Structural design and analysis of a low-rise building

Diunggah oleh

Mohammed SumerDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Structural design and analysis of a low-rise building

Diunggah oleh

Mohammed SumerHak Cipta:

Format Tersedia

Supervised by : Dr.

Khaled El-Sawy

ID# Name

200303838 Saeed Mohammad Al Kaabi

200304178 Ahmed Obaid Al Dhaheri

200303853 Mohammad Owais AL Daraei

200303840 Ahmed Abdullah Al Braiki

United Arab Emirates University

College of Engineering

Department of Civil and Environmental Engineering

Industrial Training & Graduation Projects

-Introduction

-Structural design of :

o Slabs

o Beams

o Stairs

o Columns

o Tie-beams

o Footing

-Environmental, Financial, and Social Impact

-Conclusion

.f

c

` Compressive strength of concrete = 28MPa

.f

y

Yielding strength of steel = 420 MPa

.I

g

Moment of inertia

.A

g

Area gross

.I

e

Effective moment of inertia

.w

u

Ultimate weight

.V

u

Ultimate shear

.M

u

Ultimate bending moment

.M

cr

Cracking moment

.I

cr

Cracking moment of inertia

.K Effective length factor

.E

c

Elasticity of concrete

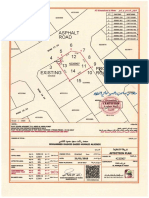

The considered low-rise building consists of three blocks

The Majles and Kitchen were designed in GP-I

The Villa is designed in GP-II

The slabs, beams, columns, tie- beams, stairs and footings are

structurally designed.

This structural design in project followed the ACI-318-02M code.

Prokon, AutoCAD and Excel sheets are used in the design.

Project area = 903 m

2

Each floor area of villa

Ground floor = 338 m

2

First floor = 261 m

2

Each floor consist of several bedrooms, sitting rooms,

family hall

Kitchen in ground floor

What is structural design?

It is finding concrete dimensions and reinforcing steel areas of each

structural element with insurance of safety and serviceability of the

member.

Before designing :

Type of the structural element (i.e., beam, column etc)

The loads carried by the member

The architectural limitations on the member dimensions

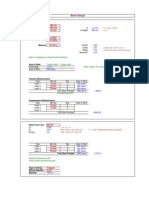

Figure 2:

Architectural plan for first floor.

Figure 1:

Architectural plan for ground floor.

Figure 3:Typical structural elements

it is one way

blocks and solid part for R1:

5.3m

5.2m

2 >

short

long

L

L

0.3m

0.43m

n

b

=22

n

r

=7

Width of Rib 0.2m

Width of Block 0.38m

No. of Ribs n

r

7

No. of Blocks along Ls n

b

22

Width of Solid part S

1

0.43m

Width of Solid part along Ls (S

2

) 0.3m

L 5.3m

Ls 5.2m

m

kN

8.104 0.58) 1.7(2 1.4(4.28) 1.7(L.L) 1.4(D.L) w

u

= + = + =

Load Calculation

160 160 160 420

420

380 200 380 200

Block

Rib

300

60

Dimensions in mm

cover) (floor block) of (weight rib) of (weight slab) top of (weight D.L + + + =

m

kN

4.38 0.58) (2 0.2) (5 25) 1 0.3

2

0.2 0.16

( 25) 1 0.58 (0.06 D.L = + +

+

+ =

Figure 4: Drawing for ribbed slab (R1)

Figure 5: Binding moment diagram for R1

Bending Moment for Simply Supported Rib R1

Length (m)

Bending moment

(kN.mm)

Figure 6: Required steel area for R1

Area of steel is 252mm

2

(2#13)

Steel Area R1

Length (m)

Steel Area

(mm

2

)

Shear design for R1

Length (m)

Shear Force

(kN.mm)

Figure 7: Shear diagram for R1

From PROKON software (Vu = 21.1 kn)

stirrups need

2

V

V

20.24KN,

2

0.85x47.6

2

V

c

u

c

>

= =

22.78kN

0.85

0.85(47.6) 21.1

V V

V

c u

s

=

=

mm

V

d f A

S

s

y v

450 434

22780

300 420 5 . 78

~ =

= =

S w c s

V kN d b f V > = = = 4 . 190 300 180 28

3

2

3

2

max ,

kN 6 . 7 4 300 180 28

6

1

d b f

6

1

V

w c c

= = =

From PROKON software (Vu = 21.1 kN)

#10@150mm choose

150mm S

994mm

180

3x2x71x420

b

f 3A

150mm 0.5(300) 0.5d

600mm

of smallest S

max

w

y v

max

=

(

(

(

(

(

(

= =

= = =

95.25kN 300 180 28

3

1

d b f

3

1

V

w c s

= = s

22.78kN V

s

=

mm S 450 =

2#13

2#10

#10@150mm

Check Deflection for R1

Simply supported beam

Minimum thickness of R1 = L/16 = 5.2/16=0.325 m

The actual thickness of R1= 0.36 m > 0.325

It is acceptable

Steel Arrangement

Figure 6:

Final drawing for ribbed slab (R1)

77.112kN/m 8.26 1.7 45.05 1.4 1.7W 1.4W W

8.26kN/m W

45.05kN/m 10.5 3 3 28.55

W W O.W reaction) (from W W

kN/m. 10.5 3.5 3 h 3kN/m W

3kN/m 25 0.3 (0.2x2) W

kN/m. 3 0.2 0.6 25 b h O.W

8.26kN/m

0.58

2.72 2.07

0.58

R

reaction) rib (from W

28.55kN/m

0.58

7.15 9.41

0.58

R

reaction) rib (from W

L D u

L.L

D(wall) part solid beam D D.Total

2

D.L(Wall)

part Soild

beam

L.L

L.L

D.L

D.L

= + = + =

=

= + + + =

+ + + =

= = =

= =

= = =

=

+

= =

=

+

= =

Beam : DB5

20cm

350cm

Solid

part

Solid

part

20cm

20cm

20cm

Beam

30cm

30cm

Wall

Steel arrangement

Figure 7: Drawing of DB5

Figure 8: The stair design.

Slope of the stairs

1

28.98

380

210

tan = =

Length of the stair

Thickness to control deflection

4.342m = 1 . 2 3.8 = L

2 2

+

mm mm

L

h 300 272

20

1100 4342

20

min

~ =

+

= =

Load calculation for the stair

2.8kN/m 1.4 2 w

/ 1 . 16 5 . 10 8 . 2 8 . 2 w

/ 8 . 2 4 . 1 2 w

/ 8 . 2 25 08 . 0 4 . 1 w

/ 5 . 10 25 3 . 0 4 . 1 o.w

Liveload

L D.

cover floor

step

slab

total

= =

= + + =

= =

= = =

= = =

m kN

m kN

m kN h b

m kN h b

stair

beam

m kN L L w

m kN L D w

/ 8 . 2 .

/ 4 . 18

cos

1 . 16

.

2

1

= =

= = =

u

Length (m)

Bending moment

(kN.mm)

Length (m)

Area of steel (mm

2

)

From Prokon A

s

=1270mm

2

should be between A

s, min

and A

s

,

max

A

smin

= 0.0033*1400*230=1062.6 mm

2

A

s,max

= 0.02125*1400*230=6842.5 mm

2

, A

smin

< A

s

< A

smax so we

will use 7 bars diameter 16

0.02125

420 600

600

420

28 0.85 0.85

0.75

f 600

600

f

` f` 0.85

(0.75)

0.0033

0.00315

420 4

28

0.0033

420

1.4

4f

f

f

1.4

of greater

y y

c

max

y

c

y

min

1

=

|

.

|

\

|

+

=

|

|

.

|

\

|

+

=

=

(

(

(

(

=

=

(

(

(

(

(

=

Length (m)

V (kN)

Length (m)

A

s

(mm

2

/mm)

Shear design

stirrups for need no so kN

V

V

kN d b

f

V

KN V

c

u

w

c

c

u

, 7 . 120

2

4 . 241 10 230 1400

6

28

85 . 0

6

'

82 . 70

3

= <

= = =

=

|

| |

stirrups f or need no so kN

V

V

kN d b

f

V

kN V

c

u

w

c

c

u

, 4 . 157

2

8 . 314 10 300 1400

6

28

85 . 0

6

'

86

3

= <

= = =

=

|

| |

mm h S

S than less be should mm spacing

900 300 3 3

200

7

1400

max

max

= = =

= =

Figure 9

The drawing for the stair.

Column (C1)

2 12

d

g c

L D

D

d

4 9

3 3

g

u

c u

3

N.mm 8.33x10

1

/2.5 I E

EI

0.88

P

P

buckling Check

19.58kN x4.35 0.3x0.6x25 Weight Own

mm 1.35x10

12

600x300

12

bh

I

968kN P

0.09m 0.3x0.3 0.3h r

29000MPa E 4.35m, l , kN/m 25

600mm x 300mm is section cross column Assume

frame unbraced 1.5, K Assume

=

+

=

= =

= =

= = =

=

= = =

= = =

=

+

Column (C1)

1.51 K : figure(9) Using

2.78

EI/l

EI/l

1.08

EI/l

EI/l

beam n

column u

B

beam n

column u

A

=

= =

= =

72.02kN.m hP

h

e

M

0.08 0.03

0.3

0.015

h

e

3.1

P /0.75 P 1

1

N 10 19.06

) (Kl

EI

P

u s u

c u

s

5

2

u

2

c

= =

= + =

=

=

= =

Figure 10

Effective length factor K

Column (C1)

300mm spacing tie Then

300mm

456mm

300mm

305.6mm

of smallest ties of Spacing

#10 is size tie Then

19) # 7 (choose

1800mm 600 300 0.01 A A

0.01 use

0.78Ksi 89 5.38MPa/6.

0.6 0.3

968

A

P

0.2Ksi 89 1.33MPa/6.

3 0.3x0.6x0.

72.02

h A

M

2

g s

min

g

u

g

u

=

=

(

(

(

=

= = =

=

= =

=

= = =

Figure 11

Interaction Diagram

Figure 12:

The drawing for the column C1.

Tie-beam (TB1)

The longest tie beam is TB1 which has a length of 7m

which was designed as the critical case. Then, compared

with the minimum steel area and take the biggest area of

steel:-

In practice, A

s,min

should be greater than the area of steel in

a column that can enough to resist at least 10% of the

heavily loaded column load (maximum load is 968 kn)

In practice A

s,min

> 0.5 % A

concrete of tie beam x-sec

Length (m)

M (kN.mm)

Length (m)

V (kN)

Figure 13: Moment diagram and shear diagram for TB1.

For TB1 , A

s

=573 mm

2

which is (3 # 16) and compare it with:

10% of the column load (maximum load is 968 kN)

1- A

s,min

=(10% P

u

) / (0.9 F

y

) =0.1 968 1000 / 0.9 420 = 256 mm

2

(2 # 13)

All the tie beams have a cross-section 20cm x 60cm

2- A

s,min

= 0.5 % A

concrete

= 0.005 200 600 = 600mm

2

(3 # 16)

So, the biggest area is 3 # 16.

For shear (stirrups):

max s, s

w c max s,

sv s

sv

V V 395.1kN

560 200 28

3

2

d b f

3

2

V

1 Check

kN 38.5728 0.164 420 560

A fy d V Find,

957mm

0.164

78.5 2

S So,

S

As n

fy d

Vs

0.164 A

< =

= =

= =

=

=

= =

#10@280mm choose

S S

280mm S

989.1mm

b

f 3A

280mm 0.5d

600mm

of smallest S

197.6kN 560 200 28

3

1

d b f

3

1

V

2 Check

max

max

w

y v

max

w c s

>

=

|

|

|

|

|

|

.

|

\

|

=

= =

= = s

Footing (F1)

94.8kN 20.2 26 48.6 TB1) (from P P

291kN 40 251 B11) (from P P

253.5kN 35.5 218 HB10) (from P P

L D

L D

L D

= + + = +

= + = +

= + = +

( ) 2.2m 2.2m Choose 4.69m

150

63.93 639.3

A

63.93kN ) P (P 0.1 P Assume

A capacity bearing P P P

639.3kN3 94.8 291 253.5 P P

150kN/m 1.5Kg/cm capacity Bearing

F1

2

footing

L D extra

footing extra L D

L D

2 2

=

+

=

= + =

= + +

= + + = +

= =

0.95m

0.3m

0.6m

2.2m

2.2m

0.8m

180.76kN.m )

2

0.95

( 0.95 2.2 227.44 )

2

z

( Lz q M

122.6kN.m )

2

0.8

( 0.8 2.2 227.44 )

2

z

( Bz q M

227.44kN/m

2.2 2.2

1100.8

A

1.7L 1.4D

q

150kN/m 136.05kN/m

2.2 2.2

19.206 639.3

A

P P P

63.93kN 19.206kN 15) 0.4)(24 0.6(1.5 0.3 15) 0.4(24 2.2 2.2

) h)( lb(1.5 ) LBh( P

: Check

2

2 u long u,

1

1 u short u,

2

chosen

u

2 2

chosen

extra L D

soil concrete soil concrete extra

= = =

= = =

=

=

+

=

< =

+

=

+ +

=

< = + =

+ =

12#16) (choose 2323.2mm 320 2200 0.0033 bd A

choose

0.02125

420 600

600

420

28 0.85 0.85

0.75

f 600

600

f

` f` 0.85

(0.75)

0.0033

0.00315

420 4

28

0.0033

420

1.4

4f

f

f

1.4

of greater

0.00216

28 0.85

0.89 2

1 1

420

28 0.85

` 0.85f`

2R

1 1

f

` 0.85f`

0.89MPa 891.52kN/m

0.08) (0.4 2.2 0.9

180.76

bd

M

R

ent reinforcem Long

2

s

min min

y y

c

max

y

c

y

min

c

n

y

c

2

2 2

u

long

1

= = =

<

=

|

.

|

\

|

+

=

|

|

.

|

\

|

+

=

=

(

(

(

(

=

=

(

(

(

(

=

=

|

|

.

|

\

|

=

|

|

.

|

\

|

=

= =

= =

11#16) (choose 2178mm 300 2200 0.0033 A

) choose 0.00167(

28 0.85

0.69 2

1 1

420

28 0.85

0.69MPa 688kN/m

0.1) (0.4 2.2 0.9

122.6

bd

M

R

ent reinforcem Short

2

s

min min

2

2 2

u

short

= =

< =

|

|

.

|

\

|

=

= =

= =

0.95m

0.3m

0.6m

2.2m

2.2m

0.8m

| | | |

| | | |

Ok V V

1847.09kN

400 2 320) (300 320) (600

12

28 4

0.85 2h d) (b d) (l

12

f 4

V

750.552kN 0.32) 0.32)(0.3 (0.6 2.2 2.2 227.44 d) d)(b (l BL q V

shear way Two

Ok V V

527.74kN 320 2200

6

28

0.85 Bd

6

f

0.85 V

265.2kN 0.32) (0.95 2.2 227.44 d) B(z q V

ent reinforcem Long

Ok V V

527.74kN 320 2200

6

28

0.85 Bd

6

f

0.85 V

190.14kN 0.32) (0.8 2.2 227.44 d) B(z q V

ent reinforcem short

shear way One

c u

c

c

u u

c u

c

c

2 u u

c u

c

c

1 u u

<

=

+ + +

= + + + =

= + + = + + =

<

= = =

= = =

<

= = =

= = =

0.95m

0.3m

0.6m

2.2m

2.2m

0.8m

C1(7#19) column as ent reinforcem same Use

Safe (Design) P P

2728.8kN (Design) P 15.16MPa 2.2Ksi

Ag

Pu

figure this Using

OK 0.01 0.011

600 300

1985

A

A

180000mm 600 300 A 1100.8kN, P

Column Neck

u u

u

g

s

4

g u

<

= = =

> =

= =

= = =

Figure 14: Interaction diagram

Figure 15:

The drawing of the footing F1.

12#16

2.2m

0.4m

0.85m

12#16

The environmental aspects and impact of the project should be

controlled by the involved parties to control the bad effects in both

sides either by the environment on the building or on the other way.

- here in UAE, the building usually consumes some of the countrys energy

and water resources and this could be reduced by using green house

technology where solar and wind energies can be used extensively.

- Although the building material considered in this project (i.e., reinforced concrete) is

relatively cheap compared to the steel material, it is, unfortunately, not

environmental friendly

Impact

Each building in this world represents a unique and creative

idea that is made real by the cooperation of the involved design and

construction parties.

It is an event that starts by developing the owner ideas on the hands of

engineers to achieve safety, serviceability and creativity of project.

For example, as a social aspects, here in UAE, traditions and the

cultural background of the people is totally different from the

western countries. Thats should be achieved by the architectural

design to represent the cultural identity in the scope of the project

design beside the modernity.

Impact

Conclusion and recommendation

The experience gained in the design process is invaluable

and represents a major stone in building an efficient

structural designer engineer.

Finally, it is recommended that the design work achieved

in this project is originally performed by two groups

using two different structural systems.

This would provide information enough to compare the

cost of each system and get experience with cheaper

solutions.

Anda mungkin juga menyukai

- Manual Beam DesignDokumen14 halamanManual Beam DesignRonald Kaaku50% (2)

- Pad Footing DesignDokumen15 halamanPad Footing DesignMalayan TigerBelum ada peringkat

- OHSRDokumen48 halamanOHSRsachingadage100% (2)

- RCC Design SheetsDokumen40 halamanRCC Design SheetsAnonymous nwByj9L100% (2)

- Beam DesignDokumen37 halamanBeam DesignYinka Akinkunmi100% (1)

- Pile Cap Design - ColumnsDokumen6 halamanPile Cap Design - Columnssssmou100% (1)

- Punching Shear Calculation AS Per ACI - 318Dokumen6 halamanPunching Shear Calculation AS Per ACI - 318Mohammed SumerBelum ada peringkat

- Column Footing 1Dokumen5 halamanColumn Footing 1Ayreesh Mey SpntBelum ada peringkat

- Fobasv 6Dokumen3 halamanFobasv 6Satyabrat Gaan100% (3)

- Mechanical Columns Buckling FailureDokumen19 halamanMechanical Columns Buckling FailurePraful Patil100% (1)

- Anchor Bolt DesignDokumen2 halamanAnchor Bolt Designmail2meanwar7865Belum ada peringkat

- Combined Strap FootingDokumen12 halamanCombined Strap FootingBang Joy100% (1)

- Design of SlabDokumen26 halamanDesign of SlabSumanth SangemBelum ada peringkat

- Design of Beams - BS 8110Dokumen3 halamanDesign of Beams - BS 8110thanigai veluBelum ada peringkat

- RCC Design SheetsDokumen40 halamanRCC Design SheetsIbrahim El SharBelum ada peringkat

- Advanced Design of Steel Structure Composite Beam DesignDokumen6 halamanAdvanced Design of Steel Structure Composite Beam DesignNaim YaqeenBelum ada peringkat

- Fin Glass 6Dokumen6 halamanFin Glass 6EIWAA100% (1)

- Ganga Raya Bhandari Analysis Report PDFDokumen37 halamanGanga Raya Bhandari Analysis Report PDFsantosh sahBelum ada peringkat

- Combined Footing Design CF-3 Data and Reinforcement DetailsDokumen2 halamanCombined Footing Design CF-3 Data and Reinforcement DetailsnaveenaeeBelum ada peringkat

- Chapter 24 WexDokumen7 halamanChapter 24 WexCiprian VarlanBelum ada peringkat

- One Way Slab DesignDokumen4 halamanOne Way Slab DesignMario FeghaliBelum ada peringkat

- Design of Isolated Rectangular FootingDokumen3 halamanDesign of Isolated Rectangular FootingdsanandaBelum ada peringkat

- Purlin Cleat 220908Dokumen24 halamanPurlin Cleat 220908kalpanaadhi100% (2)

- Base Plate DesignDokumen32 halamanBase Plate DesignGautam Sharma50% (2)

- Pile Cap Design - ColumnsDokumen6 halamanPile Cap Design - Columnsntah8450% (2)

- FinalDokumen42 halamanFinalVishnu Kumar0% (1)

- Slab Design Spread SheetDokumen1 halamanSlab Design Spread Sheetgvp_sagar5284Belum ada peringkat

- RCC DESIGN CASE STUDYDokumen25 halamanRCC DESIGN CASE STUDYWHATS APP STATUSBelum ada peringkat

- Civil Auditorium Building DesignDokumen23 halamanCivil Auditorium Building DesignRamachantran RamachantranBelum ada peringkat

- Mix Design PresentationDokumen313 halamanMix Design Presentationbsk109Belum ada peringkat

- One Way Slab DesignDokumen16 halamanOne Way Slab DesignAssad Mohammed AliBelum ada peringkat

- One Way Slab DesignDokumen10 halamanOne Way Slab DesignBijendra PradhanBelum ada peringkat

- Ba Culvertf TestDokumen16 halamanBa Culvertf TestsanjuktaacharyyaBelum ada peringkat

- Design of Slab: Ly/lx 2. So This Is Two Way SlabDokumen6 halamanDesign of Slab: Ly/lx 2. So This Is Two Way SlabSudip ShresthaBelum ada peringkat

- Design of BeamsDokumen14 halamanDesign of BeamsNoor MohdBelum ada peringkat

- Design of Rectangular Columns with Biaxial BendingDokumen21 halamanDesign of Rectangular Columns with Biaxial BendingBhaskar BabiBelum ada peringkat

- Design of Critical Two-Way SlabDokumen8 halamanDesign of Critical Two-Way SlabBevelyn Manalo100% (1)

- Column DesignDokumen68 halamanColumn DesignPiyush Tiwari100% (1)

- RCC Design SheetsDokumen40 halamanRCC Design SheetsAnonymous 9iK0i8h0dPBelum ada peringkat

- SlabDokumen6 halamanSlabBishal ShresthaBelum ada peringkat

- Example 2 Simply Supported Beam - Flanged Section PDFDokumen7 halamanExample 2 Simply Supported Beam - Flanged Section PDFWee Ren100% (1)

- Design of Combined FootingDokumen12 halamanDesign of Combined FootingAhmmed Muhsee100% (2)

- RC Column Design BS8110Dokumen5 halamanRC Column Design BS8110dantevariasBelum ada peringkat

- Axial Circular Column DesignDokumen5 halamanAxial Circular Column Designkalpanaadhi100% (1)

- Continuous BeamsDokumen450 halamanContinuous BeamssreenivasaeeBelum ada peringkat

- Design of Two-Way Slab and BeamsDokumen36 halamanDesign of Two-Way Slab and Beamsveenabalu20Belum ada peringkat

- Isolated Sloped Footing SpreadsheetDokumen283 halamanIsolated Sloped Footing Spreadsheetarif_rubin100% (3)

- 13 - 8 Design of 2 Way Slab For PrintingDokumen7 halaman13 - 8 Design of 2 Way Slab For PrintingAlbert DimayugaBelum ada peringkat

- Solid Slab Inspection ChecklistsDokumen2 halamanSolid Slab Inspection ChecklistsMohammed SumerBelum ada peringkat

- Manual de Partes y Operación de Trituradora Vsi Canica Modelo 65Dokumen105 halamanManual de Partes y Operación de Trituradora Vsi Canica Modelo 65Jose AlfaroBelum ada peringkat

- Doubly Reinforced Concrete ExcelDokumen83 halamanDoubly Reinforced Concrete ExcelShielaSabadoBelum ada peringkat

- Design of Composite BeamDokumen7 halamanDesign of Composite BeamMohammed SumerBelum ada peringkat

- Load Combination and Flexural Design of Roof Deck BeamsDokumen123 halamanLoad Combination and Flexural Design of Roof Deck BeamsMarkBelum ada peringkat

- Design of Metal Anchors in Concrete According to ACI318-08Dokumen4 halamanDesign of Metal Anchors in Concrete According to ACI318-08tamerragaaBelum ada peringkat

- CONCRETE LAB MANUALDokumen55 halamanCONCRETE LAB MANUALSatyabrata NayakBelum ada peringkat

- Concrete Beam DesignDokumen3 halamanConcrete Beam DesignArnel DodongBelum ada peringkat

- Beam Deflection CheckDokumen7 halamanBeam Deflection Checkajith chandranBelum ada peringkat

- Eccentric footing design and analysisDokumen74 halamanEccentric footing design and analysisSujay Santra100% (1)

- Ficha Tecnica Komatsu 400 - 7Dokumen52 halamanFicha Tecnica Komatsu 400 - 7bariciado1Belum ada peringkat

- Design - of - Steel - Structure-I PDFDokumen54 halamanDesign - of - Steel - Structure-I PDFNi Mesh100% (1)

- R C Beam DesignDokumen6 halamanR C Beam Designdaddakoli007Belum ada peringkat

- Design of Square Footing F2Dokumen18 halamanDesign of Square Footing F2Mohammed Sumer100% (1)

- 5.3 Slab 5.3.1 Slab: Office Area: Ref. Calculation OutputDokumen27 halaman5.3 Slab 5.3.1 Slab: Office Area: Ref. Calculation OutputNH SyzlnBelum ada peringkat

- Design BookDokumen53 halamanDesign BookmollikaminBelum ada peringkat

- Design of Reinforced Concrete Structures Enlighten To Bangladesh National Building CodeDokumen42 halamanDesign of Reinforced Concrete Structures Enlighten To Bangladesh National Building CodeAfif AdnanBelum ada peringkat

- Design steel column axial loadsDokumen2 halamanDesign steel column axial loadsGihan Chathuranga100% (1)

- Jutpani SS20Dokumen23 halamanJutpani SS20Suman NakarmiBelum ada peringkat

- Eurocode 2 Concrete Design GuideDokumen50 halamanEurocode 2 Concrete Design GuideanhkhoacgBelum ada peringkat

- Base Plate Design-Umbrella Car ParkDokumen5 halamanBase Plate Design-Umbrella Car Parkmsiddiq1Belum ada peringkat

- Uniform Building Code Volume 21997Dokumen545 halamanUniform Building Code Volume 21997raymond100% (1)

- Checklists For PT Slab-22th FloorDokumen3 halamanChecklists For PT Slab-22th FloorMohammed SumerBelum ada peringkat

- Dispute Case RegisteredDokumen1 halamanDispute Case RegisteredMohammed SumerBelum ada peringkat

- Wind Speed Design Pressures Building EnclosureDokumen3 halamanWind Speed Design Pressures Building EnclosureRamachandra SahuBelum ada peringkat

- Final DWG - DWG 14-1 Lower Version-Model PDFDokumen1 halamanFinal DWG - DWG 14-1 Lower Version-Model PDFMohammed SumerBelum ada peringkat

- Jdivision Name: Find I NextDokumen2 halamanJdivision Name: Find I NextMohammed SumerBelum ada peringkat

- South - PPT - PPT HydDokumen6 halamanSouth - PPT - PPT HydMohammed SumerBelum ada peringkat

- 2016-FL3030说明书50m臂长最后版-2016 11 3 PDFDokumen96 halaman2016-FL3030说明书50m臂长最后版-2016 11 3 PDFMohammed SumerBelum ada peringkat

- Requirement of DrawingDokumen1 halamanRequirement of DrawingMohammed SumerBelum ada peringkat

- Punching Shear Design for Critical Node in STAADDokumen2 halamanPunching Shear Design for Critical Node in STAADAntonysamy SanthanamBelum ada peringkat

- 423 NumDokumen1 halaman423 NumMohammed SumerBelum ada peringkat

- Punching Shear Design for Critical Node in STAADDokumen2 halamanPunching Shear Design for Critical Node in STAADAntonysamy SanthanamBelum ada peringkat

- Sitting Layout PDFDokumen1 halamanSitting Layout PDFMohammed SumerBelum ada peringkat

- 20190226095531Dokumen1 halaman20190226095531Mohammed SumerBelum ada peringkat

- Punching Shear Design for Critical Node in STAADDokumen2 halamanPunching Shear Design for Critical Node in STAADAntonysamy SanthanamBelum ada peringkat

- Thank You from DAT Engineering ConsultancyDokumen2 halamanThank You from DAT Engineering ConsultancyMohammed SumerBelum ada peringkat

- Architectural Drawings1548765409825 PDFDokumen12 halamanArchitectural Drawings1548765409825 PDFMohammed SumerBelum ada peringkat

- Khalfan Final All (30.aug.2016) - Model - pdf5Dokumen1 halamanKhalfan Final All (30.aug.2016) - Model - pdf5Mohammed SumerBelum ada peringkat

- A B C D E F G A': Ground FloorplanDokumen1 halamanA B C D E F G A': Ground FloorplanMohammed SumerBelum ada peringkat

- Two Pile GroupDokumen12 halamanTwo Pile GroupJammy KingBelum ada peringkat

- Eng - Khalil&mr - Basem With Majid Hilal AgreementDokumen7 halamanEng - Khalil&mr - Basem With Majid Hilal AgreementMohammed SumerBelum ada peringkat

- Khalfan Final All (30.aug.2016) - Model - pdf1Dokumen1 halamanKhalfan Final All (30.aug.2016) - Model - pdf1Mohammed SumerBelum ada peringkat

- Eng - Khalil&mr - Basem With Majid Hilal AgreementDokumen7 halamanEng - Khalil&mr - Basem With Majid Hilal AgreementMohammed SumerBelum ada peringkat

- TABLE: Load Combinations Name Load Case/Combo Scale Factor Type AutoDokumen27 halamanTABLE: Load Combinations Name Load Case/Combo Scale Factor Type AutoMohammed SumerBelum ada peringkat

- Phaser3300MFP Firmware Upgrade Instructions CWISDokumen2 halamanPhaser3300MFP Firmware Upgrade Instructions CWISAlgenis De Leon RamirezBelum ada peringkat

- UML Modeling and Performance Evaluation of Multithreaded Programs On Dual Core ProcessorDokumen10 halamanUML Modeling and Performance Evaluation of Multithreaded Programs On Dual Core ProcessorseravanakumarBelum ada peringkat

- BHEL - PresentationDokumen32 halamanBHEL - Presentationsenthil031277Belum ada peringkat

- Soil CompactionDokumen13 halamanSoil Compactionbishry ahamedBelum ada peringkat

- Cable Memebres ProfiledirectoryDokumen5 halamanCable Memebres ProfiledirectoryMigration Solution100% (1)

- Pfaff 360 Sewing Machine Instruction ManualDokumen55 halamanPfaff 360 Sewing Machine Instruction ManualiliiexpugnansBelum ada peringkat

- EC2151 Electric Circuit Important QuestionsDokumen47 halamanEC2151 Electric Circuit Important QuestionschitragowsBelum ada peringkat

- 10 Inch Pipe Calculations For HydrostatDokumen13 halaman10 Inch Pipe Calculations For Hydrostatגרבר פליקסBelum ada peringkat

- 2011 Equipment Packing InstructionsDokumen3 halaman2011 Equipment Packing InstructionsNidhi MurthyBelum ada peringkat

- Standing Waves Worksheet SolutionsDokumen6 halamanStanding Waves Worksheet SolutionsMaher TrabelsiBelum ada peringkat

- Ci-2001 Ab OmDokumen30 halamanCi-2001 Ab OmEnrique FlowersBelum ada peringkat

- Xlpe - Ls243Nta: - 1 Technical Data Sheet Crosslinkable Polyethylene CompoundDokumen3 halamanXlpe - Ls243Nta: - 1 Technical Data Sheet Crosslinkable Polyethylene CompoundLe MinhBelum ada peringkat

- pd1185 Fire CodeDokumen3 halamanpd1185 Fire CodeCamille MangaranBelum ada peringkat

- PDF Main - PsDokumen34 halamanPDF Main - PsIsaiah GarciaBelum ada peringkat

- Evaporation: (I) Vapour PressureDokumen15 halamanEvaporation: (I) Vapour Pressurevenka07Belum ada peringkat

- Ecdis-W: Warship Electronic Chart Display and Information SystemDokumen2 halamanEcdis-W: Warship Electronic Chart Display and Information SystemEngr Muhammad SalmanBelum ada peringkat

- Reading 03 - Iron Lady The Eiffel TowerDokumen2 halamanReading 03 - Iron Lady The Eiffel TowerFernando Elías Valderrama GómezBelum ada peringkat

- USBN Bahasa Inggris 2021Dokumen6 halamanUSBN Bahasa Inggris 2021Indah timorentiBelum ada peringkat

- 2.ARC - ARC Binh Duong ASRS - Quotation For PK2 - Panel and Refrigeration System - Phase 2 - 2020 10 28Dokumen12 halaman2.ARC - ARC Binh Duong ASRS - Quotation For PK2 - Panel and Refrigeration System - Phase 2 - 2020 10 28vu nguyen ngocBelum ada peringkat

- Physics Exit 3q1718 .Dokumen16 halamanPhysics Exit 3q1718 .Mikaella Tambis0% (1)

- Xtrons - TD609 User ManualDokumen16 halamanXtrons - TD609 User ManualadrianBelum ada peringkat

- Robohawks Team HandbookDokumen11 halamanRobohawks Team Handbookapi-376756259Belum ada peringkat

- Tds G. Beslux Tribopaste L-2-3 S (26.03.09)Dokumen1 halamanTds G. Beslux Tribopaste L-2-3 S (26.03.09)Iulian BarbuBelum ada peringkat

- PLKKKDokumen36 halamanPLKKKelecompinnBelum ada peringkat

- Combination Woodworking Machine Quotation PDFDokumen2 halamanCombination Woodworking Machine Quotation PDFAlunel TapuBelum ada peringkat

- Çimsa Eco White TDS (EN)Dokumen1 halamanÇimsa Eco White TDS (EN)Babu NysemereBelum ada peringkat