Clase Prueba

Diunggah oleh

Moisés Vázquez ToledoHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Clase Prueba

Diunggah oleh

Moisés Vázquez ToledoHak Cipta:

Format Tersedia

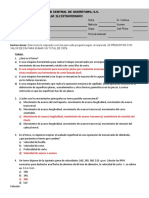

Aplicaciones con

ANSYS

Presenta:

Moiss Vzquez Toledo

26 agosto del 2013, Silao, Gto Clase muestra

Contenido

Introduccin

o Interfaz de ANSYS

Modelado con ANSYS

o Anlisis Modal

o Anlisis Harmnico

o Anlisis Estructural

Modelos Analticos

o Anlisis Modal

o Anlisis Harmnico

o Anlisis Estructural

Resultados

Conclusin

Clase muestra 26 agosto del 2013, Silao, Gto

Introduccin

Clase muestra 26 agosto del 2013, Silao, Gto

Introduccin

Clase muestra 26 agosto del 2013, Silao, Gto

Preprocessing

Solution

Postprocessing

Interfaz de ANSYS

Modelado con ANSYS

Clase muestra 26 agosto del 2013, Silao, Gto

Analizar el comportamiento dinmico de un micro-

cantilevers, este microresonador es el componente

mecnico de un sensor basado en tecnologa MEMS.

Geometra

500 28 5

Propiedades de Silicio

= 169.8

= 0.066

= 2330 .

3

Modelado con ANSYS

Clase muestra 26 agosto del 2013, Silao, Gto

Anlisis Modal

Numerical Model

o Natural frequency

May 14 , 2013, Albuquerque, NM Department of Mechanical Engineering

| |{ } | |{ } | |{ } ( ) { } t F u K u C u M = + +

| |{ } | |{ } { } 0 = + u K u M

) sin( t U u e =

| | | | ( ){ } { } 0

2

= u M K e

Sensor design

(17)

(18)

(19)

o Harmonic Solution

May 14 , 2013, Albuquerque, NM Department of Mechanical Engineering

} { { } } { } {

} { { } } { } {

t i t i i

t i t i i

e u i u e e u u

e F i F e e F F

e e |

e e

) (

) (

2 1 max

2 1 max

+ = =

+ = =

| | | | | | } { } { { } { }) ( ) )( (

2 1 2 1

2

F i F u i u K C i M + = + + + e e

Sensor design

(20)

(21)

Introduction

MEMS technology can allow the development of

magnetic field sensors.

Advantages:

o Small size

o Low power consumption

o High resolution

o Fast response

o Minimum cost

May 14 2013, Albuquerque, NM Department of Mechanical Engineering

Fig. 1. Sensor applications. [1]

[1] http://www.diarioelectronicohoy.com/sensor-de-movimiento-mems/

Introduction

Application

May 14 2013, Albuquerque, NM Department of Mechanical Engineering

a) b)

Fig. 2. a) Schematic diagram of the size and speed measure of vehicle , b) Future medical application of magnetic

field sensor for visualing magnetically market diagnostic capsule [2]

[2] Herrera-May AL, Aguilera-Cortes LA. Garca-Ramirez PJ. Resonant Magnetic Field Sensors Based On MEMS Technology. Sensors. 2009; 9(10): 7785-7813. doi:

10.3390/s91007785.

Introduction

Application

May 14 2013, Albuquerque, NM Department of Mechanical Engineering

a)

Fig. 3. a) Schematic vies of an inspection platform of oil pipeline wall that consiste of a rotating permanent magnetic

exciter and an array of magnetic field microsensor[3], b) Effect on the vehicle stability achieved with an ESP system

[3] Herrera-May AL, Aguilera-Corts LA, Garca-Ramrez PJ, Nelly B. Mota-Carrillo, Wendy Y, Padrn-Hernndez, Figueras E. Development of Resonant Magnetic Field

Microsensors: Challenges and Future Applications. Microsensors. India: INTECH; 2011: 65-84. ISBN 978-953-307-170-1.

Sensor design

SUMMit V process

May 14 2013, Albuquerque, NM Department of Mechanical Engineering

Fig. 4. SUMMit V fabrication process.

Sensor design

Structural configuration

May 14 2013, Albuquerque, NM Department of Mechanical Engineering

Fig. 5. Main dimensions of MEMS sensor.

26

2

8

2

150

2

0

0

466

3

0

30

1

0

0

100

2

Sensor design

Principle operation

May 14 2013, Albuquerque, NM Department of Mechanical Engineering

Fig. 6. Operation principle of the MEMS sensor.

Sensor design

Principle operation

May 14 2013, Albuquerque, NM Department of Mechanical Engineering

Fig. 7. Schematics of the signal conditiong system

for the magnetics field sensor. [2]

B

y

Magnetic field

densities

VCSEL

Phototransistor

PIC

L

C

D

Regulator 2

Electronic

oscillator

Current

source

Regulator 1

Battery

Sensor design

Analytical Model

o Natural frequency

May 14 2013, Albuquerque, NM Department of Mechanical Engineering

(05)

(06)

(07)

(08)

Sensor design

Analytical Model

o Damping Models

Viscous damping

May 14 2013, Albuquerque, NM Department of Mechanical Engineering

(09)

(10)

(11)

(12)

Sensor design

Analytical Model

Support Loss

Thermoelastic damping

May 14 2013, Albuquerque, NM Department of Mechanical Engineering

(13)

(14)

(15)

1

=

3

sinh + sin

cosh + cos

=

=

1

2

(16)

Numerical Model

o Natural frequency

May 14 , 2013, Albuquerque, NM Department of Mechanical Engineering

| |{ } | |{ } | |{ } ( ) { } t F u K u C u M = + +

| |{ } | |{ } { } 0 = + u K u M

) sin( t U u e =

| | | | ( ){ } { } 0

2

= u M K e

Sensor design

(17)

(18)

(19)

o Harmonic Solution

May 14 , 2013, Albuquerque, NM Department of Mechanical Engineering

} { { } } { } {

} { { } } { } {

t i t i i

t i t i i

e u i u e e u u

e F i F e e F F

e e |

e e

) (

) (

2 1 max

2 1 max

+ = =

+ = =

| | | | | | } { } { { } { }) ( ) )( (

2 1 2 1

2

F i F u i u K C i M + = + + + e e

Sensor design

(20)

(21)

Sensor design

Numerical Model

May 14 2013, Albuquerque, NM Department of Mechanical Engineering

Fig. 8. Element type

Result

May 14 2013, Albuquerque, NM Department of Mechanical Engineering

Fig. 8. Initial displacement (Joule effect).

Data Value

Current (mA) 1

Voltage (mV) 5.03

Electrical

Resistecial ()

5.03

Initial

Deformation (nm)

8.46

Result

May 14 2013, Albuquerque, NM Department of Mechanical Engineering

10.66 %

Models

Frequenc

y (kHz)

Numeric 48.326

Analytic 54.094

Fig. 8. Modal analysis

Result

May 14 2013, Albuquerque, NM Department of Mechanical Engineering

Fig. Linear respounse.

0

1

2

3

4

5

6

7

8

100 600 1100 1600 2100 2600

D

i

s

p

l

a

c

e

m

e

n

t

(

m

)

Magnetic Field (mT)

Displace

0

1

2

3

4

5

6

7

8

32,320 37,120 41,920 46,720 51,520

O

u

t

p

u

t

D

i

s

p

l

a

c

e

m

e

n

t

(

m

)

Frequency (kHz)

1000 mT

2000 mT

3000 mT

Fig. 8. Maxima displacement in resonans respons.

Atmospheric pressure

Result

May 14 2013, Albuquerque, NM Department of Mechanical Engineering

Pressure work 10 Pa

Pressure

(Pa)

Resolutio

n (T)

Power

consumption

(W)

101 325 3000 5.03

10 117 5.03

Result

May 14 2013, Albuquerque, NM Department of Mechanical Engineering

0

20

40

60

80

100

120

32,320 37,120 41,920 46,720 51,520

O

p

e

r

a

t

i

o

n

S

t

r

e

s

s

(

M

P

a

)

Frequency (Hz)

Principal Stress

1000 105.872

= 9.4

= 1000

= 0.5

()

500 105.872

=4.7

Conclusions

May 14 2013, Albuquerque, NM Department of Mechanical Engineering

The sensor consists of two u-shaped beams. These beams

are orthogonally joined between them.

This sensor can work for both atmospheric pressure and

10 Pa pressure, respectively.

This sensor has a simple optical sensing system.

The FEM and analytical models were made to resonanse

frequency of the sensor.

This sensor presented a linear response for cases studied.

Acknowledgments

May 14 , 2013, Albuquerque, NM Department of Mechanical Engineering

Anda mungkin juga menyukai

- Problemas 1ra Evaluacion 2.0Dokumen21 halamanProblemas 1ra Evaluacion 2.0Moisés Vázquez Toledo100% (1)

- Conciliacion Bancaria EjerciciosDokumen1 halamanConciliacion Bancaria EjercicioseduardBelum ada peringkat

- Document PDFDokumen33 halamanDocument PDFMoisés Vázquez ToledoBelum ada peringkat

- Document PDFDokumen33 halamanDocument PDFMoisés Vázquez ToledoBelum ada peringkat

- Cómo hacer biol caseroDokumen2 halamanCómo hacer biol caserojorge ciezaBelum ada peringkat

- Practica 4Dokumen3 halamanPractica 4Moisés Vázquez ToledoBelum ada peringkat

- Hoja de Cotejo EjerciciosDokumen1 halamanHoja de Cotejo EjerciciosMoisés Vázquez ToledoBelum ada peringkat

- Practica 5Dokumen2 halamanPractica 5Moisés Vázquez ToledoBelum ada peringkat

- Guía 5to - EnERO 1ra. Semana.Dokumen22 halamanGuía 5to - EnERO 1ra. Semana.Moisés Vázquez ToledoBelum ada peringkat

- Examen Extraordinario Maquinaria IndustrialDokumen7 halamanExamen Extraordinario Maquinaria IndustrialMoisés Vázquez ToledoBelum ada peringkat

- Practica 2 Realizar Operación de Torneado Usanso MasterCAMDokumen2 halamanPractica 2 Realizar Operación de Torneado Usanso MasterCAMMoisés Vázquez ToledoBelum ada peringkat

- 2do Examen Parcial Maquinaria IndustrialDokumen3 halaman2do Examen Parcial Maquinaria IndustrialMoisés Vázquez Toledo100% (2)

- Normativa para Evaluar Vibraciones en Ma PDFDokumen21 halamanNormativa para Evaluar Vibraciones en Ma PDFlubricacionBelum ada peringkat

- 1er Examen Parcial Maquinaria IndustrialDokumen1 halaman1er Examen Parcial Maquinaria IndustrialMoisés Vázquez ToledoBelum ada peringkat

- 1 KG Falda o Cuehete de ResDokumen1 halaman1 KG Falda o Cuehete de ResMoisés Vázquez ToledoBelum ada peringkat

- 1er Eparcial Maquinaria IndustrialDokumen5 halaman1er Eparcial Maquinaria IndustrialMoisés Vázquez ToledoBelum ada peringkat

- Guia TallerDokumen5 halamanGuia TallerMoisés Vázquez ToledoBelum ada peringkat

- Document PDFDokumen5 halamanDocument PDFMoisés Vázquez ToledoBelum ada peringkat

- IntroduccionDokumen17 halamanIntroduccionMoisés Vázquez ToledoBelum ada peringkat

- Document PDFDokumen27 halamanDocument PDFMoisés Vázquez ToledoBelum ada peringkat

- Atomos, Ecuacion de ShoringerDokumen0 halamanAtomos, Ecuacion de ShoringerFabian ChaconBelum ada peringkat

- 3 Pinturas SA PDFDokumen7 halaman3 Pinturas SA PDFMoisés Vázquez ToledoBelum ada peringkat

- IntroduccionDokumen17 halamanIntroduccionMoisés Vázquez ToledoBelum ada peringkat

- IntroduccionDokumen17 halamanIntroduccionMoisés Vázquez ToledoBelum ada peringkat

- ACTnn2n1nPASADOnCONTINUOnOnPROGRESIVO 565ec4a28399f28Dokumen5 halamanACTnn2n1nPASADOnCONTINUOnOnPROGRESIVO 565ec4a28399f28Moisés Vázquez ToledoBelum ada peringkat

- Carpetas Ejecutivas-OficinaDokumen6 halamanCarpetas Ejecutivas-OficinaMoisés Vázquez ToledoBelum ada peringkat

- 1.2.1 Departamento de MarketingDokumen4 halaman1.2.1 Departamento de MarketingMoisés Vázquez ToledoBelum ada peringkat

- Acumulacion de ToleranciasDokumen10 halamanAcumulacion de ToleranciasbryamBelum ada peringkat

- Fuentes de información para diseñar instalaciones de manufacturaDokumen10 halamanFuentes de información para diseñar instalaciones de manufacturaMoisés Vázquez ToledoBelum ada peringkat

- Planeacion Distibución Mod MVTDokumen11 halamanPlaneacion Distibución Mod MVTMoisés Vázquez ToledoBelum ada peringkat

- 1.1.2 Procedimiento Del Diseño de InstalacionesDokumen3 halaman1.1.2 Procedimiento Del Diseño de InstalacionesMoisés Vázquez ToledoBelum ada peringkat

- Proyecto Administracion v02Dokumen2 halamanProyecto Administracion v02Moisés Vázquez ToledoBelum ada peringkat

- Convenio de Acuerdo A Ley (1) TripartitoDokumen9 halamanConvenio de Acuerdo A Ley (1) TripartitoCarlosEnriqueFelixYañezYañezBelum ada peringkat

- Presupuesto Analitico de Obra: Especifica Und Cant P. Unit Clasificado R de GastoDokumen3 halamanPresupuesto Analitico de Obra: Especifica Und Cant P. Unit Clasificado R de GastoroberBelum ada peringkat

- Seminario de Actualizacion Ii UvmDokumen4 halamanSeminario de Actualizacion Ii UvmAbimael AlonsoBelum ada peringkat

- Casuistica de Cierre. P.E.A.T.colegio de Contadores Profesor BrownDokumen43 halamanCasuistica de Cierre. P.E.A.T.colegio de Contadores Profesor Brownkimberly ramirezBelum ada peringkat

- Auto Que Saca Los Bienes A RemateDokumen1 halamanAuto Que Saca Los Bienes A RemateLicArzateBelum ada peringkat

- Folleto Ing Industrial 2022Dokumen12 halamanFolleto Ing Industrial 2022Yerald PeraltaBelum ada peringkat

- Muros de Bloques de PiedraDokumen8 halamanMuros de Bloques de PiedraYorsh MéndezBelum ada peringkat

- 04 - BarridoDokumen49 halaman04 - BarridoJorge GalindoBelum ada peringkat

- Neuro Navegador S7Dokumen2 halamanNeuro Navegador S7Rosmar Samarith González CarrilloBelum ada peringkat

- El Efecto Portafolio de La Regulacion de Precios de Medicamentos - STAR - BID - Sep2018 PDFDokumen44 halamanEl Efecto Portafolio de La Regulacion de Precios de Medicamentos - STAR - BID - Sep2018 PDFJaime Enrique Diaz RicoBelum ada peringkat

- GUIA de CVV Ejercicios Resueltos y PruestosDokumen37 halamanGUIA de CVV Ejercicios Resueltos y PruestosMisti Furioso100% (1)

- MozillaDokumen2 halamanMozillaDaniel HernandezBelum ada peringkat

- Características de Sistemas Operativos JesusDokumen8 halamanCaracterísticas de Sistemas Operativos JesusJesus saavedraBelum ada peringkat

- Las Pruebas A Gran Escala en EducaciónDokumen2 halamanLas Pruebas A Gran Escala en EducaciónIsaac ValderrabanoBelum ada peringkat

- Trazabilidad del caféDokumen14 halamanTrazabilidad del caféJoan Sebastian Arbelaez CaroBelum ada peringkat

- Cap 3 Capital Social y Capital ContableDokumen21 halamanCap 3 Capital Social y Capital ContableveroBelum ada peringkat

- Desactivar La Vista Protegida en Office (Excel, Word..Dokumen2 halamanDesactivar La Vista Protegida en Office (Excel, Word..Daniel RospigliosiBelum ada peringkat

- Escrito para Inscripción Cancelacion de Nombramiento de Rep LegalDokumen6 halamanEscrito para Inscripción Cancelacion de Nombramiento de Rep LegalClaudia EscobarBelum ada peringkat

- Tarea Virtual 4 LegislaciónDokumen4 halamanTarea Virtual 4 LegislaciónBenllyJ.PachoQuintanaBelum ada peringkat

- Simulacion en Solidworks TransferenciaDokumen9 halamanSimulacion en Solidworks TransferenciaWagner Aguirre RiveraBelum ada peringkat

- Propuestas de Negocios PersuasivasDokumen4 halamanPropuestas de Negocios PersuasivasCarlos CastroBelum ada peringkat

- Acuerdo de divorcio y regulación de alimentosDokumen4 halamanAcuerdo de divorcio y regulación de alimentosCaro IturraBelum ada peringkat

- Mapa Conceptual Ley 1751 Del 2015 Ley EstatutariaDokumen3 halamanMapa Conceptual Ley 1751 Del 2015 Ley EstatutariaLUIS ARTURO SARMIENTO TOLOZABelum ada peringkat

- El Periodico Mural - ImpresoDokumen2 halamanEl Periodico Mural - ImpresoGladys Marleny Alva LeonBelum ada peringkat

- 2-Gestion de Memoria en Minix 3Dokumen29 halaman2-Gestion de Memoria en Minix 3Lino GHBelum ada peringkat

- Aut 3era Entrega OrlistarDokumen1 halamanAut 3era Entrega OrlistarPts PtsBelum ada peringkat

- Sesion Diseño y Elaboracion de Instrumentos de InvestigacionDokumen17 halamanSesion Diseño y Elaboracion de Instrumentos de InvestigacionAlexander Briceño CarhuanchoBelum ada peringkat

- Ejercicios de Puertas LogicasDokumen2 halamanEjercicios de Puertas LogicasDaniel LopezBelum ada peringkat