Powermag200908 2 DL

Diunggah oleh

Orlando BarriosDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Powermag200908 2 DL

Diunggah oleh

Orlando BarriosHak Cipta:

Format Tersedia

BUSINESS AND TECHNOLOGY FOR THE GLOBAL GENERATION INDUSTRY

A

u

g

u

s

t

2

0

0

9

V

o

l

.

1

5

3

N

o

.

8

Vol. 153 No. 8 August 2009 www.powermag.com

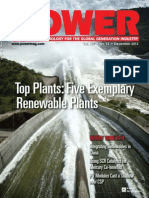

2009 Plant

of the Year

The Hague Repowering Project

Wins Marmaduke Award

GT Flex Fuel Design for LNG

IGCC: Are We There Yet?

FGD Dewatering Cuts Cost

City of Springfield's

Dallman 4

Balances Energy

and the

Environment

CIRCLE 1 ON READER SERVICE CARD

August 2009

|

POWER www.powermag.com 1

Established 1882 Vol. 153 No. 8 August 2009

www.powermag.com

TK

TK

TK

On the cover

By building a new Illinois coalfired unit on the shore of Lake Springfield, City Water, Light

& Power of the City of Springfield, Ill., has ensured that it will no longer have to buy power

on the wholesale market. KBV Springfield Power Partners was the Dallman 4 engineer-

ing, procurement, and construction contractor. Photo courtesy Terry Farmer Photography,

terryfarmer.com

COVER STORY: 2009 PLANT OF THE YEAR

28 City of Springfields CWLP Dallman 4 Earns POWERs Highest Honor

The $515 million Dallman 4 is the most expensive project ever built by the City of

Springfield, Ill., but it was completed ahead of schedule and under budget. Thanks to

using local coal, it will pay dividends to the municipal utilitys customers for years to

come in the form of low rates supported by income from the sale of surplus power

to the wholesale market. As one of the cleanest coal-fired plants in the U.S., the plant

makes environmental sense, too.

SPECIAL REPORTS

2009 MARMADUKE AWARD

38 The Hague Repowering Project Upgrades CHP System,

Preserves Historic Building

This years winner of the Marmaduke Award for excellence in O&M goes to a project

that pulled off something much harder than a facelift. The challenge was to preserve

the century-old historic exterior of The Hague Power Station while replacing its ag-

ing heart with high-efficiency turbines to ensure that the plant will provide heat and

power to the Dutch city for many years to come.

SOLID WASTE MANAGEMENT

46 Improved FGD Dewatering Process Cuts Solid Waste

How would you like to save over half a million dollars in costs related to flue gas de-

sulfurization solids? The plant in this case study shows you how it did just that. (Can

you really afford not to read this?)

GENERATION TECHNOLOGY

52 IGCC Update: Are We There Yet?

Integrated gasification combined cycle has for many years been a promising tech-

nology. Three experts weigh in on the current balance of pros and cons, and on when

IGCC is likely to deliver on its promises.

FEATURES

CARBON MANAGEMENT

58 Commercially Available CO

2

Capture Technology

Fluor Corp.s Econamine FG Plus (EFG+) technology has been widely used in the gas-

treating industry for two decades. Here the company makes the case for using EFG+

in coal-fired power plants by explaining how the process works and sharing its oper-

ating experience with the process at a gas-fired power plant.

28

CIRCLE 4 ON READER SERVICE CARD

TK

www.powermag.com POWER

|

August 2009 2

STEAM TURBINES

62 Preventing Turbine Water Damage: TDP-1 Updated

The latest revision of ASMEs Recommended Practices for the Prevention of Water

Damage to Steam Turbines Used for Electric Power Generation: Fossil-Fuel Plants in-

cludes recommendations that apply to the newest power plant technologies, includ-

ing combined cycles and digital controls. Consider its design and operating advice

an ounce of prevention.

COMBUSTION SYSTEM DESIGN

66 Flexible Fuel Combustor Design Accommodates LNG

Variations in the constituent elements of liquefied natural gas (LNG) can adversely

affect the operation of power generation turbines using the fuel. Siemens explains

how it is developing an LNG-capable turbine, and modifications for currently avail-

able turbines, to handle the fuel variations that are likely to affect increasing num-

bers of plants.

CLASSIC MARMADUKE

71 Marmys Deep-Freeze Blackout

Each year, as a companion to our report on the Marmaduke Award winner, we reprint

a story about the fictional plant troubleshooter Marmaduke Surfaceblow. This year

we dusted off a tale based on a true scenario set in Greenland.

DEPARTMENTS

6 SPEAKING OF POWER

Politics Trump Scientific Integrity

GLOBAL MONITOR

8 Help Build the Global Energy Observatory

10 Revived FutureGen Faces Renewed Funding Obstacles

11 How Much Coal and Gas Does the U.S. Really Have?

11 Of Fracking, Earthquakes, and Carbon Sequestration

13 Floating and Flying Wind Turbines

14 Major Scottish Coal Plant Starts CCS

Pilot Program

15 European Interest in Saharan Solar

Project Heats Up

16 Turning Sewage Sludge

into Renewable Energy

16 POWER Digest

FOCUS ON O&M

18 Managing Minimum Load

22 Polymeric Solution

for Pump Cavitation

25 The 7,000-Foot Challenge

26 LEGAL & REGULATORY

Old Challenges Persist in Impeding

Renewable Energy Goals

74 NEW PRODUCTS

80 COMMENTARY

Carbon Offsets: Scam, Not Salvation

By H. Sterling Burnett, PhD, National

Center for Policy Analysis.

66

The easiest way to comment on any

story in POWER is to use the Comment

tab at the bottom of the individual

online story pages at www.powermag

.com. (This is also true for POWERnews,

COAL POWER, and MANAGING POWER

content.) Our editorial staff reviews and

approves comments daily. This feature

allows readers to share comments and

ideas with us and each other more quick-

ly than when we ran selected letters to

the editor in the print magazine.

If you have a story proposal, please

continue to e-mail ideas to editor@

powermag.com after reviewing our con-

tributor guidelines (downloadable from

the About Us link at the bottom of the

powermag.com home page).

Want to Comment

on a Story?

POWER magazine has served

the generation industry for more

than 125 years. Now POWER is

making it easier than ever for

industry professionals to fnd

career opportunities and for

hiring authorities to fnd the best

candidates for open positions. The

Careers-in-POWER job board on

powermag.com allows visitors to

post resumes anonymously, view the

latest job positions, post job listings,

and set up personal job alerts.

JOB SEEKERS:

Access the most recent positions

available to engineers, operations

and maintenance managers,

corporate and general managers at

coal, nuclear, combined-cycle, and

alternative power facilities.

EMPLOYERS/RECRUITERS:

Attract highly qualifed candidates

by posting open positions on the

Careers-in-POWER job center.

Visit Careers-in-POWER on

powermag.com to become part of

the fastest growing site dedicated

to connecting power generation

employers and employees. Contact

Diane Hammes at dianeh@

powermag.com; 713.343.1885.

Ramp Up

Your Career!

CIRCLE 5 ON READER SERVICE CARD

www.powermag.com POWER

|

August 2009 4

Now incorporating and

EDITORIAL & PRODUCTION

Editor-in-Chief: Dr. Robert Peltier, PE

480-820-7855, editor@powermag.com

Managing Editor: Gail Reitenbach, PhD

Senior Editor: Angela Neville, JD

Contributing Editors: Mark Axford; David Daniels; Bill Ellison, PE; Steven F. Greenwald;

Tim Hurst; Jim Hylko; Kennedy Maize; Douglas Smith; Dick Storm;

Dr. Justin Zachary

Senior Writer: Sonal Patel

Senior Designer: Leslie Claire

Senior Production Manager: Tracey Lilly, tlilly@accessintel.com

Marketing Manager: Jamie Reesby

ADVERTISING SALES

North American Offices

Southern & Eastern U.S./Eastern Canada/

Latin America: Matthew Grant, 713-343-1882, mattg@powermag.com

Central & Western U.S./Western Canada: Dan Gentile, 512-918-8075, dang@powermag.com

International Offices

UK/France/Benelux/Scandinavia: Peter Gilmore, +44 (0) 20 7834 5559, pgilmores@aol.com

Germany/Switzerland/Austria/Eastern Europe: Gerd Strasmann, +49 (0) 2191 931 497, info@strasmann-media.de

Italy: Ferruccio Silvera, +39 (0) 2 284 6716, ferruccio@silvera.it

Spain/Portugal: Vibeke Gilland, +34 91 553 42 06, vibeke.gilland@publistar-es.com

Japan: Katsuhiro Ishii, +81 3 5691 3335, amskatsu@dream.com

Thailand: Nartnittha Jirarayapong, +66 (0) 2 237-9471, +66 (0) 2 237 9478

India: Faredoon B. Kuka, 91 22 5570 3081/82, kuka@rmamedia.com

South Korea: Peter Kwon, +82 2 416 2876, +82 2 2202 9351, gulfk@unitel.co.kr

Malaysia: Tony Tan, +60 3 706 4176, +60 3 706 4177, nmedia@tm.net.my

Classified Advertising

Diane Hammes, 713-343-1885, dianeh@tradefairgroup.com

POWER Buyers Guide Sales

Diane Hammes, 713-343-1885, dianeh@tradefairgroup.com

AUDIENCE DEVELOPMENT

Audience Development Manager: Terry Best

Fulfillment Manager: George Severine

CUSTOMER SERVICE

For subscriber service: powermag@halldata.com, 800-542-2823 or 847-763-9509

Electronic and Paper Reprints: lyndsay.bahn@theYGSgroup.com, 717-666-3052

List Sales: Statlistics, Jen Felling, j.felling@statlistics.com, 203-778-8700

All Other Customer Service: 713-343-1887

BUSINESS OFFICE

TradeFair Group Publications, 11000 Richmond Avenue, Suite 500, Houston, TX 77042

Publisher: Brian K. Nessen, 713-343-1887, briann@tradefairgroup.com

President: Sean Guerre

ACCESS INTELLIGENCE, LLC

4 Choke Cherry Road, 2nd Floor, Rockville, MD 20850

301-354-2000 www.accessintel.com

Chief Executive Officer: Donald A. Pazour

Exec. Vice President & Chief Financial Officer: Ed Pinedo

Exec. Vice President, Human Resources & Administration: Macy L. Fecto

Divisional President, Business Information Group: Heather Farley

Senior Vice President, Corporate Audience Development: Sylvia Sierra

Senior Vice President & Chief Information Officer: Robert Paciorek

Vice President, Production & Manufacturing: Michael Kraus

Vice President, Financial Planning & Internal Audit: Steve Barber

BUSINESS AND TECHNOLOGY FOR THE GLOBAL GENERATION INDUSTRY

Visit POWER on the web: www.powermag.com

Subscribe online at: www.submag.com/sub/pw

POWER (ISSN 0032-5929) is published monthly by Access

Intelligence, LLC, 4 Choke Cherry Road, Second Floor,

Rockville, MD 20850. Periodicals Postage Paid at Rockville,

MD 20850-4024 and at additional mailing offices.

POSTMASTER: Send address changes to POWER, P.O. Box

2182, Skokie, IL 60076. Email: power@halldata.com.

Canadian Post PM40063731. Return Undeliverable Canadian

Addresses to: Station A, P.O. Box 54, Windsor, ON N9A 6J5.

Subscriptions: Available at no charge only for qualified

executives and engineering and supervisory personnel

in electric utilities, independent generating companies,

consulting engineering firms, process industries, and other

manufacturing industries. All others in the U.S. and U.S.

possessions: $59 for one year, $99 for two years. In Canada:

US$64 for one year, US$104 for two years. Outside U.S. and

Canada: US$159 for one year, US$269 for two years (includes

air mail delivery). Payment in full or credit card information is

required to process your order. Subscription request must

include subscriber name, title, and company name. For new

or renewal orders, call 847-763-9509. Single copy price: $25.

The publisher reserves the right to accept or reject any order.

Allow four to twelve weeks for shipment of the first issue on

subscriptions. Missing issues must be claimed within three

months for the U.S. or within six months outside U.S.

For customer service and address changes, call 847-763-

9509 or fax 832-242-1971 or e-mail powermag@halldata

.com or write to POWER, P.O. Box 2182, Skokie, IL 60076.

Please include account number, which appears above name

on magazine mailing label or send entire label.

Photocopy Permission: Where necessary, permission is

granted by the copyright owner for those registered with

the Copyright Clearance Center (CCC), 222 Rosewood Drive,

Danvers, MA 01923, 978-750-8400, www.copyright.com,

to photocopy any article herein, for commercial use for the

flat fee of $2.50 per copy of each article, or for classroom

use for the flat fee of $1.00 per copy of each article. Send

payment to the CCC. Copying for other than personal or

internal reference use without the express permission of

TradeFair Group Publications is prohibited. Requests for

special permission or bulk orders should be addressed to the

publisher at 11000 Richmond Avenue, Suite 500, Houston, TX

77042. ISSN 0032-5929.

Executive Offices of TradeFair Group Publications: 11000

Richmond Avenue, Suite 500, Houston, TX 77042. Copyright

2009 by TradeFair Group Publications. All rights reserved.

NV Energy Tracy Station celebration luncheon for

achieving a million work hours with no lost time

accidents.

Serving Up Perfection in Power Solutions

atmb200901.007.indd

2009 CH2M HILL

Celebrating safety milestones is a fullling way to acknowledge great

achievements. On the NV Energy Tracy Station Project , CH2M HILL

performed over 1,000,000 work hours with no lost time accidents.

CH2M HILLs performance reects the value we place on having every

employee return home each day without injury, being good stewards of

the environment, and striving for continual improvement.

CH2M HILL will work with you to meet the worlds demand for energy by

safely delivering the most challenging programs and complex projects

globally and locally. Our expertise enables us to respond to your needs

quickly.

CH2M HILL provides innovative engineering, procurement, construction,

operations and consulting solutions that span the entire power value

chain.

CH2M HILL recently completed the

Xcel Energy High Bridge Project in

St. Paul, Minnesota.

..the performance of [CH2M HILL]

on this project has been exemplary.

Their approach to safety,

production, planning and leadership

has been impressive. Xcel and I

personally consider this project to

be near perfection. My compliments

and congratulations on a job well

done.

David Wilks, President of Power

Generation for Xcel Energy

ch2mhill.com/power

CIRCLE 16 ON READER SERVICE CARD

www.powermag.com POWER

|

August 2009 6

SPEAKING OF POWER

Politics Trump

Scientific Integrity

I

n their recent endangerment finding draft technical support

document (TSD), scientists at the U.S. Environmental Protec-

tion Agency (EPA) conclude that carbon dioxide emissions

are a public health hazard and should be regulated under the

Clean Air Act. Federal law requires that regulations be based

on scientific information that is accurate, clear, complete, and

unbiased; the most recent available; and collected by the best

available methods. The EPAs TSD on carbon emissions violates

all of these requirements.

Rush to Judgment

Lisa Jackson, the new EPA administrator, gave her staff only a

few weeks to prepare a TSD for carbon emissions. It should have

taken a year or two. The TSD is the technical documentation

that must be finalized before the EPA can promulgate carbon

regulations, hence the haste. The short schedule to prepare the

TSD forced staff scientists to pick between two poor choices:

maintain the required scientific checks and balances but miss

the TSD deadline of April 2 (the second anniversary of the Su-

preme Courts decision allowing the agency to regulate CO

2

) or

compromise their internal scientific review processes and meet

the schedule. They chose option two.

The EPA working group that authored the TSD circulated its

draft in mid-March for an internal review. Staff researcher Dr.

Alan Carlin, a 38-year EPA veteran, was given less than five days

to prepare his comments. Carlin prepared a blistering 98-page

report that was extremely critical of the TSDs scientific rigor

because EPA decisions [were] based on a scientific hypothesis

that does not appear to explain most of the available data.

Action, Meet Reaction

The EPAs overreaction was immediate when Carlins report went

public. The EPAs director of the National Center for Environmental

Economics (NCEE), Al McGartland, first worried about the inevi-

table political fallout in a March 17 e-mail: The administrator and

the administration has decided to move forward . . . and your

comments do not help the legal or policy case for this decision.

McGartland obviously missed Jacksons January memo promising

to keep the politics out of scientific inquiry: I will ensure EPAs

efforts to address the environmental crises of today are rooted in

three fundamental values: science-based policies and programs,

adherence to the rule of law, and overwhelming transparency.

McGartlands next knee-jerk response was to issue a gag or-

der: Please do not have any direct communication with anyone

outside of (our group) on endangerment. There should be no

meetings, e-mails, written statements, phone calls, etc. In an

interview with CBSNews.com, Carlin said, I was told . . . not to

work on climate change.

The EPAs final comments were simply outrageousthey seek

to discredit the messenger. In a written statement in response to

media questions about Carlins report, the EPA noted that The

individual in question is not a scientist and was not part of the

working group dealing with this issue. The EPA completely ig-

nores Carlins credentials (a BS in physics from CalTech and PhD in

economics from MIT), yet he was sufficiently qualified to be part

of the internal review team of the draft TSD and to work at the

NCEE for many years. Carlin suddenly became unqualified when he

asked hard questions and was unwilling to rubber-stamp the TSD.

Three Categories of Errors Found

Carlins report outlines six specific reasons why the scientific

basis for the TSD is flawed. I dont have room here for the de-

tails, but theyre persuasive and worth reading at http://cei

.org/cei_files/fm/active/0/DOC062509-004.pdf. Carlin suc-

cinctly summed up the TSDs flawed science this way: Until and

unless these and many other inconsistencies . . . are adequately

explained it would appear premature to attribute all or even any

of what warming has occurred to cha nges in GHG/CO

2

atmo-

spheric levels.

Carlin pointed out that the EPA used short-cuts to buttress the

endangerment findings. Much of the TSD is based on Intergov-

ernmental Panel on Climate Change (IPCC) studies and models

rather than on independent research and studies conducted by

EPA scientists, as has been its historical practice. These incon-

sistencies are so important and sufficiently abstruse that in our

view EPA needs to make an independent analysis of the science

of global warming rather than adopting the conclusions of the

IPCC and the CCSP [Climate Change Science Program] without

much more careful and independent EPA staff review than is evi-

denced by the TSD, he wrote.

Carlin also pointed out that there is an obvious logical prob-

lem posed by steadily increasing US health and welfare measures

and the alleged endangerment of health and welfare discussed in

this draft TSD during a period of rapid rise in at least CO

2

ambient

levels. This discontinuity either needs to be carefully explained

in the draft TSD or the conclusions changed.

The EPA has not responded to the concerns raised in Carlins

critique of the TSD in the three months since it was made public.

The Essence of Science

Carlin wrote in his critique that science requires experimentally

determining the correctness of a hypothesis by comparing em-

pirical data with real-world data. Its not a statement of belief.

Heres my critique of the TSD: Its EPAs scientific integrity

that is endangered.

Editor-in-Chief Dr. Robert Peltier, PE

The EPA has not responded to

the concerns raised in Carlins

critique of the TSD in the three

months since it was made public.

GE Energy

I promise

David Chapin, Lead Product Manager,

Filtration Technologies

Boiler cleaning outages whether planned or not are costly and disruptive. Now you can do something

about it. The Powerwave+

impulse cleaning system helps keep your boilers working even while theyre being

cleaned. Which not only helps reduce scheduled shutdowns, it also helps eliminate unscheduled outages due

to buildup. And thats not just a promise. Its the promise of something better. Find out how Powerwave+

technology is already hard at work for your peers at ge-energy.com/powerwave.

CIRCLE 7 ON READER SERVICE CARD

www.powermag.com POWER

|

August 2009 8

GLOBAL MONITOR

GLOBAL MONI TOR GLOBAL MONI TOR GLOBAL MONI TOR GLOBAL MONI TOR GLOBAL MONI TOR GLOBAL MONI TOR GLOBAL MONI TOR GLOBAL MONI TOR GLOBAL MONI TOR GLOBAL MONI TOR GLOBAL MONI TOR GLOBAL MONI TOR GLOBAL MONI TOR GLOBAL MONI TOR GLOBAL MONI TOR GLOBAL MONI TOR GLOBAL MONI TOR GLOBAL MONI TOR GLOBAL MONI TOR GLOBAL MONI TOR

Help Build the Global

Energy Observatory

How would you like to be able to access data

on all the power plants in the world and all

of their performance metrics, analyze that

data, and map it? Those abilities are part

of the vision behind the Global Energy Ob-

servatory (GEO), an OpenModel website that

serves as a wiki for global energy data.

Like Wikipedia, this enterprise uses

wiki software that allows for the creation

and editing of interlinked web pages by

a collaborative community of users. GEO

seeks to promote an understanding, on

a global scale, of the dynamics of change

in energy systems, quantify emissions and

their impacts, and accelerate the transi-

tion to carbon-neutral, environmentally

benign energy systems while providing af-

fordable energy to all. It is attempting to

do so by using open source software tools,

including Google Earth, and encouraging

community participation. Thats where the

power generation community comes in.

GEOs databases are organized into three

categories: GEOpower for power genera-

tion, GEOresources for fuels and resources,

and GEOtransmission (under construction)

for the transmission of electricity and fu-

els. The GEOpower database can account

for coal, gas, geothermal, hydro, nuclear,

oil, solar PV, solar thermal, waste, and

wind plants of all sizes, though to date

it includes mostly utility-scale plants for

which public data are available.

The project was conceived and devel-

oped by Dr. Rajan Gupta, a fellow of Los

Alamos National Laboratory and a theoret-

ical high energy physicist with wide-rang-

ing research interests. It is sponsored by

the New Mexico Consortium and has been

built primarily by Gupta and four Univer-

sity of New Mexico electrical and computer

engineering masters students.

A Virtual World of Information

Although GEOpower contains information

on many power generation facilities around

the world, the initial data have come from

publicly available sources, so plant entries

are necessarily incomplete. The GEO web-

site explains that the project developed

scripts to scrape data available from open

credible websites and publications in dif-

ferent formats (Excel, html, KML, pdf) into

the database. Data for U.S. plants, for

example, have been imported from Energy

Information Administration and Environ-

mental Protection Agency (EPA) sources.

Gupta estimated that by the end of May,

GEOpower included 40% to 50% of global

power generation capacity.

The GEOpower home page includes links

to tools that allow you to map data, view

and edit data, add a plant, view the his-

tory of edits, download data, and analyze

data. If you map all hydro plants in India,

for example, you can click on any plant lo-

cation to see capacity, and then click into

the database for additional information.

Users must register and log in to edit

and add data, use analysis tools, and

download data so that the consortium

representatives can track and validate

changes, and work with and acknowledge

high quality users.

Because the majority of data included to

date came from official sources, they are

considered prevalidated. Gupta told POWER

that when considering data from other

sources, the system will be analogous to a

peer review system used by scientific jour-

nals: the editors and moderators in this

system would be subject area experts.

Data analysis looks as if it could be very

interesting when the database is more

fully populated. The interface includes 25

performance metrics, from gigawatt-hours

generated to NH

3

(ammonia) emitted. Cur-

rently, data are typically limited to metrics

tracked by regulatory agencies (for exam-

ple, seven years of the EPAs eGRID data for

U.S. plants).

Drilling Down into the Database

To test the database, POWER searched for

the small Valmont Station in Boulder, Colo.

(Figure 1). GEOpower shows the plant as

being owned by Public Service Co. of Colo-

rado (an Xcel Energy subsidiary), having a

design capacity of 236.9 MWe, firing bi-

tuminous coal as its primary fuel, and

using water from Boulder Creek. It also

includes the commissioned date for both

units. Performance data as of mid-June

were GWh generated; heat input; and CO

2

,

SO

x

, NO

x

, and mercury emissions. (Inter-

estingly, GEO showsas does the EPAs

original eGRID data, according to Gupta

CO

2

emissions increasing between 2000

and 2004 even though gigawatt-hours

generated dropped.)

For comparison, we looked at informa-

tion on Xcel Energys Valmont Station web-

site, which gives 229 MW as the plants

size and low-sulfur coal from western

Colorado mines and natural gas as its

fuels. Xcel also provides the following in-

formation about the plant: Unit 5 (V5)

went into service in 1964 and can burn

either coal or natural gas. The unit uses

three surrounding lakes for circulating

1. Getting a grip on global energy data. The collaborative Global Energy Observa-

tory seeks to provide easy access to data on all energy systems around the globe. To date, this

work in progress includes publicly available information on power plants in nine countries. This

screen shot shows the interface for selecting a plant whose data you want to examine and/or

edit. Source: New Mexico Consortium

Be Right

Source code: M925CD HAC-0300

Solutions for continuous power generation.

We know how hard you work to manage your water chemistry. Hach helps

you optimize your efforts for maximum uptime with the most complete

line of process and lab instruments, all backed by a team of experts.

866-450-4248 www.hach2O.com

Your formula for water analysis.

CIRCLE 21 ON READER SERVICE CARD

www.powermag.com POWER

|

August 2009 10

GLOBAL MONITOR

cooling water. Unit 6 (V6) began generat-

ing electricity in 1973. (It also includes

the interesting historical note that when

Unit 1no longer operatingwent into

service in 1924, Valmont was the largest

power station west of the Missouri River.)

Plant Manager Mark Fox confirmed that

Unit 5 burns gas when the economics of

doing so are favorable. He also resolved

the apparent discrepancy in water source

by noting that cooling water comes from

reservoirs (also called lakes) that are fed

by Boulder Creek.

Xcel notes that Valmont Station is the

companys most efficient power plant. Unit

5 has a scrubber to reduce SO

2

emissions,

low-NO

x

burners to reduce NO

x

emissions,

and a baghouse that removes particu-

late emissions from the flue gas by more

than 99%. (GEOpower includes fields for

Type of SO

x

First Control Device, Type

of NO

x

First Control Device, and Type of

Mercury Control Device, but those were

empty fields for Valmont.) The reservoirs

used for cooling water have also been

recognized as a wildlife refuge, and the

plant was chosen by Audubon Colorado as

the first important Bird Area in Boulder

County. Some of that qualitative infor-

mation would be invisible to GEOpower,

which doesnt acknowledge that Unit 5

can switch fuels. Gupta noted that GEO

allows users to correct mistakes and add

missing information.

When asked how GEOpower would ac-

count for changes in equipment (includ-

ing emissions control systems) and hours

run year-over-year as those factors affect

emissions, Gupta responded that the anal-

ysis will correlate those data. Whether we

will be able to get all the data needed is

an open research question.

We hope that GEO becomes a ready

reference for journalists and advocacy

groups that come to appreciate the value

of structured scientific information that

is available from one place, Gupta told

POWER. Our goal is not to be antagonistic

to power companies and their associated

partners but to provide a forum for a sci-

entific discussion and analysis that leads

to cheap, clean energy for all. GEO is de-

signed to highlight efforts by industry to

take innovative steps towards this.

Gupta, who clarified that GEO is still a

research project and not a finished prod-

uct also noted that the more complete

the picture is, the more information we

can infer, and this inferred information

can then become the starting point for

validation through the wiki process.

To add a new plant to the database, or

to provide additional or correct data for

your plant, register at http://openmodel

.newmexicoconsortium.org.

Revived FutureGen

Faces Renewed

Funding Obstacles

A little more than a year after the Bush

administration abruptly withdrew its sup-

port for the FutureGen project, the De-

partment of Energy has again announced

it will back the proposed Illinois gasified

coal power plant and carbon capture ini-

tiative. Though the 275-MW project may

be different in technical aspectsit will

be initially designed for 60% carbon cap-

ture, not 90%, and gasify only Illinois Ba-

sin Coal (Figure 2)it is still riddled with

many of same funding problems. Making

matters worse, it may have been revived

too late: Since the DOE withdrew its sup-

port, several major carbon capture and

storage (CCS) projects and alliances have

sprouted in the U.S., and these could give

FutureGen a run for its money.

Project costs for FutureGen now stand

at about $2.4 billion, with construction

expected to cost between $1.7 billion and

$1.9 billion. In June, the DOE pledged

$1.073 billion to the project$1 bil-

lion of which would come from American

Recovery and Reinvestment Act of 2009

funds for CCS research. But it required

under a provisional agreement with the

FutureGen Industrial Alliance that the al-

liance expand to 20 members by years

end and that each member contribute be-

tween $20 million and $30 million over

the next four to six years. Other condi-

tions included development of a com-

plete funding plan and a rapid restart

of preliminary design activities, including

completion of a site-specific design and

a detailed cost estimate.

Then, barely a week after the DOEs an-

nouncement, news broke that American

Electric Power (AEP) and Southern Co.

two of the FutureGen Alliances major

membershad abruptly withdrawn their

financial support, leaving the alliance

with only nine members, most of whom

are multinational coal companies.

AEP told POWER that its decision was

based on qualms about the projects fund-

ing. The uncertainty about FutureGen

brought by DOEs decision last year to with-

draw funding, combined with financial con-

straints brought by the current economic

downtown, led to our difficult decision to

withdraw from FutureGen, said AEP spokes-

person Pat Hemlepp, in a sentiment echoed

by Southern Co. Hemlepp added that AEP

would direct funds to other projects, par-

ticularly to its Mountaineer plant project in

West Virginia, which is expected to validate

the commercial viability of chilled ammonia

CCS technology when it begins operations

this September.

Both Southern and AEP have also said

they would focus on the newly launched

National Carbon Capture Center (NCCC),

of which the companiesalong with the

DOE, Electric Power Research Institute,

and four other industry heavyweights

are members. While supporting work from

scientists, government, industry, and aca-

demia, the NCCC has said it would facili-

tate testing and analyses in a power plant

setting, at a size large enough to provide

meaningful performance data under real

operating conditions, enabling scale-up

2. One step forward, two steps back. The DOEs conditional backing of the Future-

Gen project revived hopes for the Illinois gasified coal power plant and carbon capture initiative.

But the project is still riddled with many of its old funding problems, which poses risks that Future-

Gen Alliance members are not willing to face. Barely a week after the DOE announced renewed

support, American Electric Power and Southern Co. withdrew from the alliance. Both companies

have said they will redirect funds to other carbon capture initiatives, like the National Carbon Cap-

ture Center, of which the DOE is also member. Source: DOE; modification: Leslie Claire

August 2009

|

POWER www.powermag.com 11

GLOBAL MONITOR

of the technologies, when it is fully operational in 2010. The

center is to be located partly at the Power Systems Development

Facility (PSDF), a coal plant research complex south of Birming-

ham, Ala., that is run by the public-private consortium. Southern

Co. said existing facilities at the PSDF would be modified to test

precombustion CO

2

capture while postcombustion CO

2

capture

will be tested at Plant Gaston, a coal plant adjacent to the PSDF

that is operated by Southern Co. subsidiary Alabama Power.

Meanwhile, as the DOEs regional sequestration partnerships

make significant gains in their carbon sequestration tests, major

projects with better initial design capture capabilities than Fu-

tureGensuch as Tenaskas proposed $3.5 billion Trailblazer En-

ergy Center in Sweetwater, Texasare pushing forward. If built,

that 600-MW plant could capture 85% to 90% of CO

2

emissions

while using supercritical steam, pulverized coal technology. The

CO

2

will then be provided for use in enhanced oil recovery and

geologic storage.

How Much Coal and Gas

Does the U.S. Really Have?

The U.S. Geological Survey (USGS), a federal mapping agency,

has of late been propounding the difference between resources

and reserves. It says that although the two terms are used in-

terchangeably, the distinction is simple: Reserves are a subset of

resources. Coal resources, as an example, include those in-place

tonnage estimates determined by summing the volumes for iden-

tified and undiscovered deposits of coal, whereas coal reserves

are those resources considered economically producible at the

time of classification, even though extraction facilities are not in

place and operative.

That distinction becomes especially important in light of new

assessments from separate groups that claim coal reserves in

the U.S. have been wildly overestimated and gas reserves un-

derestimated. And it throws into question the Energy Informa-

tion Administrations (EIAs) assessments, which have long been

a yardstick for comparable estimates.

In 2007, the EIA said the U.S. had a demonstrated reserve

base of nearly 500 billion metric tons of coal, and it regarded 267

million metric tonsenough for 240 yearsof that as economi-

cally recoverable. But an extensive USGS analysis of Wyomings

Gillette coal fieldthe nations largest and most prolificre-

leased this June determined that of 182 billion metric tons of

resources in place, less than 9.16 billion (or 6%) were found to

be recoverable under current technological and economic circum-

stances. This compares with an earlier assessment from 2002 by

the USGS in which 20.87 billion metric tons were estimated to

be recoverable. The USGS engineers, geologists, and economists

explain the discrepancy is a result of using an improved method-

ology, which incorporates a new dataset with 10 times as many

data points as were used in previous assessments.

In June, meanwhile, the Potential Gas Committee (PGC), a

group of industry, government, and academic volunteers, said in

a study that U.S. natural gas reserves were likely 1,836 trillion

cubic feet. This assessment is up 39%the highest increase on

recordfrom the groups estimate of 1,321 trillion cubic feet two

years ago. New and advanced exploration, well drilling and com-

pletion technologies are allowing us increasingly better access to

domestic gas resourcesespecially unconventional gaswhich,

not all that long ago, were considered impractical or uneconomi-

cal to pursue, said John Curtis, a committee member and profes-

sor of geology at the Colorado School of Mines.

The increase has been tagged to a reevaluation of shale in

the Appalachian Basin and in the midcontinent, Gulf Coast, and

Rocky Mountain areas. When the PGCs results are combined with

the DOEs latest available determination of proven gas reserves

(238 trillion cubic feet as of 2007), the report says that the U.S.

has a total available future supply of 2,074 trillion cubic feet.

Thats an increase of 542 trillion cubic feet over the previous

evaluation. Curtis cautioned, however, that the current assess-

ment assumes neither a time schedule nor a specific market

price for the discovery and production of future gas supply.

Estimates of the Potential Gas Committee are base-line esti-

mates in that they attempt to provide a reasonable appraisal of

what we consider to be the technically recoverable gas resource

potential of the United States, he explained.

The USGS Wyoming Gillette coal field assessment is available

at http://tinyurl.com/lw7yv5; the PGCs complete report can be

purchased in August from http://www.mines.edu/.

Of Fracking, Earthquakes,

and Carbon Sequestration

Hydraulic fracturingthe process of drilling and then pumping

fluid deep into a formation to generate fractures or cracks, typi-

cally for extracting natural gas from shale formationshas been

under fire lately, owing to concerns that it contaminates drink-

ing water. But while Congress debates proposed legislation that

would impose new restrictions on the technology, an entirely dif-

ferent concern related to fracturingor frackingis emerging:

It may trigger earthquakes.

The claim is not new, but attention to it has been renewed

following a June 2 earthquake recorded at Cleburne, Texasthe

first in the towns 140-year historyand four subsequent smaller

quakes, none with a magnitude greater than 2.8. Speculators as-

CIRCLE 9 ON READER SERVICE CARD

www.powermag.com POWER

|

August 2009 12

GLOBAL MONITOR

sert that whats causing the temblors is fracking, which began

in earnest in 2001 in the Barnett Shale, a geologic formation

said to be the nations richest gas field. A geologist has yet to

confirm the claim.

At the same time, fracking-related quake concerns are mount-

ing in northern California, around The Geysers region, where

start-up company AltaRock Energy is looking to tap geothermal

energy in a demonstration of Engineered Geothermal Systems

technology. The technology essentially pumps water into the

earth, creating fractures in the hot dry rock (Figure 3). The

water then flows into the fissures, creating a reservoir of very

hot geothermal fluid that is continuously heated, and when it is

returned to the surface, the pressure decrease produces steam,

which is used to turn a turbine. That project has secured more

than $36 million from the DOE and has the backing of several

large venture capital firms.

But it has caught bad press from The New York Times, which

points out that the project proposes fracturing hard rock more

than 2 miles deep in an area overlying two fault lines. The news-

paper draws similarities between the Alta Rock demonstration

and a Swiss geothermal prospecting project in Basel, which is

believed to have triggered a massive earthquake on Dec. 8, 2006,

after prospectors drilled 3 miles into a significant fault.

Alta Rock has disputed the comparison, saying that Basel sits

on top of a large (200-km long) locked fault that previously

ruptured and heavily damaged the city in the 14th century. We

carefully chose our site to avoid Basels problems, the company

said in a statement. There has been geothermal energy produc-

tion at the Geysers since 1965. AltaRocks project is located in

a seismically active area adjacent to smaller faults (the closest

faults are 3 and 11 km long) which are not locked due the con-

stant stress relief resulting from small seismic movements.

Can Fracking Cause Earthquakes?

There is no consensus among geologists on whether drilling

causes earthquakes. But, according to Dr. David Oppenheimer, a

seismologist with the U.S. Geological Survey (USGS), the fracking

process could certainly generate seismic activity because that

is how the fractures are made, he told POWER in July. Concern-

ing the Alta Rock project, he said, After the fractures have been

established at the Geysers and an enhanced geothermal system

has been implemented where cold water introduced in the injec-

tor flows through the fractures to the second well to return to

the surface, it is possible that seismicity could be induced due to

thermal contraction of the reservoir rock.

There are also certain conditions that could trigger a large

earthquake, and foremost among them is sufficient, pre-existing

tectonic stress, conditions that exist at The Geysers because the

geothermal field is located near the Pacific-North American plate

boundary, he said. However, even in areas like Colorado, far from

a plate boundary, a magnitude 5.3 quake was induced by pump-

ing of waste fluids into a deep disposal well at the Rocky Moun-

tain Arsenal. With regard to fracking and earthquakes associated

with natural gas extraction, Oppenheimer said that the pressures

3. Cracks that run deep. Hydraulic fracturinga process that

involves drilling and then pumping fluid deep into a formation to gener-

ate fractures or crackshas been thought to cause earthquakes, most

recently in Cleburne, Texas, where fracturing, or fracking, is used to

extract natural gas from shale. But Alta Rocks geothermal demonstra-

tion plant, which uses Engineered Geothermal Systems technology

(shown here) has also come under scrutiny because the project pro-

poses fracturing hard rock more than 2 miles deep in an area overlying

two fault lines. Courtesy: Department of Energy

Production well

Engineered

fracture

system

Hot rock

Energy conversion plant

Injection

well

CIRCLE 10 ON READER SERVICE CARD

August 2009

|

POWER www.powermag.com 13

GLOBAL MONITOR

introduced by the process would have to exceed a minimum

compressive tectonic stress to encourage an earthquake. If the

hydrofracture pressures are lower, then no fractures should oc-

cur, he said.

Implications for Carbon Sequestration

The fracking-quake debate raises questions about whether geolog-

ical carbon sequestrationstoring carbon dioxide by injecting it

deep within geologic formationscould prompt quakes. Dr. Chris-

tian Klose, a geophysical hazards research scientist from Columbia

University, says it couldas much as any geological fluid injec-

tion can. He told POWER in July that three processes could trigger

seismic activity, large and small: pore fluid pressure changes; fluid

mass (volume) changes, which can cause stress on the rock; and

migration of the CO

2

through the rock over decades to centuries.

CO

2

is buoyant since its density is [lower] than saline water deep

in the crust, he said. Thus it will come upward through cracks

and fractures and faultseven in so-called cap rocks are rock

discontinuities that cause leakages.

Klose said that the quake risk is intensified by hydrofracturing,

a process that is recommended by the DOEs Midwest Regional

Carbon Sequestration Partnership to provide a better injection

rate into rocks that have moderate porosity and low effective

permeability. The recommendation comes as one of several les-

sons learned from a sequestration field test at FirstEnergys R.E.

Burger Plant near Shadyside, Ohio, in the Appalachian Basin.

But, according to Traci Rodosta, a geological sequestration

project manager for the National Energy Technology Laboratory,

quake risk is well-assessed during research and development of

any given project. Potential sequestration reservoirs are thor-

oughly characterized prior injection, she told POWER. In order

to eliminate and reduce the potential for fault activation and

slippage along preexisting fractures that could be caused when

injecting fluids at high pressures, regulatory agencies limit in-

jection rates and pressure to avoid unintentional hydrofractur-

ing. CO

2

storage projects would operate under similar guidelines,

and the risk managed through site characterization, injection

design, and monitoring.

Floating and Flying Wind Turbines

After months of preparation, Norways StatoilHydro and Germa-

nys Siemens in June erected the worlds first large-scale floating

deepwater wind turbine some 7 miles offshore Karmy, southeast

Norway, on the 720-feet-deep waters of the Amoy Fjord. The de-

velopers are now gearing up to connect the Hywind turbine to

the local grid, and it could begin producing power as early as

mid-July.

Siemens provided the SWT2.3-MW wind turbine, which has a

rotor diameter of about 270 feet and a nacelle that towers 213

feet above the waves (Figure 4). The company said that the Hy-

wind was designed to be suitable for installation in water depths

of between 390 feet and 2,300 feet, opening up new possibili-

ties for offshore wind technologies. Currently relying on turbines

mounted firmly on the seabed, offshore wind turbines are limited

to shallow waters because it is costly to install foundations at

water depths of more than 100 feet to 165 feet.

The wind turbine sits atop a Spar-buoy, which is based

on the design of oil production platforms and offshore loading

buoys. The steel floaterwhich extends more than 330 feet be-

neath the surfaceis filled with ballast and fastened to the sea-

bed by three anchor wires. The control system for the turbine, a

joint development between StatoilHydro and Siemens, addresses

operating conditions of a floating structure, allowing it, for in-

stance, to dampen out part of the wave-induced motions of the

floating system.

Offshore wind development has taken off around the world

especially in Europe, where Denmark and the UK have taken the

reins, installing a combined nameplate capacity of 1,103 MW.

Including the Hywind in Norway, offshore projects have also been

installed by Belgium, Sweden, Finland, Germany, the Netherlands,

and Ireland. France, Italy, Poland, and Spain, meanwhile, have

plans to complete installations by 2015.

The U.S.the country that leads the world in land-based in-

stalled wind capacity, with 28,200 MW (as of April 2009)has

yet to build its first offshore wind farm, though a number of

projects are moving through the development process. Earlier

this year, the industry received a boost when the Department

of the Interior (DOI) and Federal Energy Regulatory Commission

agreed to end a long-standing turf war that had hampered per-

mitting and stalled renewable energy projects in offshore waters.

This June, for the first time ever, the DOI issued five exploratory

leases for wind energy development on the Outer Continental

Shelf offshore New Jersey and Delaware. The leases will allow

companies to construct weather towers 6 to 18 miles offshore to

collect data on wind speed, intensity, and direction.

As some companies test new ways to make deepwater offshore

wind power viable, several others are looking to pilot wind tech-

nologies that harness jet streams so high in the sky that cruising

airliners would have to steer around them. According to Stanford

environmental and climate scientists Cristina Archer and Ken Calde-

ira, winds in these high-altitude jet streams hold roughly 100 times

more energy than all the electricity being consumed on Earth.

If you tapped into 1% of the power in high-altitude winds,

that would be enough to continuously power all civilization, Cal-

deira said. In comparison, similar solar cells would cover roughly

100 times more area than a high-altitude wind turbine, he said.

The researchers findings, published in the May issue of the

journal Energies, were reached from analysis of 27 years of data

from the National Center for Environmental Prediction and the

European Centre for Medium-Range Weather Forecasts. By study-

ing the distribution of wind power in the atmosphere, by location

and time, they found that winds at altitudes around 32,000 feet

have the highest wind power density. Some regionslike Tokyo

4. Floating an idea. Siemens and Statoil Hydro in June erected

the worlds first large-scale floating deepwater wind turbine 7 miles

offshore Karmy, southeast Norway, in waters that are 720 feet deep.

The Siemens SWT2.3-MW turbine has a rotor diameter of about 270

feet and a nacelle that towers 213 feet above the waves. To keep it

afloat, the Hywind turbine sits atop a buoybased on the design of

oil production platforms and offshore loading buoysthat has been

anchored to the seabed by three wires. The project could be connected

to the local grid as early as mid-July. Courtesy: Siemens

www.powermag.com POWER

|

August 2009 14

GLOBAL MONITOR

and Seoul, which are affected by the East Asian jet streamhad

a higher power density. On the other hand, Mexico City and So

Paolo, which are located at tropical latitudes, are rarely affected

by polar and subtropical jet streams and therefore have lower

wind power densities.

Archer and Caldera claim that tethered wind-turbine kites are

the most cost-competitive technologies to harness the energy

from jet streamsthough these still have not overcome the chal-

lenge of fluctuating wind, they note. While the winds at high

altitude are much more consistent than the winds at the surface,

theyre still not consistent enough, Caldeira said. Other hurdles

include airliner interference, storage issues, and cost.

Even so, the scientists point to several designs with potential,

such as Sky WindPowers model, a single tethered kite of four

connected turbines, each with spinning rotors (Figure 5). That

kite transfers electricity back to a hub on the ground through

its tether.

Other models include the Kite Gen, an Italian project, which

looks like an inverted carousel that pilots a kite or an array of

kites over a predefined flight path. The kite is maneuvered by dif-

ferentially unrolling and recovering the two lines on two winches

controlled by engines. New Yorkbased Magenn Power takes a

different approach with its Magenn Air Rotor System (MARS),

floating a helium balloonlike turbine that rotates around a hori-

zontal axis in response to winds at altitudes between 600 feet

and 1,000 feet. Rotation of the MARS device is kept stable by

the Magnus effect, which provides additional lift and keeps the

MARS stabilized.

Major Scottish Coal Plant

Starts CCS Pilot Program

Energy provider ScottishPower on May 29 flicked on the switch

of a carbon capture and storage (CCS) pilot program at its 2,304-

MW coal-fired Longannet power plant, in Fife, Scotland, marking

the beginning of a seven-month testand the first time a UK

coal-fired power plant has reportedly attempted to capture its

carbon emissions.

The prototype, developed by Norwegian firm Aker Clean Car-

bon, is an exact, 1-MW replica of the full-scale carbon capture

plant (Figure 6). It will use Aker Clean Carbons postcombus-

tion capture process, which employs an amine solvent to remove

carbon dioxide from flue gas. If successful, ScottishPower could

use the technology to scale up the prototype and deliver a full

National Steel Erection, Inc.

NSE is a Full-Service Mechanical

Contractor devoted to providing Quality

Fabrication and Erection Services to the

Power & Heavy Industrial Markets!

1115 Industrial Drive

Owensboro, KY 42301

Ph (270) 926-2534

Fax (270) 683-1960

Info@NationalSteelErection.com

NSE

Qual i t y, Safet y & Pr i de. . .

Throughout t he U. S. A.

5. Taking to the sky. A study by Stanford researchers concludes

that sky-high winds at altitudes around 32,000 feet have the highest

wind power density, and that tapping just 1% of the power of these

winds would be enough to power all civilization. Several prototypes

of turbines that seek to harness the energy in high-altitude winds have

been proposed. An example is Sky WindPowers model, a single teth-

ered kite of four connected turbines, each with spinning rotors. Cour-

tesy: Ben Shepard, Sky WindPower

6. A carbon footprint. ScottishPower in May switched on the

UKs first reported 1-MW prototype of a full-scale carbon capture plant

at its 40-year-old Longannet coal-fired power station in Fife, Scotland.

The prototype employs Norwegian firm Aker Clean Carbons postcom-

bustion amine solvent process. If ScottishPower wins a government

carbon capture and storage competition, it could receive 1 billion to

fund the project and deliver a full demonstration project by 2014. Cour-

tesy: ScottishPower

CIRCLE 11 ON READER SERVICE CARD

August 2009

|

POWER www.powermag.com 15

GLOBAL MONITOR

CCS demonstration project by 2014a ti-

mescale that aligns perfectly with the UK

governments plans.

But ScottishPower has yet to gain the

UK governments backing for the project.

The company is in competition with two

other contendersE.ON and Peel Power

in a government contest, whose winner

would secure 1 billion in funding for a

postcombustion technology that captures

90% of emitted greenhouse gases at a

300-MW to 400-MW coal-fired unit. E.ON

in June opted for Mitsubishi Heavy Indus-

tries KM-CDR process, which uses a pro-

prietary solvent (KS-1) for CO

2

absorption

and desorption.

If E.ON wins, it said it would use that

technology to build a capture plant at its

proposedand highly controversial1-

,600-MW supercritical pressure coal plant

proposed for the Kingsnorth Station in

Kent. Peel Power, meanwhile, has joined

forces with Denmarks DONG Energy and

Germanys RWE to build a facilitythough

its scope has not been described yet. The

government is expected to announce the

winner this summer.

Akers prototype at Longannet weighs

30 metric tons, covers an area of 85 square

meters (m), and is said to process 1,000

m

3

of exhaust gases per hour. The two

companies will now test the technology

to determine how much heat is required

to break the bond between CO

2

and the

amine, and how long the capture chemical

can keep capturing CO

2

effectively. They

also plan to test three different amine so-

lutions over seven months.

Aker, whose technology is also in use

at the Mongstad project in Norway, said

in a release in May that early results from

tests at a gas power plant show a capture

rate above 85%, and that the amines had

successfully demonstrated lower energy

requirements and less degradation.

European Interest

in Saharan Solar Project

Heats Up

Plans to install a series of solar panel

farms in the Sahara Desert to power Eu-

rope and North Africa are heating up.

The idea was discussed in May as part of

the newly formed Mediterranean Union,

launched at a summit in Paris, and it now

has the backing of both UK Prime Minister

Gordon Brown and French President Nico-

las Sarcozy.

More recently, Germanys Wuppertal In-

stitute for Climate, Environment and En-

ergy and the Club of Rome issued a study

that said the project could generate some

2 trillion worth of power through 2050.

And this July it received yet another ma-

jor boost, with 12 companies congregat-

ing at the request of German insurance

firm Munich Re and formally agreeing to

analyze and develop a multidimensional

framework for the 400 billion project.

The Desertec Industrial Initiative, as the

12-company coalition is now called, in-

cludes European giants Deutsche Bank,

Siemens, ABB, and utilities E.ON, RWE,

and Abengoa Solar.

At the heart of the ambitious Desertec

project is the goal to establish 6,500

square miles of concentrated solar pow-

er plants in the vast African and Middle

Eastern deserts, along with a super-grid

of high-voltage transmission lines, to sup-

ply countries in Europe and Africa with

electricity. The project could supply conti-

nental Europe with up to 15% of its total

energy needsproducing a stunning 20

GW of power by 2020, as Guenter Gloser,

Germanys deputy foreign minister, told

Reuters in June. The first possible power

station would be a 2-GW solar thermal

power station in Tunisia with power lines

to Italy, a project that would take five

years to build.

According to the Desertec Foundation,

satellite studies conducted by the Ger-

man Aerospace Center show that by using

less than 0.3% of the entire desert of the

Middle East/North Africa region, enough

electricity and desalinated seawater can

be produced to meet the growing needs

of these countries and of Europe (Figure

7). The German Aerospace Center also

assumes that in 10 to 15 years, electric-

ity from solar power plants will be able

to compete with medium-load electricity

from fossil power plants

But not everyone is convinced that the

project is feasible. Vattenfall prefers not

to support the undertaking, because it

costs too much money and transmission

costs are too high, as the Swedish state-

owned utilitys CEO Lars Josefsson told the

Financial Times in June. I dont think its

realistic, he said, adding that securing

Europes future energy needs should be

focused on developing carbon capture and

storage technology for coal-fired power

plants.

Even Munich Rewhich spurred a me-

dia frenzy about the project by publicly

inviting Europes energy giants to discuss

the projectrecognizes the cost obstacle.

The insurer said recently in a statement

that, despite the use of known technolo-

gies, implementation of such a visionary

concept will require substantial initial

financing. Therefore, DESERTEC can prob-

ably only be put into practice if suitable

incentivisation mechanisms are in place

to make such investments worthwhile for

investors.

Other critics have expressed concerns

about becoming energy dependent on po-

7. Built on sand. Several European countries are backing an ambitious project that seeks

to establish 6,500 square miles of concentrated solar power plants and a super-grid of high-

voltage transmission lines in the vast deserts of North Africa and in the Middle East, saying that

they could power 15% of Europes energy needs by 2050. The project got a major boost this

July, when 12 major European companies agreed to study and devleop the 400 billion project.

Courtesy: Desertec Foundation

www.powermag.com POWER

|

August 2009 16

GLOBAL MONITOR

litically unstable North African countries

in the Sahara and about the concept of

centralized transmission lines, which could

be vulnerable to terrorist attacks. Project

proponents counter by saying that the EU

already imports energy from regions and

sources that are not risk free.

Turning Sewage Sludge

into Renewable Energy

News has been emerging from around the

world about several projects that seek to

turn human sewagearguably the dirtiest

of manmade wastesinto clean energy.

This June, Atlanta start-up EnerTech

Environmental unveiled the first U.S.

commercial biosolids-to-energy facility in

Rialto, Calif. (Figure 8). The $160 million

facility employs SlurryCarb technology, us-

ing heat and pressure to transform sewage

sludge80% of which is waterfrom five

Southern California municipalities into

fuel pellets to be burned at local cement

kilns. Currently, the plant operates at 60%

capacity. At full capacity, it will be able to

process 270,000 wet tons of biosolids.

The so-called E-fuel is 95% solid and

interchangeable with coal, the company

said. SlurryCarb can also treat animal

manure, lumber and paper wastes, and

agricultural wastes. The technology was

developed from demonstration plants pro-

cessing municipal solid waste in Ube City,

Japan, and a demonstration plant in At-

lanta, which can process 1.6 tons of sludge

per day. The company is now looking at

building a similar plant in New York, but

it expects thatespecially because some

7 million tons of biosolids are produced in

the U.S. each yearmunicipalities across

the nation will show interest in the renew-

able fuel.

Across the pond in the UK, mean-

while, United Utilities teamed up with

grid operator National Grid to produce

biogas from wastewater sludge at one

of the UKs largest wastewater treatment

plants at Davyhulme in Manchester, using

anaerobic digestion. The biogas is then

upgraded to biomethane, compressed,

and injected into the local gas pipe-

line network or used as fuel for a fleet

of sludge tankers. The 4.3 million pilot

plantwhich United Utilities describes

as a poo power projecthas been in

development for some time, but it only

recently received funding from the coun-

trys environment department. The plant

should be operational by 2011.

Few Manchester residents are raising a

stink about the governments determina-

tion to put its money in the toilet, be-

cause the pilot project has been touted

as a renewable project that will help the

country meets its target of 15% renewables

by 2020. United Utilities also stresses that

sewage treatment is a 24-hour process

that provides an endless supply of biogas.

National Grid, too, is confident that there

should be no fundamental technical dif-

ficulties in injecting biomethane into the

gas distribution network. Several plants in

Europe have already demonstrated it can

be done, it said.

POWER Digest

News items of interest to power industry

professionals.

Worley Parsons to Consult with Gov-

ernments for New Nukes in Egypt, Ar-

menia. WorleyParsons said on June 19

that it had signed separate contracts to

provide consultancy services to the Egyp-

tian Nuclear Power Plant Authority and

the Ministry of Energy and Natural Re-

sources of the Republic of Armenia for

new nuclear projects in those countries.

The companys EGP 900 million (US$160

million) contract with the Egyptian gov-

ernment includes site and technology

selection studies for that countrys first

nuclear power plant, as well as design,

construction management, commission-

ing, and start-up. Execution of the eight-

year project will be carried out from the

companys office in Sofia, Bulgaria, and

supported locally in Cairo.

The scope of the $430 million contract

signed with the Armenian government will

be implemented in four phases, with the

first two phases scheduled to begin in

2009. The major work during the first two

phases includes development of a feasibil-

ity study and then managing and assessing

the tender process for strategic project in-

vestors. The duration of these two phases

is expected to be one year. Phases three

and four require the company to organize

and manage a tender, eventually recom-

mend EPC contractors for selection, and

then provide consulting services to the

ministry during the design, construction,

and project start-up. This contract will

also be managed by WorleyParsons Sofia

office.

ABB Wins Order to Power Algerian

Seawater Desalination Plant. Power

and automation group ABB on June 22

announced it had won a $28 million

contract from environmental solutions

company Hyflux for a turnkey electri-

cal solution to power the worlds larg-

est membrane-based reverse osmosis

seawater desalination plant. The Magtaa

desalination plant is being constructed

in the western Oran region of Algeria. It

will have a designed capacity of 500,000

cubic meters per day of drinking water to

serve about 5 million people. The project

is part of the Algerian governments ef-

fort to provide clean drinking water to its

growing population.

As part of the contract, ABB will set up

a 220-kV outdoor substation to provide

power to the facility and also supply prod-

ucts such as power transformers, medium-

voltage drives and a range of medium- and

low-voltage switchgear. ABB will be re-

8. Greenif not cleanenergy. Atlanta start-up EnerTech Environmental this June

unveiled the first U.S. commercial biosolids-to-energy facility in Rialto, Calif. The facility turns

sewage sludge80% of which is waterfrom five Southern California municipalities into fuel

pellets that will be burned in local cement kilns. The so-called E-fuel is 95% solid and inter-

changeable with coal, the company said. Courtesy: EnerTech Environmental

August 2009

|

POWER www.powermag.com 17

GLOBAL MONITOR

sponsible for the design, engineering,

supply, installation, and commissioning of

the electrical plant system. The project is

scheduled for completion by 2011.

AREVA T&D Inaugurates GI Substa-

tion Factories in China. AREVA Trans-

mission and Distribution (T&D) and

Chinese partners on June 18 inaugurated

two factories in Wuxi and Yangzhou, in

Jiangsu province, that will manufacture

key components for gas-insulated (GI)

substations in China and throughout the

world. The Wuxi Alumin Casting Plant

is a joint venture between AREVA and

Wuxi Alumin Casting, and the AREVA

T&D (Yangzhou) High Voltage Bus-ducts

Plant is a joint venture between AREVA

and Jiangsu Jinxin Electric Appliance.

The products of both factories will be

used in AREVA T&Ds production plants

and substations in China and throughout

the world.

The investments, which total some 30

million, follow similar ventures by the

company in Suzhou and Xiamen. Those

factories manufacture complete GI sub-

stations (GIS) up to 550 kV. Since 1988,

when AREVA installed the first GIS in

China, it has installed more than 1,500

GIS and inaugurated seven GIS manufac-

turing sites worldwide.

Chilean Supreme Court Revokes Per-

mit for AES-Proposed Coal Plant. The Su-

preme Court of Chile on June 22 upheld a

ruling by a lower court and invalidated an

environmental permit granted by Chilean

regulatory authorities for the Campiche

thermal power plant, a 270-MW coal plant

located in Ventanas, Chile. Virginia-based

AES Corp. indirectly owns a 71% interest

in Campiche through its subsidiary AES

Gener, the second-largest generator of

electricity in Chile.

The Supreme Court upheld the Valparaiso

Appeals Court ruling that the environment

commission for the region had awarded

the permit erroneously in May 2008, as the

land where the plant was to be built had

been designated for conservation. As a re-

sult of the Supreme Courts ruling against

the local permitting authority, Gener

stopped work on Campiche, which was pre-

viously expected to commence commercial

operations in the second quarter of 2011.

The company said that construction on the

project would resume when a solution has

been implemented that complies with all

applicable laws.

GE to Provide Equipment, Services

for Bahrains Largest Power Plant. GE

Energy on June 11 signed contracts to-

taling more than $500 million to supply

two steam turbines and four heavy-duty

Frame 9FA gas turbines for the proposed

1,250-MW Al Dur Independent Water and

Power Projectthe largest power plant

in the Kingdom of Bahrain. The plant is

expected to support the countrys report-

ed power demand growth rate of 7% to

10% per year. GE also signed a 20-year

contractual service agreement contract

for the project, which will support the

long-term operability and performance of

the turbines.

By Sonal Patel, senior writer,

and Gail Reitenbach, managing editor.

Correction

The June editorial (Gone with the

Wind, p. 6) incorrectly quoted an es-

timate of the installed cost for offshore

wind turbines. The estimate is actually

$5,000/kW.

POWER regrets the error.

CIRCLE 12 ON READER SERVICE CARD

www.powermag.com POWER

|

August 2009 18

FOCUS ON O&M FOCUS ON O&M FOCUS ON O&M FOCUS ON O&M FOCUS ON O&M FOCUS ON O&M FOCUS ON O&M FOCUS ON O&M FOCUS ON O&M FOCUS ON O&M FOCUS ON O&M FOCUS ON O&M FOCUS ON O&M FOCUS ON O&M FOCUS ON O&M FOCUS ON O&M FOCUS ON O&M FOCUS ON O&M FOCUS ON O&M FOCUS ON O&M FOCUS ON O&M FOCUS ON O&M FOCUS ON O&M

FOCUS ON O&M

STEAM TURBINES

Managing Minimum Load

Reducing the minimum load at which a steam turbine can reli-

ably operate is one way to increase revenue for marginal base-

loaded units during periods of low electrical demand. For this

reason, it is not unusual to see merchant plants operating at

super minimum load levels that are well below the typical

25% rated full-load limits. However, such units are operating

well outside the original equipment manufacturer (OEM) design

basis, and owners may experience undesirable damage to their

turbines for a number of reasons. Thats why it is important for

owners to understand the trade-offs and risks that come with

such operation.

The following is an overview of the main steam turbine and

generator issues that must be considered before deciding to

operate a steam turbine generator below OEM minimum load

limits.

Anticipate Increased

HP-IP Rotor Vibration

Units with partial arc admission, where the lower arc valves

open first, are more susceptible to increased vibration at re-

duced minimum loads. This is due to unbalanced upward steam

pressure forces that tend to lift the rotor and partially unload

the high-pressure/intermediate-pressure (HP-IP) bearings.

Older units employing plain journal bearings may experience

oil whip and related vibration at reduced bearing loads. Assum-

ing that proper supervisory instrumentation exists, a load test

can determine if this is a concern. The operator can perform a

load test and perform bearing adjustments at the next outage

to determine if minimum load can be reliably reduced. Proper

bearing clearances and preloads may be sufficient to eliminate

this concern.

If adjustments to the bearings alone do not address oil whip

concerns, the operator has two options: change the admission

sequence such that the cover valves open first and convert to

full arc admission, or retrofit the unit with tilt-pad bearings.

A tilt pad retrofit to maintain stability and acceptable bearing

vibration level is often the best option.

Modern units usually already employ tilt pad bearings. How-

ever, even with tilt pads, maintaining correct clearances and

preloads is important to ensure sufficient damping. Adding tilt

pad bearing preloads (Figure 1) normally addresses damping and

subsynchronous stability concerns.

Expect Higher Nozzle and Valve Erosion Rates

At super minimum loads, particles exfoliating from the boil-

er are throttled at much higher velocities through the inlet

2. Nozzle block erosion. Minute solid material that is thrown

off from the boiler is accelerated through the steam turbine nozzle

valves and can increase erosion. The nozzle valves accelerate the

steam much as a garden hose nozzle accelerates the velocity of wa-

ter. This increased velocity increases the erosion on the valves and

nozzle block. Courtesy: TG Advisers Inc.

3. Nozzle block weld repairs. The HP nozzle block vanes

may also experience increased particle erosion but can, under most