Biomass Power

Diunggah oleh

Veerapathran KurumbanDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Biomass Power

Diunggah oleh

Veerapathran KurumbanHak Cipta:

Format Tersedia

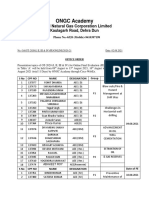

PROPOSAL FOR BIOMASS BASED POWER PROJECT CAPACITY 2.

0 MWe

From M/s. Benti Energies Limited, Accra

PROJECT SUMMARY

A. Objective of the project: To achieve rural level energy self sufficiency through better utilization of locally available fuel resources and thereby improves the standard of living and provides opportunity to promote industries. This waste land Energy Cultivation and Agro Waste to Briquette to Power will raise almost a million more Guineans out of poverty by 2020, improve rural livelihoods significantly, and make a dent in the poverty of the rural Savannah, especially in the North.

B. Key energy issues in Guinea: Future of Guineas energy sector lies in addressing the three key issues listed below: Non-availability or inaccessibility of modern energy sources to a large fraction of the population, Non-affordability of commercial fuels, and High energy import dependence.

Under CAADP (Comprehensive African Agricultural Development Plan) the World Bank in 2007 dedicated its annual world development report to Agriculture. One of the joint activities agreed by UN-Energy is directly related to a major energy-related objective of World Summit on Sustainable Development (WSSD), namely, increasing the proportion of energy obtained from renewable energy sources. While fossil fuel resources in Guinea are very limited it has reasonable resources of biomass, wind, solar and micro hydro. These renewable resources could help to increase the available energy supply, reduce the countrys energy import bill and enhance security of energy supply. This project addresses the opportunity for better utilization of Guineas biomass resource

C. Power Scenario in Guinea: The extreme energy poverty in most African countries is a major opportunity for them to leapfrog into electricity via renewable energy technologies indicates Ansgar Kiene, Coordinator of the African Renewable Energy Alliance. According to the Africa Energy Outlook 2040 by Programme for Infrastructure Development in Africa (PIDA), energy demand will grow 8.9% per annum. Also, access to energy is only 39% in Sub-Saharan Africa, suggesting pent-up demand. The two primary markets for energy are industry and households. Most of the major energy projects on the continent are focused on the industry market as governments realize they can generate revenue immediately from industry whereas sufficient revenue from households may have longer time horizons. Also, many of these projects are focused on fossil fuels or hydropower, a renewable energy option but one that has issues of concern like displacement of people and potential environmental degradation. While renewable energy can serve both industry and households, it may be the household or small-scale industry market that causes renewable energy to take off. Ansgar Kiene, Coordinator of the African Renewable Energy Alliance points out that it is quite expensive for governments to connect rural areas to electrical grids. Even if they succeed in connecting all households, the cost of maintenance could easily make it unsustainable. However, many renewable energy options provide off-grid solutions, e.g., solar panels on houses, or even micro-grid solutions using Biomass Gasifier based Power for communities. One issue for implementation of renewable energy technologies is the upfront cost compared to traditional energy options. Kiene suggests that the diesel generation market in Guinea demonstrates that there is enough money to fuel

the renewable energy sector. In Guinea alone, there are over 1 million diesel generators (larger ones used in industry) that are used every day. At a price of $5.00 per gallon and use of two gallons per week (a very low use threshold), this translates to $520 million a year. It can easily be imagined that usage is 10 times as much. If just one years diesel revenue was dedicated to implement renewable energy solutions, there would be enough funds to kick start renewable energy projects across Guinea. Guinea has 5900 MW of installed generating capacity; however, the country is only able to generate 1600 MW because most facilities have been poorly maintained. Guinea's power sector has high energy losses (30 - 35 % from generation to billing), a low collection rate (75 - 80 %) and low access to electricity by the population (36 %). There is insufficient cash generation because of these inefficiencies and NEPA is consequently reliant on fuel subsidies and funding of capital projects by the government. At present only 10 % of rural households and 40 % of the countrys total population have access to electricity? The Guinean Energy Commission and the Solar Energy Society of Guinea have been tasked with generating a solarpowered solution for the remote rural dwellers not served by the national power grid. This is where Biomass Gasifier Technology could be beneficially implemented. It has been reported that NEPA is to be split into 30 units to facilitate its privatization. The current NEPA is to be broken into smaller units to make it more manageable and attractive to investors. The government is seeking independent power producers to generate and sell electricity to NEPA. producers using locally available biomass. Guinea has experienced an energy supply crisis in recent years. Speaking at the workshop on renewable energy development organized by ECN in collaboration with the United Nations Development Program (UNDP) in Abuja, the Director-General of ECN, Prof. Abu-Bakr Sambo said government is This is a tremendous opportunity for Private Players especially small private power

developing a master plan that would enable the exploitation of renewable energy sources in the areas of solar energy, small hydro, wind and biomass energy generating systems. Guineas decision to attain 7 percent renewable energy use by 2025 has been tagged to be a very proactive commitment. An important fact to note is that more than 60 percent of the nations population is not connected to the national grid and the remaining population can only boast of epileptic power supply. Guinea Africas most populous country and second largest economy is underperforming in terms of the provision of power security to its 160 million people. The countrys present over-dependence on gas fired generation plants has resulted in supply disruptions in times of gas shortages which are very common occurrences. The need for alternative power generation options cannot be overstated considering the countrys current demand for power. In 2011, Guinea emerged as the country with the largest gap between demand and supply of electricity in the world according to a progress report submitted by the countrys presidential task force committee on power reforms. This is definitely inadequate to stimulate economic growth.

(Biomass is a natural woody substance available, which stores solar energy by the process: of photosynthesis in the presence of sunlight)

GASIFICATION

BASED

POWER - GENERATION THE TECHNOLOGY

SYSTEM

(Gasifier Technologies offer the possibility of converting Biomass into producer gas, an energy carrier, which can then be burnt for delivering heat or electrical power in an efficient manner).

(Our 2.7 MW Gasifier under Installation) Gasification concept and principle: Biomass is a natural substance available, which stores solar energy by the process of photosynthesis in the presence of sunlight. It chiefly contains cellulose. Hemi-cellulose and lignin, with an average composition of C6H10O5 with slight variations, depending on the nature of the biomass. Theoretically, the ratio of air-to-fuel required for the complete combustion of the biomass, defined as stoichiometric combustion is 6:1 to 6.5:1, with the end products being CO2 and H2O. In gasification the combustion is carried at substoichiometric conditions with air-to-fuel ratio being 1.5:1 to 1.8:1. The gas so obtained is called producer gas, which is combustible.

This process is made possible in a device called GASIFIER, in a limited supply of air. A gasifier system basically comprises of a reactor, where the gas is generated, and is followed by a cooling and cleaning system, which cools and cleans the gas. The clean combustible gas is thus available for power generation application.

Uses of producer gas: The producer gas obtained by the process of gasification can have end use either for THERMAL application or for mechanical/ electrical power generation. Like any other gaseous fuel, producer gas has the advantage of better and finer power control when compared to that of solid fuel, in this case solid biomass/wood. This also paves way for more efficient and environment friendly operation. The gas can thus be conveniently used in number of applications, more specifically, (1) Power Generation (2) Thermal Applications. Power generation By using producer gas it is possible to operate a stand-alone producer gas Engine coupled to an Alternator, to produce GRID QUALITY ELECTRICITY. Where diesel engines are available, we can switch to the dual fuel mode with marginal changes to the air inlet .Diesel substitution of the order of 70 to 85% can be obtained at nominal loads in the dual fuel mode... The mechanical energy thus derived can be used either for energizing a water pump for irrigational purpose or coupling with an alternator for electrical power generation, either for local consumption or for grid synchronization. Thermal applications Thermal energy of the order of 4.5 to 5.0 MJ is released, flaring 1 m3 of wood gas in the burner. Flame temperatures as high as 1200oC, can be obtained by optimal premixing of air with gas. For processes, which require thermal energy, gasifiers can be a good option as a gas generator, and retrofitted with existing devices. Such a retrofit is possible in dryers, kilns, furnaces etc where temperatures up to 1100 deg C are required. Apart from these, energy requirements in poultry farms, cold storage Devices (vapour compression refrigerator), rubber industry and so on could be met using biomass gasifiers.

Bio-Mass gasifiers in the Capacity range of 500 KW to 2.0 MW each( which can be linearly multiplied ) have been perfected in India and large number of Small Scale Industries and Villages have benefitted from the Bio-Mass Power availability so far . The Bio-Mass Gasifier Programme has been reoriented with a twin objective of attaining better Quality and favourable Economics. Advantages: The conventional routes for the generation of base load electric power are Thermal, Nuclear and Hydroelectric. The Thermal Route uses non-renewable energy resources such as Coal, Naphtha, Natural Gas and other Petroleum products which have inherent inflation built into their costs in direct proportion to the rate of foreign exchange, the rate of depletion of the resource and the level of scarcity of the fuel feedstock. This route also adds to the net CO2 load in the atmosphere. This route also suffers from high cost of installation per MW, high and rising production cost per unit of electricity, problems of fuel linkage and long gestation of over 5 years. Hydroelectric resources are typically located in hilly and inaccessible terrains and the logistics of their installation and regular operation and maintenance are therefore difficult to manage. Wind systems are very site specific and can promise a plant load factor rarely exceeding 30%. Solar photovoltaic systems have similar features in terms of performance and in addition are at least eight to ten times more expensive for similar performance. The major advantages that Biomass Gasification technology enjoys over other strategies are:

The costs of installation per we are about the same as for large power levels (of the order of hundreds of MWs) and the plant load factor is about the same as for large thermal power plants, since the biomass is essentially stored solar energy that can be harvested throughout the year.

Also when the power generation package is suitably selected, the cost of energy is perhaps the generation strategies. lowest amongst all the power

Hence it provides a sustainable, affordable and eco-friendly alternative to fossil fuel based power plants at low power levels. Therefore, it improves the countrys energy self-reliance and reduces the crippling oil import bill.

The entire project is additionally positioned such that it is carbondi-oxide neutral and generates very little sulfur dioxide and nitrogen oxides compared to coal based power plants.

The process produces very low emissions of un-burnt primary fuel and no fly ash, since the solid fuel is subjected to multistage thermochemical conversion process. Carbon trading/CO2 benefits. Financial benefit:

This arises from the fact that the net savings on the energy cost are lower compared to the grid or use of fossil fuel technology. Employment generation potential: Power generation is a chain of activities related to operation, maintenance, fuel collection, fuel preparation, ash handling and related issues. These activities involve use of man power at various capacities. With the focus being power plant where the deliverables are clearly identified, many of the activities which are at present less organized would move towards being professionals. One of the areas where the main focus would be is towards the

procurement of biomass in a sustainable manner and of this kind of exercise. Along with this the economics of the biomass sector would improve.

Basis of Offer Terms of reference Further to the discussions we had with Mr.Oyenuga Kayode, we are enclosing a proposal for 2 MWe of power generation to be fed to the grid and if required utilization of associated thermal energy for purpose of refrigeration/chilling and/or Water Purification, but not included in our proposal. PLANT AND MACHINERY Main Plant and Machinery will comprise: 1. Biomass Gasifier 2. Gas Engines of combination DELIVERABLES: 2 Nos x 1250 kg/hr 1 Nos. x 1970 kW each or any other suitable

The proposal envisages supply of plant and machinery capable of delivering the following: Peak power output Rated power capacity Captive consumption Net power output Power output Thermal energy 2,000 Kwe 1970 kWe + 5% 250 Kwe + 10 % 1,720 Kwe 11,500,000 +200,000 units equal to 400 Tons of Refrigeration

GENERAL DESCRIPTION OF GASIFIER Gasifiers will conform to specifications drawn up by I.I.Sc and manufactured to drawings provided by them. It is specially designed and developed and has state-of-the-art Technology, incorporating a patented system. The gasifier will also include the following sub-systems: 1. Cooling System The cooling system would consist of direct and indirect coolers and would include a chilling plant designed to assist the cleaning operations. 2. Cleaning system: The cleaning system would include de-misters; fabric filters and / or an appropriate combination. 3. Flare system: Flare system for gas ignition prior to system

stabilization. 4. Measurement system: Consisting of pressure gauges, temperatures indicator and oxygen analyzers. 5. Gasifier Control: Complete automation of start-up operation and shut down sequence including pneumatically actuated devices for top cover lifting, biomass conveyor chute retraction system, Butterfly control valve for Flare system and Main Burner.

6.

Electrical System: Gasifier Auto / Manual control system consisting of PLC based control desk with instrumentation, Motor control center and push button station for local operations with complete built in safety features as per IS standards. (Complete plant automation with SCADA can also be considered at the clients option)

7. Biomass processing system: This will include Rotary sieve for Biomass cleaning and Biomass drying equipment. 8. Biomass Conveyor System: The gasifier system will include a hoist, which will carry the biomass from the ground level to the top of the gasifier. Other conveying systems required to convey the biomass from the feed preparation section to the gasifier bottom are not included, as they will depend on the site conditions and have been included separately in the project cost. 9. Water treatment and recycling system: The cooling water from the direct coolers shall be treated to remove tar and other suspended matter for recycling into the system 10. Biomass preparation system:

This would be Saw Cutter or Cutting machine, dryer accessories etc. depending on the type of biomass. In addition to the above, the following ancillary equipments and items will be required and considered separately in the project. 11. Electrical System: This would cover requirements for feeding the power generated to the point of consumption or the grid depending on the project requirement. Electrical systems relating to the gasifier, accessories and engine controls are however included in Our Supply Scope...

Salient Features of the system are given below Open top, twin air entry system, which ensures a better thermal environment compared to the conventional closed top model. Multi-fuel capability wood residues and agro residues in briquetted form with moisture content less than 10%. Permits high gasification efficiency above 85%, with biomass consumption between 0.8 kg to 1.2 kg/KWH Producer gas generated is of a very high quality. It is environment sound with low NOx in the engine exhaust. The gasifier is robust in construction with ceramic lining inside. Gas Engines Producer Gas Engines Generating Sets are now available from a number of large players and bearing capacity. have unique features, with proven technology providing Some of the Gas Engine suppliers that we use are: GE high engine performance, fuel economy, load emission and greater load Jenbacher, Cummins, Waukesha and Schmitt. Civil Works & Foundation All necessary civil works pertaining to the project and foundation for the major equipments will be handled by and responsibility of the Client. M/s. Acclaim Technology Services will arrange necessary drawings and specifications. About 15,000 Sq.ft of covered area including temporary raw material storage will be required. Scope of Services Acclaim Technology Services shall undertake turnkey services for the plant. Services shall include: a. Procurement and supply of complete plant and machinery b. Erection, Integration and Commissioning Services c. Complete Project Management Services d. Assistance in recruitment and training of manpower in plant operation

SCOPE OF SUPPLY Supply ATS Client X X X X X X X X

Bio mass processing Biomass cutter Belt conveyor Rotary Sieve Holding bin Screw conveyer Drier Drier blower Drier insulated ducting

Qty 2 2 2 2 2 2 2 1 lot

Gasifier Reactor Shell Main Screw Assembly Wet extraction Multi-clone Raw water scrubber Chilled water scrubber Moisture traps Fabric filter Filter internals incl. Fabric Water tanks/dumpsGasifier Structure Top cover system SS Ducting Air nozzles+ water piping Fasteners Top feeding arrangements Platform gratings Refractory Brick lining Stand by chilling plant- 10 TR Blowers Air compressor+ piping Hoist Pneumatic items Inverters Oxygen monitor Electrical and instrumentation PLC cont. panel Laboratory equipment Flare burner system

Qty 2 2 2 2 4 2 4 8 8 sets 8 1 set 2 1 lot 2 sets 1 lot 2 1 set 1 set 1 3 1 1 1 set 3 2 1 set 1 set 1 lot 2

ATS X X X X X X X X X X X X X X X X X X X X X X X X X X X X X

Client

Note: Acclaim reserves the

right to change the scope of supply and the configuration without in any way compromising the deliverables Clients scope a) All civil constructions/foundations masonry tanks and sumps b) All bulk raw material handling c) Transportation of material d) Unloading of equipment at site e) All insurance from dispatch till erection f) Start-up power, lighting and water for erection and site fabrication wherever required g) Transport & Accommodation at site for workforce during erection h) Responsibility for obtaining statutory clearances i) Absorption chiller for clients application

Expected output: Each 2 MW power plant will annually generate about 15 million units-kw (50400 GJ) of energy. This is equivalent to the per capita consumption of 4200 persons at the 2005 level of 12 GJ per capita.

The project will provide direct employment to about 100 persons Energy plantation - 60 persons Power plant - 40 persons

The project will save direct import of 3500 kl of fossil fuel annually.

The project will reduce 12500 t CO2 emissions annually

Delivery: Within 24-30 weeks from date of order with advance for gasifier and accessories and engines as per engine suppliers terms

BOUNDARY LIMITS FOR GASIFIER SUPPLY

Exhaust gas piping

Bio mass cutter Bio mass Water treatment

Drier

Biomass sieve & Conveyors

Gasifier and accessories Make up Water power & Chemicals charcoal start up

VAM

Engine & Accessories

Electrical Evacuation

MECHANISM FOR MONITORING AND EVALUATING PROGRESS OF THE PROJECT

Complete project schedule will be uploaded on View path and updated daily so that all project stake holders will be able to access the same and monitor the progress.

Anda mungkin juga menyukai

- Deployment of Hybrid Renewable Energy Systems in MinigridsDari EverandDeployment of Hybrid Renewable Energy Systems in MinigridsBelum ada peringkat

- Feasibility Study of Developing Large Scale Solar PV Project in Ghana: An Economical AnalysisDokumen65 halamanFeasibility Study of Developing Large Scale Solar PV Project in Ghana: An Economical AnalysisFocus ArthamediaBelum ada peringkat

- Rural ElectrificationDokumen12 halamanRural ElectrificationRavikanth ReddyBelum ada peringkat

- Feasibility Study of Biomass Power PlantDokumen40 halamanFeasibility Study of Biomass Power PlantSuman Ghosh100% (2)

- SWL Solar ProjectsDokumen22 halamanSWL Solar ProjectsSiddharth SainiBelum ada peringkat

- Cost Estimates-MeralcoDokumen44 halamanCost Estimates-MeralcoambiBelum ada peringkat

- Karnataka Solar Policy 2014-21 - (As Amended)Dokumen14 halamanKarnataka Solar Policy 2014-21 - (As Amended)Soham DasguptaBelum ada peringkat

- Final Report - HybridDokumen67 halamanFinal Report - HybridohiozuaBelum ada peringkat

- Eks Energy PresentationDokumen17 halamanEks Energy PresentationFrancisco Javier Marín SuárezBelum ada peringkat

- EFB Combustion - Power Gen Asia 2014 VFDokumen28 halamanEFB Combustion - Power Gen Asia 2014 VFcram1960Belum ada peringkat

- 25 MW Biomass Plant China - CDMDokumen72 halaman25 MW Biomass Plant China - CDMLavu Anil Chowdary100% (4)

- Microgrids Smart Grids and Energy Storage SolutionsDokumen28 halamanMicrogrids Smart Grids and Energy Storage SolutionsDGGBelum ada peringkat

- Solar Farm Diagramnov17 2014Dokumen1 halamanSolar Farm Diagramnov17 2014Sikumbang MobilBelum ada peringkat

- Biogas Consultants ContractorsDokumen8 halamanBiogas Consultants ContractorsuemaaplBelum ada peringkat

- Grid-Connected Photovoltaic Systems: An Overview of Recent Research and Emerging PV Converter TechnologyDokumen15 halamanGrid-Connected Photovoltaic Systems: An Overview of Recent Research and Emerging PV Converter TechnologyLukas Ramírez MarínBelum ada peringkat

- Helwan University Faculty of Engineering Dep. Electric Power and Machine EngineeringDokumen37 halamanHelwan University Faculty of Engineering Dep. Electric Power and Machine EngineeringSamah MostafaBelum ada peringkat

- 2mw Biomass Gasification Gas Power Plant ProposalDokumen9 halaman2mw Biomass Gasification Gas Power Plant ProposalsabrahimaBelum ada peringkat

- Standalone Solar PVDokumen17 halamanStandalone Solar PVGetie Tesfaye ZelieBelum ada peringkat

- Performance of Solar Power Plants PDFDokumen43 halamanPerformance of Solar Power Plants PDFRavi Ranjan Verma100% (1)

- A Report On An Overview of Renewable Energy Scenario and Its Share To The Total Energy Demand in NepalDokumen45 halamanA Report On An Overview of Renewable Energy Scenario and Its Share To The Total Energy Demand in NepalIndra Kumar Maharjan67% (3)

- Solar Power Plants - Detailed GuideDokumen102 halamanSolar Power Plants - Detailed GuideBrkaBrkati100% (5)

- 2 10 MW Biomass Plant Feasibility Study FinalDokumen55 halaman2 10 MW Biomass Plant Feasibility Study Finalairlanggaputra100% (1)

- Power System Chapter-1Dokumen70 halamanPower System Chapter-1abdul hadi psBelum ada peringkat

- Customer Satisfaction Project of Green TechDokumen52 halamanCustomer Satisfaction Project of Green TechRajkamalChichaBelum ada peringkat

- Tender 10 KW Rooftop SolarDokumen14 halamanTender 10 KW Rooftop Solarsrirajt4uBelum ada peringkat

- Solar Power in IndiaDokumen9 halamanSolar Power in IndiaIAS EXAM PORTAL100% (1)

- Floating Windmill PowerpointDokumen25 halamanFloating Windmill PowerpointPavan Kumar100% (1)

- Potential of Solar Energy in Developing Countries For Reducing EnergyDokumen3 halamanPotential of Solar Energy in Developing Countries For Reducing EnergyPrashannaBelum ada peringkat

- Renewable Energy in IndiaDokumen20 halamanRenewable Energy in IndiabenoypBelum ada peringkat

- Energy Conversion PDFDokumen20 halamanEnergy Conversion PDFpushpendra singhBelum ada peringkat

- 05 MW Pv-Solar Power Plant Brochure Dec 2013Dokumen4 halaman05 MW Pv-Solar Power Plant Brochure Dec 2013Muhammad Asif ShafiqBelum ada peringkat

- Plexos Modeling PDFDokumen76 halamanPlexos Modeling PDFLuis Angel Cuevas OrtegaBelum ada peringkat

- Biogas Analysis - PakistanDokumen10 halamanBiogas Analysis - PakistantabinahassanBelum ada peringkat

- Energy Audit Assignment FinalDokumen6 halamanEnergy Audit Assignment FinalHarneet TyalBelum ada peringkat

- 2mw Biomass Gasification Gas Power Plant ProposalDokumen9 halaman2mw Biomass Gasification Gas Power Plant ProposalAnthony WoodardBelum ada peringkat

- EE2451 EEGUC Hand WrittenDokumen256 halamanEE2451 EEGUC Hand Writtensrivaas131985100% (1)

- A Study On The Project Management of Monte Solar Energy IncDokumen3 halamanA Study On The Project Management of Monte Solar Energy IncitsmenatoyBelum ada peringkat

- Proposal For 1kwp Roof-Top Solar PV PlantDokumen5 halamanProposal For 1kwp Roof-Top Solar PV PlantAnonymous kw8Yrp0R5rBelum ada peringkat

- Lao People's Democratic Republic: Energy Sector Assessment, Strategy, and Road Map 2013 UpdateDokumen53 halamanLao People's Democratic Republic: Energy Sector Assessment, Strategy, and Road Map 2013 UpdateAsian Development BankBelum ada peringkat

- PNG Off-Grid Code GuidelinesDokumen35 halamanPNG Off-Grid Code GuidelinesAndrew GroganBelum ada peringkat

- Biomass Power Plant-Broercycle Green EnergyDokumen29 halamanBiomass Power Plant-Broercycle Green EnergyChoirul Anwar100% (1)

- Ocean EnergyDokumen14 halamanOcean EnergyConnielyn BautistaBelum ada peringkat

- Prefeasibility Report Rajasthan Ganganagar As Per MoEF GuidelinesDokumen25 halamanPrefeasibility Report Rajasthan Ganganagar As Per MoEF GuidelinesAmol DeshmukhBelum ada peringkat

- Construction and Operation of Solar Farms CopDokumen65 halamanConstruction and Operation of Solar Farms CoptammamshBelum ada peringkat

- Wind Turbine Feasibility StudyDokumen157 halamanWind Turbine Feasibility Studyalassadi09Belum ada peringkat

- Bataan PDD v06Dokumen48 halamanBataan PDD v06RolenRivera100% (1)

- Small-Scale Solar PV Net Metering RegulationsDokumen39 halamanSmall-Scale Solar PV Net Metering RegulationsahmedBelum ada peringkat

- Ruzaida Daud - Malaysia Renewable Energy in Grid ExpansionDokumen15 halamanRuzaida Daud - Malaysia Renewable Energy in Grid ExpansionAsia Clean Energy ForumBelum ada peringkat

- Solar Petrol Station PDFDokumen41 halamanSolar Petrol Station PDFco2bin100% (10)

- Fuel Source For A Renewable Future: BiogasDokumen27 halamanFuel Source For A Renewable Future: BiogasAbdul LathifBelum ada peringkat

- OAG - LED Replacement September Executive Summary 2014 FinalDokumen4 halamanOAG - LED Replacement September Executive Summary 2014 Finaldean robertsBelum ada peringkat

- Grid Forming Energy Storage System Addresses Challenges of Grids With High Penetration of Renewables (A Case Study)Dokumen13 halamanGrid Forming Energy Storage System Addresses Challenges of Grids With High Penetration of Renewables (A Case Study)RaviBelum ada peringkat

- Pre-Feasibility Study For Roof PV Power SystemDokumen12 halamanPre-Feasibility Study For Roof PV Power SystemAnte TojčićBelum ada peringkat

- 3.1.1 EPC - Engineering (Design of Off-Grid and Hybrid Systems) REV EG 2022.11.23Dokumen26 halaman3.1.1 EPC - Engineering (Design of Off-Grid and Hybrid Systems) REV EG 2022.11.23waltdisneyyBelum ada peringkat

- Design of 12MW Power System Interconnecting Negros Siquijor and CebuDokumen26 halamanDesign of 12MW Power System Interconnecting Negros Siquijor and CebuRonn AlbertBelum ada peringkat

- Africa Energy Review 2021Dokumen37 halamanAfrica Energy Review 2021Jedson SilvaBelum ada peringkat

- Swot Analysis of Flow BatteriesDokumen5 halamanSwot Analysis of Flow BatteriesJp GuptaBelum ada peringkat

- Atimonan Power PlantDokumen8 halamanAtimonan Power PlantkimzairelleBelum ada peringkat

- Solar Energy Services BrochureDokumen4 halamanSolar Energy Services BrochureAnkit MaheshwariBelum ada peringkat

- ABB LTD.: Affolternstrasse 44 CH-8050 Zurich SwitzerlandDokumen34 halamanABB LTD.: Affolternstrasse 44 CH-8050 Zurich SwitzerlandAnd WebBelum ada peringkat

- Term Paper: Methanol ProductionDokumen3 halamanTerm Paper: Methanol ProductionNavket JhaBelum ada peringkat

- QER Analysis - A Review of The CO2 Pipeline Infrastructure in The U.S - 0Dokumen52 halamanQER Analysis - A Review of The CO2 Pipeline Infrastructure in The U.S - 0saepcc TsaoBelum ada peringkat

- Energy Research Paper TopicsDokumen5 halamanEnergy Research Paper Topicsupvipbqlg100% (1)

- Preparation For Loading LNG CargoDokumen18 halamanPreparation For Loading LNG Cargoocto20016962Belum ada peringkat

- Navien NR180NG Tankless Condensing Gas Water HeaterDokumen4 halamanNavien NR180NG Tankless Condensing Gas Water Heatere-ComfortUSABelum ada peringkat

- Natural Gas Transmission Pipeline Temperature Drop CalculationDokumen5 halamanNatural Gas Transmission Pipeline Temperature Drop CalculationCarina QuibinitBelum ada peringkat

- Alkanes and CycloalkanesDokumen5 halamanAlkanes and CycloalkanesAlineBelum ada peringkat

- Detailed and Const Support Eng Pre QuaDokumen45 halamanDetailed and Const Support Eng Pre QuaRavikumar mahadevBelum ada peringkat

- CSEC Rates of Reaction 2014Dokumen90 halamanCSEC Rates of Reaction 2014Carl Agape Davis100% (2)

- Basics of OIl RefineryDokumen28 halamanBasics of OIl RefineryDebasis Kumar Saha50% (2)

- Engineers India Annual Report 2009-10Dokumen149 halamanEngineers India Annual Report 2009-10bhu_300Belum ada peringkat

- Kamar TimbalDokumen6 halamanKamar TimbalAl Akil100% (1)

- Fired HeatersDokumen24 halamanFired HeatersCynthia Magali Márquez Ramírez100% (1)

- 2) Haseeb PresentationDokumen27 halaman2) Haseeb PresentationBilalAshrafBelum ada peringkat

- Steam Plant Operation 10th Edition 10th Edition Ebook PDFDokumen61 halamanSteam Plant Operation 10th Edition 10th Edition Ebook PDFclarence.terry830100% (39)

- Orbit V31N1 2011 Q1Dokumen60 halamanOrbit V31N1 2011 Q1KrishnaBelum ada peringkat

- Basics of Fracturing IDokumen26 halamanBasics of Fracturing IAnonymous MPRQFuYMMBelum ada peringkat

- BiomassDokumen34 halamanBiomassWoldemariam Worku100% (1)

- AIChE 2018 Improving Catalytic Reformer Heaters Using Split Flow TechnologyDokumen31 halamanAIChE 2018 Improving Catalytic Reformer Heaters Using Split Flow Technologyashutosh_garg_10Belum ada peringkat

- Heat Balance DiagramDokumen10 halamanHeat Balance DiagramKartheek RamishettiBelum ada peringkat

- Astmd1265 1547Dokumen8 halamanAstmd1265 1547dilan michel rojasBelum ada peringkat

- Future Fuels Apec RegionDokumen104 halamanFuture Fuels Apec RegionmalikscribdBelum ada peringkat

- 6 44 0005 Rev5 PDFDokumen439 halaman6 44 0005 Rev5 PDFprasadBelum ada peringkat

- Accumulator BOP Volume Calculation - Jean-VergesDokumen12 halamanAccumulator BOP Volume Calculation - Jean-VergesSudish Bhat100% (1)

- Design and Structural Analysis of CNGDokumen5 halamanDesign and Structural Analysis of CNGIJARTETBelum ada peringkat

- Natural Gas Processing SaadDokumen9 halamanNatural Gas Processing SaadAlexander SashaBelum ada peringkat

- Barcap Global Energy Outlook Feb 2010Dokumen76 halamanBarcap Global Energy Outlook Feb 2010deanmaitBelum ada peringkat

- FE PresentationOrder-ModDokumen8 halamanFE PresentationOrder-ModHrishabhJainBelum ada peringkat

- Experience The Benefits of Tomorrow'S Fuel, Today: What ChoiceDokumen2 halamanExperience The Benefits of Tomorrow'S Fuel, Today: What ChoiceUJJWALBelum ada peringkat

- J5212 H2FC Supergen Energy Systems WEBDokumen200 halamanJ5212 H2FC Supergen Energy Systems WEBDasthagirBelum ada peringkat

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDari EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterBelum ada peringkat

- Electric Motors and Drives: Fundamentals, Types and ApplicationsDari EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsPenilaian: 4.5 dari 5 bintang4.5/5 (12)

- Electric Motor Control: DC, AC, and BLDC MotorsDari EverandElectric Motor Control: DC, AC, and BLDC MotorsPenilaian: 4.5 dari 5 bintang4.5/5 (19)

- Well Integrity for Workovers and RecompletionsDari EverandWell Integrity for Workovers and RecompletionsPenilaian: 5 dari 5 bintang5/5 (3)

- Introduction to Power System ProtectionDari EverandIntroduction to Power System ProtectionPenilaian: 5 dari 5 bintang5/5 (1)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDari EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesPenilaian: 4.5 dari 5 bintang4.5/5 (21)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentDari EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentPenilaian: 4.5 dari 5 bintang4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDari EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialBelum ada peringkat

- VSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsDari EverandVSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsBelum ada peringkat

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsDari EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsBelum ada peringkat

- Building Energy Management Systems and Techniques: Principles, Methods, and ModellingDari EverandBuilding Energy Management Systems and Techniques: Principles, Methods, and ModellingBelum ada peringkat

- Handbook on Battery Energy Storage SystemDari EverandHandbook on Battery Energy Storage SystemPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsDari EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Well Control for Completions and InterventionsDari EverandWell Control for Completions and InterventionsPenilaian: 4 dari 5 bintang4/5 (10)

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ADari EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ABelum ada peringkat

- Thermal Power Plant: Design and OperationDari EverandThermal Power Plant: Design and OperationPenilaian: 4.5 dari 5 bintang4.5/5 (23)

- Electrochemical Technologies for Energy Storage and Conversion, 2 Volume SetDari EverandElectrochemical Technologies for Energy Storage and Conversion, 2 Volume SetBelum ada peringkat

- Photovoltaic Solar Energy: From Fundamentals to ApplicationsDari EverandPhotovoltaic Solar Energy: From Fundamentals to ApplicationsBelum ada peringkat

- Pipeline and Energy Plant Piping: Design and TechnologyDari EverandPipeline and Energy Plant Piping: Design and TechnologyPenilaian: 5 dari 5 bintang5/5 (2)

- Shorting the Grid: The Hidden Fragility of Our Electric GridDari EverandShorting the Grid: The Hidden Fragility of Our Electric GridPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Practical Power Distribution for IndustryDari EverandPractical Power Distribution for IndustryPenilaian: 2.5 dari 5 bintang2.5/5 (2)

- Heat Transfer Engineering: Fundamentals and TechniquesDari EverandHeat Transfer Engineering: Fundamentals and TechniquesPenilaian: 4 dari 5 bintang4/5 (1)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsDari EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsBelum ada peringkat