Conrol 4

Diunggah oleh

Solha MubarakDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Conrol 4

Diunggah oleh

Solha MubarakHak Cipta:

Format Tersedia

CONTROL OF POWER PLANTS

Adaptive multiple model algorithm for hydro generator speed and power control

Teofana Puleva, Alexandar Ichtev

Abstract Application of nonlinear models for local network speed and power control of hydro generator is considered. Such models are recommended under a wide range of load conditions. One way of achieving such control goals for systems with complex nonlinear dynamics is through application of multi-model adaptive control strategy. A bank of models is considered. Each of the models corresponds to a different load condition. An algorithm for probability estimation for each model is proposed. On their base soft adaptation is performed. The control signal is a weighted sum of particular controls designed for local load conditions. Such algorithm ensures smooth behaviour of the control signal. Simulations with proposed algorithm are carried out in order to explore the systems performance. The control system satisfies the technological requirements of such hydro engineering plants control. Keywords : hydro turbine, modelling, multiple model algorithm, adaptive control

Introduction

The advanced turbine governors include the widespread application of electro hydraulic speed control both in the new construction and in modernization of older power plants. In modern programmable logical controllers more complicated and high effective control algorithms can be applied. These algorithms make most of the precise information about plants model, load disturbances and measurement noises. Applications of computer control systems in hydropower engineering provide an opportunity to implement the recommended from IEEE Working Group more detailed models of the hydro generator power control under a wide range of load conditions [1]. One of the main challenges in the hydraulic turbine governor design is related to the nonlinear characteristics of the turbine. The turbine model parameters vary significantly with the unpredictable load variations. Such nonlinearities make the governor design a non-trivial task due to the fact that a controller designed for specific operating conditions may not perform well under different loads. This fact leads to the adaptive control algorithms [2]. However, in practice, the most governor design is based on the linearised turbine model at one load condition. The resulting controller is then de-tuned so that it can provide satisfactory performance for the worst operating conditions [3]. Jiang considers the analysis and design of a hydraulic turbine governor using optimal robust control theory [4]. The advantage of this approach is that the designed governor guaranties the stability and performance of the speed control for the entire load range. One way of controlling hydro generators with complex nonlinear dynamics can be archived with multi-model adaptive control strategy [5, 9]. In this research a nonlinear model of the hydro turbine generator system is considered. The plant consists of three subsystems, the turbine wheel and rotor, the waterway with the nozzle and the servomotor to actuate the nozzle plunger. Models for initial speeding up of the turbine as well as four models for different load conditions are considered. These models are obtained using identificaAT&P journal PLUS2 2008

tion procedure. The multiple model algorithm consist of three stages: off-line system models determination; on-line mode probabilities estimation for each model; control signal computation via weighted sum of multiple local controls. The weighting coefficients are obtained by minimization of performance index. These parameters can be regarded as probabilities for the particular load condition, modelled in the model bank, to coincide with load conditions of the turbine. The adaptation provides smooth transition between local controllers as well as control of load conditions whish are convex combination of the modelled ones. The controller meets all requirements for water turbine process control. The results of the multi-model adaptive control strategy are compared with the control of the hydro generator by the same type of controller but designed with single model.

1. Turbine Dynamics Description

The research have been carried out by simulations with bank of PI control algorithms in MATLAB/Simulink environment with a nonlinear plant hydro turbine generator, described in [6,7]. The dynamic behaviour of a hydroelectric power system is considered. It consists of a pipe that transports water from reservoir with water level h to a Pelton type impulse turbine. Between the outlet of the pipe and the turbine there is an actuator (nozzle) that adjusts the cross section A of the water flowing into the turbine. The input variable is a function of nozzle aperture variation while the turbine speed is the output. The model of the system can be developed by deriving the model of the water column, the control device model and the turbine shaft motion model. The complete model can be obtained by connecting the three component models. 1.1 Turbine shaft motion mathematical model The turbine shaft motion equation is given by the equation

CONTROL OF POWER PLANTS

& J t t = M t M l ,

(1)

where J t is the moment of inertia of the turbine shaft, is the turbine shaft speed and M l is the load torque which is typically the driving torque for an electrical generator. All variables are presented in per units i.e. scaled by their rated values. M t max q = , M r r r qr (2)

Assuming that the water is incompressible with density . The equation of the water motion in the pipe is & Lq = mgh + Ap ( p0 p p ) , (9)

where mgh is the constant gravity force in the flow direction that acts on the water in pipe, p0 is constant ambient pressure, and p p is the pressure at the end of the pipe. Then the water column transfer function is

H pq ( p ) = p p q =

max = 2 for Pelton turbines. r

Note that this will lead to a run away speed of twice nominal and a standstill torque twice the torque at nominal speed. A small braking torque during the initial speeding up to the sub synchronous speed is due to the air and bearing friction. It is assumed to be proportional to speed: Ml =af Mr r . (3)

Lp

Ap

(10)

1.3 Water turbine control device mathematical model The inlet of the control device has a constant cross section Ap and the inlet pressure is p p . At the outlet of the control device the cross section is controlled to , the pressure is p, and the water velocity is v = q / A . It is assumed that the outlet pressure is small and constant so that p 0 can be used. The relation between the inlet and the outlet pressure and velocity can be described by Bernoullis equation

As typical value is used a f = 0.01 . Thus

d . Mt Ml = J dt

pp =

(4) (5)

q2

2 A2

q2 . A2 p

(11)

Mt Ml d ( / r ) = Tm , Mr Mr dt where

Linearization of the control device equation (11) around the nominal area A0 and a corresponding nominal flow q0 results in

p p =

(6)

q0

2 A0

q

2 A0

2 q0 3 A0

A ,

(12)

Tm =

Jr . Mr

where = 1

A typical value is Tm = 3 s. Using equations (1), (2) and (3) it can be obtained M t M l max q = r q r M r M r r af r . (7)

A2 p

Dividing equation (12) by q it can be obtained

2 q0 A 3 A0

q0

2 A0

p p q

(13)

The turbine control device transfer function is 1.2 Pipe dynamics mathematical model The pipe is of length L , cross section A p and has inlet at the elevation h where inlet pressure is zero. The outlet of the pipe has pressure p p and volumetric flow q (water velocity v p = q / A p ). The pipe can be regarded as a system with pressure and volumetric flow as output and input variables respectively. The inlet pressure is supposed to be the constant ambient pressure pa = 0 . Wherefore, the flow q at the outlet of the pipe will depend on the outlet pressure p p . The linearized pipe dynamics is given is given by the transfer function

H qA ( p) = q ( p ) , A( p )

where A is the input variable and q is the output variable. This transfer function is obtained after rearrangement equation (13) under the assumption p p ( p ) = H pq ( p )q ( p ) in accordance with (10)

2 q0 q0 + H pq q = 3 A . 2 A A0 0

Therefore the transfer function from the control input A to the flow q is

H pq ( p ) =

p p ( p ) q ( p )

(8)

H qA ( p ) =

q q = 0 . A A0

where q = q q0 and p p = p p p p 0 are the deviation from a constant solution (q0 , p p 0 ) . Note that the negative pressure change p p is used in the definition of the transfer function to ensure that H pq ( p ) has positive gain. where

1 , T 1+ w p 2

(14)

Tw =

2 LA02 qmax q , = 0 . 2 q max q 0 Ap

(15)

AT&P journal PLUS2 2008

CONTROL OF POWER PLANTS

Typical values are Tw = 1 s and = 0.01 (during the initial speeding up to sub synchronous speed). This leads to a first order lag with unity gain and a very short time constant compared with the rotor run speed time constant Tm . Fig. 1 visualizes connections for the subsystems presented above.

A Ar

Nonlinear model response

Control

Adjustable linear model

Optimisation procedure

2 Tw

max r

Fig.3 Model parameters tuning via identification

Mt

_

Ml Mr

1 Tm

af

Fig.4 Identification model structure during initial speeding up

Turbine speed, opening [p.u.]

1 0.9 0.8 0.7

Fig.1 Model of the waterway and rotor dynamics

Original data

2. Speed and power control design of a power generating unit

Traditional approach in water turbine speed and power control is to use conventional controllers. In fig. 2 the simulation model for speed control of hydro turbine local network operation is shown. The main function of the turbine governor in this mode of operation is to compensate unpredictable load in order to keep the frequency on its nominal value. In order to obtain a zero steady state error in the case of load disturbance rejection an integral control low has to be used [8]. The cascade control system is proposed. It provides speed and turbine opening position feedbacks. The dead zone element in turbine opening position feedback is used in order to reduce the hydraulic servo-system fluctuations in accordance with the technological requirements.

Model response

0.6 0.5 0.4 0.3 0.2 0.1 0 0 5 10 15 20 25 30 35 40 45 50

Turbine opening

Time [s]

Fig.5 Turbine speed, opening position during initial speeding up (original data and model response) The nonlinear characteristics of the hydraulic turbine vary significantly with the unpredictable load of the unit. Therefore the linearized plant models under different load conditions using identification procedure are obtained too. The model structure used by identification is shown in fig. 6. The model parameter values under different load disturbances are shown in table 1.

Fig.2 Simulation model of hydro turbine speed control A continuous PI controller is designed using LQR technique. The following controller parameters are obtained:

Fig.6 Identification model structure under load conditions k Load 25% Load 50% Load 75% Load 100% 4.84 3 2.29 1.95

T1

11.83 14.55 16.09 18.87

T2

14.13 18.54 23.06 28.6

T3

24.74 20.94 20.3 21

K p = 2.54 , K i = 0.3 .

A linear plant model during initial speeding up is obtained using identification procedure. In fig. 3 a classical scheme of optimal model parameter tuning via identification procedure is presented. The optimal procedure is based on the minimization of performance index that presents the deviation between the measured output and the computed linear model output. The model input signal is the control signal. The linear model structure used by the identification procedure is shown in fig. 4 The obtained model parameters are k=98.33, T1 = 202.82 ,

T2 = 3.6 , T3 = 2.49 . Fig. 5 shows the original data and model response for the turbine speed and opening position during initial speeding up.

Tab.1 Model parameters

3. Multiple model approach

In the considered multiple model approach there are three stages: The models of the system are obtained off-line; Probabilities for each of the model are computed on-line Soft control, as a weighted sum of local controllers, is computed.

AT&P journal PLUS2 2008

CONTROL OF POWER PLANTS

3.1 Multiple models Hydro turbine generator can be subjected to abrupt as well as gradual changes of the load. One way of describing this nonlinear system is by modelling it as a hybrid dynamic system, whose state may jump as well as vary continuously. These jumps between the different load conditions are used to model random abrupt changes in the generators demand, such as switching on or off other generators from the electrical grid. The dynamics between the jumps is used to model the system behaviour in the case of gradual load change. The hydro turbine generator is a system with two inputs and two outputs. The controlled output is the turbine speed. One of the turbine inputs is opening of the nozzle, which is control variable. The other one is the turbine load. The load is determined by the electricity demands and it is not possible to be controlled. Thus the second input has a characteristic of a disturbance. In order to be operational (connected to the electrical grid) the load of the turbine should be between 25% and 100% . In accordance to the multiple model (MM) approach it is proposed a set of four models to approximate the hybrid system. The chosen load models are 25% , 50% , 75% and 100% . They are presented in tab. 1.

M l : yl (k ) = f l ( y (k 1), y ( k 2), u ( k ), u ( k 1)) , l = 1,L 4

tial inclusions are defined as a set of all systems that are a convex combination of the models in M [5, 9].

M : y ( k ) = l ( k ) yl (k )

l =1

(17)

(k ) = 1 ,

l =1 l

(18)

where is the vector containing the probabilities for each of the modes. Below this vector is called the mode probability vector. The probabilities in provides the certainty that this model is the true one. Probability 1 means the load conditions of the system are exactly the same as modelled for this particular model. Probability closed to 0 means that the load condition of the system is very different from the modelled ones. For the adaptation purpose, the mode probabilities must be calculated for each time instant. The proposed controllers in this paper are from PI type. They have been designed on the base of LQR technique. A bank of such controllers has been created, in such way that there is a separate controller for each model (in M). In the paper it is proposed that the final control signal to be computed as a weighed sum from the control signals, obtained from the individual controllers. For the weights the mode probability vector is used. The input to the turbine is the opening of the nozzle.

(16)

Each of the equations corresponds to a particular systems load condition. Collectively these models are referred to as the model set M. 3.2 Adaptive control Usually, control of the multiple model systems is done by choosing one model from the model set M (hypothesis testing) and then control action is applied based on the selected model as if it were the true one. The main drawback of such approach is that it only allows a hard decision i.e. only one model can be chosen at a given moment of time. This method does not give a good representation of partial turbine loads and hence the control performance can be poor in such case. The model set could be extended by adding partial loads modes to it. However this is not a solution, because when the models are too close to each other, problems with the statistical testing occur [10]. Furthermore, at the moment when the control system switches from one model to another (in case of a gradual change of the load) frequent jumps of the control signal may occur. Or even worse: in the case of a load condition which is between two models the switching between the models (jumps in the control signal) may occur very frequently. One way to solve this is by an extension of the method to linear differential inclusions. Considering the model set M, the linear differen-

o(k ) = l (k ) wl (k ) ,

l =1

(19)

where the o is the input to the turbine, i.e. the opening of the nozzle and wl are control signals computed from the individual controllers. Then the control of the system boils down to computing the probabilities for each model form M. The whole Simulink block-diagram is presented in fig. 7. 3.3 Probability estimation The idea behind the probability vector is to make assessment of the load condition. In this paper as a performance index it is proposed to be used the difference between the real outputs of the system and the predicted ones [5]. Also in the working (on-line) regime the use of outputs is more convenient (less demanding from a computational point of view) than using estimates on their base. Of course, if the error in respect to certain model is small then the load of the system is close to the modelled one. In this paper it is proposed to be used the inverse of the square root of the error. The square root is chosen, because sign of the error is not important.

100

y _Turbine mu1

In1

Dead Zone

1 s

Gain7

Opening

In1 Out1 In2

y _Model1 mu2

Out1 In2

Product7

Switch

ks Gain3 Saturation

1/T s Gain4

Opening

speed

Integrator1

Load Torque

Speed

Model 100

In1 Out1 In2

y _Model2

Reg 100

In1 Out1 In2

Product6

0.6 Constant6

1 5s+1 T urbine

T orque

Model 75

mu3

Reg 75

In1 Out1 In2

In1 Out1 In2

T ransfer Fcn2

y _Model3

Parallel Operation1

Product5

Band-Limited White Noise

Load1

Model 50

In1 Out1 In2

y _Model4 mu4

Reg 50

In1

Model 25

Probabi lity Estimator

Out1 In2

Product4

Reg 25

Ki

Step1

1 s

Gain

Integrator Kp Gain1

Fig.7 Simulink Block-diagram

AT&P journal PLUS2 2008

CONTROL OF POWER PLANTS

Turbine speed, Opening, Load

1 (k ) = ( y yl ) 2

1 ( y y )2 , l = 1,L 4 . l =1 l

1.4

(20)

1.2

speed opening load

In general, the real system is subjected to noise and disturbances. To make mode probabilities insensitive to the noise or to some disturbances, special methods have been developed. For linear systems, these include Kalman filtering, diagnostic observers, parity relations, parameter estimation and symptom analysis [10]. In the MM framework, techniques are available for linear systems with known mathematical models for all modes [10]. When probabilities are evaluated only on the base of the inputs and outputs of the system, only for the current time instant, it is possible that some momentary discrepancies may appear. In presence of strong noise the error for the correct model can become equal or even bigger than the other model(s). Another problem occurs in the transitions between two operating points (for example, after applying step signal as a reference). In order to overcome this problem it is proposed to be used the moving average of the probabilities estimation. This is done at the right side of fig.8. This slows down the probability transition process, but copes with these momentary discrepancies in the measured turbine speed.

0.8

0.6

0.4

0.2

50

100

150

200

250 Time [s]

300

350

400

450

500

Fig.9 Turbine speed, opening in the case of sinusoidal load change On fig. 10 the load conditions and the estimated probabilities are presented. It can be observed that the probability estimates track the load variation. This is true not only for modelled conditions, but also for any convex combination of the modelled ones.

Model probabilities

1.4

(k ) = 0.98 (k 1) + 0.02 (k ) l = 1,L 4

1 y_Turbine 1e-6 Constant7 1 Constant 2 y_Model1

Product

(21)

0.98 Gain4 Memory

1 mu1

1.2

0.02

Load Load Load Load Load

100% 75% 50% 25%

Divide4

Divide5

Gain3 0.98

1e-6 Constant8

1

Memory1

2 mu2

1 Constant9

Divide6

Gain6

Divide1

0.02 Gain5 0.98

0.8

3 y_Model2

Product1

1e-6 Constant1

1 Constant2

Divide2

Divide7

0.02 Gain8

Gain9

Memory2

3 mu3

0.6

4 y_Model3

Product2

0.98

0.4

Memory3

4 mu4

1e-6 5 y_Model4

Product3

Constant10

1 Constant3

Divide8

0.02

Gain11

Divide3

Gain10

0.2

Fig.8 Model probabilities estimation

0 100

150

200

250

300 Time [s]

350

400

450

500

4. Simulation results

In this section the simulation results, obtained from the proposed algorithm are presented. Two experiments are carried out. The first experiments consist of varying the load conditions with a harmonic signal. The idea is to present the system performance in the whole operational range. Simulation is carried out for five hounded seconds. The results from the simulations are presented on fig. 9. In this figure the turbine speed, the opening and the load conditions are shown. In the first fifty seconds the hydro turbine generator reaches the nominal speed and in during the next fifty seconds the hydro turbine works in no load regime. Thus, the proposed algorithm starts from time t = 100 s. The goal of the proposed controller is to keep the speed close to its nominal value. It can be seen that only at the switching moment there is a speed deviation in about ten percent from its nominal value. After the initial switching of the proposed controller the speed deviation is less than two percent, while the load is changes in the whole operational range. This performance is in accordance with the UCTE primal frequency control requirements. This excellent quality of the system performance is due to the fact that the control signal is composed as a weighted sum from the outputs of multiple controllers, each of them designed for different load condition. Such results, for the whole load range can not be obtained with a single controller.

Fig.10 Model probabilities in the case of sinusoidal load change In the next experiment random load conditions are applied. Every fifty seconds different load condition is simulated. Again, during the first hounded seconds the turbine speeds up to its nominal value and works in no load condition. The simulation time is again five hounded seconds. Although, hydro turbine generators typically work long time intervals under almost constant load conditions, such sudden changes in the load conditions can accrue. The turbine speed, opening and load conditions are presented in fig. 11.

Turbine speed, opening, Load

1.4

speed opening load

1.2

0.8

0.6

0.4

0.2

50

100

150

200

250 Time [s]

300

350

400

450

500

Fig.11 Turbine speed, opening in the case of random load change

AT&P journal PLUS2 2008

CONTROL OF POWER PLANTS

It can be seen that the speed deviation is not greater that four percent and this corresponds to the load change in width range. The speed deviation is in the two percent margin when the load change is less than thirty percent. In fig.12 the mode probabilities are presented. The change of the load conditions can be compared with the mode probability estimates. Again it can be seen that the probability estimator correctly identifies not only modelled load conditions, but also each convex combination from the modelled ones. The turbine speed, opening position and load conditions for the conventional turbine control based on a single controller are presented in fig. 13. It can be seen the speed deviation is about thirty percent for the fifty percent load change. Therefore the conventional controller designed at one load condition doesnt work well under different loads conditions.

Model probabilities

References

[1] IEEE Working Group, Hydraulic Turbine and Turbine Control Models for System Dynamic Studies, Transactions on Power System, 1992, Vol.7, 1, pp.167-179. [2] MALIK, O.P, ZENG, Y., Design of a robust adaptive controller for a water turbine governing system, IEEE Transaction on EC, 1995, Vol.10, 2, pp.354-359. [3] PHI, D.T., BOURGUE, E.J, Thorne, D.H., Hill, E.F., Analysis and application of the stability limits of a hydrogenerating unit, IEEE Transaction on PAS, 1981, Vol. PAS100, 7, pp.3203-3212. [4] JIANG, J., Design an optimal robust governor for hydraulic turbine generating units, IEEE Transaction on EC, 1995, Vol.10, 1, pp.188-194. [5] ICHTEV, A. Multiple Fuzzy Models for Fault Tolerant Control. International Journal of Fuzzy Systems, 2003, Vol.5, pp.31-40. [6] EGELAND, O., GRAVDAHL, J., Modeling and Simulation for Automatic Control, Marine Cybernetics 2002. [7] GLATTFELDER, A., SCHAUFELBERGER, W., Control Systems with Input and Output Constraints, Springer, 2003. [8] PULEVA, T.,Water turbine power and speed optimal controller design. Information technologies and control, 2004, 2, pp. 44-48. [9] ICHTEV A., HELLENDOORN, J., BABUSKA, R., MOLLOV S. Fault Tolerant Model Based Predictive Control Using Multiple Takagi-Sugeno Fuzzy Models. In Proceedings of the 2002 IEEE International Conference on Fuzzy Systems , FUZZ-IEEE'02, pp.346-351. [10] GERTLER, J. Fault Detection and Diagnosis in engineering systems, 1998, Marcel Dekker, Inc.

1

Load Load Load Load Load 100% 75% 50% 25%

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0 100

150

200

250

300 Time [s]

350

400

450

500

Fig.12 Model probabilities in the case of random load change

Turbine speed, opening, Load

1.4

Speed Opening Load

1.2

Acknowledgments The authors would like to acknowledge Ministry of Education and Science Fund of Bulgaria, Joint Research Project No: Bg - Sk 105/07 Modified controllers design for nonlinear hydro power engineering plants control

0.8

0.6

0.4

0.2

Dr. Teofana Puleva Technical University of Sofia

0

50

100

150

200

250 Time [s]

300

350

400

450

500

Fig.13 Conventional turbine control in the case of random load change

CONCLUSION

A nonlinear model of hydro turbine generator system is presented. A multi-model adaptive control algorithm is presented in this paper. This approach is applied to the hydro turbine generator speed and power control under wide range of load conditions. A bank of models is considered. Each of the models corresponds to a different load condition. An algorithm for probability estimation for each model is proposed. On their base soft adaptation is performed. The control signal is a weighted sum of particular controls designed for local load conditions. Different simulations are carried out. The results are discussed and compared with the conventional control based on a single controller.

Faculty of Automatics Department of Systems and Control Engineering 8, Kliment Ohridski str. 1000 Sofia Tel.: (+359 2) 965 2526 E-mail tpuleva@tu-sofia.bg

Dr. Alexandar Ichtev Technical University of Sofia Faculty of Automatics Department of Systems and Control Engineering 8, Kliment Ohridski str. 1000 Sofia Tel.: (+359 2) 965 2420 E-mail ichtev@tu-sofia.bg

AT&P journal PLUS2 2008

Anda mungkin juga menyukai

- PolymerizationDokumen30 halamanPolymerizationSolha MubarakBelum ada peringkat

- Analysis of Cost EstimationDokumen58 halamanAnalysis of Cost Estimationccsreddy100% (3)

- 17 - Gas Absorption PrinciplesDokumen20 halaman17 - Gas Absorption PrinciplesSolha MubarakBelum ada peringkat

- Fuels and CombustionDokumen28 halamanFuels and CombustionDrupad PatelBelum ada peringkat

- Smith - Van Ness - Abbot - Chemical Engineering Thermodynamics - 2Dokumen621 halamanSmith - Van Ness - Abbot - Chemical Engineering Thermodynamics - 2Solha MubarakBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- A Case Study From The: PhilippinesDokumen2 halamanA Case Study From The: PhilippinesNimBelum ada peringkat

- 1610-2311-Executive Summary-EnDokumen15 halaman1610-2311-Executive Summary-EnKayzha Shafira Ramadhani460 105Belum ada peringkat

- Airport Demand ModelDokumen26 halamanAirport Demand ModelbsvseyBelum ada peringkat

- Steris Amsco Century v120Dokumen2 halamanSteris Amsco Century v120Juan OrtizBelum ada peringkat

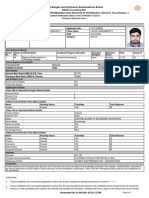

- West Bengal Joint Entrance Examinations Board: Provisional Admission LetterDokumen2 halamanWest Bengal Joint Entrance Examinations Board: Provisional Admission Lettertapas chakrabortyBelum ada peringkat

- Scout Activities On The Indian Railways - Original Order: MC No. SubjectDokumen4 halamanScout Activities On The Indian Railways - Original Order: MC No. SubjectVikasvijay SinghBelum ada peringkat

- Mind Mapping BIOTEKDokumen1 halamanMind Mapping BIOTEKAdrian Muhammad RonalBelum ada peringkat

- South West Mining LTD - Combined CFO & HWA - VerDokumen8 halamanSouth West Mining LTD - Combined CFO & HWA - Verapi-3809359Belum ada peringkat

- Cam 12 Test 2 ReadingDokumen7 halamanCam 12 Test 2 ReadingLê Nguyễn Ái DuyênBelum ada peringkat

- 671 - BP Well Control Tool Kit 2002Dokumen19 halaman671 - BP Well Control Tool Kit 2002Ibama MirillaBelum ada peringkat

- MAS-02 Cost Terms, Concepts and BehaviorDokumen4 halamanMAS-02 Cost Terms, Concepts and BehaviorMichael BaguyoBelum ada peringkat

- Claim Age Pension FormDokumen25 halamanClaim Age Pension FormMark LordBelum ada peringkat

- 15.910 Draft SyllabusDokumen10 halaman15.910 Draft SyllabusSaharBelum ada peringkat

- 13 - Conclusion and SuggestionsDokumen4 halaman13 - Conclusion and SuggestionsjothiBelum ada peringkat

- RA 9184 & RA 3019 NotesDokumen5 halamanRA 9184 & RA 3019 Notesleng_evenBelum ada peringkat

- E14r50p01 800 MhaDokumen4 halamanE14r50p01 800 Mha'Theodora GeorgianaBelum ada peringkat

- Innova M3 New: 3. InstallationDokumen8 halamanInnova M3 New: 3. InstallationAndreea DanielaBelum ada peringkat

- 2 Players The One With Steam BaronsDokumen1 halaman2 Players The One With Steam BaronsBrad RoseBelum ada peringkat

- BSDC CCOE DRAWING FOR 2x6 KL R-1Dokumen1 halamanBSDC CCOE DRAWING FOR 2x6 KL R-1best viedosBelum ada peringkat

- Galanz - Galaxy 7-9-12K - SPLIT PDFDokumen42 halamanGalanz - Galaxy 7-9-12K - SPLIT PDFUbaldo BritoBelum ada peringkat

- Personal Information: Witec Smaranda 11, A3 Bis, Blvd. Chisinau, Bucharest, Romania 0040722597553Dokumen6 halamanPersonal Information: Witec Smaranda 11, A3 Bis, Blvd. Chisinau, Bucharest, Romania 0040722597553MirelaRoșcaBelum ada peringkat

- GGSB MibDokumen4 halamanGGSB MibShrey BudhirajaBelum ada peringkat

- Future Generation Computer SystemsDokumen18 halamanFuture Generation Computer SystemsEkoBelum ada peringkat

- Radix Sort - Wikipedia, The Free EncyclopediaDokumen13 halamanRadix Sort - Wikipedia, The Free EncyclopediasbaikunjeBelum ada peringkat

- Burberry Annual Report 2019-20 PDFDokumen277 halamanBurberry Annual Report 2019-20 PDFSatya PhaneendraBelum ada peringkat

- Midterm Quiz 01 - Adjusting Entries From Accrual To Provision For Uncollectible AccountsDokumen3 halamanMidterm Quiz 01 - Adjusting Entries From Accrual To Provision For Uncollectible AccountsGarp Barroca100% (1)

- X606 PDFDokumen1 halamanX606 PDFDany OrioliBelum ada peringkat

- Hi 3 Yt 318201Dokumen3 halamanHi 3 Yt 318201partha khatuaBelum ada peringkat

- cv20672778 Prashanth - Sadak Operations-ManagerDokumen4 halamancv20672778 Prashanth - Sadak Operations-ManagerBhasker NiftyBelum ada peringkat

- Wilo49608 Wilo Ge LeafletDokumen46 halamanWilo49608 Wilo Ge LeafletJair Jimenez HerreraBelum ada peringkat