Separator Sizing

Diunggah oleh

HusenburgDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Separator Sizing

Diunggah oleh

HusenburgHak Cipta:

Format Tersedia

SEPARATOR

SIZING

Theory and Calculation

SEPARATION THEORY

Gas/Liquid Separation Theory

Liquid droplet settling

Liquid drops separated from gas phase when its

velocity reach terminal (settling) velocity

Terminal velocity when Drag Force = Buoyant Force

Drag Force depends on Drag Coefficient

Re < 10

Re > 1000

D

C

Re

24

=

D

C

34 . 0

Re

3

Re

24

2 / 1

+ + =

D

C

Cont.

Terminal velocity equations for different conditions

Re < 10

Re > 1000

The value of is estimated and then used in the

calculation of gas capacity constraint

( )

u

2

6

. . 10 78 . 1

m

t

d G S

V

A

=

2 / 1

0199 . 0

|

|

.

|

\

|

=

D

m

g

g l

t

C

d

V

p

p p

D

C

Cont.

But in production facility, flow almost always has Re >

1000. So how to find ?

Start with Re >>1000 so that ~ 0.34

Use = 0.34 to calculate

Use to calculate Re

Use Re to calculate new

Repeat process until values beginning to be the same

Use this latest value in the gas capacity equation

D

C

D

C

D

C

D

C

D

C

t

V

D

C

t

V

Cont.

Liquid retention time

Retention time is average time a liquid molecule is

retained in vessel

To ensure liquid and gas reach equilibrium so that

gas molecule can evolve from liquid phase

Retention time = Volume of liquid storage in vessel

Liquid flow rate

Usually 1 to 3 minutes

Oil/Water Separation Theory

Oil drop/water drop settling

Flow around oil drops in water or water drops in oil is

laminar so water droplets fall at their terminal velocity

Oil/water retention time

Need certain amount of oil storage so that oil reaches

equilibrium, entrained gas liberated, and free water

coalesced to fall into water storage

Need certain amount of water storage for entrained large

droplets of oil have time to coalesce and rise to oil-water

interface

Retention time 3 30 minutes

SEPARATOR SIZING:

TWO-PHASE SEPARATOR

General sizing procedure

CALCULATE

1. Gas capacity constraint

Minimum vessel diameter OR Relationship between diameter

and effective length that satisfy gas capacity constraint

2. Liquid capacity

Relationship between diameter and effective length OR height

that satisfy liquid capacity constraint

3. Seam-to-seam length, L

ss

For Gas capacity and Liquid capacity

4. Slenderness ratio

For each L

ss

calculated

SELECT reasonable vessel size (diameter and length)!

VERTICAL SEPARATOR

Liquid capacity

Seam-to-seam Length L

ss

Diameter d

Height h

Liquid Outlet

Inlet

Gas capacity

Mist extractor

Gas outlet

Vertical separator sizing procedure

1. Determine C

D

using iterative procedure

2. Calculate d for gas capacity constraint using

3. Calculate d

2

h for liquid capacity constraint

2 / 1

2

5040

|

|

.

|

\

|

=

m

D

g l

g g

d

C

P

TZQ

d

p p

p

12 . 0

2

l r

Q t

h d =

Cont. vertical

4. Set retention time t

r

to be 1, 2 and 3 minutes

(usual case)

5. For each t

r

, calculate and tabulate values of

a) d

b) h

c) L

ss

OD < 36

OD > 36

d) Slenderness Ratio (SR), (12)L

ss

/d

12

76 +

=

h

Lss

12

40 min+ +

=

d h

Lss

Cont. vertical

From table, select possible choices of separator size

(d x L

ss

) based on the values of (12)L

ss

/d

Select (12)L

ss

/d values range 3 4

d values must be greater than the calculated minimum

vessel diameter for gas capacity constraint (Step 2)

Your final selection should be based on your

judgment on the costs of each possible separator

Example of separator selection

Possible size

36 x 10

30 x 10

30 x 10 or

30 x 8

HORIZONTAL SEPARATOR

Liquid capacity (50%)

Gas capacity (50%)

Seam-to-seam Length L

ss

Effective Length L

eff

Inlet

Liquid Outlet

Gas molecule flowing at average gas velocity, V

g

Liquid droplet dropping at settling velocity V

t

relative to gas phase

Gas-oil interface

Diameter d

Gas outlet

Horizontal separator sizing procedure

1. Determine C

D

using iterative procedure

2. Calculate dL

eff

for gas capacity constraint

3. Calculate d

2

L

eff

for liquid capacity constraint

7 . 0

2

l r

eff

Q t

L d =

2 / 1

P

420

|

|

.

|

\

|

m

d

C

TZQ

dL

D

g g

eff

g l

p p

p

Cont. horizontal

4. Set retention time t

r

to be 1, 2 and/or 3 minutes

(usual case)

5. For each t

r

, calculate and tabulate values of

a) d

b) L

eff

for

Gas capacity from equation Step 2

Liquid capacity from equation Step 3

Cont. horizontal

c) L

ss

for

Gas Capacity

Liquid capacity

d) Slenderness ratio (SR), (12)L

ss

/d

12

d

L L

eff ss

+ =

eff ss

L L

3

4

=

Cont. horizontal

From table, compare the values of L

eff

for each gas

and liquid capacity that governs the design of the

separator

The one with larger required length governs

Then, select possible choices of separator size

(d x L

ss

) based on the values of SR

Select SR values range 3 5

L

ss

values selected are the one that governs the design

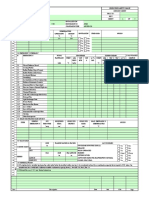

Example of separator selection

t

r

d Gas L

eff

Liquid

L

eff

Gas L

ss

Liquid

L

ss

SR

16 2.5 33.5 44.7 33.5

20 2 21.4 28.5 17.1

24 1.7 14.9 19.9 9.9

3 30 1.3 9.5 12.7 5.1

36 1.1 6.6 9.1 3

42 0.9 4.9 7.4 2.1

48 0.8 3.7 6.2 1.6

Horizontal Separator Example

Diameter vs. Length

Liquid capacity constraint governs since it has the largest required length

Use the liquid Lss values

to select separator size

Possible size

36 X 10

Thats basically it.

Anda mungkin juga menyukai

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentDari EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentBelum ada peringkat

- Separator Sizing - PPTDokumen21 halamanSeparator Sizing - PPTD K SBelum ada peringkat

- Two Phase Vertical Separator SizingDokumen4 halamanTwo Phase Vertical Separator Sizingkamal100% (2)

- Separation Processes Separator Sizing I: Nazir Mafakheri Petroleum EngineeringDokumen42 halamanSeparation Processes Separator Sizing I: Nazir Mafakheri Petroleum EngineeringHemenMoBelum ada peringkat

- Vertical Separator SizingDokumen8 halamanVertical Separator SizingAnonymous yLPPdPwBelum ada peringkat

- Process Design: Vessel Sizing (Liquid & Vapour Separators)Dokumen36 halamanProcess Design: Vessel Sizing (Liquid & Vapour Separators)Krishanu SahaBelum ada peringkat

- Horizontal Three Phase Separator DesignDokumen5 halamanHorizontal Three Phase Separator DesignAymen KhlifiBelum ada peringkat

- Liquid-Vapor Separation Efficiency (Envp0102)Dokumen24 halamanLiquid-Vapor Separation Efficiency (Envp0102)jbl_Belum ada peringkat

- Guide For Vessel Sizing PDFDokumen24 halamanGuide For Vessel Sizing PDFManish542Belum ada peringkat

- Gas Liquid Separators Bothamley JM CampbellDokumen9 halamanGas Liquid Separators Bothamley JM CampbellLTORRESMBelum ada peringkat

- Separator (1) Sizing Spread SheetsDokumen21 halamanSeparator (1) Sizing Spread SheetsSteve WanBelum ada peringkat

- Slug Catcher Sizing SpreadsheetDokumen14 halamanSlug Catcher Sizing Spreadsheettoño16Belum ada peringkat

- Datasheet For PACE Mist Eliminator/s (Demister) : Existing DetailsDokumen1 halamanDatasheet For PACE Mist Eliminator/s (Demister) : Existing DetailsAnonymous LLLK3pq50% (2)

- Vessel Sizing For Hysys SimulationDokumen1 halamanVessel Sizing For Hysys SimulationSaravanan Ilango100% (1)

- Oil and Gas Production Surface Facility Design SoftwareDokumen7 halamanOil and Gas Production Surface Facility Design SoftwareLeonardo Chávez0% (2)

- Line Sizing Using ASPEN HYSYSDokumen4 halamanLine Sizing Using ASPEN HYSYSRandomBelum ada peringkat

- DESIGN SEPARATOR 3 FASADokumen14 halamanDESIGN SEPARATOR 3 FASAAndhy Arya EkaputraBelum ada peringkat

- Specifying SeparatorsDokumen33 halamanSpecifying Separatorsdinesh_hsenid100% (1)

- GasLiquid Separators-Design RulesDokumen21 halamanGasLiquid Separators-Design Ruleswahyuriansyah100% (1)

- Design Low-Temp Separator LPG Jubilee Oil FieldDokumen38 halamanDesign Low-Temp Separator LPG Jubilee Oil FieldDela Quarme100% (1)

- Volume and Wetted Area of Partially Filled Horizontal VesselsDokumen11 halamanVolume and Wetted Area of Partially Filled Horizontal VesselsMelvin MagbanuaBelum ada peringkat

- Optimizing Gas/Liquid Separator PerformanceDokumen14 halamanOptimizing Gas/Liquid Separator PerformanceWendellReeceFrankBelum ada peringkat

- 2-TWO Phase Separator Design Guide by Manish ShahDokumen62 halaman2-TWO Phase Separator Design Guide by Manish Shahdennis_ugarteBelum ada peringkat

- Indus - PGD Process Design EngineeringDokumen2 halamanIndus - PGD Process Design EngineeringAmarjeet SandhuBelum ada peringkat

- Validation Report On The 2-Phase Line SizingDokumen18 halamanValidation Report On The 2-Phase Line SizingEbby Onyekwe100% (1)

- PipesysDokumen188 halamanPipesysKrisTian EdogawaBelum ada peringkat

- GAS PROPERTIES CALCULATION SHEETDokumen56 halamanGAS PROPERTIES CALCULATION SHEETOlumuyiwa FasehunBelum ada peringkat

- Design of Separators CourseDokumen24 halamanDesign of Separators CoursePriyanka Panigrahi100% (1)

- Sizing Sheet for 2-phase separator as per API 12J standardsDokumen5 halamanSizing Sheet for 2-phase separator as per API 12J standardsWickyBelum ada peringkat

- Flash CalculationDokumen24 halamanFlash Calculationproabbey100% (1)

- Novel Method Gas Separation-PresentationDokumen43 halamanNovel Method Gas Separation-PresentationelelefanterozadoBelum ada peringkat

- Natural Gas Processing Separator TechniquesDokumen37 halamanNatural Gas Processing Separator TechniquestahaBelum ada peringkat

- Separator SizingDokumen16 halamanSeparator SizingMichael J. BaneBelum ada peringkat

- KG Tower Loadings V1.1Dokumen13 halamanKG Tower Loadings V1.1Lee Koon PengBelum ada peringkat

- Thermosyphon Reboiler (Horizontal) GPSADokumen6 halamanThermosyphon Reboiler (Horizontal) GPSAsyamsudin2006Belum ada peringkat

- E3 Field Development Production Separator DesignDokumen5 halamanE3 Field Development Production Separator DesignhaiderBelum ada peringkat

- Tube Side Velocity CalculationDokumen20 halamanTube Side Velocity CalculationNitin KurupBelum ada peringkat

- Gas Coalescer SizingDokumen6 halamanGas Coalescer SizingAde IskandarBelum ada peringkat

- Filter Separator English LetterDokumen2 halamanFilter Separator English Lettermarcoo8Belum ada peringkat

- Line Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Dokumen12 halamanLine Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Engr TheyjiBelum ada peringkat

- Liquid - Gas Phase SizingDokumen12 halamanLiquid - Gas Phase Sizingeke23Belum ada peringkat

- Good BT PDF - Three-Phase-Separator-Sizing-Double-Weir-2 PDFDokumen3 halamanGood BT PDF - Three-Phase-Separator-Sizing-Double-Weir-2 PDFD K SBelum ada peringkat

- Packed Column DesignDokumen6 halamanPacked Column Designyamen-691904Belum ada peringkat

- Real Separator GuideDokumen23 halamanReal Separator GuideMuhammad Athar100% (6)

- Horizontal Separator Adequacy CheckDokumen4 halamanHorizontal Separator Adequacy CheckTech ManagerBelum ada peringkat

- Flow and Pressure Drop in Valves and Fittings. Valve Resistance Coefficient and DiameterDokumen21 halamanFlow and Pressure Drop in Valves and Fittings. Valve Resistance Coefficient and Diameterjroman33Belum ada peringkat

- Separator SizingDokumen3 halamanSeparator SizingMaryJane Ayisha Sado-ObahBelum ada peringkat

- Two-Phase Flow (Gas-Flow) Line SizingDokumen24 halamanTwo-Phase Flow (Gas-Flow) Line SizingvictorvikramBelum ada peringkat

- Vertical SeparatorDokumen38 halamanVertical SeparatorSaidFerdjallahBelum ada peringkat

- Vessels - Flash Drums, Surge Tanks and AccumulatorsDokumen2 halamanVessels - Flash Drums, Surge Tanks and AccumulatorsVuong Bui100% (1)

- PROYEK MINI LPG PLANT LAPANGAN JATA CALCULATIONDokumen6 halamanPROYEK MINI LPG PLANT LAPANGAN JATA CALCULATIONDIANTOROBelum ada peringkat

- High Pressure Phase Behaviour of Multicomponent Fluid MixturesDari EverandHigh Pressure Phase Behaviour of Multicomponent Fluid MixturesBelum ada peringkat

- Sizing of Oil Water SeparatorDokumen21 halamanSizing of Oil Water SeparatorJustin AlwarBelum ada peringkat

- Module 4 - Phase Separation Theory and Separator Design - LectDokumen23 halamanModule 4 - Phase Separation Theory and Separator Design - LectmahmoudBelum ada peringkat

- API-521_Flare_KOD_Design_and_Even_More__Part_2Dokumen6 halamanAPI-521_Flare_KOD_Design_and_Even_More__Part_2Huy Nguyễn Võ XuânBelum ada peringkat

- B41OA Datasheet 2016-2017Dokumen11 halamanB41OA Datasheet 2016-2017Turkan AliyevaBelum ada peringkat

- Separators and Filters: Section 7Dokumen15 halamanSeparators and Filters: Section 7SergioRinconSolanoBelum ada peringkat

- B41OA Data Sheet 2015-2016Dokumen10 halamanB41OA Data Sheet 2015-2016Leanne ChewBelum ada peringkat

- Separator Design Basics.Dokumen58 halamanSeparator Design Basics.Shijumon KpBelum ada peringkat

- DocumentDokumen2 halamanDocumentEkundayo JohnBelum ada peringkat

- No Yes No Yes No Yes No Yes No Yes No YesDokumen8 halamanNo Yes No Yes No Yes No Yes No Yes No YesEkundayo JohnBelum ada peringkat

- TRAIN 5 CONDENSATE STABILIZATION UNIT CONTROL VALVE SUMMARYDokumen2 halamanTRAIN 5 CONDENSATE STABILIZATION UNIT CONTROL VALVE SUMMARYEkundayo JohnBelum ada peringkat

- Ammonia and Urea ProductionDokumen10 halamanAmmonia and Urea Productionwaheed_bhattiBelum ada peringkat

- Control Valve Sizing for Dowtherm Q LiquidDokumen13 halamanControl Valve Sizing for Dowtherm Q LiquidEkundayo JohnBelum ada peringkat

- SoupsDokumen4 halamanSoupsEkundayo JohnBelum ada peringkat

- 9-Trigonometric Ratios PDFDokumen4 halaman9-Trigonometric Ratios PDFMark Abion ValladolidBelum ada peringkat

- Multiflash ManualDokumen262 halamanMultiflash ManualEkundayo John80% (5)

- Ne Csu Pr0 F 6053 (Appendix)Dokumen55 halamanNe Csu Pr0 F 6053 (Appendix)Ekundayo JohnBelum ada peringkat

- Overpressure Protection and Relief Valves: Process Training School 2004/5Dokumen62 halamanOverpressure Protection and Relief Valves: Process Training School 2004/5Ekundayo JohnBelum ada peringkat

- Nigeria LNG LTD NLNG Six ProjectDokumen13 halamanNigeria LNG LTD NLNG Six ProjectEkundayo JohnBelum ada peringkat

- KOHASA ENGINEERING SIZING OF PRESSURE RELIEF VALVESDokumen18 halamanKOHASA ENGINEERING SIZING OF PRESSURE RELIEF VALVESEkundayo JohnBelum ada peringkat

- Ssags PSV SizingDokumen5 halamanSsags PSV SizingEkundayo JohnBelum ada peringkat

- FLB Tank Pump Calculation 7/28/1998 P1: Document No.: Title: Sign Date Made by Rev: Checked by Contract No.: QX0032Dokumen3 halamanFLB Tank Pump Calculation 7/28/1998 P1: Document No.: Title: Sign Date Made by Rev: Checked by Contract No.: QX0032Ekundayo JohnBelum ada peringkat

- Hysys Liquid PumpingDokumen8 halamanHysys Liquid PumpingEkundayo JohnBelum ada peringkat

- Nat Gas Lec 7 - 1Dokumen6 halamanNat Gas Lec 7 - 1Ekundayo JohnBelum ada peringkat

- Purpose: The Purpose of This Document Is To Carry Out Hydraulic CalculationDokumen14 halamanPurpose: The Purpose of This Document Is To Carry Out Hydraulic CalculationEkundayo John100% (1)

- A Technical Presentation On Pumps (Final)Dokumen27 halamanA Technical Presentation On Pumps (Final)Ekundayo JohnBelum ada peringkat

- How To Size A PumpDokumen18 halamanHow To Size A PumpEkundayo JohnBelum ada peringkat

- KOHASA ENGINEERING LINE SIZING CALCULATIONSDokumen9 halamanKOHASA ENGINEERING LINE SIZING CALCULATIONSEkundayo JohnBelum ada peringkat

- Pumps CalculationDokumen16 halamanPumps CalculationEkundayo JohnBelum ada peringkat

- Sabet A - Well Test AnalysisDokumen236 halamanSabet A - Well Test Analysiscarlos801Belum ada peringkat

- Line Sizing ProcedureDokumen123 halamanLine Sizing ProcedureEkundayo John100% (3)

- Shell Tutorial Ver 611Dokumen17 halamanShell Tutorial Ver 611emaclasicBelum ada peringkat

- Sabet A - Well Test AnalysisDokumen236 halamanSabet A - Well Test Analysiscarlos801Belum ada peringkat