Core-Less Motor

Diunggah oleh

Saurabh KumarJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Core-Less Motor

Diunggah oleh

Saurabh KumarHak Cipta:

Format Tersedia

A coreless motor Saurabh Kumar,12304EN004 M.Tech(MD) Sem-2,IIT BHU.

Iron loss due to ferromagnetic core. Torque pulsations due to non uniform magnetic field.

Moderate efficiency ( 70-80 %).

Low power density ( 131W/kg in IM and 222W/kg in SM)

PM motors has core accompanying the armature which

encounter a very high frequency flux cutting (frequency proportional to speed of motor), causing high eddy current loss . (as in PMDC). P= kf2 ( f=NP/120).

The maximum flux density encountered is around 0.6 T

which is not sufficient to create a high power density machine.

YES, we can do this with the help of Halbach array

A Halbach array is a special arrangement of permanent magnets

that augments the magnetic field on one side of the array while cancelling the field to near zero on the other side.

Fig1: Basic Process of Halbach Array generation.

Fig2: Flux density plot of NdFeB- (52MGOe) magnet

For rotary disc machine applications, this array can be

made in a circular form as shown below:

F ig3: Linear array

Fig4: Circular disc array

The field decreases somewhat where the ends of the magnet

array join on itself, but this decrease is not more than 5%.

The peak value of the magnetic flux density at the active

surface of Halbach array is given by :

For example: taking a medium grade NdFeB magnet ( Br= 1.25T, =262, nM=4, hM=0.006m, we get Bmo = 0.9T which is sufficient for a high power density machine.

Fig5: Exploded view of disc type PMBM

Fig6: Multidisc configuration

The tangential torque developed can be given by the

following equation:

There is a flexibility in controlling maximum possible torque

by controlling Dout and Din. However there is a mechanical limit up to which Dout can be increased. In this case we can go for multidisc arrangement.

Fig7: Speed torque characteristics similar to sync. motor

Operation wise it is similar to sync. Motor, so speed

below base speed is achieved by frequency control. Speed above the base speed can be achieved by flux weakening. Halbach discs give a static field. However discs can be nested, and by rotating one disc relative to the other, cancellation of the field and adjustment of the direction can be achieved. As the outside field of a disc is quite low, the relative rotation does not require big forces.

Fig8: Efficiency and PF as function of current

%=92.5,p.f.=0.94 (at rated current)

Power density is 82% higher (444.25 W/kg versus 243.55

W/kg)

High efficiency coreless disc-type PMBMs are excellent

machines for application where efficiency is the primary demand and high power density is required.

Some applications are:

Airborne apparatus (lightweight construction), solar powered vehicles, solar powered boats or even solar powered aircrafts. Single disk motors are used for servo drive systems.

Some torque pulsations due to quasi sinusoidal flux very

near to the array.

Fig9: Magnet Arc Shaping

Magnet Arc Shaping Technique (MAST) can be applied to solve the above-mentioned problem. In this technique, the Laplaces equation is used to determine the magnet shapes for producing the required flux distributions.

The experimental results, analysis and the FEM simulation

show the advantages of coreless disk type PMBMs in terms of performance and mass of active materials. A 10 kW coreless motor is about 45% lighter and has 82% higher power density than its laminated counterpart. Owing to lack of ferromagnetic cores, the hysteresis and eddy current losses do not exist. High cost of manufacturing limits commercial applications of coreless PMBMs to small size machines, special servo drives, airborne apparatus (lightweight construction) and drives where ripple free torque application is required.

The high cost of manufacturing is temporarily against the mass production of coreless motors.

[1.] J. C. Mallinson, One-sided Fluxes - A Magnetic Curiosity?, IEEE TRANSACTIONS ON MAGNETICS, VOL. MAG-9, NO. 4, DECEMBER 1973, PP. 678-682. [2.] Richard F Post, Hallback Array DC Motor/ Generator, Patent U. S. 5705902, Jan 6, 1998. [3.] Jacek F. Gieras Advancements in Electrical Machinery, 1st ed., Springer, Illinois, 2008. [4.]Jacek F. Gieras, Performance Analysis of a Coreless Permanent Magnet Brushless Motor Industry Applications Conference ,VOL 4., OCTOBER 2002, PP. 2477-2482. [5.] Jae-Seok Choi and Jeonghoon Yoo, Design of a Halbach Magnet Array Based on Optimization Techniques, IEEE TRANSACTIONS ON MAGNETICS, VOL.44, NO. 10, OCTOBER 2008, PP. 2361-2366. [6.]Min-Fu Hsieh and Yu-Sheng Hsu, An Investigation on Influence of Magnet Arc Shaping Upon Back Electromotive Force Waveforms for Design of PermanentMagnet Brushless Motors, IEEE TRANSACTIONS ON MAGNETICS, VOL.41, NO. 10, OCTOBER 2005, PP. 3949-3951. [7.] Video, Helios aircraft( NASA), http://www.youtube.com/watch?v=TlFlRURUW3k

Anda mungkin juga menyukai

- Introduction To Robotics: Phillip MckerrowDokumen1 halamanIntroduction To Robotics: Phillip MckerrowAsghar AmirBelum ada peringkat

- Nine Principles of Conscious LivingDokumen57 halamanNine Principles of Conscious LivingSreeraj Guruvayoor SBelum ada peringkat

- Literacy Lesson PlanDokumen5 halamanLiteracy Lesson Planapi-437974951Belum ada peringkat

- A New PetrolDokumen9 halamanA New PetrolMariano Escobar AvilaBelum ada peringkat

- 5 Physic Magnetic-Altair FluxDokumen185 halaman5 Physic Magnetic-Altair FluxhonghieutrBelum ada peringkat

- Synchronous Reluctance Motor PDFDokumen17 halamanSynchronous Reluctance Motor PDFVamsi Kattamuri100% (4)

- Average Synchronous Torque of Synchronous Machines, With Particular Reference To Reluctance MachinesDokumen3 halamanAverage Synchronous Torque of Synchronous Machines, With Particular Reference To Reluctance MachinesAbhishek AgarwalBelum ada peringkat

- Self Measures For Self-Esteem STATE SELF-ESTEEMDokumen4 halamanSelf Measures For Self-Esteem STATE SELF-ESTEEMAlina100% (1)

- Electric Powertrain: Energy Systems, Power Electronics and Drives for Hybrid, Electric and Fuel Cell VehiclesDari EverandElectric Powertrain: Energy Systems, Power Electronics and Drives for Hybrid, Electric and Fuel Cell VehiclesBelum ada peringkat

- ABB - General Purpose Motors Cast Iron - GB 092003Dokumen49 halamanABB - General Purpose Motors Cast Iron - GB 092003ivanjaviergutierrezoBelum ada peringkat

- Calculation of Cogging TorqueDokumen4 halamanCalculation of Cogging TorqueMehdi SepehriBelum ada peringkat

- Simscape Modeling RulesDokumen3 halamanSimscape Modeling Rulesstone kleverBelum ada peringkat

- End Winding Vibration Hydro GeneratorDokumen5 halamanEnd Winding Vibration Hydro Generatorpatel chandramaniBelum ada peringkat

- Implement Field-Oriented Control (FOC) Induction Motor Drive Model - SimulinkDokumen13 halamanImplement Field-Oriented Control (FOC) Induction Motor Drive Model - SimulinkRizkia PratamaBelum ada peringkat

- QuadCopter FlightDokumen60 halamanQuadCopter Flightasso2412100% (1)

- BLDC Brushless DC MotorDokumen22 halamanBLDC Brushless DC MotorNyn SoniBelum ada peringkat

- Cogging TorqueDokumen12 halamanCogging Torqueanil_nitkianBelum ada peringkat

- Unit 3 SRMDokumen66 halamanUnit 3 SRMDr SriBelum ada peringkat

- Non - InvoluteDokumen10 halamanNon - InvolutePushparaj VigneshBelum ada peringkat

- Superior StepMotorsDokumen36 halamanSuperior StepMotorsIVANBelum ada peringkat

- Motor WindingsDokumen12 halamanMotor WindingsAbiodun IloriBelum ada peringkat

- Analysis in AdamsDokumen5 halamanAnalysis in AdamsProduct DominixBelum ada peringkat

- Induction MotorDokumen39 halamanInduction MotorSaneer M SaliBelum ada peringkat

- Wound Rotor Motor TestingDokumen5 halamanWound Rotor Motor Testingbige1911Belum ada peringkat

- BLDC Motor Catalogue 15-01-2015Dokumen6 halamanBLDC Motor Catalogue 15-01-2015nitin9860Belum ada peringkat

- E3062 ProgrammingDokumen207 halamanE3062 ProgrammingAdron Lim100% (1)

- RotorDokumen1 halamanRotorIyunk MolkoBelum ada peringkat

- A Review of Structural and Thermal Analysis of Traction MotorsDokumen11 halamanA Review of Structural and Thermal Analysis of Traction MotorsGari PastranaBelum ada peringkat

- Speed Control of Switched Reluctance Motor-LibreDokumen9 halamanSpeed Control of Switched Reluctance Motor-LibreIndrajithSrBelum ada peringkat

- 101 Ways Extract Modal Parameters Which Is One Me PDFDokumen13 halaman101 Ways Extract Modal Parameters Which Is One Me PDFValentino de GeorgeBelum ada peringkat

- PMBLDC Motor DriveDokumen55 halamanPMBLDC Motor DriveSushant SinghBelum ada peringkat

- Grippers in Motion Rom PrelucrataDokumen187 halamanGrippers in Motion Rom PrelucrataTestBelum ada peringkat

- BLDC Motor: 4 Pole 2 Phase Motor OperationDokumen10 halamanBLDC Motor: 4 Pole 2 Phase Motor OperationG.R.AzhaguvelSaranya Professor MechanicalBelum ada peringkat

- Hysteresis MotorDokumen14 halamanHysteresis Motorcamming soon100% (1)

- Chapter 1Dokumen8 halamanChapter 1alexandraanastasiaBelum ada peringkat

- UltraCapacitors in Electric VehiclesDokumen7 halamanUltraCapacitors in Electric VehiclesShardulBelum ada peringkat

- Modeling and Analysis of 6 Phase Synchronous MotorDokumen14 halamanModeling and Analysis of 6 Phase Synchronous MotorArif IqbalBelum ada peringkat

- Simcenter SPEED: Rapid Electric Machine DesignDokumen48 halamanSimcenter SPEED: Rapid Electric Machine DesignTuna TaşkıntunaBelum ada peringkat

- Electrical Transient PDFDokumen6 halamanElectrical Transient PDFalexwoodwickBelum ada peringkat

- Principles of Electric Machines and Power Electronics Second Edition PDFDokumen184 halamanPrinciples of Electric Machines and Power Electronics Second Edition PDFDimas AriaBelum ada peringkat

- Sensorless Speed Control of Brushless DC Motor With Fuzzy Based EstimationDokumen7 halamanSensorless Speed Control of Brushless DC Motor With Fuzzy Based EstimationPhạm Văn TưởngBelum ada peringkat

- H2W Technologies BrochureDokumen32 halamanH2W Technologies BrochurenemzinhoBelum ada peringkat

- Low Voltage Motors Installation Operation Maintenance PDFDokumen184 halamanLow Voltage Motors Installation Operation Maintenance PDFMohamedAhmedFawzyBelum ada peringkat

- Control Quadrotor HelicopterDokumen184 halamanControl Quadrotor Helicopternhatthang299100% (1)

- Brushless DC MotorDokumen20 halamanBrushless DC Motorahxanraza100% (1)

- Wind Energy Generation Modelling and ControlDokumen8 halamanWind Energy Generation Modelling and Controljuniorj123Belum ada peringkat

- Flux & FluxMotor New Features 12.2Dokumen88 halamanFlux & FluxMotor New Features 12.2luis900000Belum ada peringkat

- Rotary Transformer With Ferrite Core For Brushless Excitation of Synchronous MachinesDokumen7 halamanRotary Transformer With Ferrite Core For Brushless Excitation of Synchronous MachinesHuong ThaoBelum ada peringkat

- As ISO 14649.1-2004 Industrial Automation Systems and Integration - Physical Device Control - Data Model ForDokumen8 halamanAs ISO 14649.1-2004 Industrial Automation Systems and Integration - Physical Device Control - Data Model ForSAI Global - APACBelum ada peringkat

- DC Motor LabviewDokumen23 halamanDC Motor Labviewsara_ogl7Belum ada peringkat

- Novel Dual-Excitation Permanent Magnet Vernier Machine: Akio Toba Thomas A. LipoDokumen6 halamanNovel Dual-Excitation Permanent Magnet Vernier Machine: Akio Toba Thomas A. LipoNenad Kostadinovic50% (2)

- Analysis of Permanent Magnet Synchronous MotorDokumen15 halamanAnalysis of Permanent Magnet Synchronous Motormalini72Belum ada peringkat

- Tuning of PID Controller Using Ziegler-Nichols Method For Speed Control of DC MotorDokumen6 halamanTuning of PID Controller Using Ziegler-Nichols Method For Speed Control of DC Motoreubis_machado4370Belum ada peringkat

- Power Electronics Converters and their Control for Renewable Energy ApplicationsDari EverandPower Electronics Converters and their Control for Renewable Energy ApplicationsArezki FekikBelum ada peringkat

- Introduction to Discrete Linear Controls: Theory and ApplicationDari EverandIntroduction to Discrete Linear Controls: Theory and ApplicationBelum ada peringkat

- Improved Indirect Power Control (IDPC) of Wind Energy Conversion Systems (WECS)Dari EverandImproved Indirect Power Control (IDPC) of Wind Energy Conversion Systems (WECS)Belum ada peringkat

- Design Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationDari EverandDesign Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationBelum ada peringkat

- Dynamics and Control of Robotic Manipulators with Contact and FrictionDari EverandDynamics and Control of Robotic Manipulators with Contact and FrictionBelum ada peringkat

- Micropower ElectronicsDari EverandMicropower ElectronicsEdward KeonjianBelum ada peringkat

- Aim & ObjectivesDokumen6 halamanAim & ObjectivesSaurabh KumarBelum ada peringkat

- Resonant Converter ProjectDokumen14 halamanResonant Converter ProjectSaurabh KumarBelum ada peringkat

- Role of Brushless DC Motors in Environmental ConservationDokumen6 halamanRole of Brushless DC Motors in Environmental ConservationSaurabh KumarBelum ada peringkat

- World Eyes Student PresentationDokumen12 halamanWorld Eyes Student PresentationSaurabh KumarBelum ada peringkat

- Cycloconverter EqvtDokumen10 halamanCycloconverter EqvtSaurabh KumarBelum ada peringkat

- Hand Gesture Automation of Electrical AppliancesDokumen3 halamanHand Gesture Automation of Electrical AppliancesSaurabh KumarBelum ada peringkat

- Torque Calculation of Hysteresis Motor Using Fem With - 2Dokumen26 halamanTorque Calculation of Hysteresis Motor Using Fem With - 2Saurabh KumarBelum ada peringkat

- Extra High Voltage AcDokumen535 halamanExtra High Voltage AcRachid HamianiBelum ada peringkat

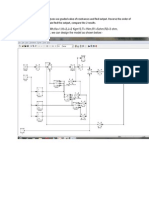

- Taking V 220v, La 10 MH, Ke 1, KT 2, J 2 KGM 2, TL 1Nm, R1 5ohm, R2 3 Ohm, R3 20hm, Ra 4ohm, B 0.4, We Can Design The Model As Shown BelowDokumen5 halamanTaking V 220v, La 10 MH, Ke 1, KT 2, J 2 KGM 2, TL 1Nm, R1 5ohm, R2 3 Ohm, R3 20hm, Ra 4ohm, B 0.4, We Can Design The Model As Shown BelowSaurabh KumarBelum ada peringkat

- AC Linear Induction MotorDokumen16 halamanAC Linear Induction MotorSaurabh KumarBelum ada peringkat

- German Short Stories For BeginnersDokumen82 halamanGerman Short Stories For BeginnersHùynh Ngọc DiễmBelum ada peringkat

- HvyyjbbDokumen128 halamanHvyyjbbAyashkanta RoutBelum ada peringkat

- (Intelligent Systems, Control and Automation_ Science and Engineering 72) B. S. Goh, W. J. Leong, K. L. Teo (Auth.), Honglei Xu, Xiangyu Wang (Eds.)-Optimization and Control Methods in Industrial EngiDokumen300 halaman(Intelligent Systems, Control and Automation_ Science and Engineering 72) B. S. Goh, W. J. Leong, K. L. Teo (Auth.), Honglei Xu, Xiangyu Wang (Eds.)-Optimization and Control Methods in Industrial EngiVu Duc TruongBelum ada peringkat

- ENFSIDokumen8 halamanENFSIkmrdBelum ada peringkat

- Deloitte IT Governance SurveyDokumen20 halamanDeloitte IT Governance Surveymrehan2k2Belum ada peringkat

- Alfred Nobel and The Nobel PrizesDokumen17 halamanAlfred Nobel and The Nobel PrizesElizabethDarcyBelum ada peringkat

- Traffic Analysis For Project San AntonioDokumen3 halamanTraffic Analysis For Project San AntonioLoraine AnnBelum ada peringkat

- Victor Vroom PresentaciónDokumen7 halamanVictor Vroom Presentaciónapi-3831590100% (1)

- UGET 2010 Engineering Cutoff RankDokumen5 halamanUGET 2010 Engineering Cutoff RankLokesh KumarBelum ada peringkat

- MGT602 Quiz 2 290411Dokumen8 halamanMGT602 Quiz 2 290411sonutilkBelum ada peringkat

- Week 9-1 - H0 and H1 (Updated)Dokumen11 halamanWeek 9-1 - H0 and H1 (Updated)Phan Hung SonBelum ada peringkat

- Visallo Brochure PDFDokumen2 halamanVisallo Brochure PDFchris jonasBelum ada peringkat

- Globalisation, Cosmopolitanism and EcologicalDokumen16 halamanGlobalisation, Cosmopolitanism and EcologicalRidhimaSoniBelum ada peringkat

- Younified LevelupDokumen9 halamanYounified LevelupMitesh NagpalBelum ada peringkat

- 5 HPHT API 6x - FowlerDokumen13 halaman5 HPHT API 6x - Fowlerchau nguyenBelum ada peringkat

- Bqs PDFDokumen14 halamanBqs PDFMiguel ColinaBelum ada peringkat

- Evermotion Archmodels Vol 40 PDFDokumen2 halamanEvermotion Archmodels Vol 40 PDFJustinBelum ada peringkat

- BTS Lesson Preparation FormDokumen1 halamanBTS Lesson Preparation FormTsz Shing WONGBelum ada peringkat

- Samsung CL21K3W PDFDokumen4 halamanSamsung CL21K3W PDFNelson Muñoz BautistaBelum ada peringkat

- Chapter 1 A CULINARY HISTORYDokumen10 halamanChapter 1 A CULINARY HISTORYMrinalini KrishnanBelum ada peringkat

- Ex 5308-Alexandra Thedeby-Heating and Cooling With Solar Powered Peltier ElementsDokumen93 halamanEx 5308-Alexandra Thedeby-Heating and Cooling With Solar Powered Peltier ElementsMohammad NaufalBelum ada peringkat

- Solutions ExercisesDokumen109 halamanSolutions ExercisesDBelum ada peringkat

- It (Cesec - Form 4 - 5) OutlineDokumen7 halamanIt (Cesec - Form 4 - 5) Outlineapi-287025606Belum ada peringkat

- Viltam User Manual enDokumen13 halamanViltam User Manual enszol888Belum ada peringkat

- Google Calendar Integrator - v2.0Dokumen21 halamanGoogle Calendar Integrator - v2.0Sumedh KakdeBelum ada peringkat

- Becoming A Rhetor - Adora CurryDokumen3 halamanBecoming A Rhetor - Adora CurryAdora CurryBelum ada peringkat

- Combination CircuitsDokumen6 halamanCombination CircuitsGordanPešićBelum ada peringkat