Af 60 e

Diunggah oleh

dm1680Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Af 60 e

Diunggah oleh

dm1680Hak Cipta:

Format Tersedia

C O M PA C T S Y S T E M

AF 60e

> The loader specialist

> F r o n t L o a d e r 0.6 0.8 m3

C O M PA C T S Y S T E M

AF 60e

Lets have a look

29 kW / 40 hp at 2500 min-1 max. payload on forks: 1,820 kg servo-controlled joystick operation

Easy, intuitive handling; all operating functions integrated in one joystick Safe, easy access on both sides

Automatic differential lock in front axle (locking factor: 45%)

Powerful P-kinematics for better visibility on all work tools

Hydraulically operated quick coupler

Wide range of attachments

C O M PA C T S Y S T E M

AF 60e

at your advantages

Easy access to all service points Comfortable cab with excellent all-round visibility

High performance Deutz diesel engine

Hydrostatic four-wheel steering

Rigid single-component chassis for maximum stability

C O M PA C T S Y S T E M

AF 60e

Agile and powerful

The Ahlmann AF 60e is an extremely agile front loader with fourwheel steering. It only needs a minimal turning radius of 2.77 m. Being only 1650 mm wide, the AF 60e can even work on footpaths. And even the tiniest of work sites is a real challenge for the AF 60e.

C O M PA C T S Y S T E M

AF 60e

Low-maintenance and economical

The rigid frame construction in conjunction with the extremely agile four-wheel steering system ensures the unrivalled stability of the AF 60e. The centre of gravity position is not changed by the steering position. With it, the operator can always use the full payload under all operating conditions. There is optimal access to all service points. Long engine maintenance intervals of up to 1,000 working hours guarantee low maintenance costs.

C O M PA C T S Y S T E M

AF 60e

Operating weight: 3,960 kg Engine power: 29 kW (40 hp) Standard bucket: 0.60 m3

Technical data

Comfortable operators cab with ROPS safety feature Servo-controlled joystick operation Power-controlled high performance hydrostatic four-wheel drive Four-wheel steering Planetary axles with self-locking front differential P-Kinematics allow precise parallel guidance Hydraulically operated quick-coupler Extensive range of attachments

Engine

Oil-cooled Deutz diesel engine 3 cylinders (emissions acc. to EU 97/68), 4-stroke, direct fuel injection Type F 3L 1011 F Net power at 2500 min-1 acc. to ISO 9249 (40 hp) 29 kW Max. torque at 1900 min-1 acc. to ISO 9249 118 Nm spec. fuel consumption at max. torque: 226 g/kWh Air intake filter: 2 level dry-air filter with safety cartridge Operating voltage: 12 Volt Battery capacity: 66 Ah 840 Watt 60 A (3.0 hp) 2.2 kW

Hydraulic system

Single circuit system with central gear pump (lift/lower, tilt, accessories) and steering (via priority valve); three-fold control valve with primary and secondary protection with servo-controlled joystick operation Max. operating pressure 40 l/min and 230 bar at 2500 min-1: Float position for lifting cylinder Cylinders: Cycle-times: 1 lifting cylinder 100 1 tilting cylinder 100 Lift (under load) 5.5 s Lower (without load) 3.3 s Crowd time 2.8 s Dump time 2.8 s

Standard features

Comfortable operators cab with ROPS safety feature and 2 lockable doors allowing access from both sides of vehicle, doors open through 180 with safety restraint on machine, tinted windows, electrical wipers front and rear, front and rear screen washers, 2 external rear-view mirrors, adjustable drivers seat, adjusts to drivers weight, hydraulic suspension, safety belt, sun blind, heater and fresh air system with external filter, interior lighting, glove-boxes, intuitive modular cockpit with symbolic display components and monitoring LEDs, 12v power outlet, 2 driving lights at front of cab roof, 2 working lights mounted at back of cab roof, indicators, rear and brake lights, electrically locking hydraulically operated quick-coupler, towing coupling, fastening and lifting points, auxiliary hydraulics 1st circuit. Color scheme: yellow, operators cab, axles and wheels grey

Electrical system: Alternator rating: Starter rating:

Performance data

Digging depth with standard bucket: 150 mm Bucket position: Tilting angle 45 Dumping angle, top 46 max. dumping angle 105 Lifting force: 2,400 daN Breakout force: 3,500 daN Thrust force: 2,500 daN Tipping load: Standard bucket Standard bucket, max. turned Payload: on forks, even ground on forks, max. turned, even ground on forks, uneven ground on forks, max. turned, uneven ground on forks, max. turned, even ground* on forks, max. turned, uneven ground*

according to ISO 14397 * Transport position 150 mm above ground, acc. to ISO 14397 (ISO 8313) with safety margin

Drive

Hydrostatic drive with automotive control, 2 stages for maximum propulsive force, gear-engage under load, multifunctional lever (joystick) for drive and working hydraulics control Axles: planetary axles with four-wheel steering for maximum flexibility, oscillating rear axle self-engaging, automatic differential lock in front axle locking factor 45% tyre size: 12,5-18 optionally: 15,5/55 R18 road gear: 0-20 km/h (optionally 30 km/h) field gear: 0-5 km/h under load 60% max. oscillation angle +/- 10

Optional equipment

30 km/h version, tyres 15,5/55 R18, 360 warning light, internal rear-view mirror, reverse warning system, bucket protection compliant to road-safety standards, pipe-burst protection system, boom suspension, bio-degradable oil fill for hydraulic system, radio, pressureless return line, immobilizer, various attachments possible such as pallet fork, load hook, hydraulic breaker etc.

2,400 kg 2,400 kg 1,650 kg 1,650 kg 1,230 kg 1,230 kg 1,820 kg 1,360 kg

Differential lock:

Wheels: Speeds:

Weight

Machine with quick-coupler and standard bucket 0.6 m3 and teeth permissible axle load front permissible axle load rear 3,960 kg 3,000 kg 3,000 kg

Hill climbing: Oscillation:

Brakes

Operating brakes: 1. hydraulically operated drum brake in front axle, acting on all 4 wheels 2. hydrostatic inching brake, acting on all 4 wheels Parking brake: Mecanically actuated drum brake in front axle, acting on all 4 wheels

Chassis

Rigid single-component chassis for maximum stability. Quality steel construction, robot welded. Milled seatings for axles. P-Kinematics of loaderarm allow exact parallel adjustment and excellent visibility over all work tools. Operators cab with flexible four-point mountings for maximum driver comfort and minimum noise levels. Smooth power-assisted and accurate joystick controls.

Filling capacities Steering

Hydrostatic four-wheel steering, can be switched to rear axle steering max. steering angle +/- 35 Turning radius measured over rear end R = 2770 mm Engine with filter Fuel tank Front axle total Rear axle with gearbox Hydraulic system with tank approx. approx. approx. approx. approx. 6.0 l 45.0 l 7.0 l 7.5 l 60.0 l

C O M PA C T S Y S T E M

AF 60e

Measurements

Technical data

Buckets Standard 0.6 m3 A 4750 A2 45 B 1370 D G 815 H1 2560 H4 320 H5 400 H6 150 H8 2410 H10 3960 HH13 J 3210 L6 470 R 1650 R1 1580 S 1270

4-in-1 0.55 m3 4820 45 1450 145 740 2560 320 400 150 2330 3900 3310 3250 470 1650 1580 1270

Forklift A A5 B C D DD G HH H6 HH15 4960 22 560 1020 50 1310 70 3060

Load hook 4200 1660 3610

Range of attachments

Snowplate

Diverse

AF 60e

All data based on standard tyres. Technical data are non-committal and are subject to constructional modifications!

1. Ro ad w 2. or Ca ki ng bl e 3. la yi Co ng ns tru 4. ct La nd ion sc 5. ap In in du g st 6. ria Fa l rm in 7. g Co m m un ity

Our mission is to design, develop, manufacture and distribute quality products. Our innovative machines perform many varied and demanding tasks within your environment. Customers are the heart of our company. We provide them with our knowledge, experience and the team spirit that drives Ahlmann.

Your Local Dealer

Am Friedrichsbrunnen D-24782 Bdelsdorf phone +49 (0 ) 43 31/3 51-319 fax +49 (0 ) 43 31/3 51-303 info@ahlmann.com www.ahlmann.com

MECALAC and AHLMANN are companies from Mecalac Group

Order no. 231 05 529 02/2006

Anda mungkin juga menyukai

- 25578-Ford F350 Super-Duty 2004Dokumen5.857 halaman25578-Ford F350 Super-Duty 2004Dan100% (6)

- ZF Freedomline Transmission Diagnostics ManualDokumen192 halamanZF Freedomline Transmission Diagnostics ManualJosé Adelino100% (7)

- 2016 Llaves Ilco PDFDokumen176 halaman2016 Llaves Ilco PDFfrancisco ivan aguilar salmeronBelum ada peringkat

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideDari EverandHydraulics and Pneumatics: A Technician's and Engineer's GuidePenilaian: 4 dari 5 bintang4/5 (8)

- Pranayama Breathing ExcercizeDokumen80 halamanPranayama Breathing Excercizedm1680100% (2)

- 236D EngDokumen4 halaman236D EngElvis Eberth Huanca MachacaBelum ada peringkat

- Spec Loader Hitachi Ex2600-6Dokumen16 halamanSpec Loader Hitachi Ex2600-6Zdulkurnain MuhamadBelum ada peringkat

- Volvo Reva40dspecDokumen6 halamanVolvo Reva40dspecIzzan Ferdi Andrian0% (1)

- Banco Alu Radiator Price ListDokumen8 halamanBanco Alu Radiator Price Listflytorahul0% (1)

- T200XD SpecificationsDokumen11 halamanT200XD SpecificationsIgnatius FebriantaBelum ada peringkat

- 246DDokumen4 halaman246DJose MaraviBelum ada peringkat

- L40B L45B Specsheet GB 21 3 430 5594Dokumen6 halamanL40B L45B Specsheet GB 21 3 430 5594Adrian Constantin MihalacheBelum ada peringkat

- Skoda Fabia Body Repairs PDFDokumen113 halamanSkoda Fabia Body Repairs PDFstratosg100% (3)

- Renault Kerax 6x4 Re2484Dokumen7 halamanRenault Kerax 6x4 Re2484patrickNX9420100% (2)

- Shogun HTDokumen5 halamanShogun HTprasadgayuBelum ada peringkat

- Pressure Specs and TestsDokumen2 halamanPressure Specs and Testsluis eduardo corzo enriquezBelum ada peringkat

- R9800Dokumen12 halamanR9800tugu_tgBelum ada peringkat

- Liebherr R 996 B OEM SpecsDokumen14 halamanLiebherr R 996 B OEM Specsbas100% (1)

- ERKE Group, FUWA QUY 750 Crawler Crane CatalogueDokumen90 halamanERKE Group, FUWA QUY 750 Crawler Crane CatalogueerkegroupBelum ada peringkat

- X25 Electrical EquipmentDokumen409 halamanX25 Electrical EquipmentRick Nitrous100% (6)

- Root Cause Failure Analysis Rev 2Dokumen69 halamanRoot Cause Failure Analysis Rev 2clcoolleo100% (1)

- Cast IronDokumen34 halamanCast IronMKPashaPasha100% (1)

- 116 JCB 160 170 RobotDokumen4 halaman116 JCB 160 170 RobotLukz AlcaBelum ada peringkat

- Barko 920 Industrial TractorDokumen2 halamanBarko 920 Industrial Tractorjleonos0% (2)

- Knowledge Base: Joint DesignDokumen7 halamanKnowledge Base: Joint Designdm1680Belum ada peringkat

- PB Engine Kappa EngDokumen15 halamanPB Engine Kappa EngCore Java100% (1)

- Date Tehnice JS 220 NCDokumen12 halamanDate Tehnice JS 220 NCMB ViorelBelum ada peringkat

- TGA 33 480 6x4 BBSDokumen4 halamanTGA 33 480 6x4 BBSricardo_santos_280Belum ada peringkat

- Komatsu PC350LC-8 ManualDokumen8 halamanKomatsu PC350LC-8 Manualgraig27Belum ada peringkat

- Grove Rt760Dokumen22 halamanGrove Rt760Superdp FloresBelum ada peringkat

- TH551 Tekninen Datasheet LRDokumen6 halamanTH551 Tekninen Datasheet LRMegustas MuchoBelum ada peringkat

- SANY Reach StackerDokumen7 halamanSANY Reach StackerEmerson Batista100% (2)

- Fuel Injector CatalogueDokumen16 halamanFuel Injector Catalogue1070242585Belum ada peringkat

- HHD9 Sheet Chassis Euro3 6x6 GBDokumen4 halamanHHD9 Sheet Chassis Euro3 6x6 GBVenkata ChakradharBelum ada peringkat

- Unimog Techdata u4000 Euro5 1209 en PDF Unimog_techdata_u4000_euro5_1209_en_pdf.pdf Unimog_techdata_u4000_euro5_1209_en_pdf.pdf Unimog_techdata_u4000_euro5_1209_en_pdf.pdfDokumen2 halamanUnimog Techdata u4000 Euro5 1209 en PDF Unimog_techdata_u4000_euro5_1209_en_pdf.pdf Unimog_techdata_u4000_euro5_1209_en_pdf.pdf Unimog_techdata_u4000_euro5_1209_en_pdf.pdfIvana Ilic67% (3)

- Komatsu Excavadora PC850 - 850se-8 - PDFDokumen8 halamanKomatsu Excavadora PC850 - 850se-8 - PDFCrecencio Sanches100% (1)

- The Loader Specialist: System 180Dokumen8 halamanThe Loader Specialist: System 180dm1680Belum ada peringkat

- The Loader Specialist: System 180Dokumen8 halamanThe Loader Specialist: System 180dm1680Belum ada peringkat

- The Loader Specialist: System 180Dokumen8 halamanThe Loader Specialist: System 180dm1680Belum ada peringkat

- AS 90tele: The Loader SpecialistDokumen8 halamanAS 90tele: The Loader Specialistdm1680Belum ada peringkat

- Ex3600 6Dokumen16 halamanEx3600 6MasterAmorBelum ada peringkat

- 40 MT Tyre MountedDokumen5 halaman40 MT Tyre MountedramyaBelum ada peringkat

- 113 308.8151.3.1-2 Solaris 35-55 enDokumen2 halaman113 308.8151.3.1-2 Solaris 35-55 enDaniel TarlungaBelum ada peringkat

- 5297UK 2 JS330LR - p1 8Dokumen8 halaman5297UK 2 JS330LR - p1 8Aladina GinyBelum ada peringkat

- 544BDokumen4 halaman544BCarlos OsorioBelum ada peringkat

- Tabla de CargaDokumen32 halamanTabla de Cargavpizarro_23Belum ada peringkat

- Series IV MKII Rigid Hauler Tractors Broch18281215 EnglishWebDokumen20 halamanSeries IV MKII Rigid Hauler Tractors Broch18281215 EnglishWebAlejandro QuiñonezBelum ada peringkat

- JCB Tracked ExcavatorDokumen8 halamanJCB Tracked ExcavatorKiran Kumar K TBelum ada peringkat

- Alldrive 9 Tonne Power Swivel: SpecificationsDokumen2 halamanAlldrive 9 Tonne Power Swivel: SpecificationsQuelmis De La Cruz Vilca AmesquitaBelum ada peringkat

- Grove RT870 PDFDokumen22 halamanGrove RT870 PDFjcpullupaxi50% (2)

- HL7607ADokumen6 halamanHL7607AluismdmjBelum ada peringkat

- Cargador Frontal WA430-6 Komatsu, FolletoDokumen6 halamanCargador Frontal WA430-6 Komatsu, FolletoRoman Roa MachucaBelum ada peringkat

- Kamatsu Pc78us-8Dokumen6 halamanKamatsu Pc78us-8Piotr Gabryś Hi-this100% (1)

- JS 360 LC SpecDokumen8 halamanJS 360 LC SpecMarceloAndresCortésCastilloBelum ada peringkat

- ForkliftDokumen5 halamanForkliftpramodtry100% (1)

- BH35 2Dokumen4 halamanBH35 2muthu85100% (1)

- PC 400 LC 8Dokumen8 halamanPC 400 LC 8James RoniBelum ada peringkat

- ERKE Group, FUWA QUY 500 Crawler Crane CatalogDokumen94 halamanERKE Group, FUWA QUY 500 Crawler Crane CatalogerkegroupBelum ada peringkat

- RW1503 1504 enDokumen8 halamanRW1503 1504 enChelseaE82Belum ada peringkat

- BELAZ 7555 - enDokumen7 halamanBELAZ 7555 - endno256Belum ada peringkat

- WA500-6Dokumen6 halamanWA500-6sezidBelum ada peringkat

- Atlas Copco Explorac 220RC - Reverse Circulation Drilling RigsDokumen4 halamanAtlas Copco Explorac 220RC - Reverse Circulation Drilling Rigsவிமல் அந்தோணி100% (1)

- PC 800Dokumen9 halamanPC 800Mohammed Azhar67% (3)

- Scania P360LA6x22MNA Light Tcm48 183319Dokumen4 halamanScania P360LA6x22MNA Light Tcm48 183319Helder AlvesBelum ada peringkat

- Iveco Ad380Dokumen2 halamanIveco Ad380mr.bounceBelum ada peringkat

- PC1250 1250SP-8 PDFDokumen9 halamanPC1250 1250SP-8 PDFevon seplika kadangBelum ada peringkat

- Grove 60 Ton PDFDokumen24 halamanGrove 60 Ton PDFFabrizzio ZuñigaBelum ada peringkat

- Terex Franna 20t BrochureDokumen2 halamanTerex Franna 20t BrochureKin Siang YapBelum ada peringkat

- Nordex N60: Long-Term Experience All Over The WorldDokumen8 halamanNordex N60: Long-Term Experience All Over The Worldandy131078Belum ada peringkat

- LRB 125 XL Data Sheet en - 9800-0Dokumen12 halamanLRB 125 XL Data Sheet en - 9800-0siva_arBelum ada peringkat

- Motorcycle, Solo (Harley-Davidson Model WLA)Dari EverandMotorcycle, Solo (Harley-Davidson Model WLA)Belum ada peringkat

- Quality Casting ManualDokumen27 halamanQuality Casting ManualvisitabhinavBelum ada peringkat

- Mohrs CircleDokumen76 halamanMohrs Circlersarunprasath0% (1)

- CylinderDokumen39 halamanCylinderapi-3854910100% (1)

- Welding, Cutting and Brazing: 29 CFR 1910.251 & 1926.350 Subpart Q & JDokumen40 halamanWelding, Cutting and Brazing: 29 CFR 1910.251 & 1926.350 Subpart Q & JSudhakar VarmaBelum ada peringkat

- CaseDokumen26 halamanCasedm1680Belum ada peringkat

- Silver Brazed Stainless Steel Cable: Presented byDokumen26 halamanSilver Brazed Stainless Steel Cable: Presented bydm1680Belum ada peringkat

- 201-Mhz RF Cavity Construction (Plan) For Mice: Derun Li Center For Beam Physics Lawrence Berkeley National LaboratoryDokumen20 halaman201-Mhz RF Cavity Construction (Plan) For Mice: Derun Li Center For Beam Physics Lawrence Berkeley National Laboratorydm1680Belum ada peringkat

- Mecalac Ahlmann As 210Dokumen8 halamanMecalac Ahlmann As 210ForomaquinasBelum ada peringkat

- Superior Flux & Prince & Izant Co. Mfg. CoDokumen15 halamanSuperior Flux & Prince & Izant Co. Mfg. Codm1680Belum ada peringkat

- IE 337 W10 Lecture 3 Alloys&Heat - TreatDokumen62 halamanIE 337 W10 Lecture 3 Alloys&Heat - Treatdm1680Belum ada peringkat

- Design For Manufacture in Cost-Effective and Recyclable BrassDokumen69 halamanDesign For Manufacture in Cost-Effective and Recyclable Brassdm1680Belum ada peringkat

- Sec11 SilverBrazing WebDokumen8 halamanSec11 SilverBrazing Webdm1680Belum ada peringkat

- Superior Flux & Mfg. CoDokumen15 halamanSuperior Flux & Mfg. Codm1680Belum ada peringkat

- Ultrasonic Machining ProcessDokumen44 halamanUltrasonic Machining ProcessSaravanan KumarBelum ada peringkat

- Skyline Short BookDokumen34 halamanSkyline Short Bookapi-380679450% (2)

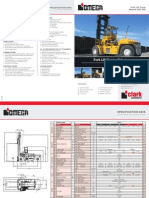

- OmegaDokumen2 halamanOmegaATHOLSCHWARZBelum ada peringkat

- LRP Technical SpecificationsDokumen4 halamanLRP Technical SpecificationsFabricioVBelum ada peringkat

- Fusíveis 2008 Honda FitDokumen5 halamanFusíveis 2008 Honda FitVitor OlivettiBelum ada peringkat

- 3000 Product Family Group 21-934. Detailed Parts Breakdown: Torque ConverterDokumen3 halaman3000 Product Family Group 21-934. Detailed Parts Breakdown: Torque ConverterAl BimaBelum ada peringkat

- Kia Seltos - Kia Motors Hits The Bullseye, But How Will It Sustain - , Auto News, ET Auto USEFULDokumen9 halamanKia Seltos - Kia Motors Hits The Bullseye, But How Will It Sustain - , Auto News, ET Auto USEFULmiriel JonBelum ada peringkat

- Sistem PowerWindowDokumen18 halamanSistem PowerWindowMuch Abdulah Nurhidayat100% (1)

- B Class w247 November 2022Dokumen2 halamanB Class w247 November 2022Dimitris EfstathiouBelum ada peringkat

- 1550 TractorDokumen277 halaman1550 TractorLouis TaftaBelum ada peringkat

- (22-03-14) GV350CEU - Supported Car Models and Logistic Parameters (All Vehicles) TableDokumen17 halaman(22-03-14) GV350CEU - Supported Car Models and Logistic Parameters (All Vehicles) Tablemohamed.khalidBelum ada peringkat

- Advanced Drivetrain AssignmentDokumen16 halamanAdvanced Drivetrain AssignmentyogapostBelum ada peringkat

- SuspensionDokumen3 halamanSuspensionPriyal PatelBelum ada peringkat

- Relee TfsiDokumen10 halamanRelee TfsiVetrea BogdanBelum ada peringkat

- Technical Guide: Heavy Duty Forklift TruckDokumen8 halamanTechnical Guide: Heavy Duty Forklift Truckabdelhadi houssinBelum ada peringkat

- Merlo TF33 7Dokumen2 halamanMerlo TF33 7Pronto AccessBelum ada peringkat

- WHITE OLIVER Power Steering Pumps PDFDokumen102 halamanWHITE OLIVER Power Steering Pumps PDFstephanebrosseauBelum ada peringkat

- VW Golf 3 Exhaust Manifold Engine AaaDokumen7 halamanVW Golf 3 Exhaust Manifold Engine AaaNPBelum ada peringkat

- CHK-En-FRCS7-01 Cherry Picker Pre-Use Checklist - Blue AreaDokumen2 halamanCHK-En-FRCS7-01 Cherry Picker Pre-Use Checklist - Blue Areapatrick ruwonaBelum ada peringkat

- HA RTJ Pro: Rough Terrain Articulating BoomsDokumen2 halamanHA RTJ Pro: Rough Terrain Articulating BoomsWajdi MansourBelum ada peringkat

- Hilux 2015 PricelistDokumen1 halamanHilux 2015 PricelistIdris AhmadBelum ada peringkat

- 2011 SCCA Solo RulesDokumen346 halaman2011 SCCA Solo RulesJason HarleBelum ada peringkat