Pathfinder HDS-1 MWD Gamma Tool

Diunggah oleh

cheeeky_monkeyDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Pathfinder HDS-1 MWD Gamma Tool

Diunggah oleh

cheeeky_monkeyHak Cipta:

Format Tersedia

Technology Applications

Dennis Denney, JPT Technology Editor

Fig. 3FlexClad System from Enventure Global Technology.

Fig. 2R&M Energy Systems Moyno ERT power section.

Fig. 1Pathfinder Energy Services Incs. Gravity MWD system.

to downhole movement during surveys, allowing operation in environments where gyroscope surveying can be problematic. The system is designed for use in casing drilling, drilling out of casing shoes and casing windows, re-entry work, geothermal wells with high magnetic interference, drilling relief wells, drilling in anticollision situations, and drilling multilateral wells, and for use with the companys Winner Well Interference Navigator passive-ranging technique for wellbore avoidance. This MWD surveying method uses a second accelerometer-sensor package to derive azimuth rather than using magnetometers. It is, therefore, not prone to magnetic interference or the resulting drawbacks of conventional MWD. The technique uses the inherent bending of a bottomhole assembly between the two sets of accelerometers, 100 ft apart, to measure the relative change in azimuth. The accumulated changes show the well-path trajectory. The system uses high-speed mud-pulse telemetry to communicate data and has been used at depths greater than 28,000 ft. Downhole Power SectionR&M Energy Systems, a unit of Robbins & Myers Inc., has introduced its Moyno ERT Power Section, with its new even-rubber-thickness stator (Fig. 2). This new stator technology can improve the overall performance of power sections used in downhole drilling applications. The stators have internal contours that

are precision-machined, rather than hydraulically formed. The resulting tubes have durability and tolerance that optimize the benefits of the technology. Applying an even thickness of rubber to the stator contour and supporting each lobe with steel minimizes the rubbers degree of dimensional change during use as a result of high temperature, chemical attack, and loading. This design allows the companys power sections to produce up to 100% more power output compared with conventional stators. This higher power density results in greater rates of penetration. The high power density allows the use of shorter power sections with performance output that is comparable with that of a longer conventional product. This shorter power section can improve the motors directional response as well as MWD and logging-while-drilling quality by placing the sensors closer to the bit. Expandable-Tubular IsolationEnventure Global Technology LLC, in conjunction with Halliburton Energy Services, recently installed the first solid-expandabletubular system in Latin America for Pemex E&P A 270-ft-long, 41/2-in.-diameter . FlexClad system (Fig. 3) was installed to isolate perforations in an oil well in the Gulf of Mexico. This system adapts expandabletubular technology to high-pressure/hightemperature wells. Expandable sealing sections, called flex hangers, are separated along the length of the liner using conventional tubulars and flush-joint connections. This configuration of expanding just the flex hangers enables the system to be used in smaller casing sizes. The system is run through existing casing, then expanded and clad to the inside wall of the existing casing. The process forms a seal to minimize loss of

Interference-Free SurveyThe Gravity MWD system from Pathfinder Energy Services Inc. is an interference-free survey technique. The system uses the modular HDS-1G tool (Fig. 1) that eliminates magnetic interference that prevents the use of conventional measurement-while-drilling (MWD) tools. The system is very insensitive

20

FEBRUARY 2005

hole diameter. In addition to its isolation capabilities, this system can repair existing casing and provide a gastight liner. Offshore-Stimulation VesselBJ Services Co. announced successful completion of hydraulic-fracturing services from its MV Vestfonn, an offshore stimulation vessel, in the Dutch sector of the North Sea. In this operation, the production string through which the treatment was to be pumped contained a travel joint that limited movement. In 1988, when the well was completed, fracturing was not considered. Therefore, the short polished-bore receptacle, which allows tubing movement of only 15 ft, was not an issue. The operational envelope is dictated by the physical conditions of the completion. Because the bottomhole temperature of this well was moderate to high, concern existed about the cooldown effect during treatment. While on the vessel, the fracturing-fluid temperature was dictated by the ambient water temperature in the storage tanks. Treatment simulation with a fluid-injection temperature of 50F indicated that the reduction in temperature gradient of the completion string would cause contraction in excess of 15 ft. Fracturingfluid temperature of 70F or higher would provide an acceptable contraction of the string. The vessel was modified to heat the water directly in the storage tanks (Fig. 4). The primary treatment could require in excess of 100,000 gal of fluid, and the pretreatment injections such as the breakdown, step-rate test, and minifrac would require additional fluid. Because of the time required to heat these large volumes, it was necessary to heat several water tanks individually. Heaters were installed in six of the vessels water tanks (i.e., 140,000 gal), as required by the design criterion of heating

the water from 50 to 70F in a 24-hour period. Two additional temporary generators were required, which had to be placed on the cargo deck and accordingly cabled to the heater in each water tank. The two-stageconfiguration elements reduced the start load on the generators. Seismic-Wave StimulationApplied Seismic Research Corp. has introduced its HydroImpact technology. The new technology uses seismic-wave stimulation to release oil trapped in existing fields. The procedure was developed to enhance oil recovery in depleted fields by restoring previously abandoned wells to productive status and to increase the yield in currently producing fields. Record of a 1-year-long stimulation of the Elk Hills field was presented to the Railroad Commission of Texas, which regulates Texas crude-oil production, and an application to treat seismic stimulation as an enhanced-recovery technique was approved, granting it tax-abatement advantages. This technology produces shockwaves with a power ranging from 2 to 10 million W (compared with 10 to 100,000 W for other methods) and a pressure at the wave front in excess of 3,000 psi. The shockwaves, traveling at 1.5 miles/sec, cover distances of more than 1 mile and in all directions. The shockwaves release oil that otherwise would never have moved. Sandstone, carbonate, diatomite, waterflood, and natural-waterdrive fields, as well as one gas-injection oil field, have benefited from use of this technology.

the tubular goods, inducing excessive stress in the metal that can affect casing-to-cement bonding. Engineered for deepwater, permafrost, and other cold-temperature environments, this packer fluid provides thermal protection for produced oil. Aqueousbased or water-miscible fluid minimizes the conduction of heat away from the production string. The base fluid resists thermal conduction and contains no suspended solids. It can be formulated for densities ranging from 8.33 to 12.5 lbm/gal. It is pH buffered and inhibited to minimize corrosion. It is hydraulically optimized to yield low plastic viscosity with elevated lowshear-rate viscosities and yield stress. The fluid has a flat rheological profile over a wide temperature range, is thermally stable over extended time periods, and can be mixed and pumped on the rig. Reducing Pipe-Wall FrictionVortex Flow LLC tools improve production by increasing the efficiency of fluid flow in pipelines and tubing strings and by reducing or eliminating the accumulation of paraffin in pipelines. The tools work by separating gas and liquids into a two-flow pattern, with the liquids flowing in a spiral along the wall of the pipe and the gas flowing through the center. This vortex (rotating) pattern prevents liquids from dropping out of the flow and permits efficient movement over long distances and through substantial changes in elevation and direction. This enhanced flow efficiency also has been observed in single-phase gas and singlephase liquid flows by reducing pipe-wall friction and, therefore, reducing pressure losses. A variation of the downhole tool, the Vortex Flow DXR, can be installed by use of slickline without the need to pull the tubing. The vortex flow in gas-well tubing strings reduces the critical gas-production velocity required to lift liquids from the wellbore. Laboratory tests have shown that the tool increases liquids lifted by 12% and reduces pressure drop from friction by up to 15%. The tools create a liquid boundary layer on the inner wall of the pipe that acts as a cushion. This cushion reduces friction and helps to reduce accumulation of paraffin or scale on pipe walls.

Insulating Packer FluidSafeTherm insulating packer fluid from M-I Swaco helps overcome temperature-related problems that can reduce, or even stop, production. The combination of cold temperature and high pressure can lead to temperature cycling in the wellbore, salt precipitation, or the formation of production-blocking hydrates, paraffin, and asphaltenes. Heat transfer away from produced fluids results in a product that can become incompatible with the available surface processing equipment. Multiple casing strings allow transfer of heat into unvented annuli and can increase temperature and pressure in the sealed space, posing a serious risk of casing collapse. Well shut-ins for short-term suspensions and interFig. 4Control room onboard BJ Services vention operations can cause therMV Vestfonn stimulation vessel. mal expansion and contraction of

For additional information on Technology Applications items, go to: www.oilonline.com/jpt. Then, click on JPT Reader Inquiry Service.

22

FEBRUARY 2005

Anda mungkin juga menyukai

- PDC Bits - All Comes From The Cutter Rock Interaction PDFDokumen9 halamanPDC Bits - All Comes From The Cutter Rock Interaction PDFMejbahul SarkerBelum ada peringkat

- Drill Bit Classifier 2007Dokumen17 halamanDrill Bit Classifier 2007amin peyvandBelum ada peringkat

- Cutting Efficiency With PDC BitDokumen6 halamanCutting Efficiency With PDC BitDanny RevillaBelum ada peringkat

- Drill Bit Classifier 2006Dokumen17 halamanDrill Bit Classifier 2006amin peyvandBelum ada peringkat

- Deliver The Well: Rodney Howard Halliburton, AberdeenDokumen100 halamanDeliver The Well: Rodney Howard Halliburton, AberdeenЮрий УсковBelum ada peringkat

- SPE-14765-MS-Applications of A BHA Analysis Program in Directional DrillingDokumen10 halamanSPE-14765-MS-Applications of A BHA Analysis Program in Directional Drillingsaeed65Belum ada peringkat

- SPE-19545-MS Predicting Wellbore TrajectoryDokumen13 halamanSPE-19545-MS Predicting Wellbore Trajectoryswaala4realBelum ada peringkat

- MONITORING DRILLING PARAMETERS OPTIMIZES RATESDokumen16 halamanMONITORING DRILLING PARAMETERS OPTIMIZES RATESAnmol JassalBelum ada peringkat

- Advances in Oil & Gas DrillingDokumen35 halamanAdvances in Oil & Gas DrillingKhanzzBelum ada peringkat

- 8 5-Mme65rDokumen1 halaman8 5-Mme65rWHWENBelum ada peringkat

- Strength Properties of Metamorphic RocksDokumen5 halamanStrength Properties of Metamorphic Rockscsreejith100% (1)

- Rolling PDC Cutter Advances Drilling Efficiency in Granite Wash FormationDokumen4 halamanRolling PDC Cutter Advances Drilling Efficiency in Granite Wash FormationRio RizkiBelum ada peringkat

- Bit BallingDokumen18 halamanBit BallingGPC100% (1)

- Bi Center Presentation Brocas PerforacionDokumen14 halamanBi Center Presentation Brocas PerforacionOscar RuedaBelum ada peringkat

- Introduction To Wellbore Positioning - V01.7.12 PDFDokumen157 halamanIntroduction To Wellbore Positioning - V01.7.12 PDFMiguelBelum ada peringkat

- 12 BT 0123 Stinger North Dakota CsDokumen2 halaman12 BT 0123 Stinger North Dakota CsdiegoilBelum ada peringkat

- HP DM and Relief Manual, 2012Dokumen115 halamanHP DM and Relief Manual, 2012VIJAY KUMAR HEER100% (1)

- Bico Handbk 11-11Dokumen88 halamanBico Handbk 11-11faishal hafizhBelum ada peringkat

- Spe 135704 MS PDFDokumen9 halamanSpe 135704 MS PDFKd FaBelum ada peringkat

- 05 PDC DullsDokumen37 halaman05 PDC DullsFahim MazherBelum ada peringkat

- Expandable Drill BitDokumen6 halamanExpandable Drill BitJohnSmithBelum ada peringkat

- Coca-Cola Marketing Vender Operation ManualDokumen74 halamanCoca-Cola Marketing Vender Operation ManualDavidBelum ada peringkat

- HC606 Drill Bit ManualDokumen1 halamanHC606 Drill Bit ManualMahdy BasimBelum ada peringkat

- Reduce Torsional Vibration and Improve Drilling Operations: Jerome Rajnauth, PHDDokumen15 halamanReduce Torsional Vibration and Improve Drilling Operations: Jerome Rajnauth, PHDAnonymous DDqgH1Y2MKBelum ada peringkat

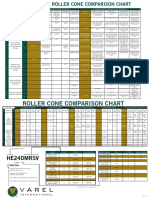

- ROLLER CONE COMPARISON CHART TUNGSTEN CARBIDE INSERTSDokumen2 halamanROLLER CONE COMPARISON CHART TUNGSTEN CARBIDE INSERTSBaitaw WanwarangBelum ada peringkat

- Schlumberger Engineer Guide MWD LWDDokumen58 halamanSchlumberger Engineer Guide MWD LWDZaid BelabassiBelum ada peringkat

- CavingDokumen15 halamanCavingTanzilBelum ada peringkat

- The Ideal Bit Drag Bits: Fishtail Type Natural Diamond Polycrystalline Diamond Compact (PDC)Dokumen45 halamanThe Ideal Bit Drag Bits: Fishtail Type Natural Diamond Polycrystalline Diamond Compact (PDC)ShourovjossBelum ada peringkat

- 511 NewscoDokumen58 halaman511 NewscoMEUBROBelum ada peringkat

- Defining BitsDokumen2 halamanDefining BitsahmedBelum ada peringkat

- SPE 88446 Making Steerable Bits: Separating Side-Force From Side-CuttingDokumen7 halamanSPE 88446 Making Steerable Bits: Separating Side-Force From Side-CuttingmsmsoftBelum ada peringkat

- Driller's Depth ErrorsDokumen2 halamanDriller's Depth Errorsnyanya2007Belum ada peringkat

- Confined Compressive Strength Model of Rock For Drilling OptimizationDokumen7 halamanConfined Compressive Strength Model of Rock For Drilling Optimizationodex100% (2)

- Blackstar II Dual Telemetry MWD Tool Spec Sheet PDFDokumen4 halamanBlackstar II Dual Telemetry MWD Tool Spec Sheet PDFDani HpBelum ada peringkat

- Redback Operations ManualDokumen11 halamanRedback Operations ManualDon BraithwaiteBelum ada peringkat

- MN Mit037 DDokumen116 halamanMN Mit037 DAriel GraneroBelum ada peringkat

- Surface Intermediate: Utica Shale Basin-Bit GuideDokumen1 halamanSurface Intermediate: Utica Shale Basin-Bit GuidependexxBelum ada peringkat

- Bit Selection PDFDokumen113 halamanBit Selection PDFAbdelkader FattoucheBelum ada peringkat

- Directional Drilling HistoryDokumen7 halamanDirectional Drilling Historyhjdb2014100% (2)

- MagTrak BrochureDokumen8 halamanMagTrak BrochurejaloaliniskiBelum ada peringkat

- Каталог инструмента 2017 eng PDFDokumen128 halamanКаталог инструмента 2017 eng PDFmoreta18100% (1)

- The Current State of PDC Bit Technology - Part 1Dokumen4 halamanThe Current State of PDC Bit Technology - Part 1djc292Belum ada peringkat

- Top-Co Type 361 Integral Centralizer Sub for Deep WellsDokumen2 halamanTop-Co Type 361 Integral Centralizer Sub for Deep WellsEmenike Donald EjiejiBelum ada peringkat

- Drilling LineDokumen41 halamanDrilling LineAboZaidBelum ada peringkat

- NCS SpotFrac Saves Troubled Flossie Lake Horizontal CompletionDokumen9 halamanNCS SpotFrac Saves Troubled Flossie Lake Horizontal CompletionMauro LozanoBelum ada peringkat

- Dependency Form PDFDokumen5 halamanDependency Form PDFVivek VenugopalBelum ada peringkat

- Latch Type Drilling JAR ManualDokumen41 halamanLatch Type Drilling JAR ManualMuhammad Zikry Alfindy HazBelum ada peringkat

- Drilling Bits SPE Series-ADIDokumen62 halamanDrilling Bits SPE Series-ADIAlfredo TintayaBelum ada peringkat

- Mud/Gas Separator Sizing and Evaluation: G.R. MacdougallDokumen6 halamanMud/Gas Separator Sizing and Evaluation: G.R. MacdougallDiego AraqueBelum ada peringkat

- H03729Dokumen4 halamanH03729AQUILES CARRERABelum ada peringkat

- Chapter 02Dokumen24 halamanChapter 02Alejandro PonceBelum ada peringkat

- W CT Downhole Electric Cutting Tool DECT001Dokumen2 halamanW CT Downhole Electric Cutting Tool DECT001casda73Belum ada peringkat

- 2 Borehole EnlargementDokumen10 halaman2 Borehole EnlargementpsaumBelum ada peringkat

- Directional Well Planning OverviewDokumen26 halamanDirectional Well Planning Overviewsanjeet giri100% (2)

- Trident PDC CuttersDokumen2 halamanTrident PDC CuttersjobsBelum ada peringkat

- Powerstroke Drilling Jar: Instruction Manual 4250Dokumen24 halamanPowerstroke Drilling Jar: Instruction Manual 4250Foros IscBelum ada peringkat

- WebtocDokumen10 halamanWebtocriobmBelum ada peringkat

- 2011 - Reelwell Company FolderDokumen12 halaman2011 - Reelwell Company FolderMohamed SadekBelum ada peringkat

- Innovative Exploration Methods for Minerals, Oil, Gas, and Groundwater for Sustainable DevelopmentDari EverandInnovative Exploration Methods for Minerals, Oil, Gas, and Groundwater for Sustainable DevelopmentA. K. MoitraBelum ada peringkat

- Fundamentals and Applications of Bionic Drilling FluidsDari EverandFundamentals and Applications of Bionic Drilling FluidsBelum ada peringkat

- The Art of Aeronautical Decision (ADM) FAADokumen12 halamanThe Art of Aeronautical Decision (ADM) FAAHuaseongBelum ada peringkat

- Household Demand For Waste Recycling ServicesDokumen10 halamanHousehold Demand For Waste Recycling Servicescheeeky_monkeyBelum ada peringkat

- Effect On Liver Cells of Stepwise Microstructures Fabricated in A Photosensitive Biodegradable PolymerDokumen6 halamanEffect On Liver Cells of Stepwise Microstructures Fabricated in A Photosensitive Biodegradable Polymercheeeky_monkeyBelum ada peringkat

- Applications of PEO in Drug Administer at IonDokumen8 halamanApplications of PEO in Drug Administer at Ioncheeeky_monkeyBelum ada peringkat

- Character Is at Ion of The Formation of Inter Facially Photo Polymer Is Ed Thin Hydrogels in Contact With Arterial TissueDokumen6 halamanCharacter Is at Ion of The Formation of Inter Facially Photo Polymer Is Ed Thin Hydrogels in Contact With Arterial Tissuecheeeky_monkeyBelum ada peringkat

- Distillation Column Control Design Using Steady StateDokumen18 halamanDistillation Column Control Design Using Steady Stateb95504048Belum ada peringkat

- Register for a WordPress account in 5 easy stepsDokumen5 halamanRegister for a WordPress account in 5 easy stepsPutriBelum ada peringkat

- UniSim Heat Exchangers User Guide PDFDokumen22 halamanUniSim Heat Exchangers User Guide PDFzhangyiliBelum ada peringkat

- Jason Cafer Biosketch 8-2009Dokumen3 halamanJason Cafer Biosketch 8-2009Jason CaferBelum ada peringkat

- DX DiagesDokumen36 halamanDX DiagesBpbd Kota BengkuluBelum ada peringkat

- Laboratory Activity No. 01 - Properties of LiquidDokumen2 halamanLaboratory Activity No. 01 - Properties of LiquidCzarina Relleve0% (1)

- Assignment (40%) : A) Formulate The Problem As LPM B) Solve The LPM Using Simplex AlgorithmDokumen5 halamanAssignment (40%) : A) Formulate The Problem As LPM B) Solve The LPM Using Simplex Algorithmet100% (1)

- Alvi Hanif Adil Ahmed Vveinhardt Impact of Organizational Culture On Organizational Commitment and Job Satisfaction-LibreDokumen11 halamanAlvi Hanif Adil Ahmed Vveinhardt Impact of Organizational Culture On Organizational Commitment and Job Satisfaction-LibreLeilane AlvesBelum ada peringkat

- TFT-LCD TV/MONITOR SERVICE MANUALDokumen54 halamanTFT-LCD TV/MONITOR SERVICE MANUALhimkoBelum ada peringkat

- Phil of DepressDokumen11 halamanPhil of DepressPriyo DjatmikoBelum ada peringkat

- Steam Technical InfoDokumen2 halamanSteam Technical InfoAnonymous 7z6OzoBelum ada peringkat

- Independent University, Bangladesh: Term Paper (Group Assignment)Dokumen16 halamanIndependent University, Bangladesh: Term Paper (Group Assignment)Johan Tausifur RahmanBelum ada peringkat

- Friction WedgesDokumen7 halamanFriction Wedgespericharla ravivarmaBelum ada peringkat

- Magazine 55 EnglishPartDokumen50 halamanMagazine 55 EnglishPartAli AwamiBelum ada peringkat

- 38-13-10 Rev 2Dokumen128 halaman38-13-10 Rev 2Gdb HasseneBelum ada peringkat

- Assignment 5: Building More Complex Tasks: 1 BackgroundDokumen3 halamanAssignment 5: Building More Complex Tasks: 1 Backgroundt_hoffmannBelum ada peringkat

- ACP160DDokumen14 halamanACP160Dinbox934Belum ada peringkat

- ButeDokumen89 halamanButeNassime AmnBelum ada peringkat

- Chapter 2 - Key Themes of Environmental ScienceDokumen34 halamanChapter 2 - Key Themes of Environmental ScienceJames Abuya BetayoBelum ada peringkat

- Trip WireDokumen19 halamanTrip Wirepinky065558100% (2)

- Myers Et Al - Clear and Present ThinkingDokumen214 halamanMyers Et Al - Clear and Present ThinkingAEBelum ada peringkat

- Risk in Clean RoomDokumen9 halamanRisk in Clean RoomABEERBelum ada peringkat

- Example4 FatigueTools WS01-SNDokumen23 halamanExample4 FatigueTools WS01-SNJosé Luciano Cerqueira CesarBelum ada peringkat

- PDF Manual de Reparaciones Estructurales Del Airbus A 320 CompressDokumen15 halamanPDF Manual de Reparaciones Estructurales Del Airbus A 320 CompressJosé LuisBelum ada peringkat

- Nursing ProcessDokumen88 halamanNursing ProcessGerard On LineBelum ada peringkat

- Case StudyDokumen5 halamanCase StudyTanzila khanBelum ada peringkat

- Mastering EES Chapter1Dokumen66 halamanMastering EES Chapter1mianvaherBelum ada peringkat

- Unit 30 WorkDokumen2 halamanUnit 30 WorkThanh HàBelum ada peringkat

- Secondary SourcesDokumen4 halamanSecondary SourcesKevin NgoBelum ada peringkat

- BMED148 Assessment 1Dokumen5 halamanBMED148 Assessment 1ROMEL ALJUN TARROBALBelum ada peringkat

- Us00-000 831 01 02 02Dokumen18 halamanUs00-000 831 01 02 02Cristian Camilo0% (1)