Rat Nesh

Diunggah oleh

Ratnesh KhandelwalDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Rat Nesh

Diunggah oleh

Ratnesh KhandelwalHak Cipta:

Format Tersedia

Session2FractureControlAnalysisTools,MethodsandLessonsLearned Morfeo/Crack,adedicatedsolutionforindustrialdamagetolerantapproaches Authors: EricWyart(Cenaero),HenkCruyssen(DutchSpace),AmineGhouali(Snecma) Since2002,CenaerohasdevelopedMorfeo/Crackforfatiguecrackgrowthanalysis. Morfeo/CrackisbasedontheeXtendedFiniteElementMethod(XFEM)andthelevelset techniqueswhichallowformodellingcrackpropagationswithouttheneedofspecific remeshingtechniques.Consequently,thetimespendbytheuserisreducedwhilethe computationaltimeremainsessentiallythesame.Morfeo/Crackisalsoavailableasaplugin solutionforgeneralpurposeFEsolversthataremorefamiliartoengineersinthestress office. ForseveralyearsMorfeohasbeensuccessfullyusedforaeronauticalandaerospace applications.Inthiscontribution,someaerospaceapplicationssuchasarocketengines componentandsatelliteswillbeconsideredtoillustratethecapabilitiesofMorfeo/Crackfor damagetolerantassessment.

nt. ************ Computationofstressintensityfactorsandenergyreleaseratecomponentswithinthe frameworkofthepversionofthefiniteelementmethod Authors: RicardoL.ActisandBarnaA.Szabo(ESRDInc.) Prediction of damage propagation events is based on the idea that some parameter, assumedtobethedriverofdamageaccumulation,whichiscomputablefromthesolutionof acontinuummechanicsproblem,canbeconsistentlycorrelatedwithdamageaccumulation observed in physical experiments. In the case of metallic structures, linear elastic fracture mechanics(LEFM)istypicallyusedforthepredictionoftheonsetoffailureinthepresence ofaflaworcrack.ThecharacterizingparameteristheStressIntensityFactor(SIF)whichis denotedbyKIformodeIloading,andthecorrespondinglimitvalueisthefracturetoughness (KIC). The reliable prediction of crack growth and the determination of residual strength require the accurate computation of SIFs for partthrough cracks and through cracks. Analytical solutions of these types of crackgeometry configurations typically are not available; therefore estimates of SIFs have to be obtained by numerical methods, such as finite elementsandboundaryelements. TherearemanyproceduresforextractingSIFsfromfiniteelementsolutions.However,most extractionproceduresarecumbersometouseandrequireagreatdealofexpertiseonthe part of the users, which makes them impractical for everyday applications. A procedure basedontheContourIntegralMethod(CIM)incombinationwiththepversionofthefinite elementmethod[1],makestheextractionoftheSIFssimpleandaccurateatanynumberof pointsalongacrackfront.

A fracture mechanics based approach to assess the damage tolerance of composite structuresisalogicalandnaturalextensionoftheLEFMtocomposites.However,inthecase oflaminatecomposites,theproblemiscomplicatedbytheanisotropyofthematerialandby the coupling between load and deformation modes (i.e., a symmetric loading may lead to asymmetric deformation) due to lack of symmetry in material properties. Mode I (Interlaminar tension), Mode II (interlaminar sliding shear) and Mode III (interlaminar scissoring shear) loading are expected to be present in most cases. Typical failure in the presenceofaninitialdefect,suchasdelamination,appearsunderamixedmodeloading. Modelsbasedontheassumptionthatfailurepropagationcanbecorrelatedwiththestrain energyreleaserate(G)associatedwitheachmodeofdeformationhavebeenproposed[2]. The critical energy release rate (Gc) is defined by a failure surface which depends on the components of the total energy release rate corresponding to each mode, Gc = Gc (GI, GII, GIII).Thereforethestrainenergyreleaserate(ERR)componentsformodeI(GI),modeII(GII) andmodeIII(GIII)mustbedeterminedwithguaranteedaccuracytoformulatemixedmode failure criteria for the determination of onset of instability of interlaminar flaws in componentsmadeofcompositematerials. OneofthemostcommonlyusedprocedurestocomputetheERRcomponentsistheVirtual Crack Closure Technique (VCCT). Numerical implementations of the VCCT within the framework of the hversion of the finite element method (hFEM) has the advantage of utilizingasingleFEsolutiontodeterminethecomponentsoftheenergyreleaserate,butthe resultsarequitesensitivetothesizeoftheelementsaroundthecrackfrontandtoelement distortion[3].TheJintegraldecomposition[45] providesanalternativewaytoaccurately computetheERRcomponentsalongacrackordelaminationfrontfromasingleFEsolution andtheresultscanbeshowntobemeshindependent. ThepresentationaddressestheuseoftheCIMforthecomputationofSIFsandtheJintegral fordeterminingtheERRcomponentsinpostprocessingoperationswithintheframeworkof pversion of the finite element method (pFEM) implemented in the professional software product StressCheck. The main benefit from combining these extraction procedures with the pFEM is the feedback information available to the user regarding the convergence of thedataofinterestwithrespecttoincreasingnumberofdegreesoffreedom,anessential prerequisite of verification and validation procedures. Several examples are presented to illustratethemeritsoftheimplementationandtodemonstratetheefficiencyandaccuracy ofbothextractionprocedures. References 1.Szab,B.A.andBabuska,I.FiniteElementAnalysis,JohnWileyandSons,Inc.NewYork, 1991. 2. R. Krueger, The Virtual Crack Closure Technique: History, Approach and Applications. ICASEReportNo.200210.NASA/CR2002211628,April2002. 3. R. Krueger. An approach for assessing delamination propagation capabilities in commercialfiniteelementcodes.PaperpresentedattheAmericanSocietyofComposites 22nd Annual Technical Conference, University of Washington, Seattle, WA, September 17 19,2007. 4. O. Huber, J. Nickel and G. Kuhn. On the decomposition of the Jintegral for 3D crack problems.InternationalJournalofFracture,Vol.64,pp.339348,1993. 5.R.H.RigbyandM.H.Aliabdi.DecompositionofthemixedmodeJintegralRevisited. Int.J.SolidsStructures,Vol.35,No.17,pp20732099,1998. ************

XFEMandotheradvancedfracture&failuremechanicsinAbaqus Authors: VincentBouwman,JohnWilliam(SimuliaBenelux) Fractureandfailuremodelingallowsforproductdesignsthatmaximizethesafeoperating lifeofstructuralcomponents.Abaqusoffersmanycapabilitiesthatenablefractureand failuremodelinginbothA/StandardandA/Explicit. Thispresentationprovidesanoverviewofthesecapabilitiesandwilldiscussdamagein FiberReinforcedComposites,FastenerFailure,SurfacebasedCohesiveBehavior,VCCT, FatigueanalysisandXFEM. ************ FractureControlDesignRecommendations Author: M.Vorel(ASTRIUMSpaceTransportation) Duringafewthoughnotallpreviousdevelopments,therewasnoformallinkbetween designanddamagetolerance.Thefocalpointofthedesignwasprimarilyoptimizationof stiffness,massandproductioncosts.Thefinaldesignwashowevernotalwayscompatibleto damagetolerancerequirementssothatdamagetolerancecapabilitycouldnotbejustified. Infewcasesthisfinallyresultedinacostlyredesign.Thesituationwasaggravatedbythe factthatadamagetoleranceverificationisbyprincipleperformedattheendofthe developmentchain(wheninputsfromdesign,static,dynamicandproductiondepartments areavailable).Atthattimethedesign,manufacturingprocessesaswellasmassandcost budgetareusuallyalreadyfrozenandanewloopofaredesignmaybecostlybothinterms ofscheduleandbudget. Theobjectiveofthepresentationisthereforetomakeawareofvariousdesignsolutions whichresultinadesignwithinherentdamagetolerantfeatures.Inparticularthisshall facilitate: achievementofdamagetoleranceindevelopment maintainabilityofdamagetoleranceinproduction

Anadvanceddesignthatrespectsdamagetoleranceprinciplesstilldoesnotguaranteethat damagetolerancewilleasilybejustifiable.Nevertheless,suchadesignisabasicassumption forasuccessfuljustificationand,inabroaderview,forasuccessfulcompletionofthe FractureControlprogramme.Withrespecttotheindustrializationofthedesignthepurpose ofthedesignrecommendationsis: keepingthecostsatpossiblylowlevel(avoidingunnecessarydiscussionsandexpensive correctiveactions) maintaininghighlevelofrobustness(reductionofriskofstructuralfailure).

Thepresentationcontentsisbasedontheconsolidationofdesignmethodsforthe developmentoftheA5MEUpperStage,asdocumentedinadedicatedhandbooklike proprietaryreport. ************

Anda mungkin juga menyukai

- Relachement Des Noeuds Interlaminar - Fracture - MechanicsDokumen10 halamanRelachement Des Noeuds Interlaminar - Fracture - MechanicsSchmetterling TraurigBelum ada peringkat

- X-FEM For Abaqus (XFA) Toolkit For Automated Crack Onset and Growth SimulationsDokumen15 halamanX-FEM For Abaqus (XFA) Toolkit For Automated Crack Onset and Growth Simulationsklomps_jrBelum ada peringkat

- CFD in Formula 1Dokumen7 halamanCFD in Formula 1delducaBelum ada peringkat

- VCCT FEM Kreuger PDFDokumen35 halamanVCCT FEM Kreuger PDFrrmerlin_2Belum ada peringkat

- Life Prediction Using Finite Elements in Complex GeometriesDokumen9 halamanLife Prediction Using Finite Elements in Complex Geometrieskoohestani_afshinBelum ada peringkat

- VCCTDokumen35 halamanVCCTAshutosh SinglaBelum ada peringkat

- 10.1016 J.procir.2017.03.252 Wear Estimation of Coated Tools Using XFEM Level Set FunctionDokumen6 halaman10.1016 J.procir.2017.03.252 Wear Estimation of Coated Tools Using XFEM Level Set Functionhamid rezaBelum ada peringkat

- A Unified Abaqus Implementation of The PDokumen19 halamanA Unified Abaqus Implementation of The PMehedi HassanBelum ada peringkat

- Selecting CFD Software: Appendix ADokumen13 halamanSelecting CFD Software: Appendix AAnil Kumar RoutBelum ada peringkat

- Systematic Design Method For Bonded Repair Based oDokumen8 halamanSystematic Design Method For Bonded Repair Based oMike PenceBelum ada peringkat

- Comput. Methods Appl. Mech. Engrg.: Sam Cuvilliez, Frédéric Feyel, Eric Lorentz, Sylvie Michel-PonnelleDokumen16 halamanComput. Methods Appl. Mech. Engrg.: Sam Cuvilliez, Frédéric Feyel, Eric Lorentz, Sylvie Michel-PonnellengBelum ada peringkat

- Composite FEMDokumen14 halamanComposite FEMbookdigitBelum ada peringkat

- Modeling SRM Internal BallisticsDokumen203 halamanModeling SRM Internal Ballisticsned_marianBelum ada peringkat

- Applications Using Finite Element Methods To Reduce The Cost of Composite StructuresDokumen25 halamanApplications Using Finite Element Methods To Reduce The Cost of Composite StructuresVenkata DineshBelum ada peringkat

- Methematical Methods of Relative Engine Performance VOLPONIDokumen27 halamanMethematical Methods of Relative Engine Performance VOLPONITurk SoloBelum ada peringkat

- Numerical Simulation in Automotive Design: G. Lonsdale C&C Research Laboratories, NEC Europe LTD., St. Augustin, GermanyDokumen7 halamanNumerical Simulation in Automotive Design: G. Lonsdale C&C Research Laboratories, NEC Europe LTD., St. Augustin, Germanybadboys123Belum ada peringkat

- ATENA-Science-GiD Tutorial FRCDokumen50 halamanATENA-Science-GiD Tutorial FRCChris LumyBelum ada peringkat

- Ingranaggi 0612 Kissling PDFDokumen9 halamanIngranaggi 0612 Kissling PDFmgualdiBelum ada peringkat

- Recent Advances in Avl'S CFD Mesh Generation Software - Ese-ToolsDokumen6 halamanRecent Advances in Avl'S CFD Mesh Generation Software - Ese-ToolsNhựt KhôiBelum ada peringkat

- Guerrero Vela ETSIDokumen11 halamanGuerrero Vela ETSIKarthik KrBelum ada peringkat

- Using Copulas in Risk AnalysisDokumen6 halamanUsing Copulas in Risk AnalysisghourisBelum ada peringkat

- Aerodynamic Simulation of A 2017 F1 CarDokumen9 halamanAerodynamic Simulation of A 2017 F1 CarjamesBelum ada peringkat

- ISO22628 - Cota de ReciclagemDokumen4 halamanISO22628 - Cota de ReciclagemJr BelancieriBelum ada peringkat

- Material Fracture and Burr Formation in Blanking Results of FEM Simulations and Comparison With ExperimentsDokumen11 halamanMaterial Fracture and Burr Formation in Blanking Results of FEM Simulations and Comparison With ExperimentsLuízaBottiBelum ada peringkat

- FITNET Fitness-For-Service Fracture Module SOFTWARE: Nenad GubeljakDokumen6 halamanFITNET Fitness-For-Service Fracture Module SOFTWARE: Nenad GubeljaklaurentdupontBelum ada peringkat

- A Novel 3D Geometric Algorithm For Aircraft Autonomous Collision AvoidanceDokumen6 halamanA Novel 3D Geometric Algorithm For Aircraft Autonomous Collision AvoidanceAnonymous t5MrKaXDBelum ada peringkat

- Mr. Fawad Tariq, Mr. Muhammad Zeeshan Siddiqui, Ms. Nausheen Naz Mr. Muhammad Fahad Ahmed, Mr. Waqas HussainDokumen35 halamanMr. Fawad Tariq, Mr. Muhammad Zeeshan Siddiqui, Ms. Nausheen Naz Mr. Muhammad Fahad Ahmed, Mr. Waqas HussainMahmoud EissaBelum ada peringkat

- Parametric Analysis of Aerodynamic Characteristics of Launch Vehicles With Strap-On BoostersDokumen12 halamanParametric Analysis of Aerodynamic Characteristics of Launch Vehicles With Strap-On Boostersali68fat64Belum ada peringkat

- Optimization of A Cockpit Structure According To ECE-R21 RegulationDokumen14 halamanOptimization of A Cockpit Structure According To ECE-R21 Regulationnarendra pinnelaBelum ada peringkat

- ISO Specifications of Complex Surfaces ApplicationDokumen8 halamanISO Specifications of Complex Surfaces ApplicationahmeterenbacakBelum ada peringkat

- 2019 - Fault Detection and Isolation Based On Bond Graph Models-Application To An Electromechanical ActuatorDokumen10 halaman2019 - Fault Detection and Isolation Based On Bond Graph Models-Application To An Electromechanical ActuatorLuiz Carlos GoesBelum ada peringkat

- External AerodynamicsDokumen14 halamanExternal AerodynamicsBharath Dv100% (1)

- Modo Rompo Problemas Por Junto de Elementos Finitos y El Método Fractal de Malla LibreDokumen23 halamanModo Rompo Problemas Por Junto de Elementos Finitos y El Método Fractal de Malla LibreEndless LoveBelum ada peringkat

- 1 s2.0 S1350630712002403 Main PDFDokumen13 halaman1 s2.0 S1350630712002403 Main PDFFrancesco MontagnoliBelum ada peringkat

- Assessing The Current Modelling Approach For Predicting The Crashworthiness of Formula One Composite StructuresDokumen19 halamanAssessing The Current Modelling Approach For Predicting The Crashworthiness of Formula One Composite StructuresGiuseppeBelum ada peringkat

- 06 NGubeljakDokumen6 halaman06 NGubeljakvahid_shoeibiBelum ada peringkat

- Split-A Simplified Continuous-Discontinuous Approach To Fracture Based On Decoupled Localizing Gradient Damage MethodDokumen34 halamanSplit-A Simplified Continuous-Discontinuous Approach To Fracture Based On Decoupled Localizing Gradient Damage MethodhungBelum ada peringkat

- State of Cold Forging Technology in Global CompetitionDokumen20 halamanState of Cold Forging Technology in Global CompetitionEldori1988Belum ada peringkat

- FEM_Module - IDokumen27 halamanFEM_Module - Irvit21bme023.rvitmBelum ada peringkat

- Research Article: Established Numerical Techniques For The Structural Analysis of A Regional Aircraft Landing GearDokumen22 halamanResearch Article: Established Numerical Techniques For The Structural Analysis of A Regional Aircraft Landing GearAashis DahalBelum ada peringkat

- Embedded Two Level Direct Adaptive Fuzzy Controller for DC Motor Speed ControlDokumen11 halamanEmbedded Two Level Direct Adaptive Fuzzy Controller for DC Motor Speed ControlMohammed SelmanBelum ada peringkat

- Entropy 21 00923Dokumen20 halamanEntropy 21 00923Ademar SoaresBelum ada peringkat

- Improving Mechanical Seal ReliabilityDokumen4 halamanImproving Mechanical Seal ReliabilityBala MuruganBelum ada peringkat

- Dynamic Mesh CFD and Its Application To Flapping Wing Micro Air VehicleDokumen29 halamanDynamic Mesh CFD and Its Application To Flapping Wing Micro Air Vehicleteguh hady a100% (1)

- Methodology To Estimate The Modulus of Elasticity of Parts Manufactured by FFF-FDM Combining Finite Element Simulations and Experimental TestsDokumen10 halamanMethodology To Estimate The Modulus of Elasticity of Parts Manufactured by FFF-FDM Combining Finite Element Simulations and Experimental TestsGogyBelum ada peringkat

- Crashworthiness Design of A Train Based On European Standard EN15227Dokumen3 halamanCrashworthiness Design of A Train Based On European Standard EN15227gustavo PabloBelum ada peringkat

- Driving Innovation in Manufacturing: Morfeo v1.1 FeaturesDokumen2 halamanDriving Innovation in Manufacturing: Morfeo v1.1 FeaturesHenrique Rodrigues OliveiraBelum ada peringkat

- Fixtures - FEADokumen5 halamanFixtures - FEAMohammedRafficBelum ada peringkat

- Krugger Shell 3DDokumen24 halamanKrugger Shell 3Dbnidhal100% (1)

- Automatic 3D Crack Propagation in Complex Welded StructuresDokumen9 halamanAutomatic 3D Crack Propagation in Complex Welded StructuresRusandi NoorBelum ada peringkat

- Structural Analysis of A Commercial Vehicle Disc Brake CaliperDokumen10 halamanStructural Analysis of A Commercial Vehicle Disc Brake Caliperhimanshu AroraBelum ada peringkat

- Thermo-hydrodynamic Lubrication in Hydrodynamic BearingsDari EverandThermo-hydrodynamic Lubrication in Hydrodynamic BearingsBelum ada peringkat

- Introduction to Optical Waveguide Analysis: Solving Maxwell's Equation and the Schrödinger EquationDari EverandIntroduction to Optical Waveguide Analysis: Solving Maxwell's Equation and the Schrödinger EquationBelum ada peringkat

- Embedded Mechatronic Systems, Volume 1: Analysis of Failures, Predictive ReliabilityDari EverandEmbedded Mechatronic Systems, Volume 1: Analysis of Failures, Predictive ReliabilityBelum ada peringkat

- Reliability of High-Power Mechatronic Systems 2: Aerospace and Automotive Applications: Issues,Testing and AnalysisDari EverandReliability of High-Power Mechatronic Systems 2: Aerospace and Automotive Applications: Issues,Testing and AnalysisBelum ada peringkat

- Rapid Prototyping Software for Avionics Systems: Model-oriented Approaches for Complex Systems CertificationDari EverandRapid Prototyping Software for Avionics Systems: Model-oriented Approaches for Complex Systems CertificationBelum ada peringkat

- Model Driven Development for Embedded Software: Application to Communications for Drone SwarmDari EverandModel Driven Development for Embedded Software: Application to Communications for Drone SwarmBelum ada peringkat

- Reliability of High-Power Mechatronic Systems 1: Aerospace and Automotive Applications: Simulation, Modeling and OptimizationDari EverandReliability of High-Power Mechatronic Systems 1: Aerospace and Automotive Applications: Simulation, Modeling and OptimizationBelum ada peringkat

- Va80 PDFDokumen4 halamanVa80 PDFomar leonBelum ada peringkat

- MAGLEV User ManualDokumen19 halamanMAGLEV User ManualAnthony LittlehousesBelum ada peringkat

- Digital BandDokumen93 halamanDigital BandTofel EmedBelum ada peringkat

- Iec 61400 Justification: E30/70 PRODokumen60 halamanIec 61400 Justification: E30/70 PROoswalfBelum ada peringkat

- Reconfigurable Vivaldi Antenna With Improved Gain For Uwb ApplicationsDokumen5 halamanReconfigurable Vivaldi Antenna With Improved Gain For Uwb ApplicationsSubhanjali MyneniBelum ada peringkat

- Highway Engineering - Gupta & GuptaDokumen470 halamanHighway Engineering - Gupta & GuptaRajat RathoreBelum ada peringkat

- Lourdes San Isidro Telacsan Road Program RevisedDokumen36 halamanLourdes San Isidro Telacsan Road Program RevisedCent TorresBelum ada peringkat

- RK-2001 Operation ManualDokumen11 halamanRK-2001 Operation Manuale-ComfortUSABelum ada peringkat

- Variational Asymptotic BeamDokumen43 halamanVariational Asymptotic BeamAdimasu AyeleBelum ada peringkat

- A320-25-1BPK R01 Dt. 25.05.21Dokumen39 halamanA320-25-1BPK R01 Dt. 25.05.21Pradeep K sBelum ada peringkat

- Low-Power Digital Signal Processor Architecture For Wireless Sensor NodesDokumen9 halamanLow-Power Digital Signal Processor Architecture For Wireless Sensor NodesGayathri K MBelum ada peringkat

- An Experimental Comparative Review - PK NanavatiDokumen9 halamanAn Experimental Comparative Review - PK NanavatiPurvesh NanavatiBelum ada peringkat

- Relief/Unloading Valve: Spool, Pilot Operated 200 L/Min (52 Usgpm) - 350 Bar (5000 Psi)Dokumen2 halamanRelief/Unloading Valve: Spool, Pilot Operated 200 L/Min (52 Usgpm) - 350 Bar (5000 Psi)Dragan LazicBelum ada peringkat

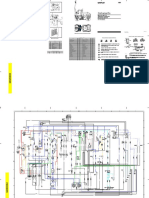

- Electric Schematic CB113 114 QENR2003 PDFDokumen2 halamanElectric Schematic CB113 114 QENR2003 PDFHipac TapicuBelum ada peringkat

- Wire Rope and Material Properties GuideDokumen100 halamanWire Rope and Material Properties GuideReynald de VeraBelum ada peringkat

- Machine Torch Parts: T100 ConsumablesDokumen2 halamanMachine Torch Parts: T100 Consumablesبسام الاغبريBelum ada peringkat

- ACSEW Cast Control Centers: Explosionproof, Dust-IgnitionproofDokumen24 halamanACSEW Cast Control Centers: Explosionproof, Dust-IgnitionproofDennis MendozaBelum ada peringkat

- Lizmontagens Group ProfileDokumen5 halamanLizmontagens Group ProfileRui Carlos Delgado Lopes AlvesBelum ada peringkat

- 6 Shifter Interlock System in 90's Transmissions-ServiceDokumen10 halaman6 Shifter Interlock System in 90's Transmissions-ServiceJack Carl100% (1)

- Hydraulic Cylinder Seal Kits: Quality With Value GuaranteedDokumen16 halamanHydraulic Cylinder Seal Kits: Quality With Value GuaranteedHenry GamboaBelum ada peringkat

- Reaffirmed Indian Standards for Water Resources DepartmentDokumen2 halamanReaffirmed Indian Standards for Water Resources Departmentjamjam75Belum ada peringkat

- Euro FirefighterDokumen2 halamanEuro FirefighterGustavo VydraBelum ada peringkat

- Handout t1124f 1511 3869 Onb Bus Das Srs TNDokumen37 halamanHandout t1124f 1511 3869 Onb Bus Das Srs TNlequangthongBelum ada peringkat

- Ship Stability 5Dokumen31 halamanShip Stability 5jeaneva guiaoBelum ada peringkat

- Soalan Assignment Stm10173Dokumen7 halamanSoalan Assignment Stm10173Razanah RozaimayBelum ada peringkat

- Crompton ProjectDokumen110 halamanCrompton Projectarunkcmt0% (2)

- Landsberg 1989Dokumen13 halamanLandsberg 1989aldoBelum ada peringkat

- AN2295Dokumen52 halamanAN2295Fernando ArrowBelum ada peringkat

- Astm D365Dokumen3 halamanAstm D365Frank LeeBelum ada peringkat

- Denison Hydraulics Goldcup Digital Hi-Iq Control: Electronic Control Card User Manual Software Version 2.2BDokumen62 halamanDenison Hydraulics Goldcup Digital Hi-Iq Control: Electronic Control Card User Manual Software Version 2.2BHassan Haghighi TajvarBelum ada peringkat