1600kVA (33-433) GTP

Diunggah oleh

chandrakanth0083396Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

1600kVA (33-433) GTP

Diunggah oleh

chandrakanth0083396Hak Cipta:

Format Tersedia

TECHNICAL SPECIFICATION OF TRANSFORMER The transformer will be designed and manufactured as per IS:2026-1977 and will be supplied with

first filling of oil to IS:335 of 1993. 1.01. GENERAL SPECIFICATIONS 1 Rated KVA 1600 2 Service & Duty Continuous 3 Make SERVOMAX INDIA LTD. 4 Type Core Type Oil Immersed 5 Location Outdoor 6 Specifications and Standard as per IS IS 2026 7 Type of Cooling ONAN 8 Wound Copper Double Wound 1.02. SYSTEM PARTICULARS 1 Nominal Voltage (V) 2 Highest System Voltage (V) 3 No. Of Phases 4 Frequency ( Hz ) 5 Voltage variation 6 Frequency Variation

33000 36000 3 50 + / - 10 % +/-3%

7 Combined Voltage and Frequency variation + / - 10 % 8 Terminal Arrangement HV Bare Bushings LV Bus duct 1.03. RATING 1 Rated Voltage of H.V.( Volts ) 2 Rated voltage of L.V.(Volts) 3 Rated current of H.V.( Amps ) 4 Rated current of L.V.( Amps ) 3 Max.Temperature rise above 50 C ambient temperature of winding by resistance method. (Deg.C) 4 Max. Temperature rise in oil by thermometer above 50 C ambient Temperature (Deg.C) 5 Over load capacity 1.04. WINDING CONNECTION DETAILS 1 Connections a. H.V. Winding b. L.V. Winding c. Neutral brought out for earthing 2 Tapings a. No.of positions b. Range c.Voltage of each step 3 Vector Symbol

33000 433 27.99 (Line current) 2133.41 55

50

As per IS : 6600

Delta Star Yes 17 (16 Steps) + 5 % to - 15 % in steps of 1.25 % 412.5V Dyn11

1.05. LOSSES AND OTHERS *1 No load losses at rated frequency and voltage (Watts) *2 Copper losses at rated current and rated frequency at 75 deg.C(Watts)At Normal Tap. *3 Percentage Impedance at 75 Deg.C at normal Tap 4 Regulation at full load at 75 Deg.C u.p.f 5 Regulation at full load at 75 Deg.C 0.8 u.p.f 1.06. EFFICIENCY 1 Efficiency at 75 Deg.C. a. 100% Full Load b. 75% Full Load c. 50% Full Load d. 25% Full Load 2 Maximum efficiency (Percentage) 3 Load at which Max.efficiency occurs KVA *Subject to IS tolerance 1.07. CONSTRUCTIONAL DETAILS 1 Type of Construction 2 Insulation between laminations 3 Type of joint between core limb and yoke 4 Type of Winding a.HV Winding b.LV Winding 1.08. WINDING INSULATION LEVEL a.HV Winding (KV uniform) b.LV Winding (KV uniform) 1.09. INSULATION OF CONDUCTORS a.HV Winding turn Insulation b.LV Winding turn Insulation c.Between HV and LV Winding d.Between LV Winding and core 1.10. TYPE OF JOINTS IN WINDING 1.11. MINIMUM CLEARANCES H.V to Earth (mm) In oil Out of oil L.V. to Earth (mm) In oil Out of oil 1.12. TEST VOLTAGES a.Impulse (1.2 / 50 micro second wave) withstand voltage H.V Winding (KV peak) L.V Winding (KV Peak) b.One minute power Frequency withstand voltage H.V Winding (KV ) L.V Winding (KV)

2300 16000 6.25 1.19% 4.59% UPF 98.87 99.07 99.22 99.18 99.25 606.56 0.8 P.F. 98.59 98.84 99.03 98.98

Core Type Carlit Mitered Continuous disc Helical 36 1.1 DPC DPC Oil Duct + Solid Cylinder + Oil Duct Solid Cylinder Brazed

60 355 7 20

170 N.A

70 3

1.13. DETAILS OF TANK AND MATERIALS M.S 1 Thickness of side plates(mm) 5 2 Thickness of bottom plates (mm) 6 3 Thickness of cover plates (mm) 6 4 Thickness of radiator (pipes or sheets) 1.25 mm 1.14. WEIGHTS AND DIMENSIONS (APPROX.) 1 Net untanking weight (Kg.) 2515 (Core and windings with clamps ) 2 Volume of insulating oil (Ltr.) 2355 3 Tank and fittings (Kg.) 1895 4 Total Weight of Transformer (Kg.) 6415 5 Overall dimensions of the transformer Length Breadth (approx.) in mm 3100 2550 1.15. Parts to be detached for transport Rollers, Breather & Radiators 1.16. STANDARD FITTINGS AND ACCESSORIES S.NO. DESCRIPTION QTY 1 Rating and terminal marking plate One 2 Earthing Terminals Two 3 Lifting Lugs Four 4 OLTC One 5 Conservator with Drain plug One 6 Oil filling hole with cap One 7 Oil Level Indicator One 8 Dehydrating Silicagel Breather One 9 Air release device One 10 Thermometer Pocket One 11 Drain valve with blanking plate One 12 Filter valve with blanking plate One 13 Explosion vent with Diaphragm One 14 Radiators (Detachable) Adequate 15 Uni- directional Flat Rollers Four 16 Separate Neutral Bushing One 17 GOR One 18 OTI One 19 WTI One 20 MARSHALLING BOX One 21 RTCC PANEL One

Height 2550

1.17. PAINTING 1 Surface preparation By Grit Blasting 2 Paint Enamel Light Grey, Shade No. 631, of IS : 5 1.18. TESTS 1 ROUTINE TESTS As per IS : 2026 all the Routine tests are carried out by our work , in the presence of your representative. We now look forward to receive your valued order Thanking you, Yours faithfully, for SERVOMAX INDIA LTD. [MARKETING INCHARGE]

Anda mungkin juga menyukai

- SWCC-Water Cooled CableDokumen8 halamanSWCC-Water Cooled CableElafanBelum ada peringkat

- Emergency oil drain pit plan and sectionDokumen1 halamanEmergency oil drain pit plan and sectionAbhay ThakurBelum ada peringkat

- Clearance IEC 61936Dokumen9 halamanClearance IEC 61936sparkCEBelum ada peringkat

- Ductile Iron Gate Valve PN16. BS EN 1171:2002 PN16Dokumen8 halamanDuctile Iron Gate Valve PN16. BS EN 1171:2002 PN16Emil AbdoBelum ada peringkat

- UEEDokumen90 halamanUEEVicky MouryaBelum ada peringkat

- Transformer Design (Electrical) WO. No. Guaranteed Technical Particulars Bharat Bijlee Ltd. Transformer DivisionDokumen3 halamanTransformer Design (Electrical) WO. No. Guaranteed Technical Particulars Bharat Bijlee Ltd. Transformer Divisionswarupkumarnayak100% (1)

- LSC Bus Industrial EsDokumen54 halamanLSC Bus Industrial EsYonatan MayVeBelum ada peringkat

- GTP 25 KV VCBDokumen8 halamanGTP 25 KV VCBDilip KumarBelum ada peringkat

- Medium Voltage Metal Clad Switchgear CatalogDokumen24 halamanMedium Voltage Metal Clad Switchgear CatalogRobert John ToledoBelum ada peringkat

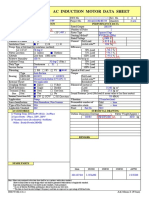

- Ac Induction Motor Data Sheet: General Specification Performance DataDokumen7 halamanAc Induction Motor Data Sheet: General Specification Performance DataMayur Gupta0% (1)

- LA Condition MonitoringDokumen20 halamanLA Condition MonitoringPET MADAKKATHARABelum ada peringkat

- KC Agarwal HitsDokumen18 halamanKC Agarwal HitskittyBelum ada peringkat

- 11kV HT Kiosk SpecificationDokumen35 halaman11kV HT Kiosk Specification10derBelum ada peringkat

- Battery Sizing - Open ElectricalDokumen7 halamanBattery Sizing - Open ElectricalPrabakaran NatarajanBelum ada peringkat

- Restricted Earth Fault Protection-Lv (Mcag14) : Stabilising Voltage CalculationDokumen3 halamanRestricted Earth Fault Protection-Lv (Mcag14) : Stabilising Voltage CalculationarsathnmaBelum ada peringkat

- Oil Soak Pit CalculationDokumen2 halamanOil Soak Pit CalculationROHIT MCBelum ada peringkat

- 1 MVA - TRANSFORMER - Technical Sheet KirloskarDokumen10 halaman1 MVA - TRANSFORMER - Technical Sheet KirloskarINDRAJIT SAOBelum ada peringkat

- Data Sheet 1500kw 6.6kv Pa Fan MotorDokumen4 halamanData Sheet 1500kw 6.6kv Pa Fan MotorRamesh CuppuBelum ada peringkat

- M3BP315MLB6 110KW PDFDokumen1 halamanM3BP315MLB6 110KW PDFPablo CorreaBelum ada peringkat

- Technical Data Sheet-DOL - SubmitDokumen1 halamanTechnical Data Sheet-DOL - Submithar singkawangBelum ada peringkat

- Is.10118.3.1982 0 PDFDokumen33 halamanIs.10118.3.1982 0 PDFBhalsingh JangraBelum ada peringkat

- IEEE STD 80-2000 Modelo2capa PDFDokumen10 halamanIEEE STD 80-2000 Modelo2capa PDFCristian Daniel Antilao PizarroBelum ada peringkat

- Specification For 1000 KV TransformerDokumen1 halamanSpecification For 1000 KV TransformerSandeep SoniBelum ada peringkat

- ABB Motors and Technical Data Sheet - DOL Generators: No. Data Unit RemarksDokumen1 halamanABB Motors and Technical Data Sheet - DOL Generators: No. Data Unit Remarksarash esmaeiliBelum ada peringkat

- Guranteed Technical Particulars of Potential Transformer FormatDokumen5 halamanGuranteed Technical Particulars of Potential Transformer FormatVikas VikasBelum ada peringkat

- GTP - 250 kVADokumen5 halamanGTP - 250 kVARamphani NunnaBelum ada peringkat

- 75kW Motor Technical SpecificationsDokumen7 halaman75kW Motor Technical Specificationsprati121Belum ada peringkat

- Disclosure To Promote The Right To InformationDokumen20 halamanDisclosure To Promote The Right To InformationpkumarmysBelum ada peringkat

- Is 5082 1998Dokumen11 halamanIs 5082 1998dipenkhandhediyaBelum ada peringkat

- Earth Flat EstimationDokumen7 halamanEarth Flat EstimationVamsi ManojBelum ada peringkat

- Load Commutated Synchronous Drives PDFDokumen13 halamanLoad Commutated Synchronous Drives PDFShubham JhalaniBelum ada peringkat

- Relay Coordination Preliminary Report Draft-BDokumen4 halamanRelay Coordination Preliminary Report Draft-Bramesh1950Belum ada peringkat

- SS SoR CombinedDokumen56 halamanSS SoR Combinedganesh100% (1)

- Calculating transformer loss cost ratesDokumen3 halamanCalculating transformer loss cost ratesRatana KemBelum ada peringkat

- Motor Pump Protection RelaysDokumen6 halamanMotor Pump Protection RelaysAnand ShuklaBelum ada peringkat

- P54X CT RequriementsDokumen5 halamanP54X CT RequriementsAsif KhanBelum ada peringkat

- DV9800E - 24 Channel Universal Input Data ScannerDokumen2 halamanDV9800E - 24 Channel Universal Input Data ScannerBalu MBelum ada peringkat

- Thermal Conductivity of SoilsDokumen322 halamanThermal Conductivity of SoilsnavigareeBelum ada peringkat

- Current Ratings for Paper-Insulated Lead-Sheathed CablesDokumen37 halamanCurrent Ratings for Paper-Insulated Lead-Sheathed Cablesmanoj_2027Belum ada peringkat

- IEEE STD C57.19.00-2004 (CN - EN)Dokumen18 halamanIEEE STD C57.19.00-2004 (CN - EN)pdrich8Belum ada peringkat

- NTDC Requirement For 132kV & 220kV GridsDokumen8 halamanNTDC Requirement For 132kV & 220kV GridsmuzammiliqbalBelum ada peringkat

- I4 Industrial UPS Catalogue (Domestic)Dokumen8 halamanI4 Industrial UPS Catalogue (Domestic)p41005679Belum ada peringkat

- Single Core Compacted Aluminium - HT Cables - Stainless Steel WiresDokumen7 halamanSingle Core Compacted Aluminium - HT Cables - Stainless Steel WiresWires CableBelum ada peringkat

- Generator Data Sheet of BHELDokumen21 halamanGenerator Data Sheet of BHELbramhanand vermaBelum ada peringkat

- Cable Sheeth EarthingDokumen15 halamanCable Sheeth EarthingVaibhav Gholase100% (1)

- 22/0.415 KV, 1000KVA TRANSFORMER Technical Specification: Balmer Lawrie & CoDokumen13 halaman22/0.415 KV, 1000KVA TRANSFORMER Technical Specification: Balmer Lawrie & Coshan shanzBelum ada peringkat

- Impedance Calculation of Cables Using Subdivision of The Cable ConductorsDokumen76 halamanImpedance Calculation of Cables Using Subdivision of The Cable ConductorsOneil ZárateBelum ada peringkat

- 110kV 1250A isolator technical parametersDokumen19 halaman110kV 1250A isolator technical parametersneerajBelum ada peringkat

- Cable HV Report PDFDokumen8 halamanCable HV Report PDFJayson PatrickBelum ada peringkat

- Summation CTDokumen1 halamanSummation CTDHARMENDRABelum ada peringkat

- Is 10322 5 2 2012 PDFDokumen10 halamanIs 10322 5 2 2012 PDFsuresh kumarBelum ada peringkat

- 51 Sdms 01rev022 For Distribution TransformerDokumen20 halaman51 Sdms 01rev022 For Distribution Transformernadeem UddinBelum ada peringkat

- Technical Data Sheet - 250kva TransformersDokumen2 halamanTechnical Data Sheet - 250kva TransformerspavanBelum ada peringkat

- Calculation of Positive Sequence ImpedanceDokumen14 halamanCalculation of Positive Sequence ImpedancesathiyaseelanBelum ada peringkat

- Transformers Losses Nov 2013Dokumen4 halamanTransformers Losses Nov 2013saji kumarBelum ada peringkat

- Final ProjectDokumen45 halamanFinal Projectrahulshandilya2k100% (1)

- Acsr Moose ConductorDokumen17 halamanAcsr Moose ConductorRam Dhani Yadav100% (1)

- Is-2026, Part-2Dokumen23 halamanIs-2026, Part-2Himansu Sekhar Jena100% (1)

- Power-system protection A Complete GuideDari EverandPower-system protection A Complete GuidePenilaian: 1 dari 5 bintang1/5 (1)

- FNC Catalogo BateriaDokumen8 halamanFNC Catalogo BateriaLuis ChonchisBelum ada peringkat

- ECIL TRansformer SpecificationDokumen116 halamanECIL TRansformer Specificationchandrakanth0083396Belum ada peringkat

- HV Induction Motors Technical IEC Catalog FINAL en 092011 LowresDokumen152 halamanHV Induction Motors Technical IEC Catalog FINAL en 092011 LowresSangeet BhandariBelum ada peringkat

- Specification of Energy Meters For R Apdrp PDFDokumen7 halamanSpecification of Energy Meters For R Apdrp PDFVara Prasad ReddyBelum ada peringkat

- 241-267 - CT and VT Basics - QuazvinDokumen27 halaman241-267 - CT and VT Basics - Quazvincarlos vidalBelum ada peringkat

- Technical Specification For 33 KV, Single Phase, Dead Tank TypeDokumen11 halamanTechnical Specification For 33 KV, Single Phase, Dead Tank Typechandrakanth0083396Belum ada peringkat

- HV Induction Motors Technical IEC Catalog FINAL en 092011 LowresDokumen152 halamanHV Induction Motors Technical IEC Catalog FINAL en 092011 LowresSangeet BhandariBelum ada peringkat

- Electrical Testing Procedures for Armatures and StatorsDokumen7 halamanElectrical Testing Procedures for Armatures and StatorsCarlosBelum ada peringkat

- Safety Standards TableDokumen4 halamanSafety Standards Tablechandrakanth0083396Belum ada peringkat

- Types of PanelsDokumen5 halamanTypes of Panelschandrakanth0083396Belum ada peringkat

- Compressed Air System Design ManualDokumen26 halamanCompressed Air System Design ManualBadrul HishamBelum ada peringkat

- Abb MotorsDokumen1 halamanAbb Motorschandrakanth0083396Belum ada peringkat

- GE Panle BoardDokumen52 halamanGE Panle Boardchandrakanth0083396Belum ada peringkat

- Design & Selection of Lightning ArresterDokumen5 halamanDesign & Selection of Lightning ArresterAnkur_soni0% (1)

- Best Practice Manual-TransformersDokumen46 halamanBest Practice Manual-Transformerschandrakanth0083396Belum ada peringkat

- Design & Selection of Lightning ArresterDokumen5 halamanDesign & Selection of Lightning ArresterAnkur_soni0% (1)

- Testing, Maintenance & Protection of Distribution TransformersDokumen47 halamanTesting, Maintenance & Protection of Distribution TransformersHarikrishnan Natarajan92% (25)

- Power Transformer MaintenanceDokumen19 halamanPower Transformer Maintenanceadnan80% (5)

- TransformerDokumen6 halamanTransformerchandrakanth008339650% (2)

- What Is An ArresterDokumen20 halamanWhat Is An ArresterRamasamy JayaramanBelum ada peringkat

- 19-8011 Lineman Slang Diccionary HUBBELLDokumen24 halaman19-8011 Lineman Slang Diccionary HUBBELLAlberto Alber100% (1)

- 743CBDokumen16 halaman743CBTenza Zangetsu MaetBelum ada peringkat

- 1 Substation Automation Solutions - SAS600 Series Rev B CompressedDokumen106 halaman1 Substation Automation Solutions - SAS600 Series Rev B CompressedcastrojpBelum ada peringkat

- Fire Extinguisher Location and Placement: Fact SheetDokumen2 halamanFire Extinguisher Location and Placement: Fact SheetEli NaguitBelum ada peringkat

- Weather and Aviation PDFDokumen10 halamanWeather and Aviation PDFSergio GasparriBelum ada peringkat

- School Data Management System ReportDokumen122 halamanSchool Data Management System ReportshekharyadawBelum ada peringkat

- Schott Ky DiodesDokumen3 halamanSchott Ky DiodesAmarnath M DamodaranBelum ada peringkat

- Fabricación de Insertos de Carburo de TungstenoDokumen5 halamanFabricación de Insertos de Carburo de TungstenoRolando Nuñez MonrroyBelum ada peringkat

- Reaffirmed Indian Standards for Water Resources DepartmentDokumen2 halamanReaffirmed Indian Standards for Water Resources Departmentjamjam75Belum ada peringkat

- Re 29037Dokumen12 halamanRe 29037BorisBelum ada peringkat

- WSST - FW - Flyer Changi EN PDFDokumen5 halamanWSST - FW - Flyer Changi EN PDFAmlan Banerjee0% (1)

- Design-Rcc Over Head TankDokumen82 halamanDesign-Rcc Over Head Tankjay_p_shah60% (5)

- MP3 - Equations of StateDokumen8 halamanMP3 - Equations of StatePatrick ValdezBelum ada peringkat

- Ms Acess 2Dokumen80 halamanMs Acess 2Mebrie1Belum ada peringkat

- User Manual Kxtda 30 600Dokumen252 halamanUser Manual Kxtda 30 600kabeh1Belum ada peringkat

- Installation & Maintenance Instructions Pressure Regulator With Integral Pilot Regulator R18Dokumen2 halamanInstallation & Maintenance Instructions Pressure Regulator With Integral Pilot Regulator R18luis ivanBelum ada peringkat

- Satellite 2755dvdDokumen2 halamanSatellite 2755dvdeduinnBelum ada peringkat

- ME301 Mechanics of MachineryDokumen2 halamanME301 Mechanics of MachineryVishnu Mohan M SBelum ada peringkat

- Linear System Theory and Desing PDFDokumen688 halamanLinear System Theory and Desing PDFJose David MartinezBelum ada peringkat

- 10 Ways To Speed Up Torrent DownloadsDokumen5 halaman10 Ways To Speed Up Torrent DownloadsricoffanyBelum ada peringkat

- Plate Girder DesignDokumen109 halamanPlate Girder Designhasib100% (3)

- UOP046-85 Wax Content in Petroleum OilsDokumen6 halamanUOP046-85 Wax Content in Petroleum OilsZiauddeen Noor100% (1)

- 6338d1285569848 Task Alfa 300ci SB Toner PDFDokumen3 halaman6338d1285569848 Task Alfa 300ci SB Toner PDFjosealcudiacastellas100% (1)

- Saf 5152 Material Safety Data Sheet PDFDokumen9 halamanSaf 5152 Material Safety Data Sheet PDFronald rodrigoBelum ada peringkat

- Aranya Housing Final To Be Submitted PDFDokumen37 halamanAranya Housing Final To Be Submitted PDFsucheta100% (4)

- THS Structural Plans (Combine)Dokumen12 halamanTHS Structural Plans (Combine)genciBelum ada peringkat

- Design Diesel-Photovoltaic Hybrid Power PlantDokumen93 halamanDesign Diesel-Photovoltaic Hybrid Power PlantDaniel Okere100% (1)

- Biometric ATMDokumen17 halamanBiometric ATMSushma100% (1)

- Bill of Quantities: Fifteen-Classrooms ADokumen1 halamanBill of Quantities: Fifteen-Classrooms AFritz NatividadBelum ada peringkat

- Zit 64 BVDokumen12 halamanZit 64 BVVT86Belum ada peringkat

- Temperature Sensors LM35Dokumen92 halamanTemperature Sensors LM35Shaik Shahul0% (1)