RD Poster - San Franscisco Conf - 6sept2012

Diunggah oleh

Akk KolDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

RD Poster - San Franscisco Conf - 6sept2012

Diunggah oleh

Akk KolHak Cipta:

Format Tersedia

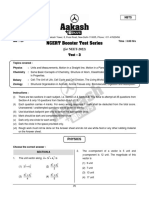

Reactive Distillation for Synthesis of Chemicals and Advanced Biofuels

Dennis Miller, Carl Lira, Aspi Kolah Department of Chemical Engineering & Materials Science Michigan State University, East Lansing, 48824 MI, USA

millerd@msu.edu (517)353-3928

Systems Studied

Lactic acid esterification to ethyl lactate

13-14 September 2012

Succinic acid esterification to di-ethyl succinate Citric acid esterification to tri-ethyl citrate Levulinic acid esterification to ethyl-levulinate and butyl-levulinate Propionic acid esterification to ethyl propionate Dilute acetic acid removal from aqueous streams Acetalization for separation of ethylene glycol and propylene glycol Acetalization reactions for acetaldehyde and formaldehyde Separation of close boiling compounds like cyclohexene and cyclohexane by esterifcation with acetic acid Separation of iso-butylene from C3 - C4 alkane mixtures and oligomerization to isooctene Dihydroxyacetone from glycerol Transesterification reactions like methyl-stearate to butyl-stearate Proprietary reactions with industrial partners and national laboratories

O HO O

MSU Reactive Distillation Miniplant Facility

Research & Industrial collaboration Feasibility analysis Technology demonstration

Katapak SP-11

Water + Ethanol

Succinate recovery from fermentation broth O k

1

OH

OH k-1

HO

O O

Succinic acid + Ethanol

H2O

Succinic Acid

O HO O O

Ethanol

k2

Mono-Ethyl Succinate

O O O O

Ethanol

OH

H2O

k-2

Mono-Ethyl Succinate

2 k3

Di-EthylEthanol Succinate

H2O

Diethyl succinate

Column specifications

Diethyl succinate

Lab capabilities

Catalysis Reaction kinetics Multiphase reactors Phase equilibria Aspen process modeling Molecular modeling

Di-Ethyl Ether

Height of vented enclosure 10.8 m (35 ft) 50 mm Glass column (Vacuum to 0.1 MPa) 50 mm SS-316 column (0.1 to 2.0 MPa) 8 m Reactive section 1 m Non reactive enriching 1 m Non reactive stripping

Reactive Distillation Column

Reactive distillation for diethyl succinate formation and simultaneous removal of acetate byproduct

Feed to Pre-reactor

Wt % Succinic Acid 25.0 Acetic Acid 2.5 Ethanol 72.5 115 C Flow, g/min Temp, oC Wt % Ethanol Water Diethyl Ether Acetic Acid Ethyl Acetate

Run 14B

Distillate

Expt. 46.5 115 Expt. 89.74 6.15 1.82 0.01 2.20 Aspen 48.6 116.5 Aspen 89.80 5.59 1.13 0.01 2.30

Diethyl Succinate

50 lit 70oC

Top Feed

30.93 g/min 90 C

Wt % Succinic Acid 1.21 Mono-et Succ 18.90 Di-et Succ 14.92 Acetic Acid 0.45 Ethyl Acetate 3.00 Ethanol 55.70 Water 5.86 Diethyl Ether 0.01

45 Psig

Results of model recovery experiments

3.8 m Katapak SP11 1 m Sulzer BX Stripping 0.6 m Suzer BX Enriching Bottom Feed 28.7 g/min 86 C

Wt % Ethanol 100.0

Bottom

Expt. 245 C Flow, g/min Temp, oC Wt % 11.7 245 Expt. Aspen 11.00 238.8 Aspen 0.00 2.10 96.70 1.22 0.00 0.00 0.01

Overall Succinic acid conv: Diethyl succinate yield: Total mass balance: Succinate balance:

> 99% 99% 99% 98%

Small loss of Ethanol to Diethyl ether DES of technical grade can be sold directly

Succinic Acid 0.16 Mono-et Succ 0.58 Di-et Succinate 97.36 Ethanol 1.55 Water 0.21 Acetic Acid 0.14 Ethyl Acetate 0.00

Synthesis of Tri-ethyl citrate using Pre- and Side-Reactors

Advantages

Advantageous for slow reaction Easy catalyst replacement preferred by industry Easy control of reactant ratio Lower capital cost & conventional equipment Distillation column hydraulics and mass transfer not affected by catalyst structure

Summary

Michigan State University has full capabilities for developing, characterizing, demonstrating new reactive distillation technologies Process and molecular modelling provide rapid evaluation of new systems New succinate acid recovery process synthesizes esters directly from fermentation broth without isolating free acid Reactive distillation produces pure diethyl succinate at nearly 100% yield from mixed acid feed

Acknowledgment

Financial support from DOE, USDA, NCGA, Chemical Companies

Anda mungkin juga menyukai

- Production of MethylacetateDokumen57 halamanProduction of MethylacetateAhmed Ali50% (2)

- Supercritical Fluids NotesDokumen19 halamanSupercritical Fluids NotesAakanksha GautamBelum ada peringkat

- Rahul PPT f3Dokumen54 halamanRahul PPT f3Rahul GucptaBelum ada peringkat

- Petrochemical Processes HandbookDokumen209 halamanPetrochemical Processes HandbookAnoop Uchagawkar100% (6)

- Formulations ToiletriesDokumen13 halamanFormulations ToiletriesErrol FernandesBelum ada peringkat

- Terephthalic AcidDokumen8 halamanTerephthalic AcidWali AhsanBelum ada peringkat

- Teo2004 PDFDokumen9 halamanTeo2004 PDFFabian Loor CadenaBelum ada peringkat

- Biodiesel Production Technologies-VanGerpen 2p PresentationDokumen22 halamanBiodiesel Production Technologies-VanGerpen 2p PresentationvivekBelum ada peringkat

- Synthesis of Carbovir and Abacavir From A Carbocyclic PrecursorDokumen8 halamanSynthesis of Carbovir and Abacavir From A Carbocyclic PrecursorDANNA SOFIA SANCHEZ CAMACHOBelum ada peringkat

- V3 Case StudiesDokumen63 halamanV3 Case StudiesNuryanti RokhmanBelum ada peringkat

- CH3-CH-OH CoohDokumen105 halamanCH3-CH-OH CoohAniket GawdeBelum ada peringkat

- Advanced Program Hanoi University of Mining and Geology: Methyl Acetate Plant DesignDokumen21 halamanAdvanced Program Hanoi University of Mining and Geology: Methyl Acetate Plant DesignTrường Tùng LýBelum ada peringkat

- Agilent generalCEDokumen32 halamanAgilent generalCEDenisa JucanBelum ada peringkat

- LR Ex 3Dokumen15 halamanLR Ex 3Fareeza SaheeraBelum ada peringkat

- Biodiesel From Waste or Unrefined Oils Using Calcium Oxide-Based CatalystsDokumen32 halamanBiodiesel From Waste or Unrefined Oils Using Calcium Oxide-Based Catalystsdoulat2000Belum ada peringkat

- Kjeltec 2100 Datasheet - GBDokumen2 halamanKjeltec 2100 Datasheet - GBg3lu06100% (1)

- Ethylene Glycol Heat-Transfer FluidDokumen4 halamanEthylene Glycol Heat-Transfer FluiderreagaaBelum ada peringkat

- RD Column For Butyl Acetate ProductionDokumen8 halamanRD Column For Butyl Acetate ProductionAbuBakar SaleemBelum ada peringkat

- Preparation of Water-Soluble ChitosanDokumen7 halamanPreparation of Water-Soluble ChitosanLili GodinaBelum ada peringkat

- ProjectDokumen28 halamanProjectAbdulwahid SultanBelum ada peringkat

- Lab ReportDokumen5 halamanLab ReportDhashJoshiBelum ada peringkat

- ETACRDDokumen53 halamanETACRDSampathkumar AttuluriBelum ada peringkat

- 4 CommercialDokumen38 halaman4 Commercialanpuselvi125Belum ada peringkat

- L004 - Ritik Jain - MSDokumen6 halamanL004 - Ritik Jain - MSritikBelum ada peringkat

- Trabaj Oxido D EtilenoDokumen3 halamanTrabaj Oxido D EtilenoJuan M LariosBelum ada peringkat

- 6 Chilev 463-474Dokumen12 halaman6 Chilev 463-474emad hayekBelum ada peringkat

- Lab 5Dokumen8 halamanLab 5Muhamad AimanBelum ada peringkat

- Supplementary ProtocolDokumen5 halamanSupplementary ProtocolsuryaBelum ada peringkat

- 0 0 1211812181211ManufacturingProcessDokumen17 halaman0 0 1211812181211ManufacturingProcessLUISBelum ada peringkat

- Esterification of Acetic AcidDokumen9 halamanEsterification of Acetic AcidMeiimeii Puri IqbalbalLzBelum ada peringkat

- Process For Ethyl Acetate ProductionDokumen9 halamanProcess For Ethyl Acetate ProductionMuhammad Yanuar AnantaBelum ada peringkat

- Modelling FinalDokumen14 halamanModelling Finalmirdza94Belum ada peringkat

- Reaction Kinetics of The Catalytic Esterification of Citric Acid With EthanolDokumen8 halamanReaction Kinetics of The Catalytic Esterification of Citric Acid With EthanolJason SanchezBelum ada peringkat

- 2013 Modelling and Simulation of Continuous Reactive DistillationDokumen24 halaman2013 Modelling and Simulation of Continuous Reactive DistillationmppatilmayurBelum ada peringkat

- AN5391 Determination of TKN in Water by Using KT8000 SeriesDokumen7 halamanAN5391 Determination of TKN in Water by Using KT8000 SeriesJaysonAbenirCabahugBelum ada peringkat

- Proses Produksi EtanolDokumen8 halamanProses Produksi Etanollarasaticandra104Belum ada peringkat

- Jan May 2017 - CH4250 - Group18 - Final Project ReportDokumen184 halamanJan May 2017 - CH4250 - Group18 - Final Project ReportPalak SinghBelum ada peringkat

- Arsenic Analysis: SMEWW 3114 B. Manual Hydride Generation/ AAS MethodDokumen23 halamanArsenic Analysis: SMEWW 3114 B. Manual Hydride Generation/ AAS Methodantolin becerilBelum ada peringkat

- High-Pressure Steam Reforming of EthanolDokumen23 halamanHigh-Pressure Steam Reforming of EthanolMuhammad NaeemBelum ada peringkat

- AceticDokumen5 halamanAceticNicoole TiuBelum ada peringkat

- 728EDokumen6 halaman728ENoman Rafiq100% (1)

- SulzerDokumen4 halamanSulzerKaycelyn BacayBelum ada peringkat

- Produxction of Vinyl Acetate From EthyleneDokumen9 halamanProduxction of Vinyl Acetate From EthyleneSajid AliBelum ada peringkat

- Harding K. G. A Life-Cycle Comparison Between Inorganic and Biological Catalysis For The Production of Biodiesel PDFDokumen11 halamanHarding K. G. A Life-Cycle Comparison Between Inorganic and Biological Catalysis For The Production of Biodiesel PDFAlejandhroBelum ada peringkat

- 2007 07 10 Methods Method 351 1 PDFDokumen7 halaman2007 07 10 Methods Method 351 1 PDFlinhpic99Belum ada peringkat

- JubilantDokumen25 halamanJubilantSagar Arora100% (1)

- Lesage 23709Dokumen8 halamanLesage 23709حاتم غيدان خلفBelum ada peringkat

- Lesage 23709Dokumen8 halamanLesage 23709حاتم غيدان خلفBelum ada peringkat

- Mini Project StyereneDokumen25 halamanMini Project StyereneMard Apik100% (1)

- An Applied Guide to Water and Effluent Treatment Plant DesignDari EverandAn Applied Guide to Water and Effluent Treatment Plant DesignPenilaian: 5 dari 5 bintang5/5 (4)

- Asymmetric Catalysis on Industrial Scale: Challenges, Approaches and SolutionsDari EverandAsymmetric Catalysis on Industrial Scale: Challenges, Approaches and SolutionsHans Ulrich BlaserBelum ada peringkat

- Advances in Biofeedstocks and Biofuels, Volume 2: Production Technologies for BiofuelsDari EverandAdvances in Biofeedstocks and Biofuels, Volume 2: Production Technologies for BiofuelsLalit Kumar SinghBelum ada peringkat

- Handbook of Transition Metal Polymerization CatalystsDari EverandHandbook of Transition Metal Polymerization CatalystsRay HoffBelum ada peringkat

- The Role of Catalysis for the Sustainable Production of Bio-fuels and Bio-chemicalsDari EverandThe Role of Catalysis for the Sustainable Production of Bio-fuels and Bio-chemicalsKostas TriantafyllidisBelum ada peringkat

- Computer-Aided Design of Fluid Mixing Equipment: A Guide and Tool for Practicing EngineersDari EverandComputer-Aided Design of Fluid Mixing Equipment: A Guide and Tool for Practicing EngineersPenilaian: 5 dari 5 bintang5/5 (1)

- Fuels, Chemicals and Materials from the Oceans and Aquatic SourcesDari EverandFuels, Chemicals and Materials from the Oceans and Aquatic SourcesFrancesca M. KertonBelum ada peringkat

- Biogas Plant: Biogas Digester Design, Gas Production and PurificationDari EverandBiogas Plant: Biogas Digester Design, Gas Production and PurificationBelum ada peringkat

- Modem Compatibility ListDokumen4 halamanModem Compatibility ListAkk KolBelum ada peringkat

- PFR Data AnalysisDokumen46 halamanPFR Data AnalysisAkk KolBelum ada peringkat

- Chemcad PFRDokumen4 halamanChemcad PFRAkk KolBelum ada peringkat

- GTL Agenda Online BrochureDokumen8 halamanGTL Agenda Online BrochureAkk KolBelum ada peringkat

- Project Director: Production of Xanthan Gum Pharmaglobal Sdn. BHDDokumen3 halamanProject Director: Production of Xanthan Gum Pharmaglobal Sdn. BHDAmirul AdeebBelum ada peringkat

- Estimation of Protein by Biu Ret MethodDokumen3 halamanEstimation of Protein by Biu Ret MethodJaphaBelum ada peringkat

- B.sc. BiotechnologyDokumen146 halamanB.sc. Biotechnologymustafa aliBelum ada peringkat

- Data of IndustriesDokumen20 halamanData of IndustriesAbdul RahmanBelum ada peringkat

- The Ribosome Ribosomes A Re The Sites of Protein Synthesis in Both Prokaryotic and Eukaryotic CellsDokumen2 halamanThe Ribosome Ribosomes A Re The Sites of Protein Synthesis in Both Prokaryotic and Eukaryotic CellsRatri MuktiBelum ada peringkat

- Mil A 8625F BaseDokumen20 halamanMil A 8625F BaseRobyn NashBelum ada peringkat

- Lab Report Template N 084224Dokumen13 halamanLab Report Template N 084224Jose B. Bajar llBelum ada peringkat

- HemoglobinDokumen15 halamanHemoglobinArya RaoBelum ada peringkat

- SBR General Introduction: HistoryDokumen3 halamanSBR General Introduction: Historyanvesha raoBelum ada peringkat

- Aakash NBTS Test 03 PaperDokumen20 halamanAakash NBTS Test 03 PaperRsrao JBelum ada peringkat

- Chemistry O Level Revision Notes Series PDFDokumen17 halamanChemistry O Level Revision Notes Series PDFhamna33% (3)

- Aqua Regia SOPDokumen4 halamanAqua Regia SOPshahinBelum ada peringkat

- Frequently Asked Questions (FAQ) About Hot-Dip Galvanized Reinforcing BarsDokumen6 halamanFrequently Asked Questions (FAQ) About Hot-Dip Galvanized Reinforcing Barsali tahaBelum ada peringkat

- Material Safety Data Sheet: Genetron AZ-50 (R-507)Dokumen7 halamanMaterial Safety Data Sheet: Genetron AZ-50 (R-507)freddyBelum ada peringkat

- New Microsoft Office Word DocumentDokumen8 halamanNew Microsoft Office Word Documentkannan2030Belum ada peringkat

- Pharmacology: Outline PharmacodynamicsDokumen11 halamanPharmacology: Outline PharmacodynamicsAlloiBialbaBelum ada peringkat

- Chemical Bonding (Advance) : ChemistryDokumen60 halamanChemical Bonding (Advance) : ChemistryManikBelum ada peringkat

- What Is Cellugel?Dokumen5 halamanWhat Is Cellugel?Fito OrtegaBelum ada peringkat

- (B) Periodic Table - LevelDokumen21 halaman(B) Periodic Table - Levelsanket sinhaBelum ada peringkat

- Digestive GlandsDokumen17 halamanDigestive GlandsPrazwal RegmiBelum ada peringkat

- Liver Function Test (LFT) Test Name Observed Values Units Biological Reference IntervalsDokumen1 halamanLiver Function Test (LFT) Test Name Observed Values Units Biological Reference IntervalsseravanakumarBelum ada peringkat

- Présentation PowerPoint PDFDokumen68 halamanPrésentation PowerPoint PDFAssis RochaBelum ada peringkat

- Biochar-Based Adsorbents For Carbon Dioxide Capture - A Critical ReviewDokumen14 halamanBiochar-Based Adsorbents For Carbon Dioxide Capture - A Critical ReviewZackkBelum ada peringkat

- Chapter 3 Introduction Composite Materials and AnalysisDokumen78 halamanChapter 3 Introduction Composite Materials and AnalysisABDELRAHMAN REDA MAAMOUN ELSAID SEYAM A19EM0638Belum ada peringkat

- Hemaxi Patel: Career ObjectiveDokumen2 halamanHemaxi Patel: Career ObjectivePatel Kartavya03Belum ada peringkat

- Unit-1 Solids: Questions Carrying One MarkDokumen159 halamanUnit-1 Solids: Questions Carrying One MarkGahan Gowda SBelum ada peringkat

- Brothers: Integration of Metabolism and Metabolic Processes in Fed, Fasting and Starvation StatesDokumen14 halamanBrothers: Integration of Metabolism and Metabolic Processes in Fed, Fasting and Starvation StatesNischal DhBelum ada peringkat

- Algas Como Fonte de Sabores Naturais em Alimentos InovadoresDokumen20 halamanAlgas Como Fonte de Sabores Naturais em Alimentos InovadoresRenan Guilherme de Oliveira GuihBelum ada peringkat

- M.sc. Chemistry Compiled SyllabusDokumen48 halamanM.sc. Chemistry Compiled SyllabusSadiaMaryamBelum ada peringkat

- Describe The Mechanism of Halogenation Reaction in BenzeneDokumen3 halamanDescribe The Mechanism of Halogenation Reaction in BenzeneNur DiniBelum ada peringkat