Car Filters 1

Diunggah oleh

Pulak DebnathJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Car Filters 1

Diunggah oleh

Pulak DebnathHak Cipta:

Format Tersedia

CAR FILTERS

Chapter 1

General describtion of

filters

1. Definition

Filtration is a process of separating dispersed particles from a dispersing

fluid by means of porous media. The dispersing medium can be a gas (or

gas mixture) or a liquid. Particles can be solid or liquid for gas medium and

solid for liquid medium.

Upstream Downstream

Filter

Channel

wall

Dispersed

particles

Dispersing

fluid

Particles deposited

inside the filter

Filter

thickness

Face of the filter with filter cake of

deposited particles

2. Types of filtration

Concerning to filtration surrouding:

Air filtration / Liquid filtration

Concerning to size of filtered particles:

Macrofiltration for particle size dp: 10

-6

m < dp

Microfiltration 10

-7

< dp < 10

-6

Ultrafiltration 10

-8

< dp < 10

-7

Nanofiltration 10

-9

< dp < 10

-8

Reverse osmosis dp < 10

-9

Concerning to filtration mechanism:

Flat filtration / Depth filtration

2.1 Air / liquid filtration

Examples of air filtration:

respirators, air ventilation systems (air condition, air

cleaning etc), vacuum cleaners, industrial filters for

incineration, power plants, chemical processing, paint

boxes, car filters (cabin filters, engine filters, exhaust

filters)

Examples of liquid filtration:

drink water treatment, waste water treatment, chemical

processing, batteries, industrial filters (cutting

operations, cooling liquids, spunlace), car filters (oil

filters, fuel (petrol) filters)

2.2 Relative size of common filtered particles

2.3 Surface filtration

All particles which are bigger than pores are captured on the

flat filter surface. It is typical for example for fabric or spunbond

filters. Thus for these filters the pores distribution and permeability are

important properties. Surface filtration is common for liquid filtration.

Surface filters are described in subject High funcional textiles

Direction

of flow

Textile filter expressed as a set

of cylinders placed in parallel

Captured

particles

2.4 Depth filtration

Depth filter are able to capture particles that are too small to be sieved

out as in flat filtration. Particles, which can be a lot of smaller than the

distances between the fibers penetrate into the fiber structure. Filtered

particles are captured in terms of the filtration mechanisms. This type

of the filtration process is importatn for the most of filter applications.

Next chapters about filtration variables, properties and mechanisms

refer first of all to the deep filtration.

Direction

of flow

Textile filter expressed as a set

of cylinders placed in parallel

Captured

particles

3. FILTRATION THEORY

Filtration variables

Filter variables

Flowing medium

variables

Captured particles

variables

Filtration properties

Efficiency

Pressure drop

Lifetime

Resistivity against

environment

Others (permeability,

porosity...)

Filtration mechanisms

Diffusion deposition

Direct interception

Inertial deposition

Electrostatic

deposition

Sieve effect

Its simple to say what is filtration but difficult to describe relations between

filter properties and filtration variables which influence the filtration process

This is what

we can

change

This is what

we try know

This is what

we need

Filter efficiency

It is the ratio of particles captured by a filter over the total number

of particles found in the air upstream of the filter. Filter efficiency

can either be based on specific particle size ranges or based on the

total number of particles of all sizes.

3.1 Filtration properties I.

100 . 1

2

1

|

|

.

|

\

|

=

G

G

E

Efficiency can be defined by formula 1,

where G

1

is an amount of penetrated

particles (which havent been captured) and

G

2

is total amount of particles upstream formula 1.

Expression G

1/

G

2

is named Penetration of filter

Efficieny is changing during the filtration process (see chapter 6.3.4

Nonstationary filtration)

Pressure drop

Pressure drop indicates the restance to flow. It is defined as a difference between the pressure

of flowing media upstream and downstream of the filter. For expression of pressure drop is

necessary to assign air flow or air velocity (linear relation).

Ap = p

1

- p

2,

where p

1

is pressure drop upstream and p

2

downstream

of the filter. Pressure drop is changed during the filtration

proces (see chapter 6.3.4 Nonstationary filtration).

Filtration properties II.

Filter lifetime

Filter lifetime determines the time when the filter must be removed. It is defined as a time or

as an amount of the filtered particles, which are loaded into the filter until the filter is full.

According to EN 779 standard the filter lifetime is defined as a Dust holding capacity:

J = E

s

.m

p

where E

s

is mean filter efficiency and m

p

is the amount of the

particles loaded into the filter until the final pressure drop (250

or 400 Pa) was reached

Permeability

It is the ability of a material to allow the passage of a liquid or gas through porous material. It

is possible to find more defininitions, whic depend on the level of simplification:

1) According to EDANA 140.1 standard it is defined by formula:

where M

s

is permeability (l/dm

2

/min), Q is the flow

(l/min)and A is the filter surface. Permeability is tested with the

pressure drop 196 Pa (98,1 Pa for some standards)

2) According to the Darcys law the permeability is defined by formula:

where K is permeability (m/Pa/sec) and Ap is the pressure

drop (Pa).

3) According to the Darcy,s law is possible to define permeability as a permeability

coefficient defined by formula:

where k

1

is the permeability coefficient (m

2

), q is the

dynamic viskosity (Pa.sec), and h (m) is the thickness of the

filter.

Filtration properties III.

A

Q

M

S

=

p A

Q

K

A

=

.

p A

h Q

k

A

=

.

. .

1

q

4. According Hagen-Dupuit-DArcys model is permeability defined as:

where K

3

is permeability coefficient and C is form coefficient.

This model is suitable for higher flow of viscose liquid (such as water etc). When we

compare HDD model with DArcys law, the main difference is nonlinear relation between

flow and pressure drop.

Permeabilityof laminated textiles

For simple DArcys law it is possible to deduce relation between the permeability of one

layer and more layers. For most of the applications we can assume that the flow through

the laminated textile is the some as flow through one layer. Than the total pressure drop

and total permeability are defined:

and ,

where Ap

i

and K

1i

are pressure drop and peremability coefficients of each layers

2

3

.

. .

.

.

.

Q

A

h C

Q

A K

h

p

q

+ = A

A = A

i

i t

p p

=

i

i total

K K

1 1

1 1

Filtration properties IV.

Porosity and pore size

Porosity of porous medium is defined as a percentage of the porous material volume not

occupied by fibers.

Very important is size or size distribution of pores, which depends on the pore definition and

on the used test method.

Testing methods:

1. Image analysis of 2D microscopic wiew direct method

2. Sifting of defined particles through the textile

3. Penetration of liquid agent into the textile relation between pore size and surface

tension of liquid.

a) Wetting agent is pushed away from textile due to pressured gas Bubble point

method

b) Non-wetting agent is pushed into the textile Mercury porosimetry

For more informations see subject High functional textiles.

Filtration properties V.

Description of simple Bubble point method:

We assume circular pores. Wetting liquid (wetting angle = 0) try to go through the pores

due to wetting force F

= t.D. . Against this force we can act by pressured gas (F

p

=

p.A

pore

). D is pore diameter, is liquid surface tension, p is gas pressure and A

pore

is pore

cross section surface. When the first bubble of gas is going through the pore both

forces are in equilibrium.

At first bubbles are going through the maximum pore. When we can measure flow rate

of gas is possible to measure the distribution of pore sizes.

D

F

= . t . D

F

p

= p . A

pore

textile

Wetting agent

bubble

Filtration properties VI.

3.1.1 Change of filtration properties

Statinary and nonstacionary filtration

It is important that the filtration properties are changing during the filtration process. A

captured particle, since it occupies a finite space, becomes part of the filter structure,

able to contribute both to pressure drop and to filtration efficiency. When we neglect

this assumption the filtration process is named stationary. It is possible in the

beginning of the filtration process. When we assume that the deposited particle

influences filter properties the filtration process is named nonstationary [Pich,

1964]. Secondary proceses of nonstationary filtration are:

1. Filter clogging particles fill the filter structure

increase of pressure drop

increase of filter efficiency

2. Particle disengagement

decrease of filter efficiency

3. Capillary phenomena

flushing of drops

formation of fluid layers in placed where the fibers are spiced

condensation of water

4. Loss of electric charge

decrease of filter efficiency

5. Filter destruction

3.1.2 Test method of filtration properties:

Tested properties are efficiency, fractional efficiency, pressure drop, pressure drop vs. air flow,

filter lifetime etc... Properties are tested as initial or during filtration process. Methods are

differ in the particle substance (electrical properties, adhesion etc...), particle size (coarse/fine),

particle size range (monodisperse, polydisperse), particle concentration etc...

1) Synthetic dust

The dust is blend prepared from melted anorganic (and organic) particles. The most known is

ASHRAE dust that has the some parameters as the dust around Arizona roads [ASHRAE 52,2,

1999]. It is used for coarse filters (particles are coarse and polydisperse). It is possible to test

change of properties during the filtration process and filter lifetime. Dust is measured by

weighting method. This method is very popular and easy to use. However, it is open to

criticism because weight measurements give predominantly the weight of the largest particles

in the sample. Used standards are: EN 779 [EN 779, 200], ASHRAE 52,2 etc...

2) Athmospheric dust spot efficiency

In the Atmospheric Dust Spot Efficiency ambient outdoor atmospheric air is passed through

the unit being tested and samples are taken at the inlet and outlet of the unit to evaluate its

collection efficiency on the dust particles suspended in the atmosphere. This test is replaced

with DEHS aerosol method because athmosperic air composition is changing. Used standard

was older version of EN 779 [Gustavsson, 1999] .

3) Oil aerosols (DEHS, DOP, paraffin oil)

As the test matter is used aerosol from liquid oily substances. The most known are:

dioctylphtalate (DOP), diethylhexylsebacate (DEHS) and paraffin oil. Two types of oil

aerosol are known: Cold and hot. If the oil is dispersed and dryed in cold ambient conditions

(Laskin nozzle) then the size range of particles is wider (polydiperse aerosol). If the oil is

dispersed and dryed in hot ambient conditions then is possible to obtain monodisperse

particles (0,1-0,3 m). Particles are analyzed by laser particle counter or by spectrofotometric

method. It is possible to detect efficiency of selected particle size (except paraffin oil).

Particles are insenzitive to electrostatic field. Initial values of This method is used for fine

and high efficient filters HEPA (high efficiency particulate air filter) and ULPA (ultra low

penetration air filter) filters.

4) NaCl aerosol

Sodium Chloride aquelous solution is dispersed and dryed. These polydisperse particles have

mean size 0, 65 m and their penetration through the filter is analysed by spectrofotometer.

This method is suitable for quick test of high efficient filters (respirators especially). Used

standards are: BS 4400 [BS 4400, 1969], EN 143 [EN 143, 2000], etc...

5) Methylen blue test

The solution of methylen blue is dispersed and dryed. Particles are analysed by comparing of

the blue colour intensity upstream and downstream the filter. It is suitable to high efficient

filters. By reason of narow gauge usage is replaced by sodium chloride aerosol test.

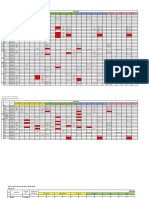

Summary of test methods:

method Test standard

name

particle substance particle

diameter

(m)

particle

preparation

particle

detection

ANSI/AHAM

Arizona roads dust 0,5 - 3 aerosol

generator

aerodynamic

sorter

ASHRAE

EN

CAN

72% fine dust

23% molocco black

5% cotton linters

-

synthetic

dust

ISO

SAE

Testing dust 2 125

10 - 40

injector

weighting

method

athmospheric

dust

ASHRAE

CAN

Athmospheric dust Cca. 0,3 straight from

air

opacitometer

(light opacity)

0,3

0,2 0,3

evaporation,

condensation

ASTM

ASME/ANSI

IES

MIL-STD

UL

DOP test;

di-octylphtalate

0,3 2 Laskin

nozzle

0,1 0,3 evaporation,

condensation

EN DEHS aerosol

diethylhexylsebacate

0,2 3

Laskin

nozzle

optical particle

counter,

spectrofotometer

oil aerosol

EN

BS

Paraffin oil;

CP27 DAB7

0,40,26 evaporation,

condensation

photometer of

the light

diffusion

aerosol NaCl BS

EUROVENT

EN

NF

NaCl particles 0,02-2

median

0,6

dispersion,

drying

spectrofotometer

Methylene

Blue test

BS

Methylen blue

particles

- dispersion of

water

solution

blue spot size

3.2 Filtration variables

Filtration variables are divided onto three groups:

1. Variables of filter material

2. Variables of filtered particles

3. Variables of filtration process

3.2.1 Variables of filter material:

Filtration area

Filter thickness

Density and surface density of filter

Uniformity of fibrous material

Parameters of filter material

surface interactions between the filter material and filtered particles

electrical properties

mechanical characteristics (tenacity, elongation...)

resistance against surrounding factors (heat, solvents...)

Parameters of fibers

fiber diameter, fiber fineness

shape of fiber cross-section

fiber surface preparations

Mechanical characteristics

Filter structure

filter density gradient

fiber orientation

3.2.2 Variables of filtered particles

Particle size

Distribution of particle size

Concentration of particles

Shape and surface of particles

Particle density

Electrical properties

3.2.3 Variable of filtration process

Face velocity (speed of filtered particles in front of filter)

Viscosity of the flow

Temperature, pressure, humidity

3.3 Filtration mechanisms

Air (gas filtration) Liquid filtration

Type of filtration Surface

Depth more common

Surface more common

Depth

Mechanisms direct interception

inertial impaction

diffusional deposition

capture by electrostatic

forces

sieve effect

direct interception

inertial impaction

sieve effect

3.3.1 Filtration mechanisms of depth filtration

R

fiber

charge on the

fiber surface

diffusional

deposition

inertial

impaction

direct

interception

capture by

electrostatic

forces

streamlines (air

moving trajectory)

Total filtration efficiency

Ec is total efficiency, E

r

is efficiency of direct interception mechanism represented by

parameter N

r

, E

i

is efficiency of inertial impaction represented by Stokes number Stk, E

d

is

efficiency of diffusional deposition mechanism represented by Peclet number Pe and E

e

is

efficiency of electrostatic mechanism represented by the parameter Nq.

( ) ( ) ( ) ( ) { } Nq E Pe E Stk E N E E E

e d i r r c c

, , , =

Mechanisms:

direct interception

inertial impaction

diffusional

deposition

capture by

electrostatic forces

.

Direct interception

Direct interception occurs when airborne particles behave in an entirely passive way with

respect to the airflow. Airborne particles follow the streamline, which in steady state are

independent of the air velocity. Particle will be captured when it is close to the fiber. This

mechanism is independent of air velocity, air viscosity and density. Particle must be small,

because inertial effects and external forces are neglected. This type of mechanism is common

for simple respirators made from fibers of about 20 m, which operate in filration velocity

about 0,04 m/sec. Furthermore interception acts along with other filtration processes.

Parameter of direct

interception:

N

r

= dp/df

(d

p

is particle diameter, d

f

is

fiber diameter)

d

f

fiber

streamlines (air

moving trajectory)

d

p

Relation between parameter N

r

and efficiency of direct interceptiom mechanism:

E

R

~ N

r

2

;

the simpliest relation is: E

R

=N

R

2

/,, more exactly:

where ,=-0,5.ln(c)-0,75 is hydrodynamic factor and m = 2/(3.(1-c))

( )

m

R

R

R

N

N

E

+

=

1 .

2

,

Inertial impaction

Any convergence, divergence or curvature of streamlines involves acceleration of the air, and

under such conditions a particle may not be able to follow the airflow. What particle does

depends upon its mass (inertia) and upon the Stokes drag exerted by the air. Stokes drag is

defined as a force which acts on the moving sferical object inside of viscous liquid: F =

3.t.q.d

p

.v (where F is the force, d

p

is the particle diameter, q is the dynamic viscosity and v is

the face velocity of the airflow).

fiber

inertial

impaction

streamlines (air

moving trajectory)

Intensity of the point particle inertia is determined by Stokes number:

where d

p

is particle diameter, is particle density, U is air face velocity, q is air viscosity

and d

f

is fiber diameter.

f

p

d

U d

St

. . 18

. .

2

q

=

Efficiency of inertial impaction

E

i

depends on the intensity of the

point particle inertia. If inertia is

negligible then E

i

will be zero, if

the inertia is infinite then E

i

will

be 100 %.

Relation between the Stokes number and efficiency of inertial impaction:

For low Stokes number efficiency is lead by direct interception:

E

ir

=E

R

+(2.)

-2

.J.St,

where E

R

is efficiency of direct interception, is hydrodynamic factor dependent on packing

fraction c and J is constant dependent on c and parameter of direct interception Nr.

For high Stokes number efficiency of inertial impaction is defined:

E

I

=1-(/St),

where is constant dependent on flow field.

Diffussional deposition

The trajektories of individual small particles

do not coincide with the streamlines of the

fluid because of Brownian motion. With

decreasing particle size the intensity of

Brownian motion increases and, as a

consequence, so does the intensity of

diffusion deposition [Pich J,1964]. However

the air flow effects on the particles motion

too. Thus the real motion of small particles

depends on Brownian motion and air flow.

Brownian motion is determined by diffusion coefficient D defined by the Einstein equation:

where k

B

is Boltzmann constant, K is Kelvin temperature, q is air viscosity, d

p

is particle

diameter and Cn is the Cunningham correction, which involve aerodynamic slip flow of

particles:

where is mean free path of molecules (at NTP it is 0,065 m) and A, B, Q are constants

(A=1,246; B=0,87; Q=0,42) [Brown RC, 1993].

diffusional

deposition

streamlines (air

moving trajectory)

fiber

p

B

d

T k Cn

D

. . . 3

. .

q t

=

|

|

.

|

\

|

+ + =

. 2

.

. .

. 2

1

p

d B

p

e Q A

d

Cn

Coefficient of diffusional deposition:

Capture of particles by a diffusional deposition will depend on the relation between the

diffusional motion and the convective motion of the air past the fiber. Dimensionless

coefficient of diffusional deposition N

D

is defined:

where d

f

is fiber diameter, U is air flow velocity and P

e

is named Peclet number.

Diffusional capture efficiency:

According to Fokker-Planck equation was aproximated relation between the N

D

(or 1/P

e

) and

diffusional capture efficiency

E

D

= 2,9 .

-1/3

. Pe

-2/3

where is hydrodynamic factor ( = -0,5. ln(c)-0,75 by Kuwabara) [Brown RC, 1993].

Previous equation was verified by experiments with model filters with the some and

observed functional dependance was the some with little different numerical coefficient:

E

D

= 2,7

. Pe

-2/3

When we calculate with the slip flow (see chapter 9) the resulting capture efficiency is bigger.

U d

D

Pe

N

f

D

.

1

= =

Electrostatic forces:

Both the particles and the fibers in the filter

may carry electric charges. Deposition of

particles on the fibers may take place

because of the forces acting between

charges or induced forces. [Pich J, 1964].

The capture of oppositely charged particles

is given by coulomb forces. The capture of

neutral particles comes about by the action

of polarisation forces. We can define three

cases of interaction between particle and

fiber. Used equations were derived from

Coulombs law.

fiber

charge on the

fiber surface

capture by

electrostatic

forces

streamlines (air

moving trajectory)

1. Charged particle, charged fiber

where q is the particle charge, Q is fiber charge per unit lenght

of fiber and x is the distance between fiber and particle.

2. Charged fiber, neutral particles

where D

1

is the dielectric constant of the particle and d

p

is

particle diameter.

3. Charged particles, neutral fiber

where D

2

is dielectric constant of the fiber and d

f

is fiber

diameter.

x

q Q

F

. . 2

1

=

3

3

1

1

2

2

.

2

1

. . 4

x

d

D

D

Q F

p

+

=

( )

1

1

.

. 4

2

2

2

2

3

+

=

D

D

d x

q

F

f

Coefficient of electrostatic mechanism, efficiency of electrostatic mechanism

We can interpret this parameter as a ratio of electrostatic forces to drag forces. From this

parameter were derived equations for efficiency [Pich J, 1964].

B is mechanical mobility of the particle, U

0

is the velocity far form the fiber, d

f

is fiber

diameter, d

p

is particle diameter and q is viscosity

Coefficient of electrostatic

mechanism

Efficiency of electrostatic

mechanism

Charged fiber and

charged particle

Charged fiber and

neutral particle

Carged paricle and

neutral fiber

0 0

. . . . . 3

. . 4

.

. . . 4

U d d

q Q

U d

B q Q

N

f p f

Qq

q t

= =

q t . .

.

.

2

1

.

. 3

4

0

3

2 2

1

1

0

U d

Q d

D

D

N

f

p

Q

+

=

1

1

.

. . . . 3

2

2

0

2

2

0

+

=

D

D

U d d

q

N

f p

q

t

0

. . . . 3

. . 4

.

U d d

q Q

N E

f p

Qq Qq

q

t = =

( ) ( )

2

1

0

2

1

.

Re ln 2

2

q Qq

N E

=

3

1

0

3

1

0

.

2

3

Q Q

N E

|

.

|

\

|

= t

3.3.2 Filtration variables vs.capture efficiency of filtration

mechanisms

Efficiency of

each filtration

mechanisms

Relations how some filtration variables increase or decrease or not affect the

efficiency of each filtration mechanisms

filter

density

fiber

diameter

particle

diameter

particle

mass

face

velocity

viscosity

of air

relative

charge

direct

interception

-

+

|

-

-

-

-

inertial

impaction

|

+

|?

|

|

+

-

diffusional

deposition

|

+

+

-

+

+

-

electrostatic

deposition

-

+

+|

-

+

+

|

3

2

1

|

|

|

|

|

.

|

\

|

+

dp

d

e

p

d

p

Efficiency of

each filtration

mechanisms

Numeric relations between the filter variables and capture efficiency of each

mechanisms

filter

density

c

fiber

diameter

d

f

particle

diameter

d

p

particle

mass

face

velocity

U

viscosity

of air

q

relative

charge

q, Q

direct

interception

-

1/d

f

2

d

p

2

-

-

-

-

inertial

impaction

1/(ln c)

2

1/d

f

or

1 k.d

f

d

p

2

or

1-1/d

p

2

or

1-k/

U or

1-k/U

1/q

-

diffusional

deposition

1/(ln

c)

1/3

1/d

f

2/3

-

1/U

2/3

1/q

2/3

-

electrostatic

deposition

-

1/d

f

1/d

p

or

d

p

2/3

or

1/d

p

1/2

-

1/U or

1/U

1/3

or

1/U

1/2

1/q

q.Q or

Q

2/3

or

q

3.3.3 Filtration mechanism of flat filtration Sieve effect

E

s

= 1 for d

p

> d

pore;

; E

s

= 0 for d

p

< d

pore

,

where E

s

is efficiency of sieve effect and d

pore

is pore diameter.

Relation between fiber and pore diameter according to Neckar [Neckar B.,

2003]:

()

where q is fiber shape factor (zero for cylindrical fibers), c is packing factor, a

and k are constats related to filter structure (usually a is ).

For cylindrical fibers with hexagonal structure is k = 2

-1/2

.

. d

pore f

d =

a

f pore

c

c

q

k

d d

|

.

|

\

|

+

=

1

.

1

.

Anda mungkin juga menyukai

- FiltrationDokumen25 halamanFiltrationKrizzz 12Belum ada peringkat

- Filtration Report.Dokumen35 halamanFiltration Report.Kartik Balasubramaniam70% (10)

- 5Dokumen31 halaman5shihabzBelum ada peringkat

- Sand FiltrationDokumen28 halamanSand FiltrationAnonymous bHh1L1Belum ada peringkat

- Filtration 2Dokumen41 halamanFiltration 2Konesi RonaldBelum ada peringkat

- Unit 2 Copy9Dokumen18 halamanUnit 2 Copy9Laughin KowBelum ada peringkat

- فلترDokumen41 halamanفلترمروان الشباليBelum ada peringkat

- FiltrationDokumen77 halamanFiltrationmeet2abhayBelum ada peringkat

- Name: Safira Fereste Class: 2A D4 TKI NIM: 1941420104: 1. Make A Text With Maximum 4 ParagraphDokumen7 halamanName: Safira Fereste Class: 2A D4 TKI NIM: 1941420104: 1. Make A Text With Maximum 4 ParagraphSAFIRA FERESTEBelum ada peringkat

- New Text DocumentDokumen7 halamanNew Text Documentamarjeet singhBelum ada peringkat

- Solid Liquid Separation - Centrifugal FiltrationDokumen12 halamanSolid Liquid Separation - Centrifugal FiltrationAminEsmaeiliBelum ada peringkat

- A Report On The 2 Experiment, Filtration Group 6: BT4110 - Downstream Processing LaboratoryDokumen19 halamanA Report On The 2 Experiment, Filtration Group 6: BT4110 - Downstream Processing LaboratoryRalvin DumpitBelum ada peringkat

- Fabric Filter Design VariablesDokumen14 halamanFabric Filter Design VariablesElumalai Srinivasan100% (1)

- Rms Polytechnic: Prepared By: Priyanka PatelDokumen40 halamanRms Polytechnic: Prepared By: Priyanka PatelBhaumik ParmarBelum ada peringkat

- Amiad Self-Cleaning Strainers For Water FiltrationDokumen10 halamanAmiad Self-Cleaning Strainers For Water FiltrationHari Krishna.MBelum ada peringkat

- Assessment of Venturi Nozzle For Filter Bag Cleaning in PDFDokumen0 halamanAssessment of Venturi Nozzle For Filter Bag Cleaning in PDFUmanath R PoojaryBelum ada peringkat

- 8 - Role of Backpulsing in Fouling Minimization in Crossflow Filtration With Ceramic Membranes PDFDokumen12 halaman8 - Role of Backpulsing in Fouling Minimization in Crossflow Filtration With Ceramic Membranes PDFRinaAprianiAapBelum ada peringkat

- SSPC Guide 16 PDFDokumen15 halamanSSPC Guide 16 PDFkishorekumar.animu100% (1)

- HepaDokumen6 halamanHepaPatricia HeraBelum ada peringkat

- Lecture No.7 (Air Filtration)Dokumen10 halamanLecture No.7 (Air Filtration)Mohsen HassanBelum ada peringkat

- PT Theory English New 2014Dokumen44 halamanPT Theory English New 2014CRISTIAN SILVIU IANUCBelum ada peringkat

- Barrier PolymersDokumen66 halamanBarrier PolymersFJNovaes454100% (1)

- Membrane Separation in Natural Gas Processing.Dokumen23 halamanMembrane Separation in Natural Gas Processing.CCESARPL100% (1)

- Plate and Frame FiltrationDokumen30 halamanPlate and Frame FiltrationRays Shearer100% (2)

- CE-311 Biological Treatment I - Trickling FilterDokumen17 halamanCE-311 Biological Treatment I - Trickling FilterShubham BansalBelum ada peringkat

- FILTRATIONDokumen18 halamanFILTRATIONPooja Choudhary100% (1)

- Filtration Unit Report: Index Terms-Pressure, Flow, Pump, Filtration, ParticleDokumen4 halamanFiltration Unit Report: Index Terms-Pressure, Flow, Pump, Filtration, Particlejuan francoBelum ada peringkat

- Science2 PDFDokumen11 halamanScience2 PDFezequieltoniBelum ada peringkat

- Lecture Filtration 1Dokumen20 halamanLecture Filtration 1LeeGonzaLgo0% (2)

- Experimental Report On RDVF New BackupDokumen11 halamanExperimental Report On RDVF New Backupmtayyab_786Belum ada peringkat

- EnE 250 Air Quality Management and Pollution Control Lecture 02 - 2 APC Stationary Sources Aug 13 2015Dokumen152 halamanEnE 250 Air Quality Management and Pollution Control Lecture 02 - 2 APC Stationary Sources Aug 13 2015Alexis Bryan RiveraBelum ada peringkat

- Absolute Rating vs. Nominal Rating For FiltersDokumen3 halamanAbsolute Rating vs. Nominal Rating For FiltersMukesh KangutkarBelum ada peringkat

- Filtration and SedimentationDokumen25 halamanFiltration and Sedimentationsalih karasuBelum ada peringkat

- For Maximum Pore Diameter and Filters For Laboratory Use' Permeability of Rigid PorousDokumen3 halamanFor Maximum Pore Diameter and Filters For Laboratory Use' Permeability of Rigid PorousROHITBelum ada peringkat

- Print 2PRES - Filtration 101Dokumen17 halamanPrint 2PRES - Filtration 101Fiqa SuccessBelum ada peringkat

- MembranesDokumen30 halamanMembranesmiraziey100% (1)

- Ijerph 16 00247 PDFDokumen19 halamanIjerph 16 00247 PDFsinghashish35Belum ada peringkat

- Preliminary Study FTUDokumen7 halamanPreliminary Study FTURizqi AmaliyahBelum ada peringkat

- Chee Lab 2 FinalDokumen26 halamanChee Lab 2 FinalOLEBOGENG RATLHOGOBelum ada peringkat

- Plate and Frame Filter PressDokumen11 halamanPlate and Frame Filter PressOmar Bassam0% (1)

- Filtration CHP 12Dokumen103 halamanFiltration CHP 12learningboxBelum ada peringkat

- University of Khartoum Faculty of Engineering Chemical Engineering DepartmentDokumen38 halamanUniversity of Khartoum Faculty of Engineering Chemical Engineering DepartmentAsila AhmedBelum ada peringkat

- Filter MechDokumen31 halamanFilter MechShiv Prasad SinghBelum ada peringkat

- FiltrationDokumen7 halamanFiltrationKers CelestialBelum ada peringkat

- Filtration PDFDokumen18 halamanFiltration PDFarno6antonio6spinaBelum ada peringkat

- Filtration ControlDokumen9 halamanFiltration ControlAlexandra Pity100% (1)

- Biotower FundamentalsDokumen40 halamanBiotower Fundamentalsram1987_rajaBelum ada peringkat

- MembranesDokumen30 halamanMembranesInamullah MaitloBelum ada peringkat

- Trickling FilterDokumen26 halamanTrickling Filterمصطفى جاسمBelum ada peringkat

- E 128 - 99 - RteyoaDokumen3 halamanE 128 - 99 - RteyoaSaurabh ChoudhariBelum ada peringkat

- 2 Particle Removal MechanismsDokumen13 halaman2 Particle Removal MechanismsThisIs MyCatBelum ada peringkat

- Some Review: Lecture 9: Synthesis of Separation System - Heterogenous Mixture SeparationDokumen13 halamanSome Review: Lecture 9: Synthesis of Separation System - Heterogenous Mixture SeparationhitenalmightyBelum ada peringkat

- SM - CH 7Dokumen50 halamanSM - CH 7Angie Dorado RodriguezBelum ada peringkat

- Modern Sensors HandbookDari EverandModern Sensors HandbookPavel RipkaPenilaian: 5 dari 5 bintang5/5 (1)

- Asymptotic Theory of Supersonic Viscous Gas FlowsDari EverandAsymptotic Theory of Supersonic Viscous Gas FlowsVladimir NeylandBelum ada peringkat

- Weaving BasicsDokumen19 halamanWeaving Basicsmastanareddy100% (2)

- Theory of MachinesDokumen44 halamanTheory of MachinesPulak DebnathBelum ada peringkat

- Weaving BasicsDokumen19 halamanWeaving Basicsmastanareddy100% (2)

- Ms W KnittingDokumen26 halamanMs W KnittingPulak Debnath100% (2)

- TNC Subscribing Videocon d2h ServicesDokumen1 halamanTNC Subscribing Videocon d2h ServicesPulak DebnathBelum ada peringkat

- D6588Dokumen6 halamanD6588Pulak DebnathBelum ada peringkat

- TNC Subscribing Videocon d2h ServicesDokumen1 halamanTNC Subscribing Videocon d2h ServicesPulak DebnathBelum ada peringkat

- Modified Btech Tex 6th Semester SyllabusDokumen11 halamanModified Btech Tex 6th Semester SyllabusPulak DebnathBelum ada peringkat

- Notice Recruit Micro 24-04-13Dokumen9 halamanNotice Recruit Micro 24-04-13Pulak DebnathBelum ada peringkat

- Modified Btech Tex 6th Semester SyllabusDokumen11 halamanModified Btech Tex 6th Semester SyllabusPulak DebnathBelum ada peringkat

- Modified Btech Tex 5th Semester SyllabusDokumen10 halamanModified Btech Tex 5th Semester SyllabusPulak DebnathBelum ada peringkat

- Job Costing: I) Specific Order or Job Costing II) Continuous Operation or Process CostingDokumen11 halamanJob Costing: I) Specific Order or Job Costing II) Continuous Operation or Process CostingPulak DebnathBelum ada peringkat

- Cost Sheet For Woven FabricDokumen12 halamanCost Sheet For Woven FabricPulak DebnathBelum ada peringkat

- Yarn RealisationDokumen7 halamanYarn RealisationPulak Debnath100% (1)

- Supply Chain Management: A Presentation by A.V. VedpuriswarDokumen54 halamanSupply Chain Management: A Presentation by A.V. Vedpuriswarramasb4uBelum ada peringkat

- Pile Structure PDFDokumen27 halamanPile Structure PDFPulak Debnath88% (8)

- PF - Omega Air D.O.O. LjubljanaDokumen2 halamanPF - Omega Air D.O.O. LjubljanaOMEGA AIR d.o.o. LjubljanaBelum ada peringkat

- Volvoconstruction Equivalencias Filtros PDFDokumen21 halamanVolvoconstruction Equivalencias Filtros PDFWladimir Amaguaña100% (1)

- Mikuni Carburetor Catalog 2012 NoBleedDokumen36 halamanMikuni Carburetor Catalog 2012 NoBleedPer ForsbergBelum ada peringkat

- Grayhound Wear Check Guide Book 21085Dokumen36 halamanGrayhound Wear Check Guide Book 21085julianmata100% (1)

- Manitou Telescopico Mrt2150 E3 Parts ManualsDokumen20 halamanManitou Telescopico Mrt2150 E3 Parts Manualswilliam100% (23)

- Losma Argos Air Filtration-Catalog-2020Dokumen8 halamanLosma Argos Air Filtration-Catalog-2020api-521872070Belum ada peringkat

- Dx180lc enDokumen12 halamanDx180lc enBhagoo HatheyBelum ada peringkat

- 325D Excavadora - Aehq5665-02Dokumen32 halaman325D Excavadora - Aehq5665-02Anthony PozoBelum ada peringkat

- Sample FAT ProtocolDokumen6 halamanSample FAT ProtocolUmer Al-Faisal50% (2)

- t-hr-rs-08001-st (Archived v1.0)Dokumen28 halamant-hr-rs-08001-st (Archived v1.0)fernanguedes2071Belum ada peringkat

- MANUAL Compactador Vertical Masalta 190342Dokumen15 halamanMANUAL Compactador Vertical Masalta 190342Nestor MedinaBelum ada peringkat

- PMS Form 1Dokumen31 halamanPMS Form 1Diane CiprianoBelum ada peringkat

- Walker Filtration Limited - Product Price Guide (EURO) - WFL1123 Rev-A-UK 0622 (Low Resolution)Dokumen64 halamanWalker Filtration Limited - Product Price Guide (EURO) - WFL1123 Rev-A-UK 0622 (Low Resolution)Fati Zora100% (1)

- Cat Long Term StorageDokumen2 halamanCat Long Term Storagesimon60sBelum ada peringkat

- Charge Air SystemDokumen12 halamanCharge Air SystemMottakin Hossain KhanBelum ada peringkat

- Lifan Motor E-StartDokumen9 halamanLifan Motor E-StartpezloBelum ada peringkat

- L4508 MaintenanceDokumen1 halamanL4508 MaintenancemosayebvalizadehBelum ada peringkat

- DI16077M 736kW PDFDokumen2 halamanDI16077M 736kW PDFYasin GargıBelum ada peringkat

- Hydraulic Catalogue. Reservoir EquipmentDokumen43 halamanHydraulic Catalogue. Reservoir Equipmentdini WFEBelum ada peringkat

- Automatic Film ProcessorDokumen37 halamanAutomatic Film ProcessorRichelle BrozoBelum ada peringkat

- 1000 Series (AA-AH YA-YD) UHDokumen58 halaman1000 Series (AA-AH YA-YD) UHВладислав ЛеоновBelum ada peringkat

- Dalgakiran Tidy20b-50 El Kitabi Komple Rev01Dokumen46 halamanDalgakiran Tidy20b-50 El Kitabi Komple Rev01Khairul Bashar100% (4)

- Miele S5000 Vacuum Cleaner ManualDokumen44 halamanMiele S5000 Vacuum Cleaner Manualfrankdoc0% (1)

- Compressed Air FiltersDokumen11 halamanCompressed Air FiltersRUN GOBelum ada peringkat

- Rotary Screw Manual-Jan 2008Dokumen51 halamanRotary Screw Manual-Jan 2008joss2207Belum ada peringkat

- Caterpillar d5b Crawler Parts Manual SN 26x878 and UpDokumen8 halamanCaterpillar d5b Crawler Parts Manual SN 26x878 and UpCarmen GarciaBelum ada peringkat

- Lubricating Oil Consumption and Acceptable LimitsDokumen19 halamanLubricating Oil Consumption and Acceptable LimitsTeguh Imam AdriBelum ada peringkat

- SB 214020Dokumen7 halamanSB 214020Hamilton MirandaBelum ada peringkat

- Husky Preassure Washer - Manual-Owner ManualDokumen8 halamanHusky Preassure Washer - Manual-Owner ManualLeonel RodriguezBelum ada peringkat

- CAT 3516bDokumen946 halamanCAT 3516bماجد السبيعي100% (1)