Erection Procedure

Diunggah oleh

Ranjit BanerjeeDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Erection Procedure

Diunggah oleh

Ranjit BanerjeeHak Cipta:

Format Tersedia

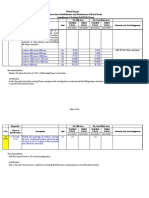

Action Plan for Site Construction Control Equipment Erection

S.No

1 1.1 1.2 2 2.1 2.2 2.3 2.4 2.5 2.6 3 3.1 3.2 3.3 3.4 3.5

Process Description

Installation Verification Check Check framework,mounting/ anchor bolt Location/ leveling Completeness off assy/ sub.assy to erect Installation Equipment Installation/ Lifting procedure if heavy lifting is required Rigging & lifting of the equipment Verification of location ( Dimensional Check) Levelling/Shimming/Grouting Bolting / torque of securing bolts Check securing of equipment by welding Mechanical Completion Alignment of rotating equipment after hook up Erect Coupling guard Fill up mechanical completion check sheet Final check on completion Final documention

Project Specific Procedure

Acceptance Criteria

Verifying Doc

Action Point Tech. sup Equip.Sup Vendor Consultant

Project drawing,equipment drawing & manufacturing's recommendation Project drawing,equipment drawing.

Manufacture's installation procedure/ criteria as per specification & tolrances As per Manufacture's drawing

Inspection Report Inspection Report

H W

H W

H W

H W

Vendor's procedure & equipment drawing Vendor's procedure & equipment drawing Project drawing,equipment drawing & manufacturing's recommendation Project drawing,equipment drawing & manufacturing's recommendation As per drawing/ Engg.Specification As per drawing.

Vendor Installation procedure Vendor Installation procedure Vendor Installation procedure Vendor Installation procedure As per design calculation and ASME standards As per drawing

Doc. Doc. Inspection Report Inspection Report Inspection Report Inspection Report

M M H H H H

M M H W W W

M M H W W W

M M H H H H

Pjt drawing,Equip.drg. Manuf's recomm. Also As per specification & manufacter's criteria before & after piping fix up. As per drawing Project Procedure Project Procedure Contract doc. Drawing & site condition Insp.records & all project drawing Insp.records & all project drawing Contract doc.

Inspection Report Inspection Report Mech.completion & commsission check sheet. Mech.completion & commsission check sheet. Final documentation & punch list

M H R+A

W H R+A

W H R+A

W H R+A

Legends

W - Witness ( Formal written notification one day ahead from agency concerned) H - Hold point ( Formal written notification one day ahead from agency concerned) M - Random/ spot check of activites ( No formal notification required) R - Review ( of certificates, record & documentation) A - Approve ( A document or an activity for which a document will be required by the indicated authority & approval obtained)

Owner

H W

A A H H H H

W H R+A

Check List for Heavy Equipment Erection Procedure

S.No

1

Check point

Transportation to site unloading storage before erection

Yes

No

Lifting arrangment

Sequence of erection as per vendor document

Tools & tackles list & quantity.

Soundness of tools & tackles ( Test certificate,random check)

Saftey Points

At Height => Height pass, Harness, life line, fall arrester, net etc,

ii

Confined Space => Evacuation system, ventilation, rescue crew etc.

iii

Control of Hanging Material => Guy rope, winch etc.

iv

Communication => Walkie talkie, Light signaling,Signalling etc.

Responsibility => Safety manager for the activity.

vi

PPE => Special PPE requirement

Clearance after erection

Inspection Format Equipment Erection Equipment Name : S.No Inspection Point Drawing Tag No : Actual Remarks

Dimension

Hole Center/dia

Finish

Completeness of assy/ sub assy

Verification of Location

Levelling/ shimming/ grouting

Bolting/ Torque of securing bolt

Check securing of welding

Alignment of rotating equipment

10

Erection of safety guard

Anda mungkin juga menyukai

- MS Constrution of Civils CausewayDokumen11 halamanMS Constrution of Civils Causewaynap_carinoBelum ada peringkat

- Estimation of Overhead TankDokumen8 halamanEstimation of Overhead TankTeja AmereBelum ada peringkat

- Indian Standard: Carbon Steel Castings For General Engineering Purposes - SpecificationDokumen8 halamanIndian Standard: Carbon Steel Castings For General Engineering Purposes - SpecificationchepurthiBelum ada peringkat

- Class Test 4 & 5 Cams - Gears - Assignment Questions KomDokumen10 halamanClass Test 4 & 5 Cams - Gears - Assignment Questions KomVenkateswar Reddy MallepallyBelum ada peringkat

- Raw Material Cutting Request Form: Raw Size SR # Date Job No Material Plate No Length Width Thickness Heat NumberDokumen1 halamanRaw Material Cutting Request Form: Raw Size SR # Date Job No Material Plate No Length Width Thickness Heat NumberAMIT SHAHBelum ada peringkat

- Human Reliability 07Dokumen4 halamanHuman Reliability 07Fernando RomeroBelum ada peringkat

- Inspection and Monitoring of Lead Acid Batteries inDokumen17 halamanInspection and Monitoring of Lead Acid Batteries inBenBelum ada peringkat

- Description: Tags: 03session7Dokumen63 halamanDescription: Tags: 03session7anon-157775Belum ada peringkat

- The Role of Control Room Operators: Andrew Brazier Principal Consultant Entec UK LTDDokumen17 halamanThe Role of Control Room Operators: Andrew Brazier Principal Consultant Entec UK LTDMatthewBelum ada peringkat

- Assignment - 4Dokumen7 halamanAssignment - 4paridhisahni0% (2)

- Hydrostatic Test ProcedureDokumen7 halamanHydrostatic Test Procedurelaleye_olumideBelum ada peringkat

- Rig Weight NormsDokumen1 halamanRig Weight NormsDPSprojectsBelum ada peringkat

- Manual For RX-Multi (en-ES) - VFebmanual RXDokumen4 halamanManual For RX-Multi (en-ES) - VFebmanual RXricardoBelum ada peringkat

- UPDATED New Cost Estimation Manual FinalDokumen26 halamanUPDATED New Cost Estimation Manual FinalBerihun AddisBelum ada peringkat

- UD06737B-A Baseline Fingerprint Time Attendance Termimal User Manual V1.1.1 20180502Dokumen144 halamanUD06737B-A Baseline Fingerprint Time Attendance Termimal User Manual V1.1.1 20180502davaasuren jargalsaihanBelum ada peringkat

- NG-018-XX-PNL-430926 - Rev04 Weld Numbering System and Procedure UnsignedDokumen20 halamanNG-018-XX-PNL-430926 - Rev04 Weld Numbering System and Procedure UnsignedFolarin Ayodeji100% (1)

- BemeDokumen1 halamanBemeAbdulyekini AhmaduBelum ada peringkat

- Piping Work 5Dokumen17 halamanPiping Work 5Sastra WinataBelum ada peringkat

- Manifold Burst Pressure TestDokumen3 halamanManifold Burst Pressure TestrajeshBelum ada peringkat

- Woodfibre LNG Information Sheets Seawater CoolingDokumen2 halamanWoodfibre LNG Information Sheets Seawater CoolingFeldon DsilvaBelum ada peringkat

- Tanhov Industrial Co.,Ltd: ITP (Inspection and Test Plan) FOR PRVDokumen2 halamanTanhov Industrial Co.,Ltd: ITP (Inspection and Test Plan) FOR PRVUmair AwanBelum ada peringkat

- Itp PWHTDokumen1 halamanItp PWHTTridib DeyBelum ada peringkat

- Estimation - Construction Time ManagementDokumen24 halamanEstimation - Construction Time ManagementJuanaBelum ada peringkat

- Dolidar Norms AdendumDokumen33 halamanDolidar Norms AdendumKiran Kumar AcharyaBelum ada peringkat

- Iia Global Internal Audit Standards Public Comment Draft English v2Dokumen132 halamanIia Global Internal Audit Standards Public Comment Draft English v2harshimadushaniBelum ada peringkat

- 1-4-2 Scheduling Techniques For ConstructionDokumen47 halaman1-4-2 Scheduling Techniques For ConstructionVũ Thị Hà TrangBelum ada peringkat

- Equipment Erection & Piping Work For Our Pilot Plant Project Pr20420Dokumen2 halamanEquipment Erection & Piping Work For Our Pilot Plant Project Pr20420Anonymous rfSdMp3FBelum ada peringkat

- ITP Sample For Piping Assembly WorksDokumen7 halamanITP Sample For Piping Assembly WorksTee Klong RungBelum ada peringkat

- Mining Equipment Sealing SolutionsDokumen5 halamanMining Equipment Sealing SolutionsSenthilKumar100% (1)

- Makum Coal FieldDokumen26 halamanMakum Coal Fieldsalim123456789100% (2)

- TF Scaffolding ProcedureDokumen11 halamanTF Scaffolding Procedureslamet4riadiBelum ada peringkat

- Construction ManualDokumen278 halamanConstruction ManualUnnikrishnan NairBelum ada peringkat

- A Study On Welding Defects of Pressure VesselDokumen24 halamanA Study On Welding Defects of Pressure Vesseladamahmad1992100% (1)

- Methods of Installation & Inspection To en 1090 2-1412867019Dokumen2 halamanMethods of Installation & Inspection To en 1090 2-1412867019yatinBelum ada peringkat

- TechnicalSpec CustodyTransferMeterDokumen10 halamanTechnicalSpec CustodyTransferMeterXarly Polite Jr.Belum ada peringkat

- Residential Duplex Draft Example DesignDokumen11 halamanResidential Duplex Draft Example DesigndualitiBelum ada peringkat

- Curriculum Vitae: Professional ExperienceDokumen5 halamanCurriculum Vitae: Professional ExperiencemanojballaBelum ada peringkat

- BI Course Ebook PDFDokumen22 halamanBI Course Ebook PDFQorina AzizahBelum ada peringkat

- Guidelines For Pipeline ConstructionDokumen56 halamanGuidelines For Pipeline Constructionsankha_durgapurBelum ada peringkat

- Corynm Project CharterDokumen6 halamanCorynm Project Charterpeter musyimiBelum ada peringkat

- Theodorsen Theory For Deformable Airfoils Full DerivationDokumen15 halamanTheodorsen Theory For Deformable Airfoils Full Derivationknk89100% (1)

- Manhour Rate INKADokumen3 halamanManhour Rate INKADeny ArifiantoBelum ada peringkat

- Construction Materials......Dokumen147 halamanConstruction Materials......iak23100% (1)

- Senior Divisional Engineer: Prakash UpadhyayaDokumen114 halamanSenior Divisional Engineer: Prakash UpadhyayakesharinareshBelum ada peringkat

- Cost Comparison 5-5-18Dokumen76 halamanCost Comparison 5-5-18Charlote EspinosaBelum ada peringkat

- Schedule - MT. Elpindo IIDokumen2 halamanSchedule - MT. Elpindo IIjoyan1426Belum ada peringkat

- 1 PMHB Complete PDFDokumen357 halaman1 PMHB Complete PDFTayyiba ImranBelum ada peringkat

- Equipment Cost EstimationDokumen3 halamanEquipment Cost EstimationLaras Wuri D.100% (1)

- Bong ADokumen2 halamanBong AchinemeikeBelum ada peringkat

- Concrete Plant: ©ramaiah University of Applied SciencesDokumen109 halamanConcrete Plant: ©ramaiah University of Applied SciencesWinfiner WebsiteBelum ada peringkat

- Interview Questions 1 TCSDokumen3 halamanInterview Questions 1 TCSSrinivas TumpalaBelum ada peringkat

- 105-Structural Steel ErectionDokumen7 halaman105-Structural Steel Erectionzaki fadlBelum ada peringkat

- TA1 English - KnuckleboomDokumen30 halamanTA1 English - Knuckleboomcristian chuquicondor torresBelum ada peringkat

- ITP Expoxy Bonded Pipeline TripatraDokumen16 halamanITP Expoxy Bonded Pipeline TripatraparwotoBelum ada peringkat

- Work Instruction For Hydrostatic TestingDokumen18 halamanWork Instruction For Hydrostatic TestingAlok SinghBelum ada peringkat

- Ball Valve PDFDokumen20 halamanBall Valve PDFRamalingam PrabhakaranBelum ada peringkat

- Vessel Module Sans RH GoodDokumen24 halamanVessel Module Sans RH GoodThaksenBelum ada peringkat

- Hydrocarbon TreatingDokumen4 halamanHydrocarbon TreatingLeDzungBelum ada peringkat

- Construction Crane RuleDokumen57 halamanConstruction Crane RuleBeste Ardıç ArslanBelum ada peringkat

- Handwriting Speed Assessment Pa TossDokumen4 halamanHandwriting Speed Assessment Pa Tossdeni44450% (4)

- Rising in The World - Orison Swett MardenDokumen575 halamanRising in The World - Orison Swett MardenWarrior SoulBelum ada peringkat

- Q #1: To What Extent Does Globalization Affect Your Identity?Dokumen3 halamanQ #1: To What Extent Does Globalization Affect Your Identity?Joseph CorpuzBelum ada peringkat

- P H I L C S T: Philippine College of Science and TechnologyDokumen9 halamanP H I L C S T: Philippine College of Science and Technologyraul gironellaBelum ada peringkat

- "Section 1. Any Person or Persons Who Shall Commit Estafa or Other Forms of Swindling AsDokumen4 halaman"Section 1. Any Person or Persons Who Shall Commit Estafa or Other Forms of Swindling AskaiBelum ada peringkat

- Candry2020 - Comparing The Merits of Word Writing and Retrieval PracticeDokumen11 halamanCandry2020 - Comparing The Merits of Word Writing and Retrieval PracticeNguyễnHoàngBelum ada peringkat

- Society 5.0Dokumen2 halamanSociety 5.0Pulihora Kat RajaBelum ada peringkat

- Bombardier Annual Report 2008Dokumen183 halamanBombardier Annual Report 2008bombardierwatchBelum ada peringkat

- OPM CHAPTER 7-SchaDokumen6 halamanOPM CHAPTER 7-SchaSyakirah HusniBelum ada peringkat

- 02 Hart and His Critics Ver 3.0Dokumen23 halaman02 Hart and His Critics Ver 3.0Anshika AgarwalBelum ada peringkat

- Revised Soen Concept PaperDokumen34 halamanRevised Soen Concept PaperIra BarbosaBelum ada peringkat

- Optimizing Leadership AcumenDokumen111 halamanOptimizing Leadership AcumenObakozuwa Edokpolo Oghogho PeterBelum ada peringkat

- Venn Diagram Infographic 02Dokumen8 halamanVenn Diagram Infographic 02Hector Tomas Reyes CumpaBelum ada peringkat

- Experience Letter DeependraDokumen1 halamanExperience Letter DeependraanimshakyaBelum ada peringkat

- OK Jurisprudence Handbook - MDbook2014Dokumen173 halamanOK Jurisprudence Handbook - MDbook2014Pavan Kumar0% (1)

- Process WritingDokumen2 halamanProcess WritingKari AleBelum ada peringkat

- 2 (1) .Corporate Social Responsibility & Corporate ResponsivenessDokumen14 halaman2 (1) .Corporate Social Responsibility & Corporate ResponsivenessHaytham NasserBelum ada peringkat

- Lasw Combine - CoopDokumen14 halamanLasw Combine - CoopJomarti OrderBelum ada peringkat

- Chapter - 1Dokumen6 halamanChapter - 1Shekhar BanisettiBelum ada peringkat

- PDT2-FLORES, KRISTINE ANGEL-BSAeE 3-1Dokumen7 halamanPDT2-FLORES, KRISTINE ANGEL-BSAeE 3-1Kristine Angel Cruz FloresBelum ada peringkat

- 001 RP en - 10Dokumen250 halaman001 RP en - 10Kgp PonnuamyBelum ada peringkat

- Department of EducationDokumen4 halamanDepartment of EducationRasalyn Cericos Valois100% (1)

- Taltal ES - ACR - 2019 NATIONAL READING MONTHDokumen2 halamanTaltal ES - ACR - 2019 NATIONAL READING MONTHSandra Elad86% (7)

- A Study On Employee Engagement With Reference To TNPL-4Dokumen4 halamanA Study On Employee Engagement With Reference To TNPL-4KARTHIK100% (1)

- Bioethics Module For GE EthicsDokumen11 halamanBioethics Module For GE EthicsErrol BuenaventuraBelum ada peringkat

- Write Up (Walmart)Dokumen2 halamanWrite Up (Walmart)Umar GondalBelum ada peringkat

- Writing Unit 8 - StudentDokumen7 halamanWriting Unit 8 - StudentQuoc Tan HuynhBelum ada peringkat

- The Philippine Health Agenda 2016 To 2022Dokumen11 halamanThe Philippine Health Agenda 2016 To 2022Sheryl Alapad100% (3)

- Coaching Fidelity Checklist Intervention 4Dokumen6 halamanCoaching Fidelity Checklist Intervention 4api-438626249Belum ada peringkat

- Dipankar Gupta Hierarchy and DifferencesDokumen28 halamanDipankar Gupta Hierarchy and DifferencesPradip kumar yadav100% (3)