06 Acidfracturing

Diunggah oleh

mahimoh18Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

06 Acidfracturing

Diunggah oleh

mahimoh18Hak Cipta:

Format Tersedia

1 Acid Fracturing

Principles of Acid Fracturing

2 Acid Fracturing

Acid Fracturing Basics

Acid is injected above fracturing pressure

- A hydraulic fracture is created

Limestone and Dolomite

Fracture faces are dissolved and etched

- Conductive channels are created

Length of etched fracture

- Determined by acid type, volume, strength, leakoff

parameters, reaction rate and spending rate.

Effectiveness determined by

- Fracture length

- Fracture conductivity

3 Acid Fracturing

Candidates for Acid Fracturing

Cleaner limestone and Dolomite formations

- Must have good fracture containment to generate length

Dirty carbonate rocks (< 70% solubility in HCl) are

poor candidates

- Acid etched channel will be impaired

- Release of insoluble material will plug the channel

Chalk formations may not be suitable

- Soft, unable to retain conductivity after closure

Not applicable to sandstone formations

- HCl, even HF will not adequately etch sandstone

fracture face

- Materials released through dissolution will plug the fracture

4 Acid Fracturing

Acid & Propped Fracturing

Comparison

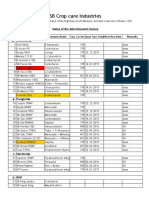

Acid Fracturing Propped Fracturing

Equipment/Treatment Less complicated More complicated

Proppant problems No Yes

Proppant Transport Problem No Yes

Fluid Loss Control Poor Better

Candidates Carbonates Only Carbonates +

Sandstones

Residual Damage in Fracture No Yes

Fracture Length Achievable Shorter Longer

5 Acid Fracturing

Factors Influencing Fracture Length

& Conductivity

Acid type, strength and volume

- Affects etched width and fracture lengths

Acid leakoff

- Additional complication due to gel cake erosion and

wormhole development

Acid viscosity

- Governs fracture width and acid transport along length

Injection rate

Formation type

- Mineralogy, temperature, saturation, wettability

6 Acid Fracturing

Consideration of Acid Fracturing

Design

Fracture propagation to the desired length

Acid is capable of dissolving large amount of

reservoir rock

Retain adequate length and conductivity after

closure

Rapid cleanup of treatment fluid

Cost effective

7 Acid Fracturing

Acid Fracture Mechanics

Acid Leakoff

Acid Reaction

Acid Transport

8 Acid Fracturing

Acid Reaction

Strength LB CaCO3

Dissolved

Type of Acid (%) /1000 gal acid

at 100F

Hydrochloric 15 1,833

20 2,515

28 3,662

Formic 9 726

Acetic 10 422

Higher strengths and higher volumes will create

more fracture width

9 Acid Fracturing

Different Acid Types and

Strengths

10 Acid Fracturing

Acid Leakoff

Acid leakoff cause the decline in treating

pressure during pumping

- Fracture extension becomes impossible

- Conventional filter cakes are destroyed by the

acid

Natural Fissures and Fractures

- Fissures get wider as more acid is introduced

- Limit the fracture propagation

Wormholes

- Divert larger volume of acid away from the

primary fracture

11 Acid Fracturing

Wormhole Development

Major source of leakoff

limiting penetration

Wormholes also

reduce fracture width

Form in the porosity of

rock matrix

12 Acid Fracturing

Wormhole Development

Effect of Temperature

13 Acid Fracturing

Wormhole Development

Effect of Acid Concentration

14 Acid Fracturing

Wormhole Development

Effect of Injection Rate

15 Acid Fracturing

Controlling Acid Leakoff

Acid Swellable Polymers

- Used to control wormhole early during treatment

Oil Soluble Resins

- Limited commercial application

Gelled water pad ahead of acid or within stages

of acid

- Increased penetration due to reduced acid reaction

rate

Gelled acid

- Reduced leakoff by increasing filtrate viscosity

16 Acid Fracturing

Controlling Acid Leakoff

Acid Swellable Polymers

- Used to control wormhole early during treatment

Oil Soluble Resins

- Limited commercial application

Gelled water pad ahead of acid or within stages

of acid

- Increased penetration due to reduced acid reaction

rate

Gelled acid

- Reduced leakoff by increasing filtrate viscosity

17 Acid Fracturing

Controlling Acid Leakoff

Acid Swellable Polymers

- Used to control wormhole early during treatment

Oil Soluble Resins

- Limited commercial application

Gelled water pad ahead of acid or within stages

of acid

- Increased penetration due to reduced acid reaction

rate

Gelled acid

- Reduced leakoff by increasing filtrate viscosity

18 Acid Fracturing

Controlling Acid Leakoff

Polymeric pad - Acid stages

Reduced leakoff due

to wormhole plug-up

Accelerated leakoff

following gel cake

erosion

19 Acid Fracturing

Controlling Acid Leakoff

DuoFrac II

Alternating stages

of acid and gel

Increased efficiency

and fracture length

20 Acid Fracturing

Acid Transport

Transport from the center of the fracture to the

fracture walls, i.e. diffusion.

Transport along the fracture length. Effects due

to pressure and density differences, i.e.

advection and convection

c

c

c

c

c

c

c

c

c

c

c

c

C

t

Cv

x

Cv

y

Cv

z z

D

C

z

x

y z

e

= +

|

\

|

.

|

advection, convection

x

y

z

diffusion

21 Acid Fracturing

Acid Diffusion

Fluid Leakoff

Rock Etching

Acid Diffusion

Acid transport due

to concentration

differences

Affects acid reaction

rate, and hence fracture

geometry

22 Acid Fracturing

Parameters Controlling Acid

Diffusion

Reduce fluid turbulence: Addition of viscosifiers

and wider fractures.

Reduce acid leakoff: Limited particle velocity to

the fracture walls.

Increase fracture width: More time for particle

transport.

Reduce temperature: Cooldown fluids

23 Acid Fracturing

Acid Transport along Fracture

Length

Governed by fluid pressure,

density differences and

gravity.

Used to promote longer

etched fracture lengths

due to viscous fingering.

24 Acid Fracturing

Acid Transport along Fracture

Length

Viscous fingering

Occurs when viscous fluid is displaced by less

viscous fluid

Three positive effects:

- Acid velocity is increased

- Acid etched length is increased

- Acid leakoff area is decreased

A DUOFRAC II treatment also experience viscous

fingering

25 Acid Fracturing

Acid Transport along Fracture

Length

Standard Analysis vs. 3-D Numerical

Analysis

0 100 200

Fracture Half-Length - ft

4896

4916

4936

4956

4976

4996

5016

W

e

l

l

D

e

p

t

h

-

f

t

0.00 - 0.01

0.01 - 0.01

0.01 - 0.02

0.02 - 0.02

0.02 - 0.02

0.02 - 0.03

0.03 - 0.03

> 0.03

0 100 200

Fracture Half-Length - ft

4896

4916

4936

4956

4976

4996

5016

W

e

l

l

D

e

p

t

h

-

f

t

0.01 - 0.02

0.02 - 0.02

0.02 - 0.03

0.03 - 0.04

0.04 - 0.05

0.05 - 0.06

0.06 - 0.07

> 0.07

One dimensional Three dimensional

26 Acid Fracturing

Acid Reaction Rate

The number of acid molecules with carbonate

rock per unit of time

Controlling mechanism

- Diffusion and reaction kinetics

The diffusion and kinetic mechanism can be

reduced

- By decreasing the temperature

- By increasing the viscosity of acid mixture

27 Acid Fracturing

Acid Reaction Rate

( )

c

c

M

t

K C C

acid

r wall eqm

m

=

M

acid

= moles of acid at fracture wall

K

r

= Reaction rate constant

C

wall

= Acid concentration at fracture wall

C

eqm

= Equilibrium acid concentration

Depends on detailed chemical composition of

species involved

28 Acid Fracturing

( ) ( )

c

c

M

t

K C C C C v

acid

g wall wall L

= +

M

acid

= moles of acid at fracture wall

K

g

= Diffusion constant

C

wall

= Acid concentration at fracture wall

C = Average acid concentration

v

L

= Leakoff velocity

Acid Reaction Equilibrium

Acid concentration at surface balanced by that

transported through diffusion

29 Acid Fracturing

Acid Reaction Equilibrium

Diffusion limited acid fracturing:

- Extremely fast reaction rate. Etching limited by diffusion

acid transport

Kinetic limited acid fracturing:

- Rapid acid transport. Limited acid - rock reaction.

30 Acid Fracturing

Optimizing Conductivity & Etched

Fracture Length

No theoretical limitation of conductivity value

- A matter of pumping more acid to widen the etched width

Maximum stimulation ratio achieved

- Corresponds to the case of infinite conductivity fracture

Optimum acid fracture penetration

x

k w

k

f

f

~

50

31 Acid Fracturing

Fluids for Deeper Acid

Penetration

Leakoff control is imperative

Decreasing leakoff through natural fissures

- 100 mesh resin/sand, or fine salt

- LCA and viscous pads

Decreasing leakoff due to wormholes

- LCA

- Viscosified acid (DGA)

- DUOFRAC II

Decreasing leakoff through fracture walls

- Viscous fluid bank

32 Acid Fracturing

Fluids for Deeper Acid

Penetration

Leakoff control is imperative

Decreasing leakoff through natural fissures

- 100 mesh resin/sand, or fine salt

- LCA and viscous pads

Decreasing leakoff due to wormholes

- LCA

- Viscosified acid (DGA)

- DUOFRAC II

Decreasing leakoff through fracture walls

- Viscous fluid bank

33 Acid Fracturing

Fluids for Deeper Acid

Penetration

Leakoff control is imperative

Decreasing leakoff through natural fissures

- 100 mesh resin/sand, or fine salt

- LCA and viscous pads

Decreasing leakoff due to wormholes

- LCA

- Viscosified acid (DGA)

- DUOFRAC II

Decreasing leakoff through fracture walls

- Viscous fluid bank

34 Acid Fracturing

Cooldown

Cooldown in Acid Fracturing

- Controls diffusion and surface reaction rates

BHST > 200F, rapid reaction with HCl

- Acid etching is limited to a flow test

Best fluid for cooldown

- High leakoff fluids

- Affected by volume, rate and fluid invasion to the

primary porosity

Requirement in a fissured reservoir

- Initiate cooldown once the leakoff to fissures has been

limited

35 Acid Fracturing

Retarded Acid

Acid with a reduced reaction rate

Penetrates more deeply into the fracture

Fracture width is decreased

The degree of retardation is defined by

retardation factor (RF)

- HCl, RF = 1

Retarded Acid, RF > 1

36 Acid Fracturing

Retardation Factor

Base values RF

- HCl, DGA and LCA 1

- DAD 2

- Surfactant retarded with

F98 2

- Organic acid 4

- SXE 10

37 Acid Fracturing

Retardation Factor-Static & Dynamic

Conditions

38 Acid Fracturing

Acid Fracturing Design

Fundamentals

Achieving acid fracture penetration

Maximize acid fracture length

- BHST < 200F, use fluid and lowest leakoff

- BHST > 200F, use cooldown + acid retardation

Acid fracture length should be limited

- Where no barrier to limit height growth

- To prevent communication with water or gas zones

- Fracture length = 1/2 thickness of producing interval

(radial)

Maximize the injection rate

- Deeper penetration

- Dictated by maximum allowable wellhead pressure

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Sondex PLT Tools User GuideDokumen24 halamanSondex PLT Tools User GuideRomanovslb100% (9)

- Sondex PLT Tools User GuideDokumen24 halamanSondex PLT Tools User GuideRomanovslb100% (9)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- SAP HCM Case StudyDokumen17 halamanSAP HCM Case StudyRafidaFatimatuzzahraBelum ada peringkat

- Well Stimulation PDFDokumen37 halamanWell Stimulation PDFmahimoh18Belum ada peringkat

- Effective Sandstone Acidizing - Best PracticeDokumen17 halamanEffective Sandstone Acidizing - Best Practicemahimoh18100% (4)

- Section 6 - Fracturing Fluids and MaterialsDokumen40 halamanSection 6 - Fracturing Fluids and Materialsmahimoh18100% (3)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Skilled Worker Overseas FAQs - Manitoba Immigration and Economic OpportunitiesDokumen2 halamanSkilled Worker Overseas FAQs - Manitoba Immigration and Economic OpportunitieswesamBelum ada peringkat

- Necromunda CatalogDokumen35 halamanNecromunda Catalogzafnequin8494100% (1)

- BS 215-2-1970-Aluminium Conductors and Aluminium Conductors Steel-Reinforced For Overhead Power TransmissionDokumen16 halamanBS 215-2-1970-Aluminium Conductors and Aluminium Conductors Steel-Reinforced For Overhead Power TransmissionDayan Yasaranga100% (2)

- Well Performance Evaluation of Stimulated Wells PDFDokumen30 halamanWell Performance Evaluation of Stimulated Wells PDFmahimoh18Belum ada peringkat

- Well Testing and Interpretation For Horizontal WellsDokumen6 halamanWell Testing and Interpretation For Horizontal WellsGaboGagBelum ada peringkat

- LinerDokumen15 halamanLinermahimoh18Belum ada peringkat

- Growing Role of Shale Gas Within The Unconventional Gas PlaysDokumen15 halamanGrowing Role of Shale Gas Within The Unconventional Gas Playshendrik3434Belum ada peringkat

- Guidelines For Hydraulic FracturingDokumen25 halamanGuidelines For Hydraulic Fracturingmahimoh18Belum ada peringkat

- Acid FracturingDokumen11 halamanAcid Fracturingmahimoh18Belum ada peringkat

- Wireline Pressure Control BRDokumen2 halamanWireline Pressure Control BRmahimoh18Belum ada peringkat

- Packer MillingDokumen35 halamanPacker Millingmahimoh18Belum ada peringkat

- Subsurface Safety Valve BasicsDokumen33 halamanSubsurface Safety Valve BasicsPun Chee100% (4)

- Advances in Treatment Design and Production OptimizationDokumen20 halamanAdvances in Treatment Design and Production Optimizationmahimoh18Belum ada peringkat

- 35904.BJ Sandstone Acid System Overview.0612Dokumen1 halaman35904.BJ Sandstone Acid System Overview.0612mahimoh18Belum ada peringkat

- Well Test Procedures ManualDokumen108 halamanWell Test Procedures Manualapi-2693096593% (29)

- Slickline BasicsDokumen86 halamanSlickline BasicsAmiromaan100% (7)

- Hydraulic FracturingDokumen3 halamanHydraulic FracturingTarek TarkanBelum ada peringkat

- 1 Advances in Carbonate StimulationDokumen10 halaman1 Advances in Carbonate Stimulationmahimoh18Belum ada peringkat

- Oil and Gas Well ServicingDokumen68 halamanOil and Gas Well ServicingHisham Al-ZuhairBelum ada peringkat

- Straddle-Packer Hydraulic TestingDokumen4 halamanStraddle-Packer Hydraulic Testingmahimoh18Belum ada peringkat

- LinerDokumen15 halamanLinermahimoh18Belum ada peringkat

- Well Test Procedures ManualDokumen108 halamanWell Test Procedures Manualapi-2693096593% (29)

- Stimulation Manual ONGC 2008Dokumen306 halamanStimulation Manual ONGC 2008rahul_storm100% (3)

- Well Performance Evaluation of Stimulated Wells PDFDokumen30 halamanWell Performance Evaluation of Stimulated Wells PDFmahimoh18Belum ada peringkat

- Well Performance Evaluation of Stimulated Wells PDFDokumen30 halamanWell Performance Evaluation of Stimulated Wells PDFmahimoh18Belum ada peringkat

- Production Logging For Reservoir TestingDokumen5 halamanProduction Logging For Reservoir Testingmahimoh18Belum ada peringkat

- Design A Fracture TreatmentDokumen7 halamanDesign A Fracture TreatmentKamran Haider Tunio100% (1)

- OM Part B - Rev1Dokumen45 halamanOM Part B - Rev1Redouane BelaassiriBelum ada peringkat

- L5T-112 Manual - 2007 - Issue 1.1 PDFDokumen16 halamanL5T-112 Manual - 2007 - Issue 1.1 PDFfluidaimaginacionBelum ada peringkat

- Market EquilibriumDokumen36 halamanMarket EquilibriumLiraOhBelum ada peringkat

- Quiz 2 I - Prefix and Suffix TestDokumen10 halamanQuiz 2 I - Prefix and Suffix Testguait9Belum ada peringkat

- Verilog GATE AND DATA FLOWDokumen64 halamanVerilog GATE AND DATA FLOWPRIYA MISHRABelum ada peringkat

- Group 4&5 Activity Syntax AnalyzerDokumen6 halamanGroup 4&5 Activity Syntax AnalyzerJuan PransiskoBelum ada peringkat

- Ep Docx Sca SMSC - V2Dokumen45 halamanEp Docx Sca SMSC - V290007Belum ada peringkat

- 1 s2.0 S2238785423001345 MainDokumen10 halaman1 s2.0 S2238785423001345 MainHamada Shoukry MohammedBelum ada peringkat

- B.e.eeeDokumen76 halamanB.e.eeeGOPINATH.MBelum ada peringkat

- Molde Soldadura TADokumen1 halamanMolde Soldadura TAMarcos Ivan Ramirez AvenaBelum ada peringkat

- EPA Section 608 Type I Open Book ManualDokumen148 halamanEPA Section 608 Type I Open Book ManualMehdi AbbasBelum ada peringkat

- Diazonium Salts Azo DyesDokumen8 halamanDiazonium Salts Azo DyesAnthony Basanta100% (1)

- Upadhyayaetal TrueliqtrigcurveDokumen14 halamanUpadhyayaetal TrueliqtrigcurveVetriselvan ArumugamBelum ada peringkat

- Star Wars Galactic Connexionstm Galactic Beckett Star Wars Story Connexions CallingDokumen4 halamanStar Wars Galactic Connexionstm Galactic Beckett Star Wars Story Connexions CallingJuan TorresBelum ada peringkat

- NCPDokumen6 halamanNCPJoni Lyn Ba-as BayengBelum ada peringkat

- Under Suitable Conditions, Butane, C: © OCR 2022. You May Photocopy ThisDokumen13 halamanUnder Suitable Conditions, Butane, C: © OCR 2022. You May Photocopy ThisMahmud RahmanBelum ada peringkat

- 353 Version 7thDokumen1 halaman353 Version 7thDuc NguyenBelum ada peringkat

- Distance SortDokumen6 halamanDistance SortAI Coordinator - CSC JournalsBelum ada peringkat

- Master Data FileDokumen58 halamanMaster Data Fileinfo.glcom5161Belum ada peringkat

- MikoritkDokumen6 halamanMikoritkChris Jonathan Showip RouteBelum ada peringkat

- Newsela Teacher Review - Common Sense EducationDokumen1 halamanNewsela Teacher Review - Common Sense EducationJessicaBelum ada peringkat

- Products ListDokumen11 halamanProducts ListPorag AhmedBelum ada peringkat

- IFSSO Newsletter Jul-Sep 2010Dokumen2 halamanIFSSO Newsletter Jul-Sep 2010rjotaduranBelum ada peringkat

- Matrices and Vectors. - . in A Nutshell: AT Patera, M Yano October 9, 2014Dokumen19 halamanMatrices and Vectors. - . in A Nutshell: AT Patera, M Yano October 9, 2014navigareeBelum ada peringkat

- Bobcat E34 - E35Z Brochure - Adare MachineryDokumen8 halamanBobcat E34 - E35Z Brochure - Adare MachineryNERDZONE TVBelum ada peringkat

- Pds Hempel's Maestro Water Borne Primer 28830 En-GbDokumen2 halamanPds Hempel's Maestro Water Borne Primer 28830 En-GbKalaiyazhagan ElangeeranBelum ada peringkat