5 (4)

- Overcoming Underearning(TM): A Simple Guide to a Richer LifeDari EverandOvercoming Underearning(TM): A Simple Guide to a Richer LifePenilaian: 4 dari 5 bintang4/5 (21)

- Accounting For Small Businesses QuickStart Guide: Understanding Accounting For Your Sole Proprietorship, Startup, & LLCDari EverandAccounting For Small Businesses QuickStart Guide: Understanding Accounting For Your Sole Proprietorship, Startup, & LLCPenilaian: 5 dari 5 bintang5/5 (1)

- Attention Pays: How to Drive Profitability, Productivity, and AccountabilityDari EverandAttention Pays: How to Drive Profitability, Productivity, and AccountabilityBelum ada peringkat

- Accounting Principles: Learn The Simple and Effective Methods of Basic Accounting And Bookkeeping Using This comprehensive Guide for Beginners(quick-books,made simple,easy,managerial,finance)Dari EverandAccounting Principles: Learn The Simple and Effective Methods of Basic Accounting And Bookkeeping Using This comprehensive Guide for Beginners(quick-books,made simple,easy,managerial,finance)Penilaian: 4.5 dari 5 bintang4.5/5 (5)

- Your Amazing Itty Bitty(R) Personal Bookkeeping BookDari EverandYour Amazing Itty Bitty(R) Personal Bookkeeping BookBelum ada peringkat

- The Intelligent Investor, Rev. Ed: The Definitive Book on Value InvestingDari EverandThe Intelligent Investor, Rev. Ed: The Definitive Book on Value InvestingPenilaian: 4.5 dari 5 bintang4.5/5 (760)