Package Substation

Diunggah oleh

Heera RamjiHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Package Substation

Diunggah oleh

Heera RamjiHak Cipta:

Format Tersedia

ADVANTAGES OF PACKAGE SUBSTATION

o AIM To Explain the Advantages and Disadvantages of proposed Package substation for G58 WTG in Place of Conventional outdoor DP Yard.

WHY PREFABRICATED SUBSTATIONS?

o Reliability: IEC 62271-202 Complaint Substations

That mean resistance to the Temperature Rise, Humidity, Pollution, etc. Equipment Life Span Service Continuity Public and Operator Safety

o Quality and Standardization

Definition of LV/MV substation design including the right components solution to fit to the standards Since factory assembled and tested, Product will fit to the needs of quality and standards Control of Quality shall be maintained at all levels.

Single line diagram of proposed Package Substation

GENERAL ARRANGEMENT

GENERAL ADVANTAGES

PACKAGE SUBSTATION

CONVENTIONAL SYSTEM

o o o o o o

Compact and Safety superior. Aesthetically superior. Fully compartmentalized no accidental access to the live parts. Transportable and Ready to install. Minimal Maintenance EB metering, The CT & PT can be housed in a separate cubicle with tamper proof sealing arrangement

LIGHTINING ARRESTOR Conventional System Package Substation

LIGHTINING ARRESTOR

Conventional System

Package Substation

Conventional System

Package Substation

Made up of porcelain

Lighter in weight almost 90% of weigh is reduced

Heavy and it is hard to handling Easy handling

Could have hidden defects that are hard to detect

Vandalism is common Pin erosion and coupling hardware corrosion

Better performance in high contamination area

Better handling of shock loads

Cement growth cracking

more resistant to vandalism

Weaker in tension

Stronger in tension

PROTECTION IN CONVENTIONAL SYSTEMS

AB SWITCH / ISOLATOR

Since the Fabrication is done is site, the alignment won't be that precise

Number of accessories are involved so it is hard to have a spares

Work at height is involved

Closing and Opening are mostly depends on the Operator physical strength

PROTECTION IN CONVENTIONAL SYSTEMS

HORN GAP FUSE

The reaction time to blown the fuse during the fault is relatively slow when compared to VCB

Once the fuse is blown it is hard to detect

At the time of replacing the blown fuse, work at height is involved, so extra safety measures to be taken

PROTECTION IN PACKAGE SUBSTATION

MV SWITCH GEAR Hence it is a factory made there will not be any alignment problem Self powered relay are used to trip the circuit

In case of fault the fault circuit is isolated by tripping VCB rapidly

MV switch gear has a disconnector switch which can be connected to earth at the time of service

Since it is a factory made the standard quality of the materials can be obtained Maintaing inventory is quite easy

BUS BAR ARRANGEMENT IN CONVENTIONAL SYSTEM

BUS ARRANGEMENT -ACSR CONDUCTOR Since there is more no of terminals and joints the voltage drop is high Hence it is exposed to atmospheric condition easily contaminated by rust

Having risk of working at height Having risk of external faults Possible of having accidental access to the live parts

BUS BAR ARRANGEMENT IN PACKAGE SUBSTATION

BUS BAR ARRANGEMENT - PACKAGE SUBSTATION

Electrical connections are done by the cable and the Aluminium bus, so voltage drop is minimized Hence it is in a cubicle the atmospheric condition may not affect

External faults wont take place Accidental access to the live parts are avoided

Personnel safety is assured

MEASURING CTPT- CONVENTIONAL SYSTEM

MEASURING CTPT- CONVENTIONAL SYSTEM

Since it is a oil type, there is a chance of oil leakage

Possible of danger of fire and explosion

Possible of External Fault (Ex. Bird Fault)

MEASURING CTPT- PACKAGE SUBSTATION

MEASURING CTPT- PACKAGE SUBSTATION

Its a dry type transformer, the life time of the CTPT is longer

Provides Excellent mechanical and short ciruit strength

Less Weight and easy to handle

No danger of fire explosion

COMPARISON BETWEEN PACKAGE SUBSTATION AND CONVENTIONAL SYSTEM

D E S C R IP T IO N 1 Erectio n time P A C KA G E S UB S T A T IO N < 2 ho urs C O N V E N T IO N A L O UT D O O R D P Y A R D 7 to 1 days 5 A s the co ntracto r is buying mo st o f the materials, very difficult to co ntro l quality and also mo re no o f accesso ries and hardwares are invo lved Since all are fabricated at site, no . o f days, no . o f labo urs and fabricatio n to o ls invo lved are mo re and hence wo rkmenship will no t be as go o d as P SS Fabricatio n and wo rking at height is invo lved High expo sure will be po o r, since do ne with "0" gauge co pper with lo cally purchased lugs and co nnecto rs difficult mo re - as all activities are at site high (1 mtrs X 9 mtrs) 2 easy as o nly fencing is available

2 Quality o f the materials

A ll materials are o f reputed make Since it is facto ry made cubicle with skilled labo urs, wo rkmenship will be go o d P erso nnel safety will be go o d as there is no fabricatio n and wo rking at height risks are invo lved No expo sure as it is metal enclo sed will be go o d as it invo lves cables and alumnium bus bars with pro per terminatio n simple almo st zero as it is prefabricated less (4 mtrs X 3.5 mtrs) difficult as it is metal enclo sed

3 Wo rkmenship 4 P erso nnel Safety at site Expo sure to external lighting, bird faults and 5 dusty,humid and mo isturo us enivo rment 6 7 8 9 1 0 Equipment interco nnectio n M aintenance and o peratio n P ending po ints Space requirement Tresspassing

1 Civil wo rks invo lved 1

1 A dditio nal civil wo rks fo r lo w lying area 2 1 High temperature, high humid and high dust area 3 1 Equipment earthing system 4 1 Sto rage at site 5 Co st o f Transpo rtatio n 1 6 Crane requirement 1 7

invo lves co ncreting fo r all the po les,transfo rmer, metering bo x, fencing, gate and flo o r co ncreting / metal spreading A dditio nal retaining wall with increased height to match gro und level and backfilling the same with so il fo r who le very less (o nly pillar height with additio nal reinfo rcement ) yard area Fo r co astal area - o nly anti co rro sio n painting to be In additio n to GI structures, equipments with higher do ne. No mo dificatio n in equipment specificatio ns creepage to be installed will be go o d as prefabricated and do ne with skilled mo re no . o f jo ints and po o r welding is po ssible, since do ne labo urs at site with unskilled labo urs Needs mo re space o n co ntracto rs sco pe High ( invo lves transpo rtatio n fro m facto ry to site yard, Co ntracto rs sco pe yard to lo catio n) Crane is required fo r unlo ading and lo ading at yard and o nly hydra fo r transfo rmer unlo ading and lo ading at yard erectio n at lo catio n and erectio n at lo catio n very less (o nly fo ur pillars after P CC)

THANK YOU

Anda mungkin juga menyukai

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsDari EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsBelum ada peringkat

- Solar Generations Impact On Fault CurrentDokumen32 halamanSolar Generations Impact On Fault CurrentchintanpBelum ada peringkat

- D2.07 Non Segregated Phase Bus DuctsDokumen3 halamanD2.07 Non Segregated Phase Bus DuctsSaraswatapalitBelum ada peringkat

- Clock Spring BrochureDokumen63 halamanClock Spring BrochureJomer J Simpson100% (1)

- Technical Specification Clamp Nut BoltDokumen20 halamanTechnical Specification Clamp Nut Boltpiyush_123456789Belum ada peringkat

- Calculating Financial Impact of Lean Six Sigma ProjectsDokumen4 halamanCalculating Financial Impact of Lean Six Sigma ProjectskbobhateBelum ada peringkat

- BOQ in GeneralDokumen9 halamanBOQ in Generalkmmansaf100% (1)

- Type of Drawout PDFDokumen58 halamanType of Drawout PDFrantaroBelum ada peringkat

- System Substation BatteryDokumen15 halamanSystem Substation BatteryCarlos Martinez100% (1)

- Technical Offer For 11kv Sm6 SwitchgearDokumen6 halamanTechnical Offer For 11kv Sm6 SwitchgeardmugalloyBelum ada peringkat

- IEC Standard For Low-Voltage Switchgear & Bus Trunking SystemDokumen27 halamanIEC Standard For Low-Voltage Switchgear & Bus Trunking SystemYasser FathiBelum ada peringkat

- Class PSDokumen9 halamanClass PSAdeel RazaBelum ada peringkat

- Sepam 10 Seped307026en Int PDFDokumen22 halamanSepam 10 Seped307026en Int PDFJeffrey Reynaldo RidwanBelum ada peringkat

- Substation Lightning Protection and Earthing PDFDokumen8 halamanSubstation Lightning Protection and Earthing PDFPritam100% (1)

- Reduced Series ReactorDokumen10 halamanReduced Series ReactorclicknagpalBelum ada peringkat

- Power System Harmonics Presentation: Sources, Effects and MitigationDokumen41 halamanPower System Harmonics Presentation: Sources, Effects and MitigationTalha MehmoodBelum ada peringkat

- Voltage Drop and Circuit Sizing CalculatorsDokumen5 halamanVoltage Drop and Circuit Sizing Calculatorsdarsh2001patelBelum ada peringkat

- 11kV SF6Dokumen6 halaman11kV SF6ahmadgce04Belum ada peringkat

- Cast Resin Transformer: Specification For ApproveDokumen6 halamanCast Resin Transformer: Specification For ApprovetuibidienBelum ada peringkat

- Battery CalculationDokumen6 halamanBattery CalculationantleBelum ada peringkat

- Selection of Surge Protective Device (SPD) - (Part 1)Dokumen5 halamanSelection of Surge Protective Device (SPD) - (Part 1)supermannonBelum ada peringkat

- Approved - Type Test Validity Guidelines PDFDokumen12 halamanApproved - Type Test Validity Guidelines PDFKiran VittalraoBelum ada peringkat

- Installation and commissioning of Serveron make Transformer online DGA monitorDokumen3 halamanInstallation and commissioning of Serveron make Transformer online DGA monitorcrazy devilBelum ada peringkat

- TESP11925R156Dokumen17 halamanTESP11925R156Osama WaheedBelum ada peringkat

- Fault Current CalculationDokumen3 halamanFault Current CalculationfarhanajnBelum ada peringkat

- HV Pressure Tests Document SummaryDokumen4 halamanHV Pressure Tests Document SummaryssBelum ada peringkat

- Basic Insulation LevelpdfDokumen2 halamanBasic Insulation LevelpdfsimplekumariBelum ada peringkat

- Current TransformerDokumen21 halamanCurrent Transformerbalaeee123Belum ada peringkat

- Transformer OilDokumen1 halamanTransformer Oilswagata12345Belum ada peringkat

- High Voltage Components PresentationsDokumen28 halamanHigh Voltage Components Presentationschristian fruto100% (1)

- Off Load Tap Changer - Part 1Dokumen20 halamanOff Load Tap Changer - Part 1Moncoz Aye100% (3)

- Erdc D0007Dokumen11 halamanErdc D0007Zaks MoreBelum ada peringkat

- BIL Levels For Switchgear - Siemens Tech Topics Rev 0Dokumen2 halamanBIL Levels For Switchgear - Siemens Tech Topics Rev 0Peter DyckBelum ada peringkat

- Surge ArresterDokumen17 halamanSurge ArrestermoosuhaibBelum ada peringkat

- Chapter1. Electrical Installations Standards and RegulationsDokumen29 halamanChapter1. Electrical Installations Standards and RegulationsHashem ZohbiBelum ada peringkat

- 6 400KV CB PirDokumen36 halaman6 400KV CB PirRAPRATSINBelum ada peringkat

- 11KV VCBDokumen3 halaman11KV VCBeagles1109Belum ada peringkat

- IEEE Color Book IndexDokumen1 halamanIEEE Color Book IndexAbhyuday GhoshBelum ada peringkat

- Types and Applications of Overcurrent Relay Part 1Dokumen10 halamanTypes and Applications of Overcurrent Relay Part 1carlos vidalBelum ada peringkat

- Design and Assembly of an Automatic Power Factor Correction Electrical PanelDokumen4 halamanDesign and Assembly of an Automatic Power Factor Correction Electrical PanelqxzyBelum ada peringkat

- Transformer SizingDokumen15 halamanTransformer SizingRaj100% (1)

- Design Guide FOR Distribution System PlanningDokumen19 halamanDesign Guide FOR Distribution System Planningdhairyashil_dspBelum ada peringkat

- Performance Availability GuaranteeDokumen28 halamanPerformance Availability GuaranteeOmar GutierrezBelum ada peringkat

- Circuit Breaker SpecificationDokumen60 halamanCircuit Breaker SpecificationYash YadavBelum ada peringkat

- GIS PresentationDokumen16 halamanGIS PresentationShubham Srivastava100% (1)

- Directional Overcurrent RelayingDokumen23 halamanDirectional Overcurrent RelayingTamjid KabirBelum ada peringkat

- Vrla Battery Data Sheet18042018 PDFDokumen12 halamanVrla Battery Data Sheet18042018 PDFSatyapriya OjhaBelum ada peringkat

- EarthingDokumen87 halamanEarthingAkhil Gangwar100% (1)

- P 3 U 30Dokumen120 halamanP 3 U 30ArcoolBelum ada peringkat

- PLCC Tech SpecsDokumen42 halamanPLCC Tech Specsevonik123456Belum ada peringkat

- MG Transformers and Packaged Substations TX5299.V2Dokumen20 halamanMG Transformers and Packaged Substations TX5299.V2engnajeeb75Belum ada peringkat

- PTS-20WM319 06 Commissioning TestsDokumen8 halamanPTS-20WM319 06 Commissioning TestsDurgaprasad RyaliBelum ada peringkat

- Sizing Circuit BreakerDokumen4 halamanSizing Circuit BreakerArnold CabadingBelum ada peringkat

- Condition Monitoring of Instrument Transformers - POWERGRID ExperienceDokumen36 halamanCondition Monitoring of Instrument Transformers - POWERGRID ExperiencebcqbaoBelum ada peringkat

- LV Relay SettingDokumen12 halamanLV Relay SettingRatheesh KumarBelum ada peringkat

- 850 KVAR 400v.doc - 400V Capacitor Bank - SpecDokumen10 halaman850 KVAR 400v.doc - 400V Capacitor Bank - Specdeepthik27Belum ada peringkat

- Cable Editor Overview Guide in 40 CharactersDokumen77 halamanCable Editor Overview Guide in 40 CharactersMichael BesaBelum ada peringkat

- Relay and Multifunctional Substation Test System: Sverker 900Dokumen12 halamanRelay and Multifunctional Substation Test System: Sverker 900Stelvio QuizolaBelum ada peringkat

- Outdoor Type Package SubstationDokumen41 halamanOutdoor Type Package Substationapjbalamurugan100% (1)

- Knowledge is "Real Power": Introduction to Power QualityDari EverandKnowledge is "Real Power": Introduction to Power QualityBelum ada peringkat

- Sop Magnesium Anode Installation - ThiessDokumen10 halamanSop Magnesium Anode Installation - ThiessbonnicoBelum ada peringkat

- Learning & Implementation AGLDokumen13 halamanLearning & Implementation AGLDurgaprasad NilamBelum ada peringkat

- Draft Mitigations - Issues For Clarification - 21 Jun 2020Dokumen4 halamanDraft Mitigations - Issues For Clarification - 21 Jun 2020Heera RamjiBelum ada peringkat

- 10MW Solar - Bhel Tech. Specification PDFDokumen217 halaman10MW Solar - Bhel Tech. Specification PDFHeera RamjiBelum ada peringkat

- PE Application Rev 4Dokumen12 halamanPE Application Rev 4Heera RamjiBelum ada peringkat

- Load Loss Capitalisation FactorDokumen5 halamanLoad Loss Capitalisation FactorHeera RamjiBelum ada peringkat

- Vasanthkumar CVDokumen4 halamanVasanthkumar CVHeera RamjiBelum ada peringkat

- (WWW - Entrance-Exam - Net) - Parttime Colleges in BangaloreDokumen8 halaman(WWW - Entrance-Exam - Net) - Parttime Colleges in BangaloreManivasaham ThiruBelum ada peringkat

- IntPE Application FormDokumen9 halamanIntPE Application FormHeera RamjiBelum ada peringkat

- P444: 132kV Line Bay Protection and MeteringDokumen5 halamanP444: 132kV Line Bay Protection and MeteringHeera RamjiBelum ada peringkat

- Engineer's 12-Year Renewable Energy ExperienceDokumen4 halamanEngineer's 12-Year Renewable Energy ExperienceHeera RamjiBelum ada peringkat

- 15mw Key SLDDokumen1 halaman15mw Key SLDHeera RamjiBelum ada peringkat

- Substation Details Dec-12Dokumen151 halamanSubstation Details Dec-12RajeshYadavBelum ada peringkat

- 1 AL59 Dog To AL59 Dog (4534)Dokumen1 halaman1 AL59 Dog To AL59 Dog (4534)Heera RamjiBelum ada peringkat

- HOME LOANS FLOATING RATESDokumen2 halamanHOME LOANS FLOATING RATESHeera RamjiBelum ada peringkat

- 10MW Solar - Bhel Tech. Specification PDFDokumen217 halaman10MW Solar - Bhel Tech. Specification PDFHeera RamjiBelum ada peringkat

- Business Development Resume - RenewableDokumen3 halamanBusiness Development Resume - RenewableHeera RamjiBelum ada peringkat

- DHBVN PDFDokumen2 halamanDHBVN PDFHeera RamjiBelum ada peringkat

- 8 Weeks Training Program On Solar TechnologyDokumen10 halaman8 Weeks Training Program On Solar TechnologyRaktima MisraBelum ada peringkat

- BatteriesDokumen21 halamanBatteriesHeera RamjiBelum ada peringkat

- 8 Weeks Training Program On Solar TechnologyDokumen10 halaman8 Weeks Training Program On Solar TechnologyRaktima MisraBelum ada peringkat

- BalancPayRecpt ARN 116594Dokumen1 halamanBalancPayRecpt ARN 116594Heera RamjiBelum ada peringkat

- Solar Technologies Upcoming - InnovationsDokumen5 halamanSolar Technologies Upcoming - InnovationsHeera RamjiBelum ada peringkat

- MED Complete ListDokumen126 halamanMED Complete ListprakashsahooBelum ada peringkat

- Loss Factor ConsultationDokumen59 halamanLoss Factor ConsultationHeera RamjiBelum ada peringkat

- Pvsyst 5Dokumen219 halamanPvsyst 5nexarsolarBelum ada peringkat

- Master Ceramico OX - English - Rev-DDokumen2 halamanMaster Ceramico OX - English - Rev-DfaniaaaBelum ada peringkat

- Conditions of Sale: EPD FORM 8-21-01Dokumen97 halamanConditions of Sale: EPD FORM 8-21-01Sabina BanegasBelum ada peringkat

- Cabletrunking - MultipleDokumen13 halamanCabletrunking - MultipleHassan FarazBelum ada peringkat

- Mechanical and Tribological Performance of Aluminium Metal Matrix CompositesDokumen27 halamanMechanical and Tribological Performance of Aluminium Metal Matrix CompositesPradeepkumar SamanthulaBelum ada peringkat

- Bearing Detail PDFDokumen1.152 halamanBearing Detail PDFJayesh MachhiBelum ada peringkat

- Section (1) : 1. With Respect To Loading Timber Cargo in Question A) Explain Under What Circumstances, Vessel Is Able To Load To Lumber Load LinesDokumen6 halamanSection (1) : 1. With Respect To Loading Timber Cargo in Question A) Explain Under What Circumstances, Vessel Is Able To Load To Lumber Load Linescanigetaccess100% (1)

- The Military Simulation, Modelling, and Virtual Training Market 2013-2023Dokumen28 halamanThe Military Simulation, Modelling, and Virtual Training Market 2013-2023VisiongainGlobal100% (1)

- Project Completion, Handover and Operations GuideDokumen11 halamanProject Completion, Handover and Operations GuideJustine Sheinna SebleroBelum ada peringkat

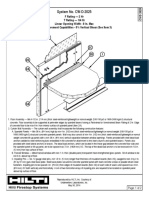

- System No. CW-D-2025: Linear Opening Width - 8 In. Max Class II Movement Capabilities - 5% Vertical Shear (See Item 3)Dokumen2 halamanSystem No. CW-D-2025: Linear Opening Width - 8 In. Max Class II Movement Capabilities - 5% Vertical Shear (See Item 3)aBelum ada peringkat

- HUDA Policy Allowing Four BasementsDokumen3 halamanHUDA Policy Allowing Four BasementsRahul JindalBelum ada peringkat

- JBT GreenDokumen3 halamanJBT GreenRagu VenkatBelum ada peringkat

- X Ce Series Catalog PagesDokumen15 halamanX Ce Series Catalog PagessourcBelum ada peringkat

- Inventory ControlDokumen4 halamanInventory ControlabassalishahBelum ada peringkat

- Salesforce API ConsoleDokumen197 halamanSalesforce API ConsoleAlbert TestersBelum ada peringkat

- As 2359.2-1985 Industrial Trucks (Known As The SAA Industrial Truck Code) OperationDokumen9 halamanAs 2359.2-1985 Industrial Trucks (Known As The SAA Industrial Truck Code) OperationSAI Global - APAC0% (1)

- Scrum Online Quiz - Testing ExcellenceDokumen16 halamanScrum Online Quiz - Testing ExcellenceKRISHNAPRIYABelum ada peringkat

- Vertex Payroll Tax Q Series Integration With Oracle Fusion HCMDokumen2 halamanVertex Payroll Tax Q Series Integration With Oracle Fusion HCMsam22nowBelum ada peringkat

- Bek MDPDokumen43 halamanBek MDPluisgalo91143Belum ada peringkat

- HSE-FRM-021-01 - Rev. 00 - General Permit To WorkDokumen2 halamanHSE-FRM-021-01 - Rev. 00 - General Permit To Workmalikshoaib8528Belum ada peringkat

- Practice-1 defining calendarsDokumen5 halamanPractice-1 defining calendarspramod nagmotiBelum ada peringkat

- Plaxis QuatationDokumen3 halamanPlaxis Quatationraaji2002Belum ada peringkat

- Sample Theme Presentation For 30th Ala MayarDokumen12 halamanSample Theme Presentation For 30th Ala Mayarhermain khanBelum ada peringkat

- RecordManager User GuideDokumen96 halamanRecordManager User GuidemandapatiBelum ada peringkat

- Assembly Manual For50ccDokumen42 halamanAssembly Manual For50ccfRANCBelum ada peringkat

- EstimateDokumen6 halamanEstimateSansar PanchalBelum ada peringkat

- LMC Tablosu-AirbusDokumen1 halamanLMC Tablosu-AirbusefilefilBelum ada peringkat

- Human Factors EngineeringDokumen54 halamanHuman Factors Engineeringganeshrams88Belum ada peringkat