Soil Constitutive Model

Diunggah oleh

Mohamed YousufJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Soil Constitutive Model

Diunggah oleh

Mohamed YousufHak Cipta:

Format Tersedia

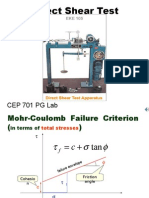

Constitutive models

Part 2

Elastoplastic

Elastoplastic material models

Elastoplastic materials are assumed to

behave elastically up to a certain stress limit

after which combined elastic and plastic

behaviour occurs.

Plasticity is path dependent the changes in

the material structure are irreversible

Stress-strain curve of a hypothetical material

Idealized results of one-dimensional tension test

Engineering stress

Engineering strain

Yield point

Yield stress

area initial force/ = o

l

l

0

A

= c

Johnsons limit 50% of Young modulus value

Real life 1D tensile test, cyclic loading

Hysteresis loops move

to the right - racheting

Where is the yield point?

Conventional yield point

Lin. elast. limit

Mild carbon steel

before and after heat treatment

Conventional yield point 0.2%

The plasticity theory covers the

following fundamental points

Yield criteria to define specific stress

combinations that will initiate the non-elastic

response to define initial yield surface

Flow rule to relate the plastic strain increments to

the current stress level and stress increments

Hardening rule to define the evolution of the

yield surface. This depends on stress, strain and

other parameters

Yield surface, function

Yield surface, defined in stress space separates stress states

that give rise to elastic and plastic (irrecoverable) states

For initially isotropic materials yield function depends on

the yield stress limit and on invariant combinations of

stress components

As a simple example Von Mises

Yield function, say F, is designed in such a way that

plasticity analytical for le inadmissib outside, 0

surface the on 0

surface the within state stress 0

>

=

<

F

F

F

0

yield effective

= o o F

0 ...) , , (

P

= K F

ij ij

c o

Three kinematic conditions are to be

distinguished

Small displacements, small strains

material nonlinearity only (MNO)

Large displacements and rotations, small strains

TL formulation, MNO analysis

2PK stress and GL strain substituted for engineering

stress and strain

Large displacements and rotations, large strains

TL or UL formulation

Complicated constitutive models

Rheology models for plasticity

Ideal or perfect plasticity, no hardening

Loading, unloading, reloading and cyclic loading in 1D

s

t

r

e

s

s

strain

+

n

e

w

y

i

e

l

d

s

t

r

e

s

s

1

-

n

e

w

y

i

e

l

d

s

t

r

e

s

s

1

i

n

i

t

i

a

l

y

i

e

l

d

s

t

r

e

s

s

Isotropic hardening

n

e

w

y

i

e

l

d

s

t

r

e

s

s

2 loading

unloading

reloading

Isotropic hardening in principal stress space

3 2 1 Y 3 1

, 0 ) (

tension in stress yield 1D and stresses principal by expressed Tresca

o o o o o o > > = F

0 2 ] ) ( ) ( ) [(

tension in stress yield 1D and stresses principal by expressed Mises von

2

Y

2

1 3

2

3 2

2

2 1

= + + o o o o o o o F

t - plane

arccos (2/sqrt(3))

s

t

r

e

s

s

strain

+

n

e

w

y

i

e

l

d

s

t

r

e

s

s

1

i

n

i

t

i

a

l

y

i

e

l

d

s

t

r

e

s

s

Kinematic hardening

loading

unloading

reloading

Loading, unloading, reloading and cyclic loading in 1D

Kinematic hardening in principal stress space

constant ... , where , 0 ) ( take we

hardening) isotropic of case in (as 0 ) ( of instead

P

c c F

F

ij ij ij ij

ij

c o o o

o

= =

=

Von Mises yield condition, four hardening models

1. Perfect plasticity no hardening

2. Isotropic hardening

3. Kinematic hardening

4. Isotropic-kinematic

Different types of yield functions

) , , (

have could we all, at general not is which Generally,

invariant. an usually , of function scalar a is ) ( e wher

hardening isotropic ) , (

way different a in of component every on depends hardening

hardening isotropic - non ) , (

constant. a is and e wher

hardening kinematic ) (

. strain plastic permanent the on depends h whic

flow) (free ns dislocatio of motion the blocking on depends hardening the Generally,

... ns dislocatio of nition Defi

ns. dislocatio of motion by caused is flow material tic Plas

region. plasticity the around

exists which structure material healthy' ' by the stabilized is it practice It

forever. so do to inclided is and flow to starts material hardening, no means

plasticity perfect ) (

P

P P

P

P

P

K F F

K K

K F F

F F

c c

F F

F F

ij ij

ij ij

ij

ij

ij ij

ij ij

ij ij

ij

ij

c o

c c

o

c

c o

c o

o o

c

o

=

=

=

=

=

=

=

Plasticity models physical relevance

Von Mises

- no need to analyze the state of stress

- a smooth yield sufrace

- good agreement with experiments

Tresca

- simple relations for decisions (advantage for hand calculations)

- yield surface is not smooth (disadvantage for programming,

the normal to yield surface at corners is not uniquely defined)

Drucker Prager

a more general model

1D example, bilinear characteristics

P E T

d d d c c c + =

o d

o

plastic elastic

|

strain

stress

total

P T

d d d

E E E

o o o

+ =

EP T

d d d c c c = =

E = o tan

T

tan E = |

Strain hardening parameter

Y

o

H

E E

E

E E

E E

E

'

=

=

/ 1

T

T

T

T

P

means total or elastoplastic

elastic modulus

tangent modulus

Strain hardening parameter again

Elastic strains removed

Initial yield

Upon unloading and reloading the effective stress must exceed

Geometrical meaning of the strain hardening parameter is

the slope of the stress vs. plastic strain plot

How to remove elastic part

T

T

P

E E

E E

E

=

1D example, bar (rod) element

elastic and tangent stiffness

L

o

A

F F

Y

o o s

Y

o o >

L

EA F

k = =

o

E

( ) L

A E

L

A F

k

P E

P P

T

T

d d

d

d

d

d

d

c c

c

c

o

o +

= = =

|

|

.

|

\

|

+

=

+

=

P

P

P

P P

T

1

/ d / d

/E d

E E

E

L

EA

E E L

A E

k

o o

o

Elastic stiffness

Tangent stiffness

Results of 1D experiments must

be correlated to theories capable

to describe full 3D behaviour of

materials

Incremental theories relate stress increments to strain increments

Deformation theories relate total stress to total strain

Relations for incremental theories

isotropic hardening example 1/9

o

o

=

t

t

d

d

lim : rates and increments between Relation

0

surface yield back to go 0

0 that means it - neutral 0 and 0

tic elastoplas 0 and 0

elastic 0 and 0

elastic 0 if

and on depends n deformatio of increment

0 ) , ( is surface yield Let the

P

eff

eff

eff

eff

P

>

= = =

> =

< =

<

=

F

F

F

F

F

F

F

ij

ij ij

c o

o

o

o

c o

Parameter only

Relations for incremental theories

isotropic hardening example 2/9

Eq. (i) increment of plastic deformation has a direction

normal to F while its magnitude (length of vector) is not yet known

defines outer normal to F

in six dimensional stress space

0 d so ns, deformatio plastic during zero be must which

d d d

al differenti total a as expressed be can

} {

and scalar unknown far so is where

1947) (Drucker, form in the assumed is rule Flow

P

P

P

P

T

31 11

P

=

c

c

+

c

c

=

c

c

+

c

c

=

c

c

c

c

=

=

c

c

=

F

F F F F

F

F

F F

F

ij

ij

ij

ij

ij

ij

ij

ij

ij

ij

c

c

o

o

c

c

o

o

o o

o

c

q

q

Relations for incremental theories

isotropic hardening example 3/9

elastic total plastic deformations

matrix of elastic moduli

(iii) eq. ) (

are increments stress

(ii) eq. 0 d d

form the in expressed be can 0 d condition the

} { Denoting

P E

P T T P T T

T

P

31

P

11

E E

p q p q

p

= =

= =

=

c

c

c

c

=

o o

c c

F

F F

Relations for incremental theories

isotropic hardening example 4/9

q E q q p

E q

T T

T

get we (iii) increments stress for and (ii) 0 d

(i), rule flow for relations the Combining

+

=

c

F

=

Dot product and quadratic form scalar

Row vector

Column vector

Lambda is the scalar quantity determining the magnitude

of plastic strain increment in the flow rule

Still to be determined

Relations for incremental theories

isotropic hardening example 5/9

= = =

P P E

with ) (

write can we increment stress for the Now,

E E

q

determined be to has still where

) (

with

form the in increment strain total of function a as

increment stress get the we for ng Substituti

T T

T

EP

EP

p

Eq q q p

Eq Eq

E E

E

+

=

=

equal to zero for perfect plasticity

diadic product

Relations for incremental theories

isotropic hardening example 6/9

ij

ij

t

t

ij ij

t

t

t

t

ij

t

ij

ij

ij ij

t

W F

A

W

W

W

F

W W f

f

F

s s J

J F

F F

o

c

o

o

o o

o

o

c

o

o c

c o o

c o

c

o

c c

=

c

c

=

c

c

=

c

c

=

c

c

c

c

c

c

=

c

c

= =

=

c

c

=

=

c

c

c

c

=

}

P

P

Y 3

2

Y

P

Y

Y 3

2

P

ij

P

P

Y

Y

P

ij

P

ij

P P

Y

P

Y

P

2

1

D2

2

Y 3

1

D2

T

P

31

P

11

and using

F

rule Chain

increments plastic by done work d ), (

at suggest th s Experiment

) ( need we evaluate to

invariant deviatoric second the is where

0 condition yield Mises von Assume

} { of ion Determinat

p

A new constant defined

At time t

Relations for incremental theories

isotropic hardening example 7/9

c

P

c

E

P

E

T

E

Y

0

o

Y

o

t

P 0

c

P

c

t

P

W

T

31 22 11

T

T

P

Y

P

Y

P

Y

Y

P

2

Y

0 2

Y

P

P

P P

Y

0

Y

t

P

Y

0

Y 2

1

P

} { finaly so

3

2

3

2

3

2

) (

2

1

) ( stics characteri bilinear 1D

) ( done work elastic the 1D in

o o o

o

o

o

o

o o

c o o

c o o

A

E E

EE

E

E

A

E

W

E

W

E

W

t

t

t

t

t

t

t t

=

= = = =

c

c

=

+ =

+ =

p

W

Relations for incremental theories

isotropic hardening example 8/9

E

bb

E E

b q Eq q Eq b q p

p

q

s

EP

T

EP

T T T

T

31 23 12 33 22 11

T

T

T

31 23 12 33 22 11

T

31 23 12 m 33 m 22 m 11

T

31 23 12 33 22 11

33 22 11 3

1

m

Y

, ,

} {

3

2

} 2 2 2 {

} { } {

) (

follows as compute can we and and given For Summary.

=

+

=

= = = =

=

=

=

= =

+ + =

c a

c a

A

E E

EE

A

s s s s s s

s s s s s s

ij ij

o o o o o o

o o o o o o o o o

o o o o

o o

J2 theory, perfect plasticity 1/6

alternative notation example of numerical treatment

) 2 , 2 , 2 , 1 , 1 , 1 ( diag ] [ with }, ]{ [ } { or

) 2 2 2 (

deviator stress of invariant second

} { } {

deviator stress

stress mean ) (

} { } {

} { } {

law s Hooke' }... ]{ [ } {

T

2

1

2

2 2 2 2 2 2

2

1

2 D2

T

m m m

3

1

m

T

T

= =

+ + + + + = =

=

+ + =

=

=

=

M s M s J

s s s s s s J J

s

E

zx yz xy zz yy xx

zx yz xy zz yy xx

zz yy xx

zx yz xy zz yy xx

zx yz xy zz yy xx

t t t o o o o o o

o o o o

c c c c

t t t o o o o

c o

J2 theory, numerical treatment 2/6

Y eff

T

2 eff

T T

behaviour plastic perfectly for criterion yield

2 / } ]{ [ } { 3 3 stress effective Mises von

) 1 /( with }, { 2 } ]{ ][ [ also and

0 since }, ]{ [ } { } ]{ [ } {

that prove can one

o o

o

o

=

= =

+ = =

= + + =

s M s J

E G s G s M E

s s s s M s M s

zz yy xx

J2 theory, numerical treatment 3/6

endif

0 else

, 0 then if

by expressed be can region elastic in n deformatio plastic no

increment , derivative time its ... } { 2 } ]{ [ } ]{ [ } ]{ [ } {

law s Hooke' ... } ]{ [ } ]{ [ } {

parameter unknown far so is ... } ]{ [

} {

} {

hypothesis Reuss - Prandtl to according rule Flow

Y eff

P

P E

T

>

= <

= =

= =

=

c

c

=

o o

c c c o

c c c o

o

c

s G E E E

E E

s M

F

Six nonlinear differential equations + one algebraic constraint (inequality)

There is exact analytical solution to this. In practice we proceed numerically

J2 theory, numerical treatment 4/6

T

2

Y

EP EP

2

Y

T

2

Y

T

2

Y

2

eff 2

T

T T

T T

eff

T

T

eff

eff

Y eff

3

with

finally

2

3

4

3

get we

3 / 4 3 / 4 4 2

that realizing and

2

for ng Substituti

0 also and 0

0

2

3

condition plasticity ating Differenti

ss E E E

s ME s

Ms s

Ms s ME s

M s Ms s

Ms s

s

s

o

o o

o o

o

o

o

o o

G

G

G G J G G

G

= =

= =

= = =

=

= =

= =

c

c

=

=

System of six nonlinear

differential equations

to be integrated

J2 theory, numerical treatment 5/6

predictor-corrector method, first part: predictor

1. known stress

2. test stress (elastic shot)

3a. elastic part of increment

T

) 1 ( s A r

T

s A r

3b. plastic part of increment

T c

. 4 s s s A + = r

t

t

) 2 /( ) 1 ( 3 . 5

2

Y

T

c

o s A = A r

E A + = A + =

t t T T

c T

'

2 . 6 s A =

A +

G

t t

J2 theory, numerical treatment 6/6

predictor-corrector method, second part: corrector

' '

' '

'

eff

Y

Y

'

eff

Y

'

eff

Y eff

'

) 1 (

have we ions considerat plasticity into enter not does

tensor stress the of part spherical the since and

) 1 (

) (

) (

) (

) (

a way that such in find For

Correction

t t t t t t

t t t t t t

t t

t t

t t

t t

t t t t

A + A + A +

A + A + A +

A +

A +

A +

A +

A + A +

=

=

=

=

=

=

=

s

s s s

s

s

s

s

s s

|

|

o

o

|

o o |

o | o

o o

| |

Secant stiffness method and the method of radial return

Anda mungkin juga menyukai

- Arnold Verruijt-Computational Geomechanics (1999) PDFDokumen212 halamanArnold Verruijt-Computational Geomechanics (1999) PDFد.م. محمد الطاهرBelum ada peringkat

- Pore-Pressures Coefficients A and B - Skempton (1954)Dokumen5 halamanPore-Pressures Coefficients A and B - Skempton (1954)Mauricio ShiguekiBelum ada peringkat

- Numerical Methods and Implementation in Geotechnical Engineering – Part 1Dari EverandNumerical Methods and Implementation in Geotechnical Engineering – Part 1Belum ada peringkat

- Solid Waste Management in ChinaDokumen9 halamanSolid Waste Management in ChinaMohamed YousufBelum ada peringkat

- Z-Transforms Solved ProblemsDokumen5 halamanZ-Transforms Solved ProblemsHarsha100% (1)

- MATH1510G Calculus For Engineers - Subclass G: LecturerDokumen2 halamanMATH1510G Calculus For Engineers - Subclass G: LecturerfishkantBelum ada peringkat

- Homework 6 PDFDokumen6 halamanHomework 6 PDFFlor Hernandez Tiscareño100% (1)

- For Finite Element AnalysisDokumen32 halamanFor Finite Element AnalysisZhenhe SongBelum ada peringkat

- Advance Soil Mechanics: Elastic, Plastic and Elasto-Plastic BehaviourDokumen52 halamanAdvance Soil Mechanics: Elastic, Plastic and Elasto-Plastic BehaviourzuluagagaBelum ada peringkat

- ZSoilDay2011 HSmodels-Course v3.1Dokumen104 halamanZSoilDay2011 HSmodels-Course v3.1Mohamed A. El-BadawiBelum ada peringkat

- Clap Users Manual Rev 4Dokumen68 halamanClap Users Manual Rev 4Birendra KumarBelum ada peringkat

- Soil Structure InteractionDokumen16 halamanSoil Structure InteractionEmad Ahmed Khan67% (3)

- Lecture25 Ground Response Analysis Part1Dokumen25 halamanLecture25 Ground Response Analysis Part1Arun Goyal100% (1)

- Pile Testing & Settlement Prediction-Poulos-2013Dokumen20 halamanPile Testing & Settlement Prediction-Poulos-2013Sorabh GuptaBelum ada peringkat

- Lecture26 Ground Response Analysis Part2Dokumen35 halamanLecture26 Ground Response Analysis Part2Arun GoyalBelum ada peringkat

- Galavi Groundwater Flow and Coupled AnalysisDokumen290 halamanGalavi Groundwater Flow and Coupled AnalysisAnonymous D5s00DdUBelum ada peringkat

- 7modified Hyperbolic Stress Strain Response PDFDokumen9 halaman7modified Hyperbolic Stress Strain Response PDFrkBelum ada peringkat

- Strength and Stiffness PropertiesDokumen36 halamanStrength and Stiffness Propertiesriz2010Belum ada peringkat

- PLAXIS Ground Response AnalysisDokumen46 halamanPLAXIS Ground Response AnalysisAnonymous D5s00DdUBelum ada peringkat

- Iss34 Art2 - Validation of The Embeded Pile Row in PLAXIS 2DDokumen4 halamanIss34 Art2 - Validation of The Embeded Pile Row in PLAXIS 2DhapsinteBelum ada peringkat

- Plaxis-Triaxial Test With Hardening Soil ModelDokumen4 halamanPlaxis-Triaxial Test With Hardening Soil Modellimara65Belum ada peringkat

- Dynamic Soil Structure Interaction - 01 - Chapter 1 - NaganoDokumen42 halamanDynamic Soil Structure Interaction - 01 - Chapter 1 - Naganonevam21100% (1)

- Evaluation of SHANSEP Parameters For Soft Bonneville ClaysDokumen67 halamanEvaluation of SHANSEP Parameters For Soft Bonneville ClaysAmanda Cervantes100% (1)

- Slope Stability Analysis by Strength Reduction - Dawson1999Dokumen6 halamanSlope Stability Analysis by Strength Reduction - Dawson1999Eden HazardBelum ada peringkat

- Lecture 3 Constative Models (Plaxis) PDFDokumen119 halamanLecture 3 Constative Models (Plaxis) PDFMohamed OudaBelum ada peringkat

- Settle3D: Settlement and Consolidation AnalysisDokumen56 halamanSettle3D: Settlement and Consolidation AnalysistentawBelum ada peringkat

- Single Pile Dynamic StiffnessDokumen40 halamanSingle Pile Dynamic Stiffnessriz2010Belum ada peringkat

- Lecture 1Dokumen37 halamanLecture 1alfredomotaBelum ada peringkat

- P-Y Curves For Group PilesDokumen5 halamanP-Y Curves For Group PilessatyaBelum ada peringkat

- Shaft 2012 ManualDokumen236 halamanShaft 2012 ManualRaynaldo JodistiroBelum ada peringkat

- 2016 - Limit Equilibrium Method For Rock Slope Stability Analysis by Using The Generalized Hoek-Brown Criterion PDFDokumen9 halaman2016 - Limit Equilibrium Method For Rock Slope Stability Analysis by Using The Generalized Hoek-Brown Criterion PDFAnonymous 0NpgiTF0gBelum ada peringkat

- ICE Paper - To Teach or Not To Teach - From Theory To PracticeDokumen9 halamanICE Paper - To Teach or Not To Teach - From Theory To PracticeBobbyBelum ada peringkat

- Duncan Chang ModelDokumen6 halamanDuncan Chang ModelMoussaàb RedaouniaBelum ada peringkat

- 2 Compressibility of SoilsDokumen96 halaman2 Compressibility of SoilsAyato KamisatoBelum ada peringkat

- 275 Course Outline 2018Dokumen2 halaman275 Course Outline 2018rivai sargawiBelum ada peringkat

- FLAC DynamicDokumen294 halamanFLAC DynamicMaximillian KrisnadiBelum ada peringkat

- Lecture 8 Critical State Soil Mechanics PDFDokumen31 halamanLecture 8 Critical State Soil Mechanics PDFZar MaghustBelum ada peringkat

- GD Pile 2013Dokumen161 halamanGD Pile 2013Ericwww100% (2)

- 26may2014 1Dokumen16 halaman26may2014 1Desai NileshBelum ada peringkat

- Foundation Engineering in The Face of Uncertainty - ASCEDokumen6 halamanFoundation Engineering in The Face of Uncertainty - ASCEbarouniamine100% (1)

- Hardening SoilDokumen24 halamanHardening SoildiegofernandodiazsepBelum ada peringkat

- Sunneset & Al (1989) - Evaluation of Soil Parameters FromDokumen14 halamanSunneset & Al (1989) - Evaluation of Soil Parameters FromJennifer MillerBelum ada peringkat

- Plaxis TunnelDokumen0 halamanPlaxis TunnelSyazwan AbhBelum ada peringkat

- Liquefaction Analysis Using PLAXISDokumen19 halamanLiquefaction Analysis Using PLAXISdehevy50% (2)

- API Sand and API Clay InformationDokumen27 halamanAPI Sand and API Clay InformationIqbal AamerBelum ada peringkat

- Practical Approaches To Seismic Design of Deep FoundationsDokumen28 halamanPractical Approaches To Seismic Design of Deep FoundationsIoannis AntonopoulosBelum ada peringkat

- Soil Behaviors - Bahan Kuliah TSA ESA USA and Shanseep - DR Endra SusilaDokumen38 halamanSoil Behaviors - Bahan Kuliah TSA ESA USA and Shanseep - DR Endra SusilaviqriBelum ada peringkat

- Settlement of Shallow Foundation 2013Dokumen154 halamanSettlement of Shallow Foundation 2013Dita Fitri100% (1)

- Critical State Soil Mechanics LectureDokumen30 halamanCritical State Soil Mechanics LecturevariablespiceBelum ada peringkat

- HS Model PresentationDokumen58 halamanHS Model Presentationgeologist84100% (2)

- Soil StiffnessDokumen24 halamanSoil StiffnessMuhamad HassanBelum ada peringkat

- Seismic Slope StabilityDokumen27 halamanSeismic Slope StabilityMUHAMMAD ALIBelum ada peringkat

- A Comprehensive Database of Tests on Axially Loaded Piles Driven in SandDari EverandA Comprehensive Database of Tests on Axially Loaded Piles Driven in SandBelum ada peringkat

- Design of Piles Under Cyclic Loading: SOLCYP RecommendationsDari EverandDesign of Piles Under Cyclic Loading: SOLCYP RecommendationsAlain PuechBelum ada peringkat

- Landslides And Their Control: Czechoslovak Academy of SciencesDari EverandLandslides And Their Control: Czechoslovak Academy of SciencesBelum ada peringkat

- Elastic Analysis of Soil-Foundation InteractionDari EverandElastic Analysis of Soil-Foundation InteractionPenilaian: 4 dari 5 bintang4/5 (1)

- Ground Improvement Case Histories: Embankments with Special Reference to Consolidation and Other Physical MethodsDari EverandGround Improvement Case Histories: Embankments with Special Reference to Consolidation and Other Physical MethodsBelum ada peringkat

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsDari EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsBelum ada peringkat

- Charting A Course For A Successful Research CareerDokumen123 halamanCharting A Course For A Successful Research CareerOmicsScienceBelum ada peringkat

- l2 NetworkplanDokumen48 halamanl2 NetworkplanramasamyBelum ada peringkat

- Science and Empiricism in Pile DesignDokumen29 halamanScience and Empiricism in Pile DesignMohamed YousufBelum ada peringkat

- Direct Shear TestDokumen32 halamanDirect Shear TestVinay YadavBelum ada peringkat

- Sananda Parbani 2012Dokumen196 halamanSananda Parbani 2012Mohamed YousufBelum ada peringkat

- Leaning Tower of Pisa Case StudyDokumen15 halamanLeaning Tower of Pisa Case StudyMohamed Yousuf50% (4)

- Precast Elements Made of UHPC: - From Research To ApplicationDokumen54 halamanPrecast Elements Made of UHPC: - From Research To ApplicationMohamed Yousuf100% (1)

- White Space MappingDokumen7 halamanWhite Space MappingMohamed YousufBelum ada peringkat

- Design of Concrete BeamsDokumen41 halamanDesign of Concrete BeamsMohamed YousufBelum ada peringkat

- Is 6403Dokumen18 halamanIs 6403Shovon Mukherjee100% (1)

- Winitzki - Approximation To Error FunctionDokumen3 halamanWinitzki - Approximation To Error Functionwinitzki100% (1)

- Chapter 3 - Applied Well Test Interpretation 2013Dokumen28 halamanChapter 3 - Applied Well Test Interpretation 2013Võ Văn VũBelum ada peringkat

- Intregation 2Dokumen4 halamanIntregation 2Rayhan KabirBelum ada peringkat

- Domain and RangeDokumen2 halamanDomain and RangePranay KhannaBelum ada peringkat

- More On Vector Products: Prof. N. Harnew University of Oxford MT 2012Dokumen10 halamanMore On Vector Products: Prof. N. Harnew University of Oxford MT 2012Afzaal GhaziBelum ada peringkat

- JWB Soal UTS Soal No 2Dokumen102 halamanJWB Soal UTS Soal No 2Sutrisno DrsBelum ada peringkat

- P4 W02 (0581 - w13 - QP - 41)Dokumen20 halamanP4 W02 (0581 - w13 - QP - 41)landscapesinthemistBelum ada peringkat

- Statistics and Probability KatabasisDokumen7 halamanStatistics and Probability KatabasisDaniel N Sherine FooBelum ada peringkat

- 1 Phase SpaceDokumen1 halaman1 Phase Spaceaaditya3015Belum ada peringkat

- Chapter4 Lecture4Dokumen12 halamanChapter4 Lecture4bulBelum ada peringkat

- Sets MCQ 2Dokumen3 halamanSets MCQ 2no nameBelum ada peringkat

- Functions SUM Product Difference Quotient: SUM Count MIN MAX AverageDokumen4 halamanFunctions SUM Product Difference Quotient: SUM Count MIN MAX AverageJay Ann DomeBelum ada peringkat

- Fundamental Issues of Smeared Crack ModelsDokumen16 halamanFundamental Issues of Smeared Crack ModelsSaroj Kumar SahuBelum ada peringkat

- 7 Linear Quadratic Control: 7.1 The ProblemDokumen10 halaman7 Linear Quadratic Control: 7.1 The Problemdude2010Belum ada peringkat

- Summary of Syllabus Mathematics G100Dokumen13 halamanSummary of Syllabus Mathematics G100Train_7113Belum ada peringkat

- Tuesday 7 January 2020: Mathematics BDokumen24 halamanTuesday 7 January 2020: Mathematics BZaaid Ahmed67% (3)

- CSE330 Assignment1 SolutionDokumen7 halamanCSE330 Assignment1 Solutionnehal hasnain refathBelum ada peringkat

- Introduction To Real Analysis 4th Edition Bartle Solutions ManualDokumen38 halamanIntroduction To Real Analysis 4th Edition Bartle Solutions Manualemareategui100% (16)

- Algebra II NoteDokumen1 halamanAlgebra II NoteMiyu TakahashiBelum ada peringkat

- ESTA3042 OSCAR CASTRILLON - Ivan.gonzalez - Trabajo 2 2020 2Dokumen3 halamanESTA3042 OSCAR CASTRILLON - Ivan.gonzalez - Trabajo 2 2020 2ivan fonzalezBelum ada peringkat

- Groups PDFDokumen414 halamanGroups PDFArafat Hinju TzBelum ada peringkat

- Lesson 5 Chapter 4: Jointly Distributed Random Variables: Michael AkritasDokumen89 halamanLesson 5 Chapter 4: Jointly Distributed Random Variables: Michael AkritasnaveengargnsBelum ada peringkat

- Second Year Syllabus BCT IOE NepalDokumen20 halamanSecond Year Syllabus BCT IOE NepalrajeshkecBelum ada peringkat

- 1st Draft AlexanderDokumen20 halaman1st Draft AlexanderHassan MtenziBelum ada peringkat

- Business MathematicsDokumen384 halamanBusiness MathematicsRiya ChawlaBelum ada peringkat