Puckering On Power Strech Fabrics (ORTArevision4.4.2012) - 1

Diunggah oleh

nubackDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Puckering On Power Strech Fabrics (ORTArevision4.4.2012) - 1

Diunggah oleh

nubackHak Cipta:

Format Tersedia

Puckering Problem on Power Strech Fabrics & Garments

Puckering is seen on highelastic garments, especially on bartack and fly areas, zippers, binding tapes etc.

After the analyses of puckering areas , we see that corespun yarn lost spandex from inside. The trials shows that the elastane could move up to 2cm inside corespun weft, especially after dyeing & washing treatments Lowering the elasticity of the fabric or garment helps solving puckering. But to maintain no puckering, elasticity levels should be decreased dramatically.

Hyosung; one of the elastane manufacturer, also studied about puckering and according to their analyses, there is no elastane breakages in the yarn and there are no big differences in physical properties of elastane between puckering and normal part.

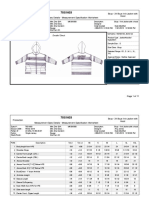

Spandex Strength [g] Length [mm] Weight [mg] Denier Elongation [%] 200%M [gr]

Garment

Av 96 Normal Range 2 Av 93 Puckering Range 3 0.05 5.1 0.39 37.9 0.06 5.3 0.40 37.3

79.8

369

19.8

13.5

32

1.5

73.9

352

20.3

24.9

75

3.5

How To Solve Puckering Problem

Puckering problem is a result of high elastic characteristics of yarns & fabrics produced with elastane(spandex) To minimize puckering, elasticity should also be minimized. But this will effect all comfort properties of the product. Besides lowering elasticity some actions in cutting, sewing, laundry processes needed not to have problem. Powerstrech fabrics always need careful attention in all cutting &sewing&washing&dying&drying processes.

SEWING The crotch area is prevelant for puckering. This is due to elastane movement and tension difference after multi-layers of fabric. We recommend the following actions: 1. Decrease SPI to 8. 2. Increase seam allowance 3. Change construction of front crotch (this is an effort to hold/stabalize the elastane.) 4. Try clean finish instead of overlock 5. If using overlock, increase this SPI on inside crotch from 10 20 6. Change top stitch to 1/4 from 1/8 at crotch. Bartacks in general should be taken out.

Increase seam allowance of busted side seams 1/8 more on either side. Increase SPI of busted outseam overlock from 10 to 20 attempting to hold elastane.

Change construction to 5 thread overlock closed seam with tight SPI.

Take top stitch off inseam Fabric layers on edges must be sewed together with overlock sticthing. If overlock stitching is already done, a tighter overlock would be more helpful. Transition from lower fabric layers to higher layers (or vice versa) transitions must be smooth. This means it is not good that the stitch passes through 2 layers to 8 layers of fabric. (vice versa) Some parts of the pattern can be adjusted longer and this pass can be; 2 layers -> 4 layers -> 6 layers -> 8 layers (Especially on the button fly or zipper fly)

Stitch tension must be lower on more layered parts.

Sewing labels after washing would be helpful We recommend SES or SPI type needles. SPI gives better performance but the strength of SES is better. Preferred needle type is Groz-Beckert SAN6.

With narrow seam allowances puckering seen more.

Very narrow seam allowance on the crotch area increasing puckering. After fabric layer combinations puckering seen more.

Clean finish on the crotch area helps decreasing puckering effect. As the seam allowance increases too.

Clean finish on the crotch area helps decreasing puckering effect. As the seam allowance increases too.

Analyses shows that dyeing & drying temperatures effects puckering. Higher temperatures results more puckering. As Orta PFD flat fabrics doesnt have sizing chemical, there is no desizing needed. Desizing process increases the puckering effect Longer wash&dye treatment times increases puckering. More than 60C is not recommended for dyeing & drying. Low temperature dye processes and low temperature drying should be applied

Mannequins (robots) should not be used for some processes in between production or end of production. The tension on the fabric is effecting elastane move inside the corespun yarn.

Anda mungkin juga menyukai

- Seam PuckeringDokumen4 halamanSeam PuckeringRavi Jain100% (1)

- Creative Garment RecyclingDokumen52 halamanCreative Garment RecyclingTay RSBelum ada peringkat

- Stitch LengthDokumen4 halamanStitch LengthAjeet KumarBelum ada peringkat

- Fabric RequirementDokumen26 halamanFabric RequirementCHARLES KINYERABelum ada peringkat

- Denim: Presented By:-Ashok Kumar Naresh KumarDokumen23 halamanDenim: Presented By:-Ashok Kumar Naresh Kumarknishant8Belum ada peringkat

- Std12 Voc TDD emDokumen239 halamanStd12 Voc TDD emreemmerBelum ada peringkat

- 2 Stitchology - Woven NXPowerLite NXPowerLiteDokumen117 halaman2 Stitchology - Woven NXPowerLite NXPowerLiteapi-3698472100% (7)

- MENSWEAR DESIGN BASICSDokumen63 halamanMENSWEAR DESIGN BASICSKhushbu DinkarBelum ada peringkat

- How To Measure BottomsDokumen42 halamanHow To Measure BottomsMayBelum ada peringkat

- Leg Twist JeansDokumen13 halamanLeg Twist Jeanshamba_dah100% (2)

- How to Measure Apparel in 40 CharactersDokumen76 halamanHow to Measure Apparel in 40 Charactersfola omotBelum ada peringkat

- In-Plant Training Report PresentationDokumen60 halamanIn-Plant Training Report Presentationrajhossie9335100% (3)

- Basic garment pattern design for standard figureDokumen11 halamanBasic garment pattern design for standard figureAhmad El TahanBelum ada peringkat

- L-9 (Spreading Equipment)Dokumen16 halamanL-9 (Spreading Equipment)Zafar JavedBelum ada peringkat

- Colour and Weave EffectDokumen15 halamanColour and Weave EffectAvishek ChandaBelum ada peringkat

- Different Grading System Used in Apparel IndustryDokumen5 halamanDifferent Grading System Used in Apparel Industryzain bajwaBelum ada peringkat

- 1 A.textile SegmentsDokumen28 halaman1 A.textile SegmentsanushkaBelum ada peringkat

- Santoni SeamlessDokumen2 halamanSantoni SeamlessSudheer SinghBelum ada peringkat

- Consumption For FabricDokumen5 halamanConsumption For Fabrickimtienthao_26289Belum ada peringkat

- Lesson Plan: ND THDokumen6 halamanLesson Plan: ND THsatexBelum ada peringkat

- Cutting MarkerDokumen66 halamanCutting MarkerTanushree RoyBelum ada peringkat

- Professional Ruffles and Pleats: Preparing The Sewing Machine: Attaching Ruffles For Fancy EffectsDokumen1 halamanProfessional Ruffles and Pleats: Preparing The Sewing Machine: Attaching Ruffles For Fancy EffectsJohn DoverBelum ada peringkat

- Fabric and Garment FinishingDokumen33 halamanFabric and Garment FinishingSurya Bakshi100% (4)

- Horniman TextilesDokumen41 halamanHorniman TextilesAlex Bojovic100% (1)

- Spreading and Marker Making For Striped and CheckedDokumen11 halamanSpreading and Marker Making For Striped and CheckedHeloiseBelum ada peringkat

- Notched Jacket LapelDokumen6 halamanNotched Jacket LapelwasyihunBelum ada peringkat

- Stitch TypesDokumen21 halamanStitch TypesAjaz777100% (1)

- Binding options for unique vestsDokumen3 halamanBinding options for unique vestsmaggiehsuehBelum ada peringkat

- Spreading Fabric Efficiently for Apparel ProductionDokumen65 halamanSpreading Fabric Efficiently for Apparel ProductionManuj Shukla100% (1)

- Fabric Studies - 1st SetDokumen30 halamanFabric Studies - 1st SetP. Lakshmanakanth100% (1)

- Fabric Spreading ProcessDokumen8 halamanFabric Spreading ProcessRatul Hasan100% (1)

- Decorative Stitch MatrixDokumen3 halamanDecorative Stitch MatrixSaid Lozi100% (1)

- Cracked Chevron Pencil SkirtDokumen24 halamanCracked Chevron Pencil SkirtEster Cellucci100% (2)

- SEWN PRODUCTS MACHINERY AND EQUIPMENT ModelDokumen8 halamanSEWN PRODUCTS MACHINERY AND EQUIPMENT ModelUjwala JainBelum ada peringkat

- 4.2BHow To Measure Guide ApparelsDokumen37 halaman4.2BHow To Measure Guide ApparelsAlokKumarBelum ada peringkat

- 3 Bed TypesDokumen42 halaman3 Bed Typesrajurana25Belum ada peringkat

- Spreading and Cutting of Apparel ProductsDokumen43 halamanSpreading and Cutting of Apparel ProductsDaniela JakimovaBelum ada peringkat

- Assignment: EmbellishmentDokumen8 halamanAssignment: EmbellishmentTommy JaxonBelum ada peringkat

- Adidas and Automated Sewbots!Dokumen7 halamanAdidas and Automated Sewbots!Akanksha MishraBelum ada peringkat

- Spme Denim TrouserDokumen45 halamanSpme Denim TrouserSupriya Nanda50% (2)

- Experiment 6,7,8Dokumen9 halamanExperiment 6,7,8Sojid khanBelum ada peringkat

- Pattern: Pre-Requites For PatternDokumen3 halamanPattern: Pre-Requites For Patternzaya sarwarBelum ada peringkat

- Lucy Printing and Sewing Instructions PDFDokumen8 halamanLucy Printing and Sewing Instructions PDFMelike TuranBelum ada peringkat

- VM Section 6 Technical Design Sample & Fit RequirementsDokumen46 halamanVM Section 6 Technical Design Sample & Fit RequirementssuditiBelum ada peringkat

- Fashion Product Marketing & Merchandising Class NotesDokumen60 halamanFashion Product Marketing & Merchandising Class NotesISHITABelum ada peringkat

- Apparel Internship atDokumen32 halamanApparel Internship atdipalimodiBelum ada peringkat

- Dartspleats and TucksDokumen34 halamanDartspleats and TucksArcade W MiguelBelum ada peringkat

- Basic Shirt MeasurementDokumen3 halamanBasic Shirt MeasurementImran TexBelum ada peringkat

- Daffodil Int'l U Lab Manual on Apparel Mfg MeasurementDokumen45 halamanDaffodil Int'l U Lab Manual on Apparel Mfg MeasurementMD OHiBelum ada peringkat

- Evaluation of Different Seam and Stitches On Jacket, Trouser, Woven Shirt, JeansDokumen14 halamanEvaluation of Different Seam and Stitches On Jacket, Trouser, Woven Shirt, JeansMahmudul HasanBelum ada peringkat

- Specification Sheet SampleDokumen11 halamanSpecification Sheet SampleNishu Jalotia0% (1)

- Screen printing and rotary printing: Methods, benefits, and comparisonDokumen9 halamanScreen printing and rotary printing: Methods, benefits, and comparisonnidhisanjeet100% (1)

- Selection & Sewing Tips For Fleece FabricDokumen3 halamanSelection & Sewing Tips For Fleece Fabricdigi1webBelum ada peringkat

- Detailed Syllabus FOR Distance Education: Bachelor of Science in Fashion Design (BSCFD)Dokumen37 halamanDetailed Syllabus FOR Distance Education: Bachelor of Science in Fashion Design (BSCFD)Virad AwasthiBelum ada peringkat

- 1.fabric Defects and IdentificationDokumen16 halaman1.fabric Defects and IdentificationRuhi gnextBelum ada peringkat

- Patch Pockets PDFDokumen2 halamanPatch Pockets PDFTesfaye MuluBelum ada peringkat

- CT MMB 198Dokumen2 halamanCT MMB 198Rosana BarakatBelum ada peringkat

- Homeroom Guidance Grade 12 Quarter - Module 4 Decisive PersonDokumen4 halamanHomeroom Guidance Grade 12 Quarter - Module 4 Decisive PersonMhiaBuenafe86% (36)

- Water 07 02314Dokumen36 halamanWater 07 02314Satyajit ShindeBelum ada peringkat

- Mediclaim - ChecklistDokumen4 halamanMediclaim - ChecklistKarthi KeyanBelum ada peringkat

- ADD MATH ProjectDokumen13 halamanADD MATH Projectmegazat27Belum ada peringkat

- Valhalla Repair ManualDokumen8 halamanValhalla Repair ManualKirby AllenBelum ada peringkat

- Flexural Analysis of Beams (Part 2)Dokumen7 halamanFlexural Analysis of Beams (Part 2)Johnnette Nafuerza AggabaoBelum ada peringkat

- Class Prophecy 012Dokumen11 halamanClass Prophecy 012Mythical Persues100% (2)

- Isaac Asimov - "Nightfall"Dokumen20 halamanIsaac Asimov - "Nightfall"Aditya Sharma100% (1)

- FloridaSharkman ProtocolsDokumen14 halamanFloridaSharkman ProtocolsgurwaziBelum ada peringkat

- Cross-Sectional Tomography: Oral and Maxillofacial RadiologyDokumen7 halamanCross-Sectional Tomography: Oral and Maxillofacial RadiologyPhanQuangHuyBelum ada peringkat

- Some Technical Aspects of Open Pit Mine Dewatering: Section2Dokumen11 halamanSome Technical Aspects of Open Pit Mine Dewatering: Section2Thiago MarquesBelum ada peringkat

- Reasons for Conducting Qualitative ResearchDokumen12 halamanReasons for Conducting Qualitative ResearchMa. Rhona Faye MedesBelum ada peringkat

- Facebook TemplateDokumen2 halamanFacebook Templateapi-352106462Belum ada peringkat

- MCS Adopts Milyli Software Redaction Tool BlackoutDokumen3 halamanMCS Adopts Milyli Software Redaction Tool BlackoutPR.comBelum ada peringkat

- Ferain Et Al, 2016 - The Fatty Acid Profile of Rainbow Trout Liver Cells Modulates Their Tolerance To Methylmercury and CadmiumDokumen12 halamanFerain Et Al, 2016 - The Fatty Acid Profile of Rainbow Trout Liver Cells Modulates Their Tolerance To Methylmercury and Cadmiumarthur5927Belum ada peringkat

- Product 243: Technical Data SheetDokumen3 halamanProduct 243: Technical Data SheetRuiBelum ada peringkat

- Colorimetric Determination of ManganeseDokumen16 halamanColorimetric Determination of ManganeseidaayudwitasariBelum ada peringkat

- Mod. 34 Classic Compact T06Dokumen4 halamanMod. 34 Classic Compact T06Jaime Li AliBelum ada peringkat

- Bond Strength of Normal-to-Lightweight Concrete InterfacesDokumen9 halamanBond Strength of Normal-to-Lightweight Concrete InterfacesStefania RinaldiBelum ada peringkat

- Cursos Link 2Dokumen3 halamanCursos Link 2Diego Alves100% (7)

- I. Specifikacija Opreme Sa Ugradnjom R.Br. Opis JM KomDokumen4 halamanI. Specifikacija Opreme Sa Ugradnjom R.Br. Opis JM KomAleksandar VidakovicBelum ada peringkat

- A Final Project For The Course Title "Monetary Policy and Central Banking"Dokumen11 halamanA Final Project For The Course Title "Monetary Policy and Central Banking"Elle SanchezBelum ada peringkat

- Chapter 27 Protists I. Evolution of EukaryotesDokumen7 halamanChapter 27 Protists I. Evolution of EukaryotesNadeem IqbalBelum ada peringkat

- Job Interview CV TipsDokumen2 halamanJob Interview CV TipsCarlos Moraga Copier100% (1)

- Arts and Culture An Introduction To The Humanities Combined Volume 4th Edition Benton Test Bank Full Chapter PDFDokumen22 halamanArts and Culture An Introduction To The Humanities Combined Volume 4th Edition Benton Test Bank Full Chapter PDFoutscoutumbellar.2e8na100% (15)

- A Study On Consumer Buying Behaviour Towards ColgateDokumen15 halamanA Study On Consumer Buying Behaviour Towards Colgatebbhaya427Belum ada peringkat

- aCTION PLAN IN HEALTHDokumen13 halamanaCTION PLAN IN HEALTHCATHERINE FAJARDOBelum ada peringkat

- Writing Lesson Plan LMDokumen6 halamanWriting Lesson Plan LMapi-457032696Belum ada peringkat

- Viviana Rodriguez: Education The University of Texas at El Paso (UTEP)Dokumen1 halamanViviana Rodriguez: Education The University of Texas at El Paso (UTEP)api-340240168Belum ada peringkat

- Trend Graphs - Sample AnswerDokumen4 halamanTrend Graphs - Sample AnswerannieannsBelum ada peringkat