Methanol Production

Diunggah oleh

Govind KumarDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Methanol Production

Diunggah oleh

Govind KumarHak Cipta:

Format Tersedia

Carbon Dioxide Hydrogenation Still under experimental stages Most sustainable method Direct Hydrogenation of CO2 to methanol CH3OH

H3OH Conversion of CO2 to CO by Reverse Water Also known as Methyl Alcohol, Carbinol Gas Shift, then being converted into Methanol Wood Adhesive Useful chemical for multi-purpose usage Coal Gasification-based Process Plastic and Dye Production Moving/Fixed Bed Reactor Solvents for paints and dyes Entrained-Flow Reactor Transportation Fuel Gas-based Process Fludized Bed Reactor Wastewater Denitrification Coal Gasification-based Process Biodiesel Transesterification Chemical Gas-based Process Carbon Dioxide Hydrogenation Process Generation of Electricity Natural Gas as feed Reformation of hydrocarbon feedstock Compression and Conversion of syngas Distillation for pure methanol production

though so, worldwide it is believed that there will still be reach a Even In year 2011, the methanol consumption

55 million metric ton per annum, which can also be raise in the methanol economy. thehydrogenation world methanol production capacity. assumed In future,as CO2 methanol production According to the chart, the price methanol generally process is believed to be able the of take over all the raised. 1990s, the price of methanol shown process is around currentIn coal gasification-based and gas-based $100/tonne while currently it is around $350/tonne. due to all the benefits in the human life. LNG affects the price of methanol the most. LNG has high demands in certain countries, causing higher cost for methanol production.

Recycle

Vapour

V-2

Water in E-6 E-11 E-9 Methanol

V-5

Mixed Stream Feed

V-1 V-3 V-4

Methanol

E-2 E-1 E-3

E-4 Liquid

E-5

Bottom Liquid

V-7

E-10 Water Out E-7 E-8

V-6

Environmental Aspects

Water

Reducing GHG emissions Preventing global warming by using CO2 as feed

Economic Aspects and Demands

Multi-use of methanol in daily productions, fuels High demand of methanol as the amount is expected to raise

by 95 million metric tons in year 2013.

Raw Materials Used

Abundant amount of CO2 available to be used. Hydrogen is the only chemical that requires cost to obtain,

hence is determined to be a cheap process of methanol production

Recycle

Vapour

V-2

Water in E-6 E-11 E-9 Methanol

V-5

Mixed Stream Feed

V-1 V-3 V-4

Methanol

E-2 E-1 E-3

E-4 Liquid

E-5

Bottom Liquid

V-7

E-10 Water Out

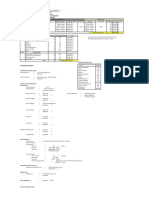

Key Technical and Performance of Data T & P needed in order for the reaction to take place (200C & 3950 kPa Structure Output Input Structure Most separation after reaction areoperations done based on b.p before Unit operations involved after Unit involved differences reactions takes place reaction takes place Conversion given by the CSTR was only 36.19% Conversion can be increased with the use of Cu/ZnO-based catalyst

E-7 Water E-8

V-6

Recycle Structure Product from Separator - Mixer

Required input data was obtained from literature & reference from similar production manufacturers Fluid package SRK Methanol is considered to be hydrocarbon chemical Capability to accurately predict the vapour pressure, liquid density, and equilibrium ratios Reactor sizing 2:1 ratio (1.7 m of diameter and 0.85 m of height) Adjustment of reactor was done until were no significant change in conversion.

The abundance of CO2

Reduce CO2 contribution to Global Warming

Profitable considering only H2 to be the only

significant cost of raw material Blooming market of the methanol industry

Anda mungkin juga menyukai

- Methane Syngas Methanol MicroprocessingDokumen14 halamanMethane Syngas Methanol MicroprocessingAtieyNoryhati-dzBelum ada peringkat

- Growth of Escherichia Coli in A 5 Litre Batch Fermentation VesselDokumen15 halamanGrowth of Escherichia Coli in A 5 Litre Batch Fermentation VesselAs'ad Mughal100% (2)

- Scale-Up - Right First TimeDokumen4 halamanScale-Up - Right First TimeDoddappa Anekal0% (1)

- Sulfolane Report - FinalDokumen61 halamanSulfolane Report - FinalAngelo SuperTello100% (2)

- Simulation of Methanol Production From Biomass Gasification in Interconnected Fluidized BedsDokumen9 halamanSimulation of Methanol Production From Biomass Gasification in Interconnected Fluidized BedsKelly TorresBelum ada peringkat

- Process Economics Program - Pta ProcessDokumen10 halamanProcess Economics Program - Pta ProcessvasucristalBelum ada peringkat

- Fuel DME Plant in East AsiaDokumen10 halamanFuel DME Plant in East AsiaHim KungBelum ada peringkat

- User Guide For Models and Physical Properties - Multiflash 4.3Dokumen74 halamanUser Guide For Models and Physical Properties - Multiflash 4.3GalileosaysBelum ada peringkat

- PFDDokumen1 halamanPFDDenny FirmansyahBelum ada peringkat

- Process Modeling, Simulation, and Environmental Applications in Chemical EngineeringDokumen358 halamanProcess Modeling, Simulation, and Environmental Applications in Chemical Engineeringamerico molinaBelum ada peringkat

- 64788Dokumen35 halaman64788ghatak2100% (1)

- Plant Design ReportsDokumen7 halamanPlant Design ReportspsjjoshiBelum ada peringkat

- Non-exhaustive structural design criteriaDokumen22 halamanNon-exhaustive structural design criteriamarin cristian100% (1)

- Chapter 3Dokumen14 halamanChapter 3Larry Jampong100% (1)

- BM15-17 UdaanDokumen105 halamanBM15-17 UdaanAnonymous HzljLSMcBelum ada peringkat

- Pipephase 9.1: User's GuideDokumen104 halamanPipephase 9.1: User's GuideGabi AraujoBelum ada peringkat

- FulltextDokumen178 halamanFulltextChandresh ChaudhariBelum ada peringkat

- Production Process of MethanolMETANOLDokumen2 halamanProduction Process of MethanolMETANOLFlávia MonteiroBelum ada peringkat

- Methanol SdsDokumen9 halamanMethanol SdsLeslieBigbearBelum ada peringkat

- TA-143-D00-G-TD005 - 0 - Employer's Requirements PDFDokumen78 halamanTA-143-D00-G-TD005 - 0 - Employer's Requirements PDFshareyhouBelum ada peringkat

- Books: Cryogenic Engineering, 2 Edition Distillation Theory and Its Application To Design of Separation UnitsDokumen1 halamanBooks: Cryogenic Engineering, 2 Edition Distillation Theory and Its Application To Design of Separation UnitsRaul tejadaBelum ada peringkat

- BUET Chemical Engineering Project on Biodiesel ProductionDokumen30 halamanBUET Chemical Engineering Project on Biodiesel ProductionTamzidul AlamBelum ada peringkat

- Manufacturing DAP using the cross processDokumen9 halamanManufacturing DAP using the cross processNabeel SiddiqueBelum ada peringkat

- Cost Estimation - Acetone Plant 1 PDFDokumen2 halamanCost Estimation - Acetone Plant 1 PDFDhananjay pathareBelum ada peringkat

- Synthesis of Vinyl Acetate Monomer From Syntesis Gas TustinDokumen11 halamanSynthesis of Vinyl Acetate Monomer From Syntesis Gas Tustindesigat4122Belum ada peringkat

- Equipments Specification For Power House: Economic Evaluation & ProfitabilityDokumen12 halamanEquipments Specification For Power House: Economic Evaluation & Profitabilitysaur1Belum ada peringkat

- HSFCCDokumen22 halamanHSFCCdonald55555100% (1)

- SCRCostManualchapter Draftforpubliccomment6!5!2015Dokumen101 halamanSCRCostManualchapter Draftforpubliccomment6!5!2015Mustika Putri PertiwiBelum ada peringkat

- Simulation of Crude Distillation Unit of Eastern Refinery Limited (ERL) Using Aspen PlusDokumen6 halamanSimulation of Crude Distillation Unit of Eastern Refinery Limited (ERL) Using Aspen PlusAndre BasantesBelum ada peringkat

- New α-SABLIN Approach for Linear Alpha Olefins ProductionDokumen3 halamanNew α-SABLIN Approach for Linear Alpha Olefins Productionsk281Belum ada peringkat

- Nicholas Oligomerization PDFDokumen16 halamanNicholas Oligomerization PDFTanase DianaBelum ada peringkat

- Thermal Oxidizer Technology SheetDokumen1 halamanThermal Oxidizer Technology SheetadrianioantomaBelum ada peringkat

- Preliminary Design Chemical Plant LAB PDFDokumen9 halamanPreliminary Design Chemical Plant LAB PDFgeorge cabreraBelum ada peringkat

- Material BalanceDokumen6 halamanMaterial BalanceMehran Rasheed GorayaBelum ada peringkat

- Coilsim Integration With HysysDokumen72 halamanCoilsim Integration With HysysJamal Safdar100% (1)

- Material and Energy BalanceDokumen28 halamanMaterial and Energy Balancemuhammad arslan100% (1)

- Rate Equation of Polymarization ReactionDokumen334 halamanRate Equation of Polymarization ReactionSherif Nour100% (1)

- Final ReportDokumen29 halamanFinal ReportpratikBelum ada peringkat

- Propylene Oxide - New MethodDokumen8 halamanPropylene Oxide - New Methodvinicius_amaral_5Belum ada peringkat

- Structured Packing Liquid DistributorsDokumen20 halamanStructured Packing Liquid Distributorsnedian_2006Belum ada peringkat

- En Analysis of Thermal Efficiency Limit of Steam Methane Reforming ProcessDokumen8 halamanEn Analysis of Thermal Efficiency Limit of Steam Methane Reforming ProcessAgam HanasichulaBelum ada peringkat

- Hydrogen Gas Storage VesselDokumen22 halamanHydrogen Gas Storage VesselSAURABH MODIBelum ada peringkat

- MTG ProcessDokumen59 halamanMTG ProcessShehzad Afzal MaharBelum ada peringkat

- Acrolein Design ProjectDokumen13 halamanAcrolein Design ProjectPeter McCormack100% (1)

- Diesel Hydrodesulphurization (DHDS) / Hydrotreating (DHDT) TechnologyDokumen10 halamanDiesel Hydrodesulphurization (DHDS) / Hydrotreating (DHDT) Technologyalok sahuBelum ada peringkat

- Scale Up of Chemical ReactorsDokumen52 halamanScale Up of Chemical ReactorsAl GhazaliBelum ada peringkat

- 5 - Equipment Cost EstimateDokumen8 halaman5 - Equipment Cost EstimateJose Yebra DeaunaBelum ada peringkat

- Methyldiethanolamine As A Solvent For Gas DesulfurizationDokumen66 halamanMethyldiethanolamine As A Solvent For Gas DesulfurizationAnime MtBelum ada peringkat

- SWEETENING (Chemical Absorption) PresentationDokumen54 halamanSWEETENING (Chemical Absorption) Presentationarsalan amirpour75% (4)

- Cost Estimation - Aadarsh ShuklaDokumen6 halamanCost Estimation - Aadarsh Shuklavidit Singh100% (1)

- Dewatering Column AA Grade MethanolDokumen15 halamanDewatering Column AA Grade MethanolIrma BrennanBelum ada peringkat

- Df-25054-Rep-03-001 (Proceso H2)Dokumen110 halamanDf-25054-Rep-03-001 (Proceso H2)María Macharé GutierrezBelum ada peringkat

- Converting Waste Plastics Into Liquid Fuel by Pyrolysis Developments in China - Yuan XingzhongDokumen27 halamanConverting Waste Plastics Into Liquid Fuel by Pyrolysis Developments in China - Yuan Xingzhongvuongcoi102Belum ada peringkat

- Direct DME Synthesis from Natural GasDokumen9 halamanDirect DME Synthesis from Natural GasM Alim Ur RahmanBelum ada peringkat

- Plastic Sorters Comparison ParametersDokumen24 halamanPlastic Sorters Comparison Parametersjustakash0% (1)

- Ammonia ManufacturingDokumen16 halamanAmmonia ManufacturingMuhammad Irfan MalikBelum ada peringkat

- Large Scale Industrial Ammonia Cracking PlantDokumen4 halamanLarge Scale Industrial Ammonia Cracking PlantZ ABelum ada peringkat

- Statistics for Process Control Engineers: A Practical ApproachDari EverandStatistics for Process Control Engineers: A Practical ApproachBelum ada peringkat

- Project 2-17sep MiriDokumen4 halamanProject 2-17sep MiriGovind KumarBelum ada peringkat

- Algebra 0001Dokumen24 halamanAlgebra 0001Govind KumarBelum ada peringkat

- Tutorial 4Dokumen1 halamanTutorial 4Govind KumarBelum ada peringkat

- Assignment 2Dokumen7 halamanAssignment 2Govind KumarBelum ada peringkat

- Chapter 8-Extraction and LeachingDokumen55 halamanChapter 8-Extraction and LeachingGovind Kumar90% (10)

- Frequency ResponseDokumen30 halamanFrequency ResponseGovind KumarBelum ada peringkat

- Chapter 8-Extraction and LeachingDokumen55 halamanChapter 8-Extraction and LeachingGovind Kumar90% (10)

- CHE 477 Ass 2014Dokumen2 halamanCHE 477 Ass 2014Govind KumarBelum ada peringkat

- Urea ModelingDokumen20 halamanUrea ModelingekmagisBelum ada peringkat

- MoodyDokumen1 halamanMoodyGovind KumarBelum ada peringkat

- NiggasDokumen1 halamanNiggasGovind KumarBelum ada peringkat

- Hello WorldDokumen1 halamanHello WorldGovind KumarBelum ada peringkat

- Boletin Técnico 06 AditivoDokumen3 halamanBoletin Técnico 06 Aditivojuanmanuel_4615958Belum ada peringkat

- A Technical Report On Gas SweeteningDokumen12 halamanA Technical Report On Gas SweeteningJiril JacobBelum ada peringkat

- 9 Energy Balance and GHG Inventory SpreadsheetDokumen227 halaman9 Energy Balance and GHG Inventory SpreadsheetQuyền MinhBelum ada peringkat

- Basics of Refining and Optimization Dec 2019Dokumen31 halamanBasics of Refining and Optimization Dec 2019AranyosiMártonBelum ada peringkat

- In Land LNG Receiving and Regas TerminalDokumen20 halamanIn Land LNG Receiving and Regas TerminaltcandelarioBelum ada peringkat

- Biomax Fuels investor presentation highlights refining capacityDokumen26 halamanBiomax Fuels investor presentation highlights refining capacityVijay Kumar NatteyBelum ada peringkat

- Hydrocracking Unit PDFDokumen9 halamanHydrocracking Unit PDFcrili69Belum ada peringkat

- DR Yenny Meliana - Riset Biomassa Di LIPI Untuk Mendukung Ketahanan EnergiDokumen27 halamanDR Yenny Meliana - Riset Biomassa Di LIPI Untuk Mendukung Ketahanan EnergiSetan TolakBelum ada peringkat

- Reference ListDokumen6 halamanReference ListMehdi Hajd KacemBelum ada peringkat

- VE Environmental Ambition 2022Dokumen29 halamanVE Environmental Ambition 2022Iman RamangBelum ada peringkat

- SelexolDokumen5 halamanSelexolJohn MutBelum ada peringkat

- CPC Diesel SpecificationDokumen1 halamanCPC Diesel SpecificationamilasriBelum ada peringkat

- Gabungan Pekan 55Dokumen5 halamanGabungan Pekan 55Break LimsBelum ada peringkat

- Licence-Checklist-Production-of-BiofuelDokumen6 halamanLicence-Checklist-Production-of-BiofuelnicktgarciaBelum ada peringkat

- 19 AlvheimDokumen3 halaman19 AlvheimLem Fei-BronjulBelum ada peringkat

- UCG For Power GenerationDokumen52 halamanUCG For Power GenerationVăn Đại - BKHNBelum ada peringkat

- BP's Biofuel StrategyDokumen17 halamanBP's Biofuel Strategyscorpion2001glaBelum ada peringkat

- Quartz 9000 Future 5W-30 PDFDokumen1 halamanQuartz 9000 Future 5W-30 PDFdnoaisapsBelum ada peringkat

- Natural Gas ProcessingDokumen4 halamanNatural Gas ProcessingChung WyBelum ada peringkat

- Development of Briquettes From Cotton Stalks With The High-Pressure Briquetting MachineDokumen6 halamanDevelopment of Briquettes From Cotton Stalks With The High-Pressure Briquetting MachineDASARADH231Belum ada peringkat

- Ethanol From Algae PDFDokumen2 halamanEthanol From Algae PDFJohnBelum ada peringkat

- Actividad de Aprendizaje Número 1Dokumen6 halamanActividad de Aprendizaje Número 1jesus manuel alvarez riveraBelum ada peringkat

- Ficha Técnica Manguera ULDokumen1 halamanFicha Técnica Manguera ULDavidGòmezBelum ada peringkat

- ISO 8217 2010 Fuel Standard For Marine Distillate FuelsDokumen2 halamanISO 8217 2010 Fuel Standard For Marine Distillate FuelstamailhamBelum ada peringkat

- 2009-11 Natural Gas Fuel System LNGDokumen2 halaman2009-11 Natural Gas Fuel System LNGSyed MajeedBelum ada peringkat

- Abdulkader - Djellout AlgeriaDokumen59 halamanAbdulkader - Djellout AlgeriasashaBelum ada peringkat

- Mm-22 No. 1, 2 H. F. O. Purifier Sj-30gDokumen44 halamanMm-22 No. 1, 2 H. F. O. Purifier Sj-30gdeli34Belum ada peringkat

- Fuel Calorific ValueDokumen3 halamanFuel Calorific Valueyw_oulalaBelum ada peringkat

- L-3 Prod Report 10.05.2020Dokumen3.260 halamanL-3 Prod Report 10.05.2020swarupkumarnayakBelum ada peringkat

- Compressed Natural Gas Asa Vehicle FuelDokumen57 halamanCompressed Natural Gas Asa Vehicle FuelHIPAP100% (1)